Automatic brick conveying, arranging and stacking equipment

A technology for stacking equipment and bricks, which is applied to the stacking, transportation and packaging of objects, loading/unloading, etc. It can solve the problems of time-consuming and laborious handling of bricks, easily damaged bricks, and small space occupation, so as to achieve fast transfer speed and not easy to collapse , neatly arranged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

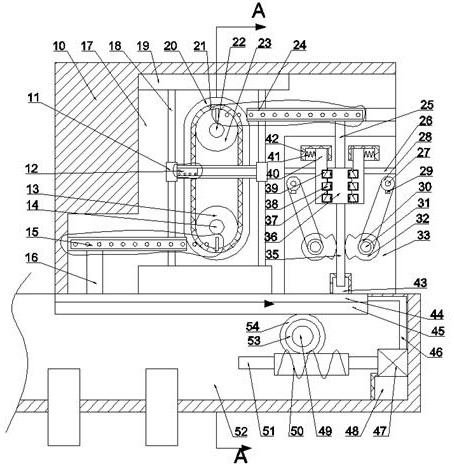

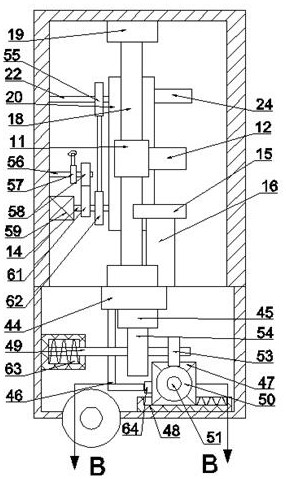

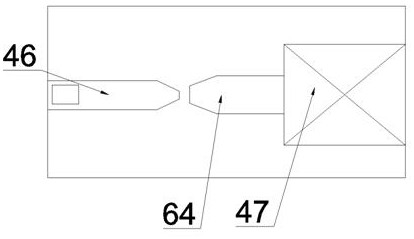

[0012] Combine below Figure 1-3 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0013] An automatic transfer, sorting and stacking device for bricks according to the present invention includes a housing 10, a transfer chamber 17 is provided on the left side of the housing 10, and symmetrical slide bar fixing blocks are fixed on the upper and lower side walls of the transfer chamber 17 19. The left and right symmetrical transfer sliders 18 are fixed between the slider fixing blocks 19, and the transfer sliders 11 are slid on the transfer sliders 18, and the transfer receivers are fixed between the transfer sliders 11. block 12, the rear side wall of the transfer cavity 17 is fixed with a receiving plate chute 20, the transfer receiving block 12 can slide on the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com