A sound insulation board mechanism suitable for municipal construction with high corrosion resistance

A corrosion-resistant and sound-insulating board technology, applied in construction, noise absorption devices, etc., can solve problems such as difficulty in achieving noise isolation and poor sound absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

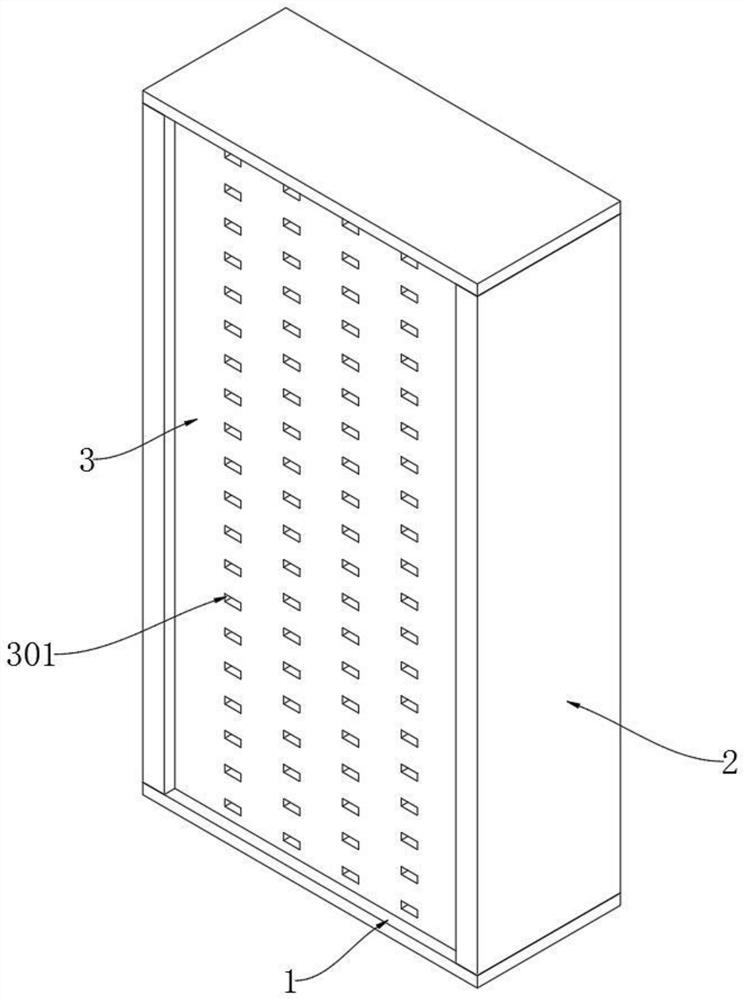

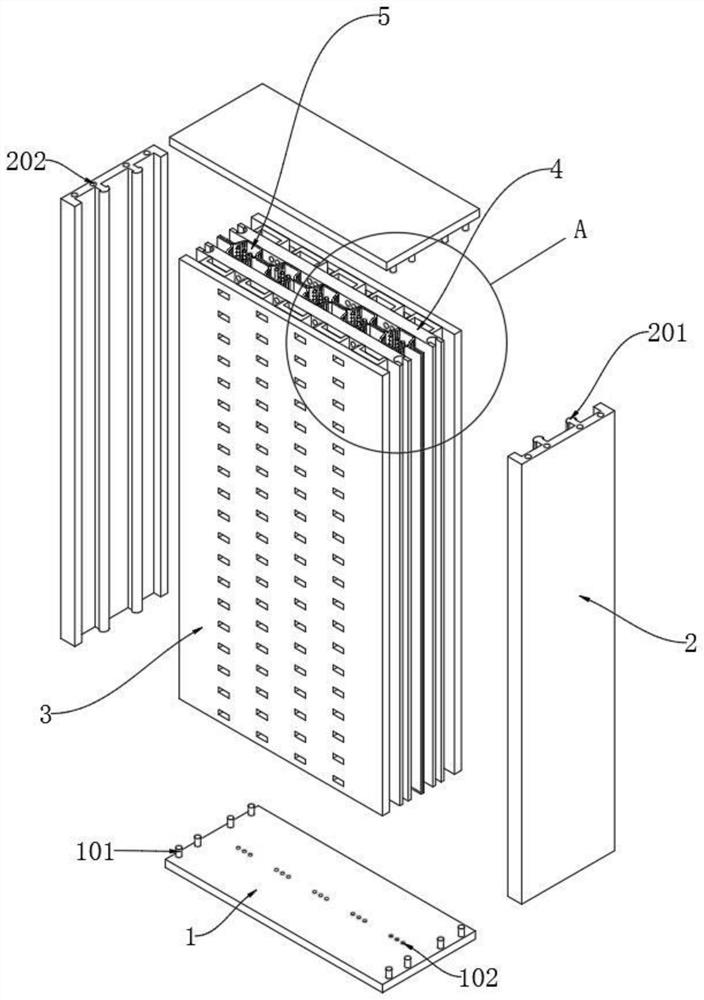

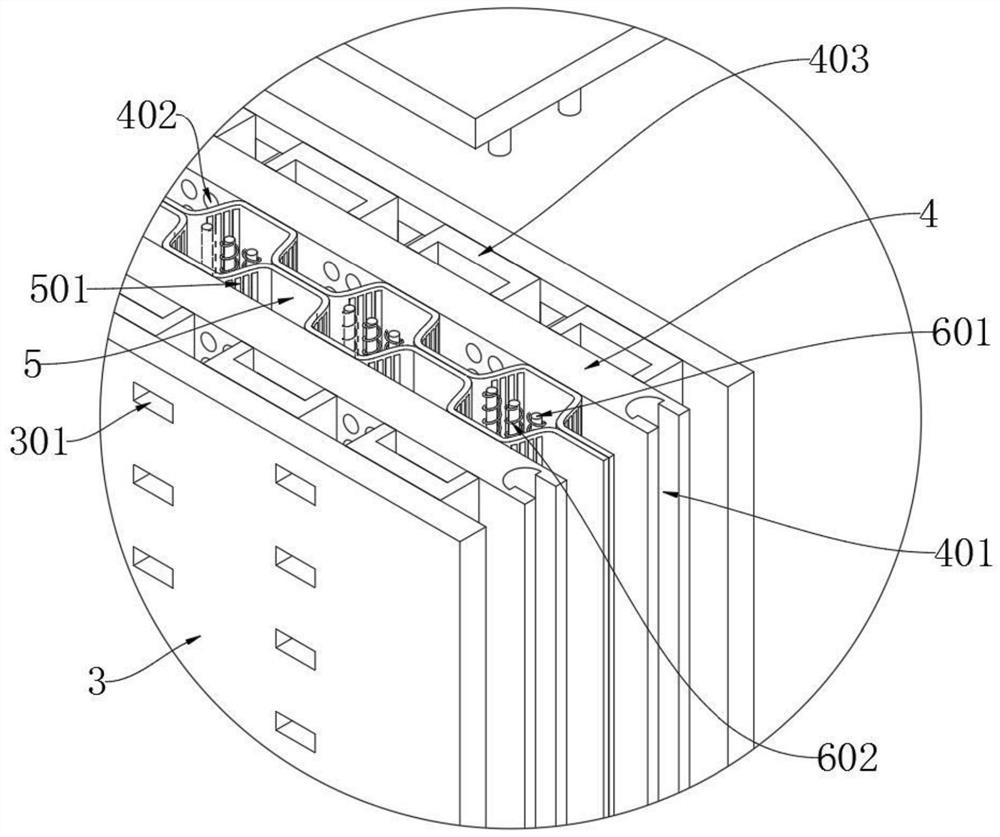

[0034] as attached figure 1 to the attached Figure 8 shown:

[0035] The invention provides a sound insulation board mechanism with high corrosion resistance suitable for municipal construction, comprising an anti-corrosion end sealing plate 1; baffle 3; the left and right ends of the front and rear two anti-corrosion outer baffles 3 are respectively connected with U-shaped side sealing plates 2 in vertical sliding and clamping; 2. T-shaped clip rails 201 are vertically installed on the opposite side walls corresponding to the muffler mechanism 4, respectively, and corresponding butt joints are provided on the top plane and bottom plane of the side sealing plate 2 at the positions corresponding to the butting columns 101 respectively. Column groove 202, the side sealing plate 2 can be vertically slid and clamped to the outside of the muffler mechanism 4 through the clamping rail 201, and can be vertically inserted into the anti-corrosion end sealing plate 1 through the butt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com