Timely released preparation and preparation thereof

A technology of timed release and preparation, which is applied in the direction of pill delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc. It can solve the problems of difficulty in making soft materials, short time lag, etc., achieve good pulse effect, reduce viscosity, and prevent rapid release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

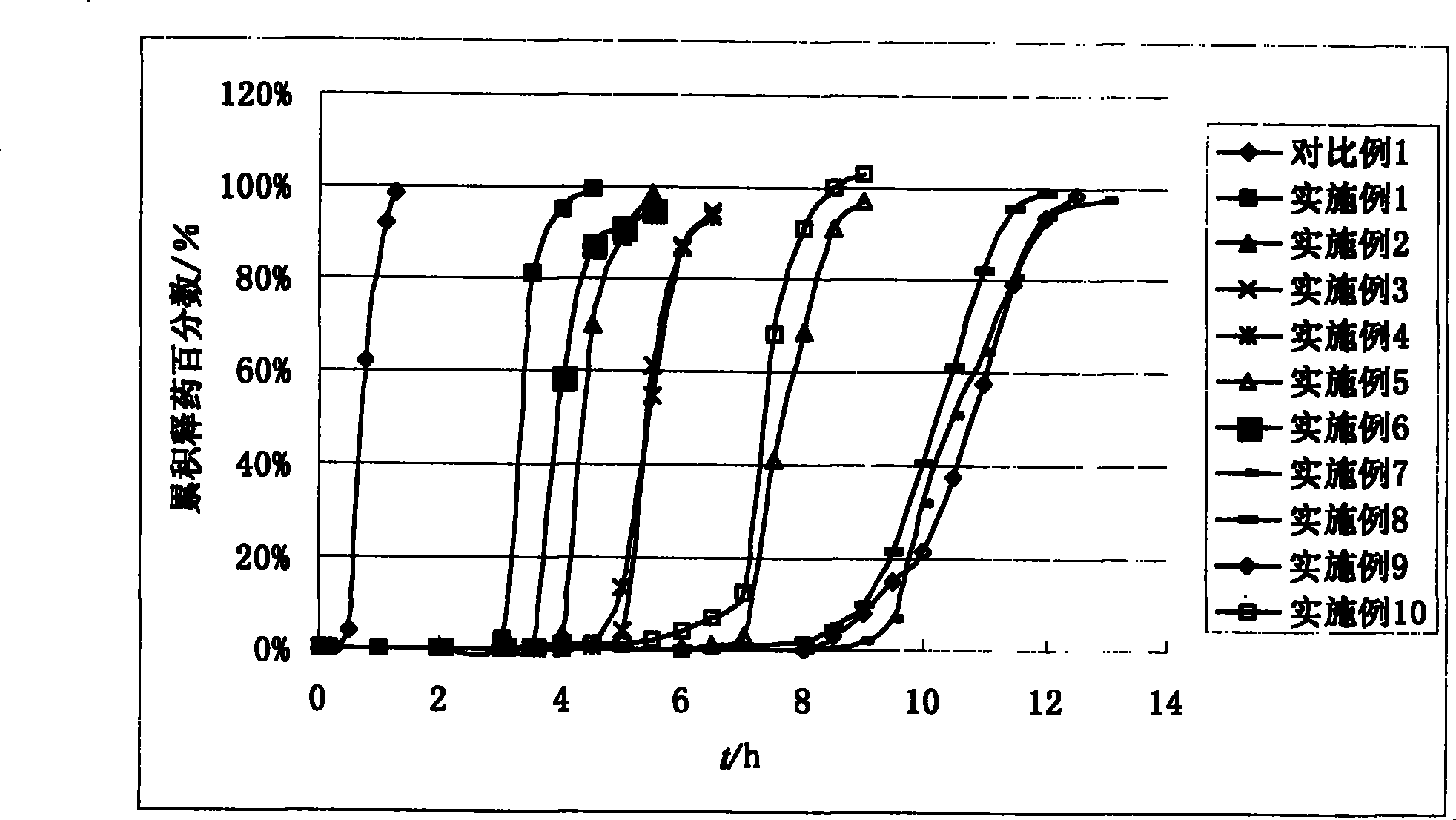

Examples

Embodiment 1

[0021] Tablet core prescription (total amount is 100mg):

[0022] %(W / W)

[0023] Isosorbide mononitrate 20

[0024] Microcrystalline Cellulose 20

[0025] Starch 46.2

[0026] Crospovidone 10

[0027] Povidone 2.8

[0029] Total 100

[0030] After mixing the above-mentioned first 4 ingredients, add 28 μl of 75% ethanol aqueous solution containing 10wt% povidone to make a soft material, sieve it, put it into an oven to dry at 50°C for 1 hour, add 1wt% talcum powder and mix for 3 minutes, Compressed into tablet cores.

[0031] Coating prescription (300mg in total):

[0032] %(W / W)

[0033] Hydroxypropyl Methyl Cellulose K100M 10

[0034] Acrylic resin RL 31.5

[0035] Povidone K30 18

[0036] Microcrystalline Cellulose 15

[0037] Lactose 22.5

[0039] Talc powder 1

[0040] Total 100

[0041] After uniformly mixing the first six auxiliary materials, granulate with 70...

Embodiment 2

[0043] Tablet core prescription (total amount is 100mg):

[0044] %(W / W)

[0045] Nitrindipine 10

[0046] Lactose 39.2

[0047] Mannitol 15

[0048] Sodium carboxymethyl starch 8

[0049] Microcrystalline Cellulose 25

[0050] Hydroxypropyl methylcellulose 1.8

[0051] Talc powder 1

[0052] Total 100

[0053] After mixing the aforementioned 5 ingredients, add 60 μl of 50% ethanol aqueous solution containing 3% hydroxypropyl methylcellulose to make a soft material, sieve it, dry it at 50°C for 1 hour, add 1 wt% talcum powder and mix for 3 minutes , pressed into tablet cores.

[0054] Coating prescription (300mg in total): % (W / W)

[0055] Hydroxypropyl Methyl Cellulose K15M 10

[0056] Povidone K30 18

[0057] Ethyl cellulose (0.01Pa.s) 30

[0058] Microcrystalline Cellulose 15

[0059] starch 23

[0061] Talc powder 1

[0062] Total 100

[0063] After uniformly mixing the first six auxiliary materials, gran...

Embodiment 3

[0065] Tablet core prescription (total amount is 100mg):

[0066] %(W / W)

[0067] Salbutamol Sulfate 8

[0068] Starch 73.4

[0069] Sodium Carboxymethyl Cellulose 15

[0070] Povidone 2.6

[0071] Talc powder 1

[0072] Total 100

[0073] After mixing the above three ingredients, add 26 μl of 75% ethanol aqueous solution containing 10% povidone to make a soft material, sieve, dry at 50°C for 1 hour, add 1wt% talcum powder and mix for 3 minutes, and press into Chips.

[0074] Coating prescription (300mg in total): % (W / W)

[0075] Hydroxyethylcellulose (Natrosol HX) 6

[0076] Povidone K30 25

[0077] Ethyl cellulose (0.01Pa.s) 30

[0078] Microcrystalline Cellulose 12

[0079] Compressible starch 22

[0080] Zinc stearate 4

[0081] Talc powder 1

[0082] Total 100

[0083] After uniformly mixing the first six auxiliary materials, granulate with 70% ethanol aqueous solution, dry, granulate, and then mix with 1wt% talcum powder for 3 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com