A dedusting equipment with detachable automatic screening for rice processing

An automatic screening and rice processing technology, applied in the direction of separating solids from solids with airflow, separation methods, solid separation, etc., can solve problems such as dust spillage, dust explosion, and staff distress, so as to reduce the replacement frequency and improve The effect of usability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

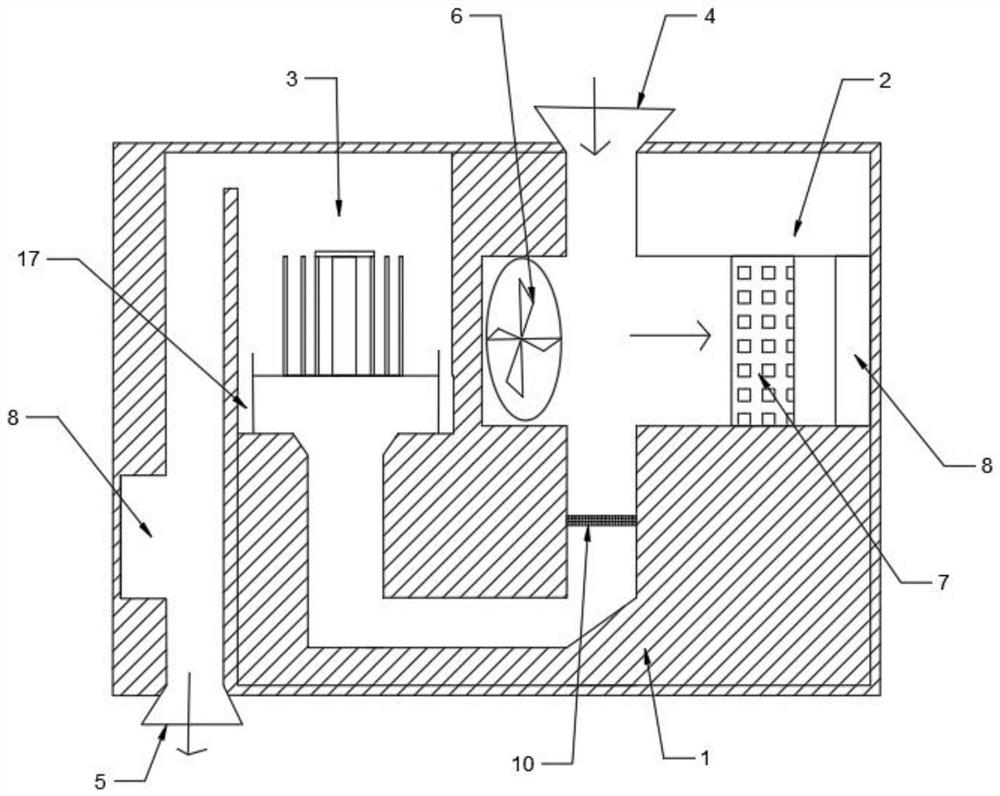

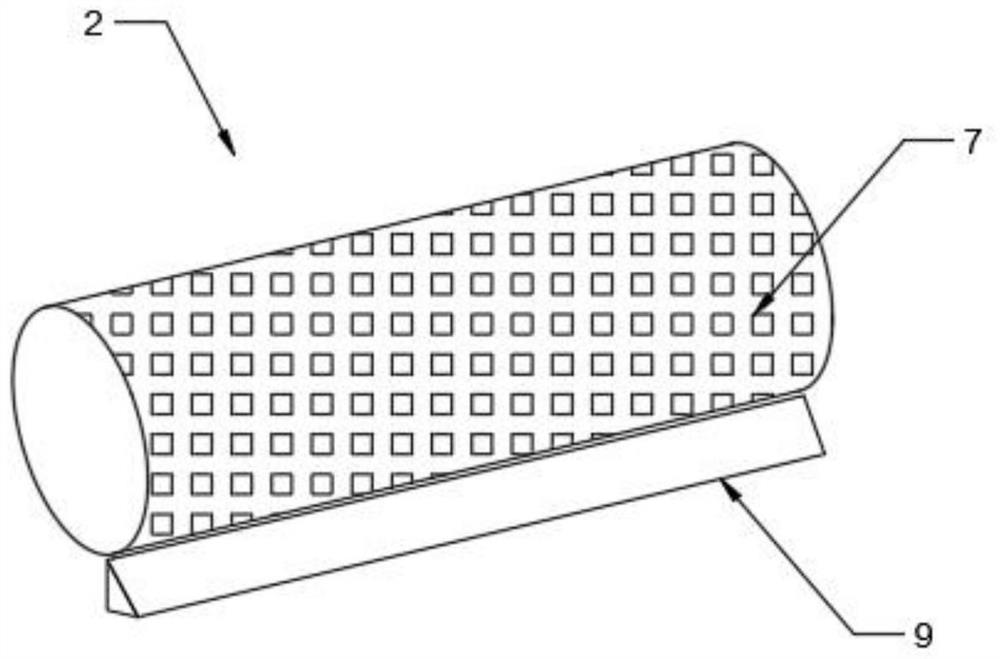

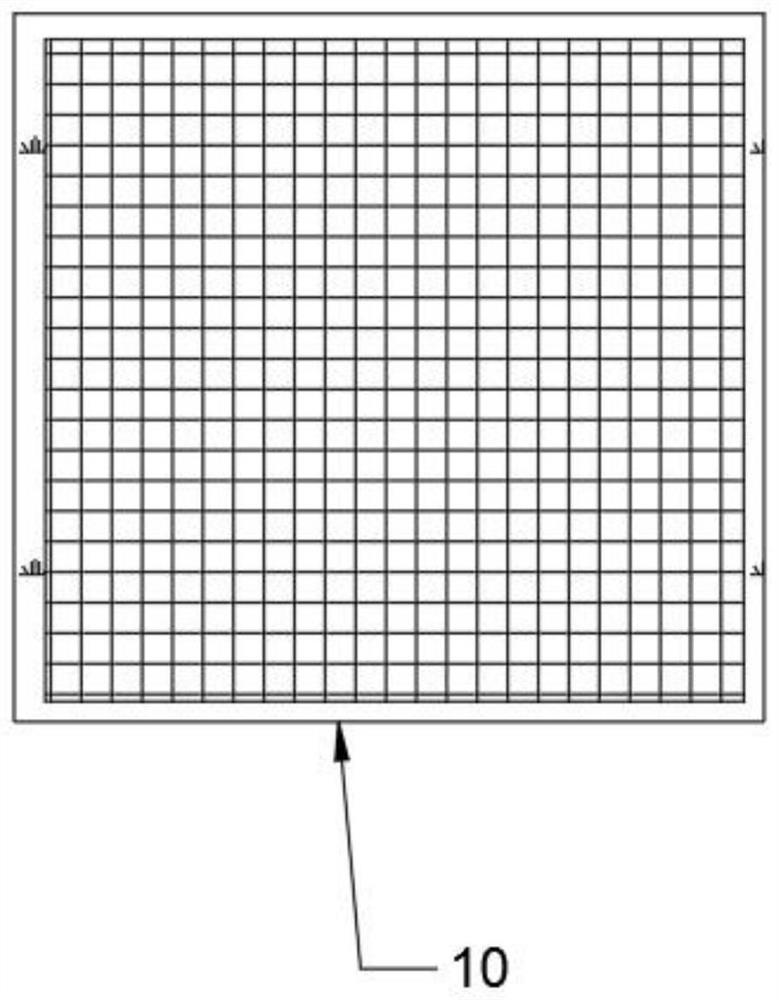

[0044] Example: see Figure 1-9 , the present invention provides a technical solution: a dedusting device for detachable automatic screening for rice processing, including a body 1, a primary separation device 2 and a secondary separation device 3, and the primary separation device 2 and the secondary separation device 3 are all located at Inside the machine body 1, the top of one end of the machine body 1 is provided with a feed port 4, and the bottom of the other end of the machine body 1 is provided with a discharge port 5. The primary separation device 2 is used to separate the dust in the rice, and the secondary separation device 3 is used to separate the dust from the rice. The sundries, the rice enters from the feed port 4, passes through the primary separation device 2 and the secondary separation device 3 successively, and discharges from the discharge port 5 to complete the separation of dust and sundries in the rice;

[0045] A blower 6 is provided on one side below...

Embodiment 2

[0054] Embodiment 2: The scraper 9 is in the shape of an arc table, the side of the scraper 9 close to the blower 6 is lower than the other side away from the blower 6, and the arc surface of the top of the scraper 9 is provided with several slots 18, several A brush 19 is fixedly connected in each slot 18, and the edge of the scraper 9 away from the blower 6 is attached to and connected with the filter screen 7. The arc surface at the top of the scraper 9 is attached to and connected with the filter screen 7 by the brush 19. The brush 19 on the arc table of the plate 9 is used to clean the dust that the scraper cannot scrape off in time, the setting of the arc table is conducive to expanding the contact area between the brush 19 and the filter screen 7, and the slot 18 is used to place the brush 19. The side of the scraper 9 close to the blower 6 is lower than the other side away from the blower 6 to reduce the amount of dust attached to the scraper 9. If the side of the scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com