An adjustable coal feeder takeover device for the coal feeding system of a circulating fluidized bed boiler

A circulating fluidized bed, adjustable technology, which is applied in the direction of fluidized bed combustion equipment, fuel burned in the molten state, combustion type, etc., can solve the problems of coal combustion, inconvenient adjustment of the angle of feeding equipment, and inconvenient adjustment of feeding Speed pipeline and other problems, to achieve the effect of increasing the adjustment function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

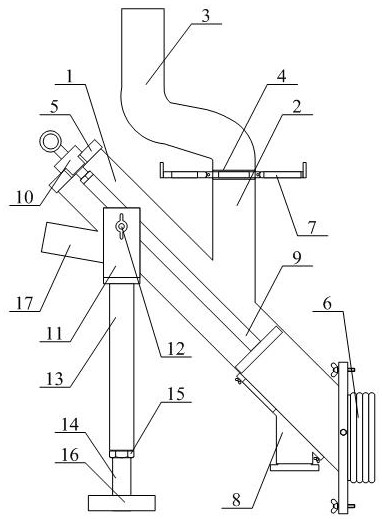

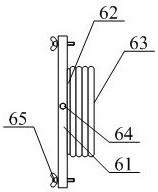

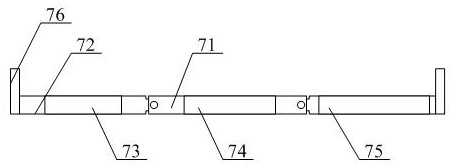

[0035] The present invention will be specifically described below in conjunction with the accompanying drawings. figure 1 and attached figure 2 As shown, an adjustable coal feeder nozzle device of a circulating fluidized bed boiler coal feeding system includes a coal falling pipe 1, a first connecting pipe 2, a second connecting pipe 3, an insertion hole 4, a fixed cover 5, Rotatable connection conveying pipe structure 6, pluggable sliding speed control plate structure 7, observable cleaning pipe structure 8, pushable isolation plate structure 9, inclined T-shaped cover 10, U-shaped bracket 11, jacking bolt 12, support pipe 13, the support rod 14, the first locking nut 15, the support seat 16 and the ventilation pipe 17, the lower end of the first connecting pipe 2 is bolted to the middle position of the upper end of the coal falling pipe 1; the second connecting pipe The lower end of 3 is welded on the upper end of the first connecting pipe 2; the insertion hole 4 is opened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com