An Axially Floating Backflow Annular Combustion Chamber Large Elbow Structure

An annular combustion chamber and floating technology, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of short service life of large elbows and inability to adjust the inner wall of large elbows independently, so as to increase service life and improve Service life, effect of reducing temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

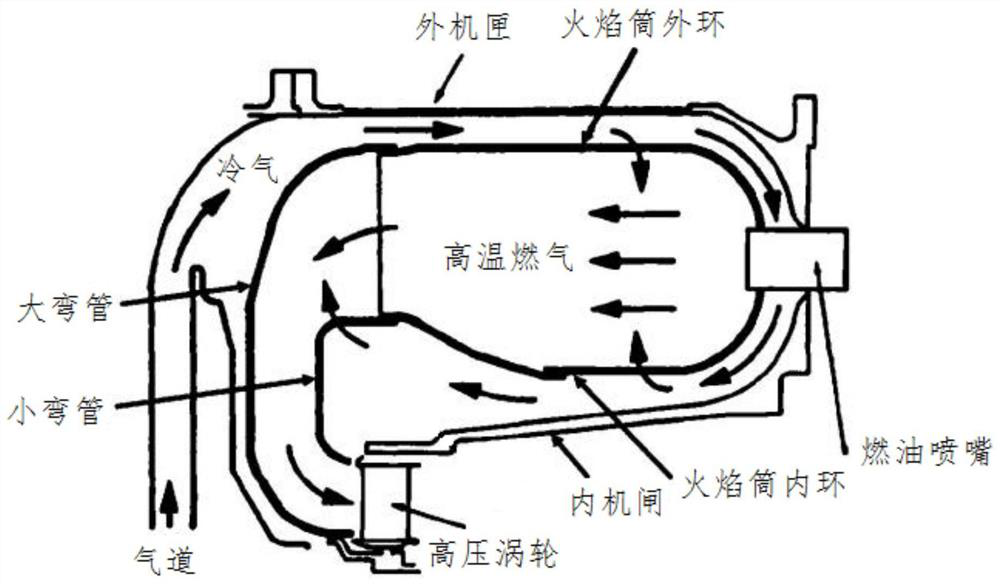

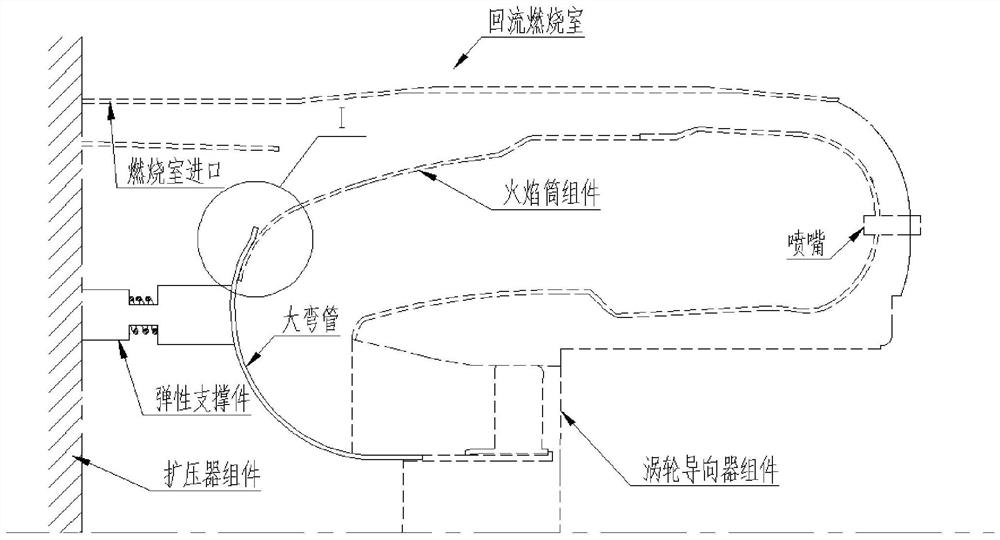

[0033] Such as Figure 3-5 As shown, an axially floating backflow annular combustion chamber large elbow structure includes a diffuser assembly, a flame tube assembly, and a turbine guide assembly. The diffuser assembly is provided with a plurality of elastic supports. A large curved pipe is arranged between the elastic support and the flame tube assembly, the central axis of each elastic support passes through the maximum point of the curvature of the large curved pipe, and the large curved pipe is fixed on the turbine guide On the device assembly, a cooling gap is formed between the large bend pipe and the flame tube assembly.

[0034]In the technical solution of the present application, the elastic support is installed on the diffuser assembly, and the large elbow is installed on the turbine guide assembly. The elastic support has no fixed connection with the large elbow, and is only in surface contact with the large elbow. In order to limit the axial expansion and contrac...

Embodiment 2

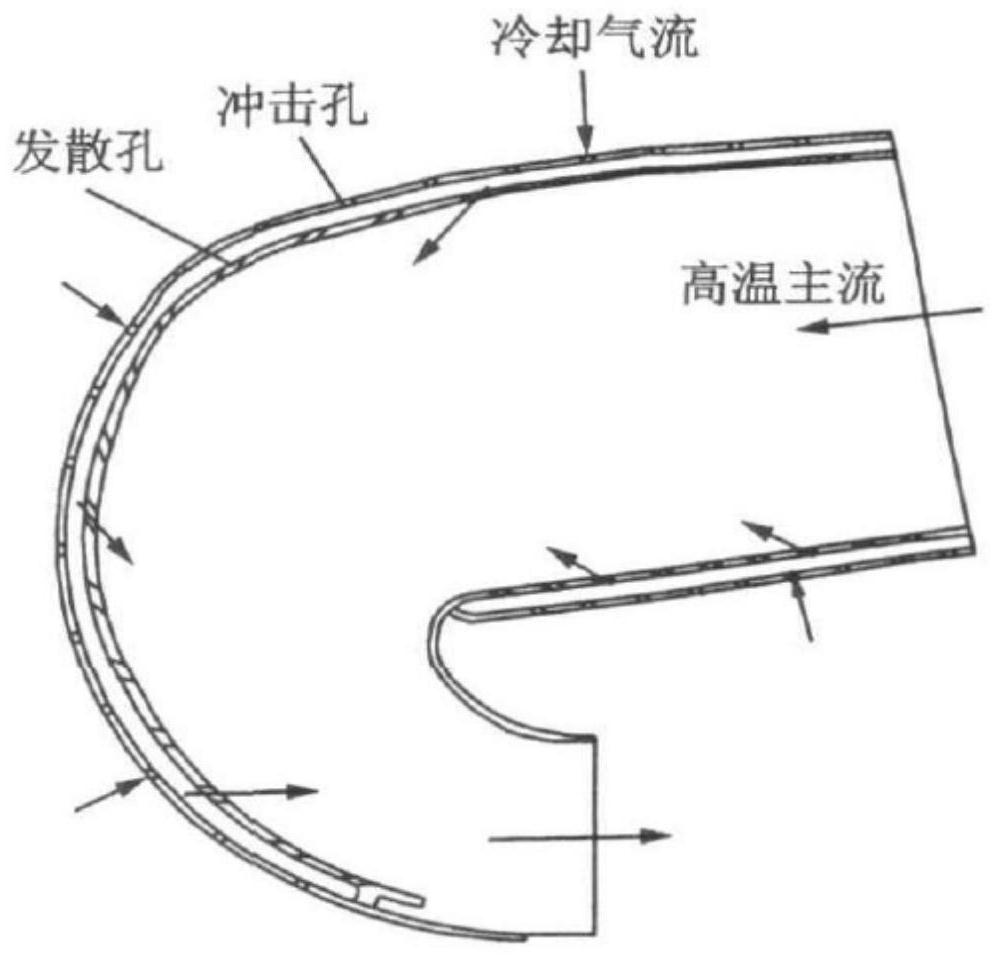

[0037] Such as Figure 3-5 As shown, on the basis of Embodiment 1, the flame tube assembly includes a flame tube outer shell and a flame tube inner shell, and the large bend coincides with the rear wall of the flame tube shell and forms the cooling gap. The large curved pipe is partially attached to the wall surface of the rear part of the flame tube shell, and the shape of the attached part is consistent.

Embodiment 3

[0039] Such as Figure 3-5 As shown, on the basis of Embodiment 1 or 2, the range of the cooling gap is 0-1.5mm. More preferably, the cooling gap may be 0mm, 0.2mm, 0.4mm, 0.6mm, 0.8mm, 1mm, 1.2mm, 1.3mm, 1.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com