Front end frame structure, front end module and vehicle

A front-end frame and body technology, applied in the field of auto parts, can solve the problems of increasing the performance burden of the front-end cooling module, a large number of auto parts, shortening the product development cycle, etc., to achieve shortened development cycle, simple structure, convenient and quick assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

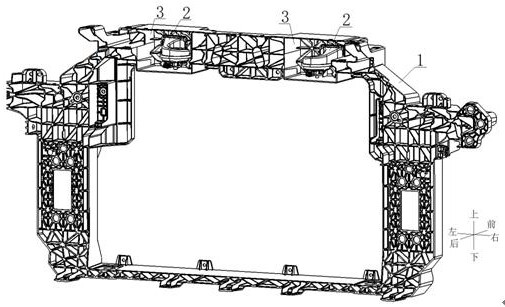

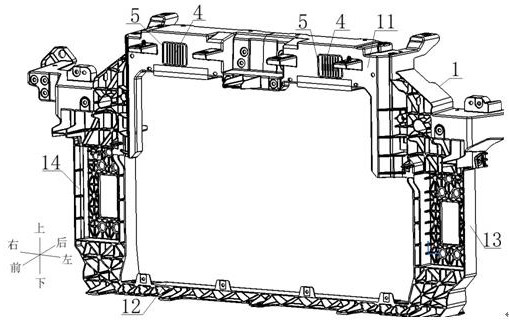

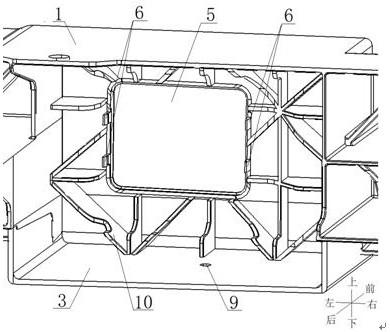

[0024] see Figure 1 to Figure 6 , the front-end frame structure shown includes a front-end frame body 1, and the front-end frame body includes an upper beam 11, a lower beam 12, a left column 13 and a right column 14, an upper beam 11, a right column 14, a lower beam 12, and a left column 13 end-to-end connections form a quadrilateral frame structure. The upper beam 11 of the front frame body 1 is integrally formed with an accommodating groove 3 with an opening facing the rear for connecting the horn 2. The number of the accommodating grooves 3 is two, which are symmetrically arranged on the left and right sides of the upper beam 1. right part. It should be noted that the position, size and size of the accommodating groove 3 can be adjusted according to the specific layout design.

[0025] The front end of the horn 2 is fixedly connected to the clip 4, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com