Axial fixing device for marine low-temperature non-insulated pipe system and using method

A pipeline system, axial fixing technology, used in pipeline supports, pipeline protection, pipes/pipe joints/fittings, etc., can solve problems such as deviation and affect the safety of pipeline systems, achieve a good limiting effect, overcome space limitations, prevent The effect of wear on the outer wall of the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention is further described below in conjunction with specific embodiments:

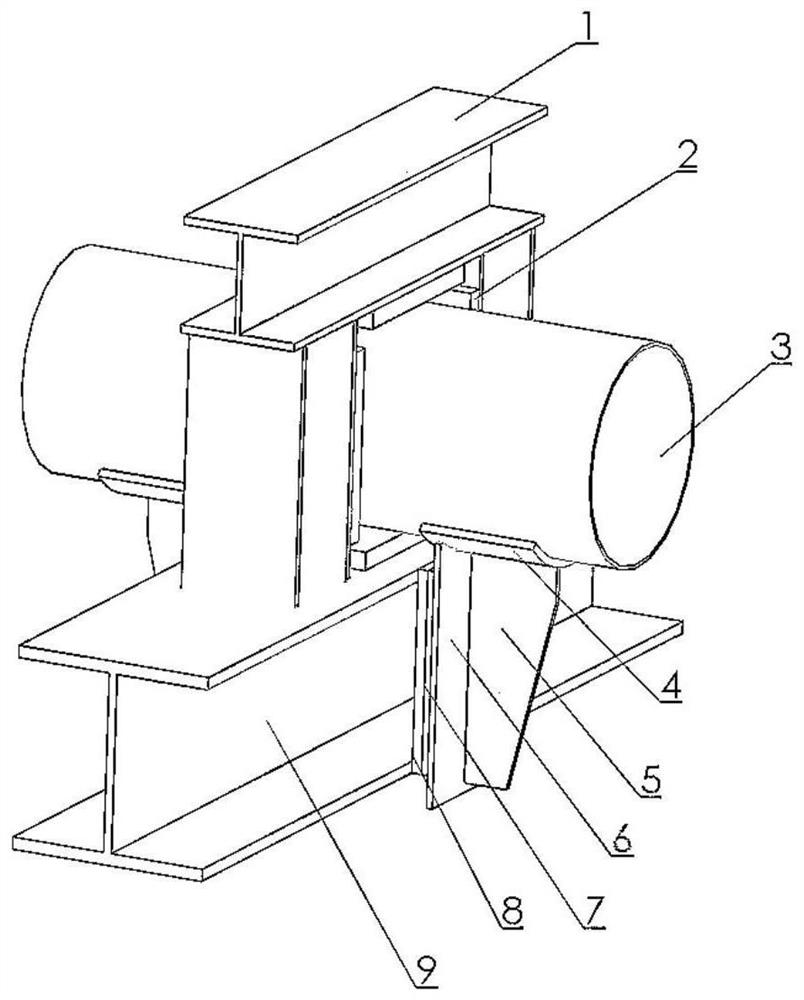

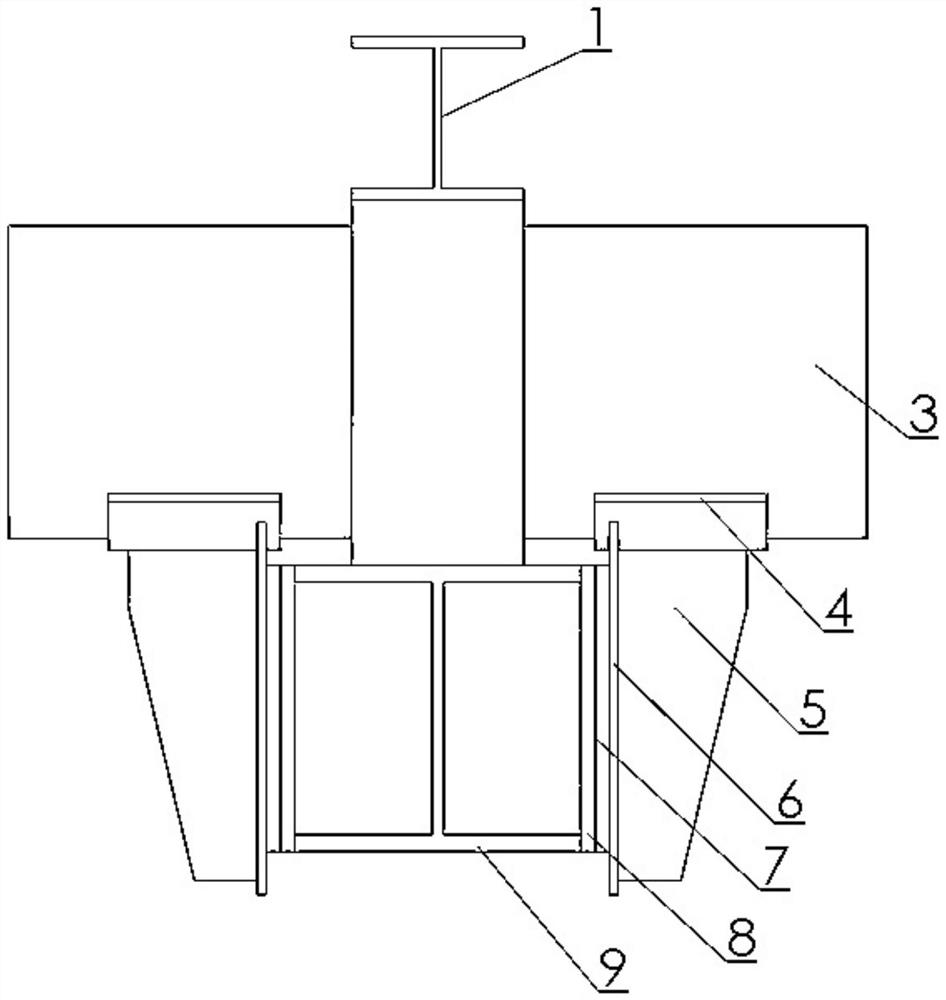

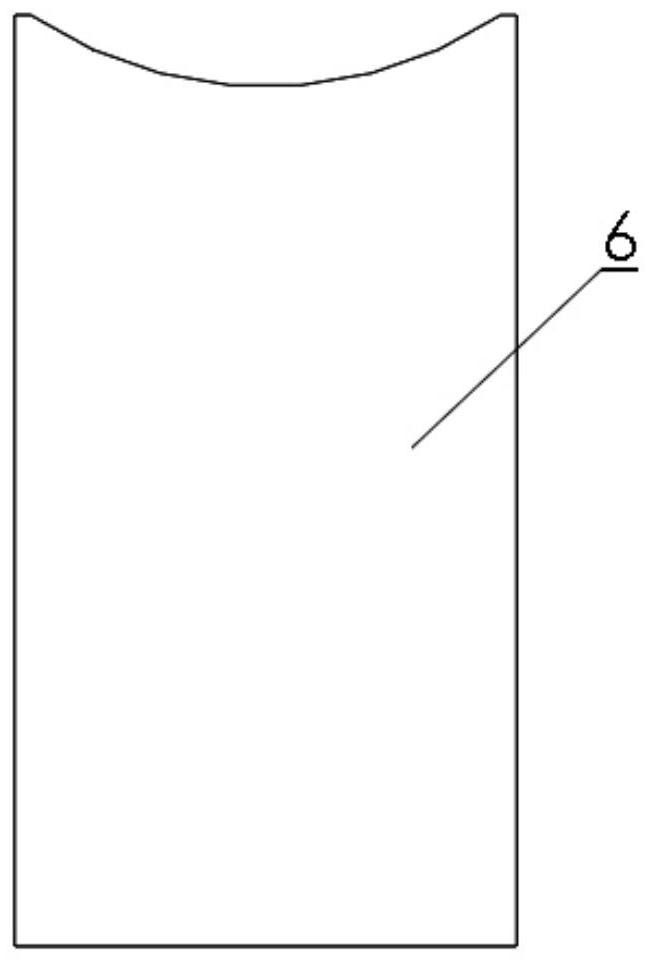

[0028] An axial fixing device for a marine low-temperature non-insulated piping system, such as Figure 1-6 As shown, it includes a pipe 3, a base 9, a pipe clamp 1, a backing plate 2 and an axial stop assembly, and the base 9 is H-shaped steel. The pipe clamp 1 is welded into a door-shaped structure by three H-shaped steels. The pipe clamp and the base are enclosed to form a pipeline passage, and the pipe clamp 1 is welded on the base 9 . The backing plate 2 is four plates of polytetrafluoroethylene material, three backing plates 2 are installed on the pipe clamp 1, one backing plate 2 is installed on the base 9, four corners of the backing plate 2 are provided with round holes, The backing plate 2 is respectively fixed on the pipe clamp 1 and the base 9 in the form of bolt connection through round holes. The axial stop assembly is installed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com