Protective assembly

A technology of components and protective parts, applied in the field of solar cell components, can solve problems such as easy to fall off, hidden cracks of solar cell components 50, and affect installation efficiency of junction box connector 20, so as to ensure installation efficiency and avoid problems of hidden cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

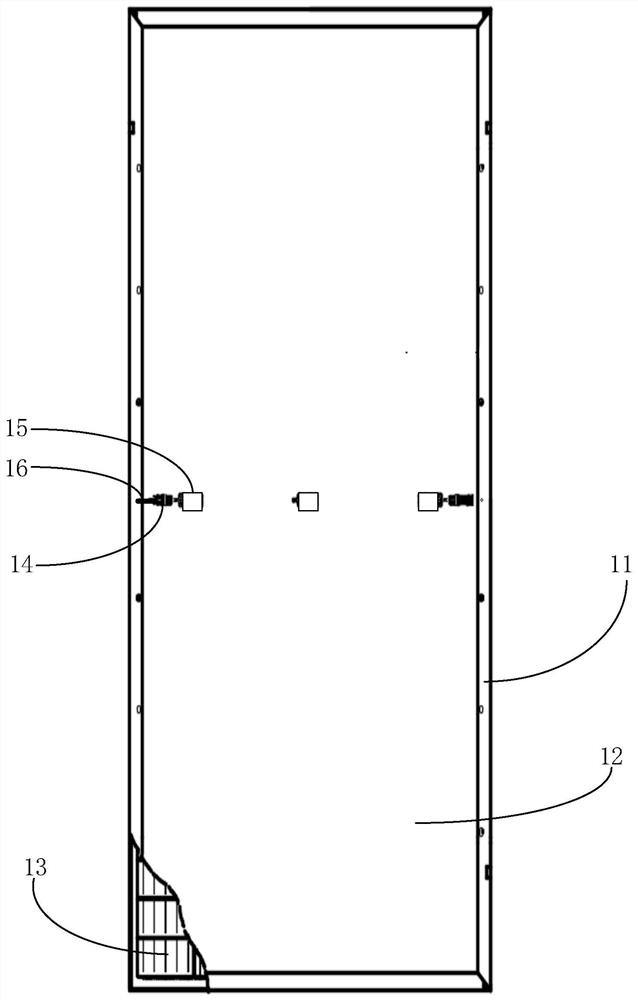

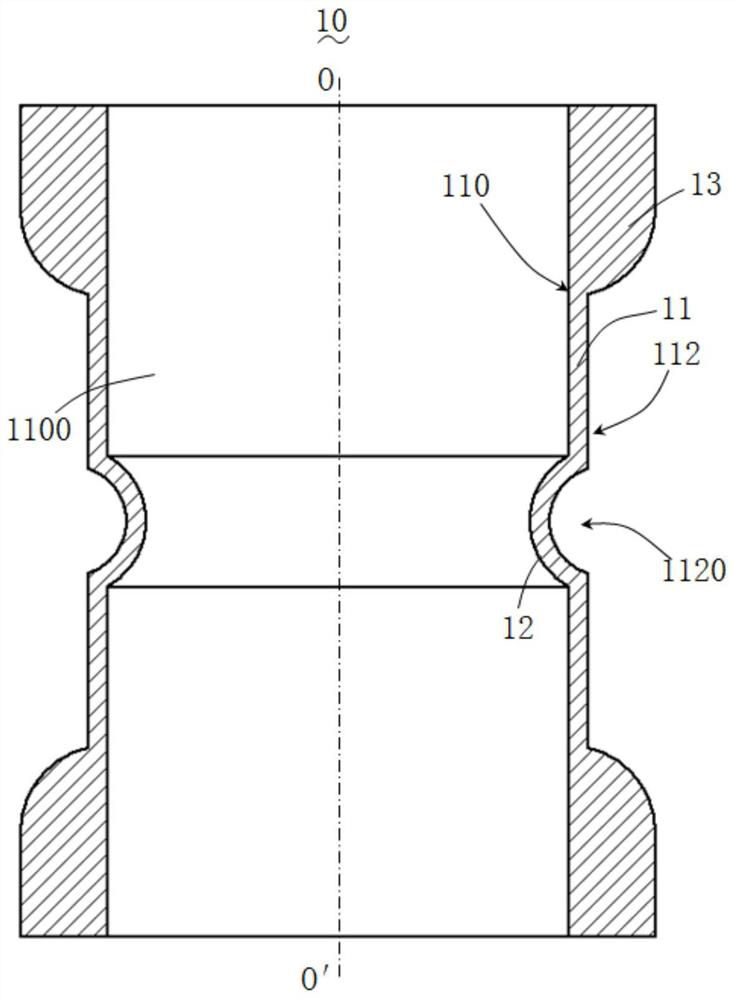

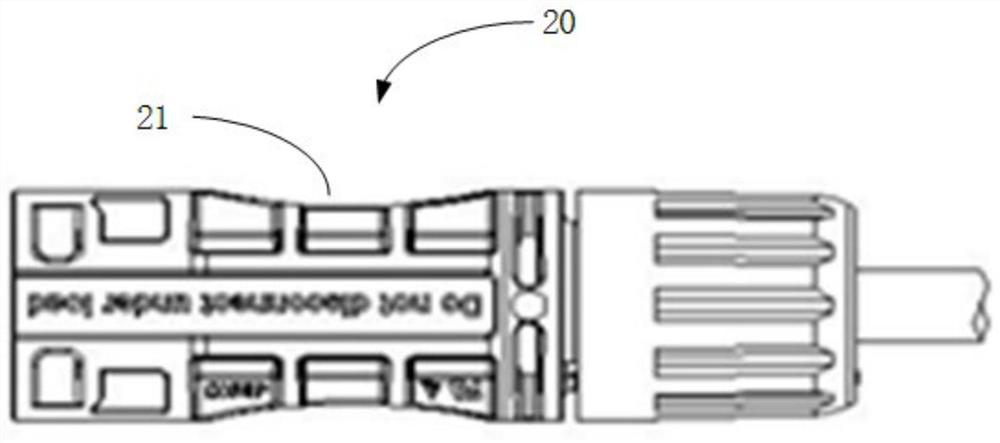

[0042]It can be known from the background art that the prior art round straight foam sleeve is easy to fall off the connector of the cable box after it is sheathed with the connector of the cable box. Therefore, after falling off, it is necessary to reinstall the round straight foam on the connector of the cable box. This affects the installation efficiency of the wire box connector; and, if the straight foam that has fallen off is not reinstalled on the wire box connector in time, the wire box connector can easily crack the solar cell module when it hits the back plate of the solar cell module.

[0043]The embodiment of the present invention provides a protection component, the protection component is sleeved on the wire box connector, the protection component mainly includes a cylindrical side wall, a limit part and a cylindrical protection part. The cylindrical side wall is elastic and encloses The through hole for accommodating the connector of the wire box; the limiting portion is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap