Soft package battery module frame assembly, battery assembly and new energy automobile

A technology of soft-pack batteries and battery modules, which is applied to battery pack parts, battery/battery traction, electric vehicles, etc. It can solve the problems of unsuitable soft-pack battery modules, improve collection methods, and improve heat dissipation performance and stability, thermal performance, and stability performance improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

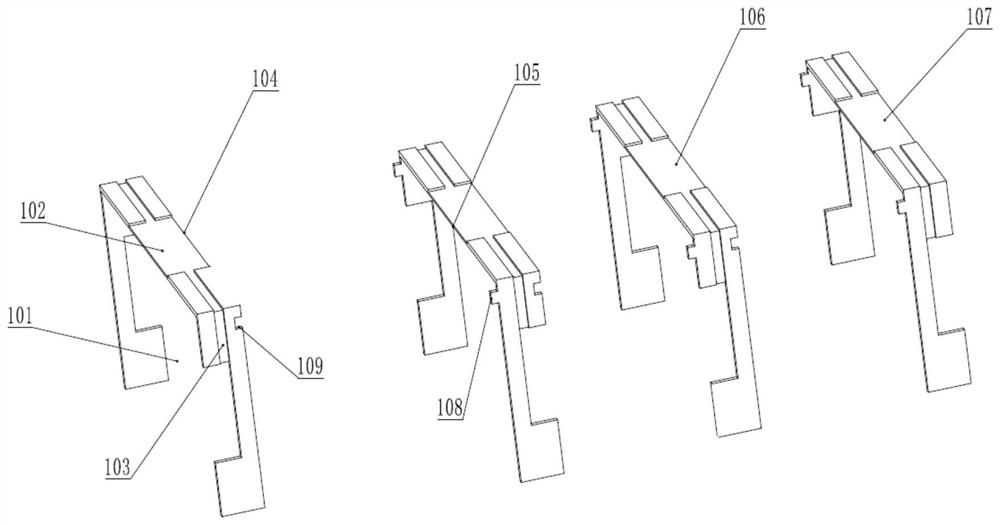

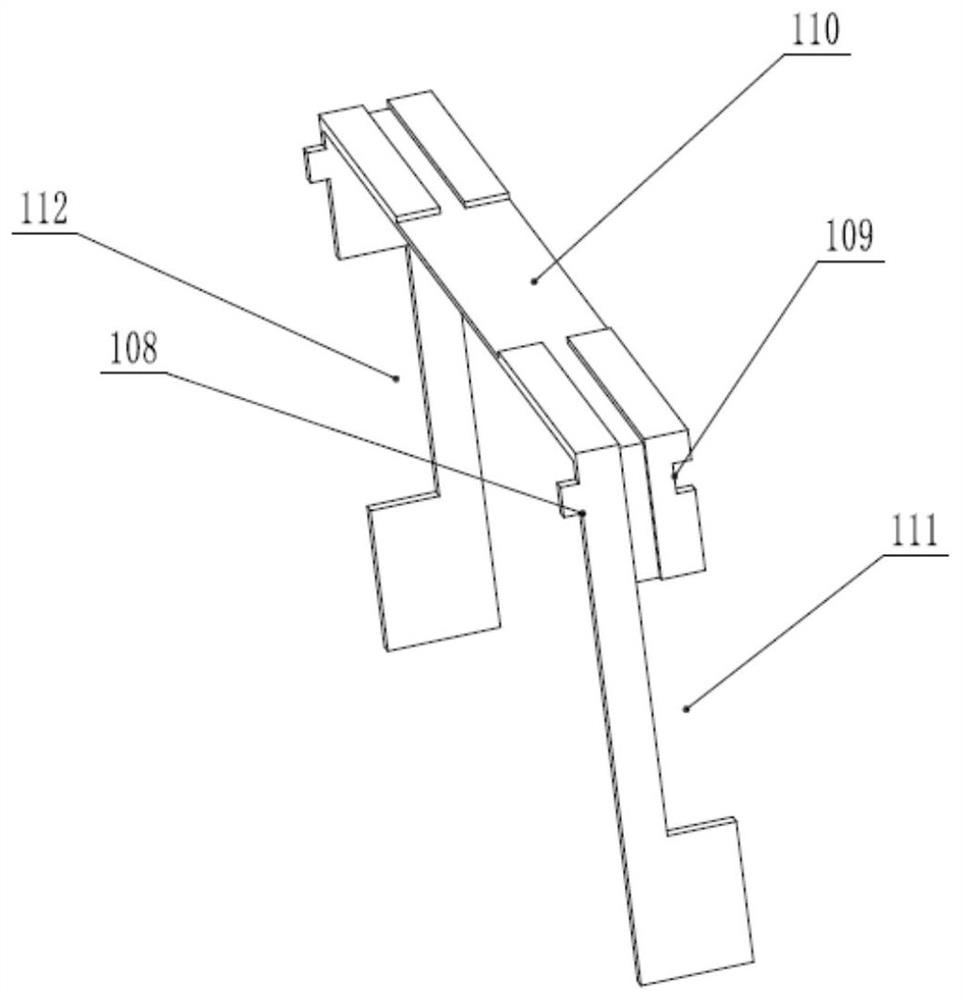

[0032] This embodiment describes in detail the pouch battery module frame assembly of the present invention.

