Anti-veining additive for casting, preparation method and application method

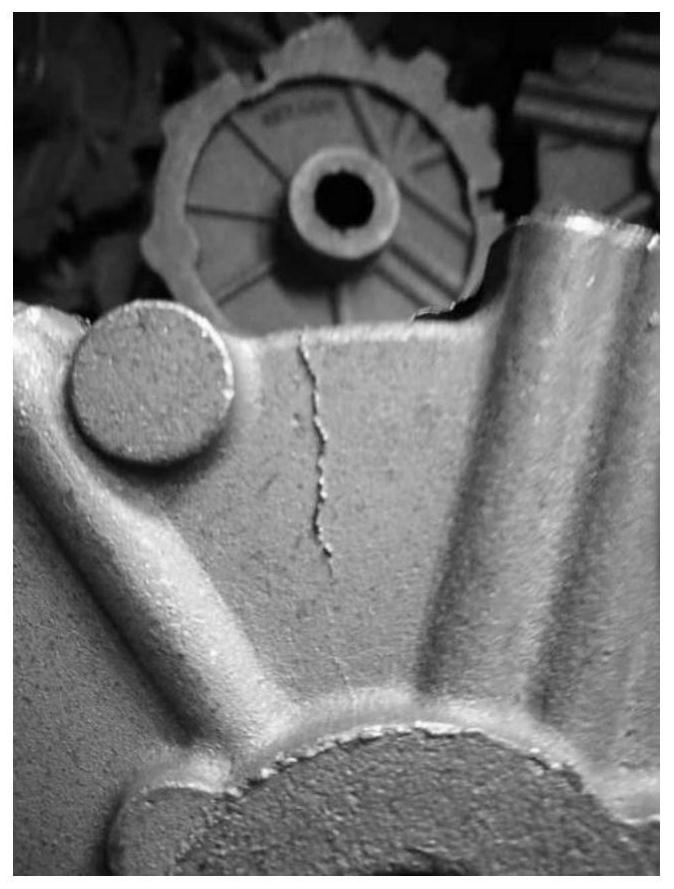

An additive and veining technology, applied in the field of foundry materials, can solve the problems of poor strength of coated sand and inability to completely eliminate veining defects, and achieve the effect of reducing cracking tendency, simple and easy addition process, and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An anti-veining additive for casting, which is composed of the following raw materials:

[0044] Glycerin 60%, glass fiber 10%, nano-titanium dioxide powder with particle size of 3nm 5%, graphite powder with particle size of 40nm 5.45%, polycarbosilane 9%, bentonite 9.5%, alkali metal oxide 0.05%, coupling agent H5501% . Alkali metal oxide is a mixture of sodium oxide, potassium oxide and lithium oxide in a mass ratio of 1:3:5.

[0045] The preparation method of the anti-veining additive is as follows:

[0046] (1) Weigh glycerin, nano-titanium dioxide powder, polycarbosilane, bentonite, alkali metal oxide, coupling agent H550 in proportion, and mix well;

[0047] (2) The uniformly mixed material is placed in an environment with a humidity lower than 60HR and a temperature lower than 150℃ for 2-5h maintenance;

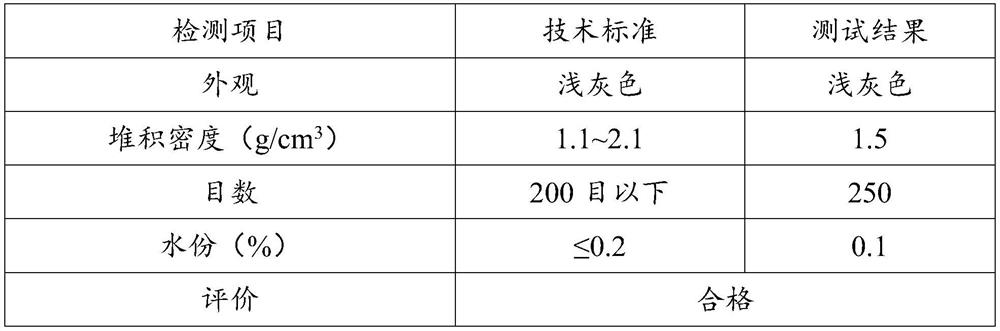

[0048] (3) adding glass fiber and nano-graphite powder in proportion to the cured material, and stirring the components evenly to obtain an anti-veining addi...

Embodiment 2

[0054] An anti-veining additive for casting, which is composed of the following raw materials:

[0055] 50% glycerin, 10% glass fiber, 10% nano titanium dioxide powder with particle size of 5nm, 10% graphite powder with particle size of 60nm, polycarbosilane 9.45%, bentonite 10%, alkali metal oxide 0.05%, coupling agent H5500. 5%. Among them, the alkali metal oxide is a mixture of sodium oxide, potassium oxide and lithium oxide with a mass ratio of 1:2:3.

[0056] The preparation method of the anti-veining additive is as follows:

[0057] (1) Weigh glycerin, nano-titanium dioxide powder, polycarbosilane, bentonite, and alkali metal oxide in proportion, and mix well;

[0058] (2) The uniformly mixed materials are placed in an environment with a humidity lower than 60HR and a temperature lower than 150℃ for 2-5h maintenance;

[0059] (3) adding glass fiber and nano-graphite powder in proportion to the cured material, and stirring the components evenly to obtain an anti-veinin...

Embodiment 3

[0062] An anti-veining additive for casting, which is composed of the following raw materials:

[0063] 70% glycerin, 5% glass fiber, 5% nano titanium dioxide powder with a particle size of 10nm, 5% graphite powder with a particle size of 100nm, 5% polycarbosilane, 8.99% bentonite, 0.01% alkali metal oxide, and coupling agent H5501% . Among them, the alkali metal oxide is composed of sodium oxide, potassium oxide and lithium oxide in a mass ratio of 1:5:8.

[0064] The preparation method of the anti-veining additive is as follows:

[0065] (1) Weigh glycerin, nano-titanium dioxide powder, polycarbosilane, bentonite, alkali metal oxide, coupling agent H550 in proportion, and mix well;

[0066] (2) The uniformly mixed materials are placed in an environment with a humidity lower than 60HR and a temperature lower than 150℃ for 2-5h maintenance;

[0067] (3) adding glass fiber and nano-graphite powder in proportion to the cured material, and stirring the components evenly to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com