Novel non-woven fabric wound dressing and preparation method and application thereof

A wound dressing, non-woven technology, applied in textiles and papermaking, rayon manufacturing, bandages, etc., can solve the problems of inability to significantly and effectively promote wound healing, difficult to scale production, single function, etc., to maintain protein Effects of structural integrity and regulation of gene expression, promotion of angiogenesis, and promotion of re-epithelialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

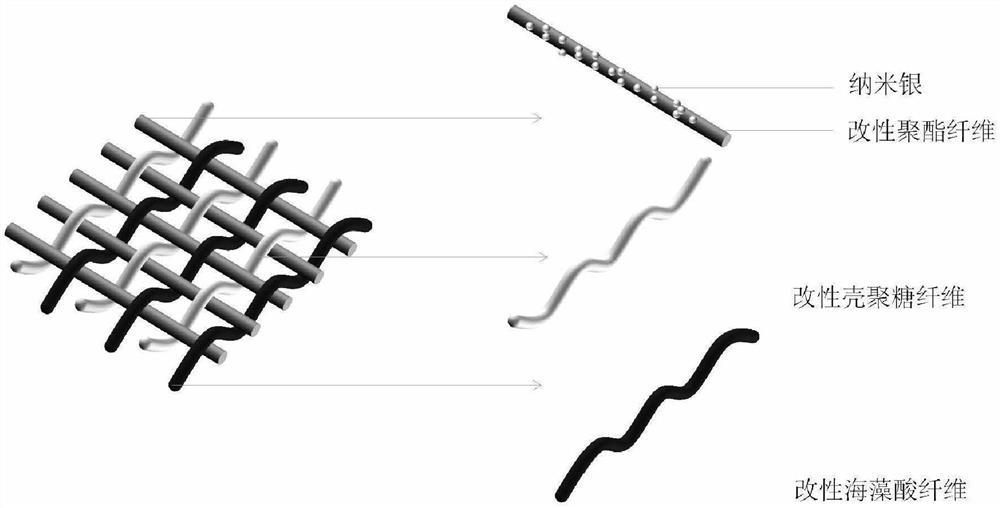

[0028] This example provides a new type of non-woven wound dressing and its preparation method. The wound dressing is made of modified polyester fiber, modified chitosan fiber and modified calcium alginate fiber through spunlace or needle-punched nonwoven processing. made, the schematic diagram of which is shown in figure 1 Shown; Wherein, by mass parts, 40 parts of modified polyester fibers, 10 parts of modified chitosan fibers and 10 parts of modified calcium alginate fibers.

[0029] Its preparation method comprises the following steps:

[0030] (1) Preparation of modified polyester fiber: it is prepared by uniformly mixing nano-silver and polyester chips, and melt spinning; the process parameters of the melt spinning are: control the moisture content at 50-100ppm (mass content), spin The filament temperature is 275-285°C, the length of the modified polyester fiber is 150mm, and the fineness is 0.3 dtex; the particle size of nano-silver is 80nm, and its added amount accoun...

Embodiment 2

[0035] This example provides a new type of non-woven wound dressing and its preparation method. The wound dressing is made of modified polyester fiber, modified chitosan fiber and modified calcium alginate fiber through spunlace or needle-punched nonwoven processing. Made; wherein, in parts by mass, 30 parts of modified polyester fiber, 20 parts of modified chitosan fiber and 20 parts of modified calcium alginate fiber.

[0036] Its preparation method comprises the following steps:

[0037] (1) Preparation of modified polyester fiber: it is prepared by uniformly mixing nano-silver and polyester chips, and melt spinning; the process parameters of the melt spinning are: control the moisture content at 50-100ppm (mass content), spin The filament temperature is 255-275°C, the length of the modified polyester fiber is 65mm, and the fineness is 3.0dtex; the particle size of nano-silver is 100nm, and the added amount accounts for 8wt% of the total weight of nano-silver and polyester ...

Embodiment 3

[0042] This example provides a new type of non-woven wound dressing and its preparation method. The wound dressing is made of modified polyester fiber, modified chitosan fiber and modified calcium alginate fiber through spunlace or needle-punched nonwoven processing. Made; wherein, in parts by mass, 40 parts of modified polyester fiber, 10 parts of modified chitosan fiber and 30 parts of modified calcium alginate fiber.

[0043] Its preparation method comprises the following steps:

[0044] (1) Preparation of modified polyester fiber: it is prepared by uniformly mixing nano-silver and polyester chips, and melt spinning; the process parameters of the melt spinning are: control the moisture content at 50-100ppm (mass content), spin The filament temperature is 235-245°C, the length of the modified polyester fiber is 38mm, and the fineness is: 10 dtex; the particle size of nano-silver is 120nm, and the added amount accounts for 5wt% of the total weight of nano-silver and polyester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com