[0033] The pouch battery module frame assembly 10 of the present embodiment has a battery module installation part 101 and a PCB data acquisition board installation groove 102, such as Figure 1~4 shown. Preferably, the pouch battery module frame assembly 10 is fitted on the battery module 20 so that the battery module 20 is located in the battery module installation part 101 and the tabs on both sides of the battery module 20 are exposed, such as Figure 4 shown. Preferably, the PCB data acquisition board mounting groove 102 is used to install the PCB data acquisition board 30 and connect the PCB data acquisition board 30 to the tabs on both sides of the battery module 20, such as Figure 4 shown. The pouch battery module frame assembly 10 of this embodiment can not only fix and protect the battery module 20, but also provide a place for the PCB data acquisition boa...

Embodiment 2

[0049] This embodiment describes the battery assembly of the present invention in detail.

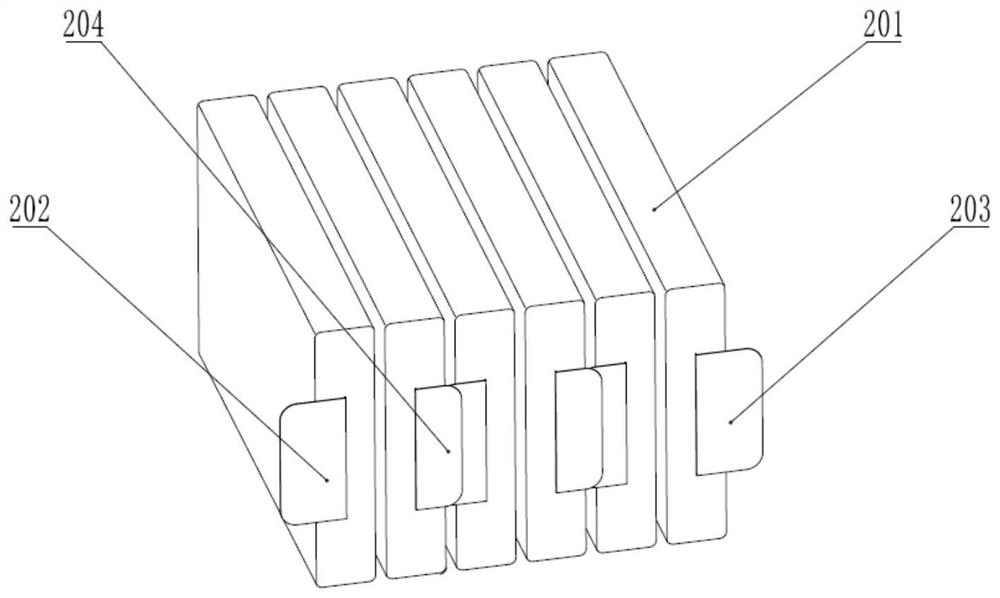

[0050] The battery assembly of this embodiment includes the pouch battery module frame assembly 10, battery module 20, PCB data acquisition board 30 and acquisition wire harness 40 of any technical solution in embodiment 1, such as image 3 with 4 shown. Preferably, the battery module 20 is composed of a plurality of single cells 201 connected in series, the pouch battery module frame assembly 10 is nested on the battery module 20 and the battery module 20 is located at the bottom of the pouch battery module frame assembly 10 Inside the battery module installation part 101 . Preferably, the PCB data acquisition board 30 is installed in the PCB data acquisition board installation groove 102 of the pouch battery module frame assembly 10 . Preferably, the collection wire harness 40 is connected between the PCB data collection board 30 and the tabs on both sides of the single battery 201...

Embodiment 3

[0056] This embodiment describes the new energy vehicle of the present invention in detail.

[0057] The new energy vehicle of this embodiment includes the battery assembly of any one of the technical solutions in Embodiment 2.

[0058] The new energy vehicle of this embodiment includes the battery assembly of any technical solution in Embodiment 2, so that the electromagnetic performance of the new energy vehicle of this embodiment is more excellent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com