Water surface cable laying device, system and method

A cable laying and water surface technology, which is applied in the direction of cable laying equipment, cable installation, cable installation on floats, etc., can solve the problems that it is difficult to monitor the location of the fault and the location of the cable recovery, and achieve convenient adjustment and convenient device spacing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

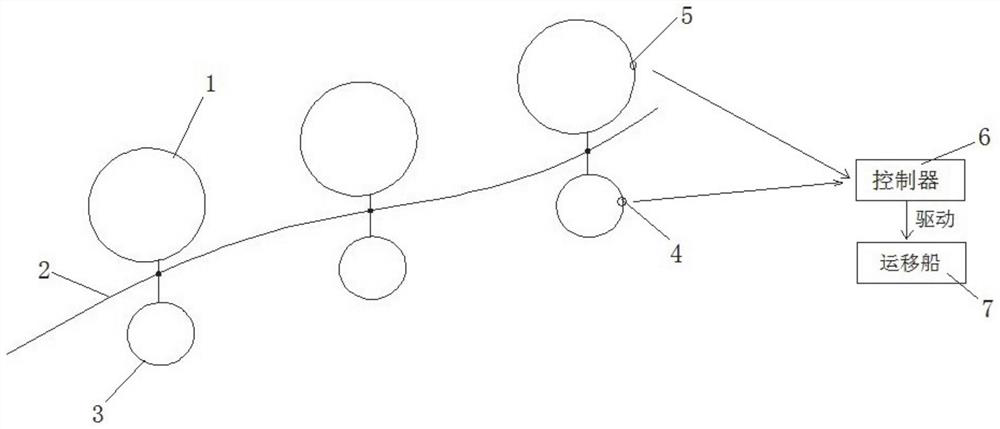

[0034] This embodiment provides a surface cable laying device, such as figure 1 As shown, it includes a floating body 1 and a cable fixing part 3, the floating body 1 is detachably connected to the cable fixing part 3, the cable fixing part 3 is used to fix the cable, and the floating body 1 can make the cable float on the water surface.

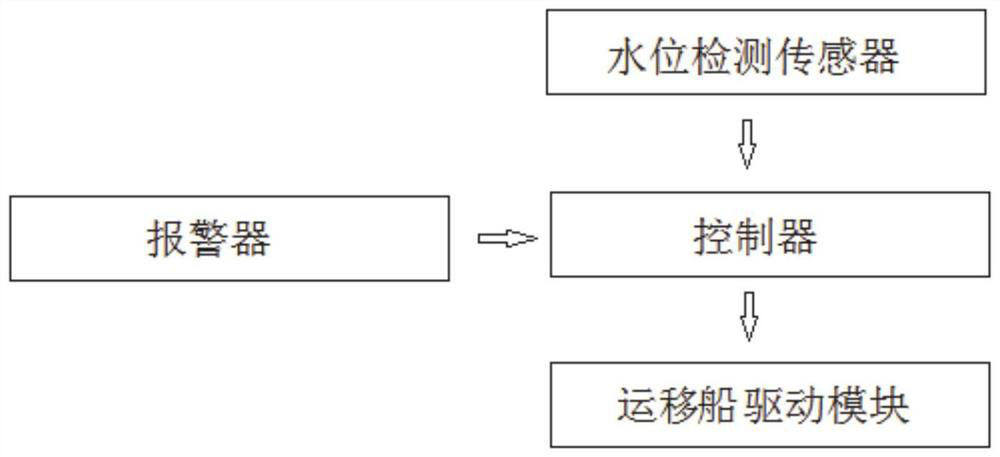

[0035] A water level detection sensor 4 is fixed on the cable fixing part 3, and an alarm 5 is installed on the floating body 2; the water level detection sensor 4 and the alarm 5 are respectively connected to the controller 6, and the water level detection sensor 4 transmits the water level information to the controller 6 , when the water level reaches the set value, the control alarm 5 sends an alarm signal.

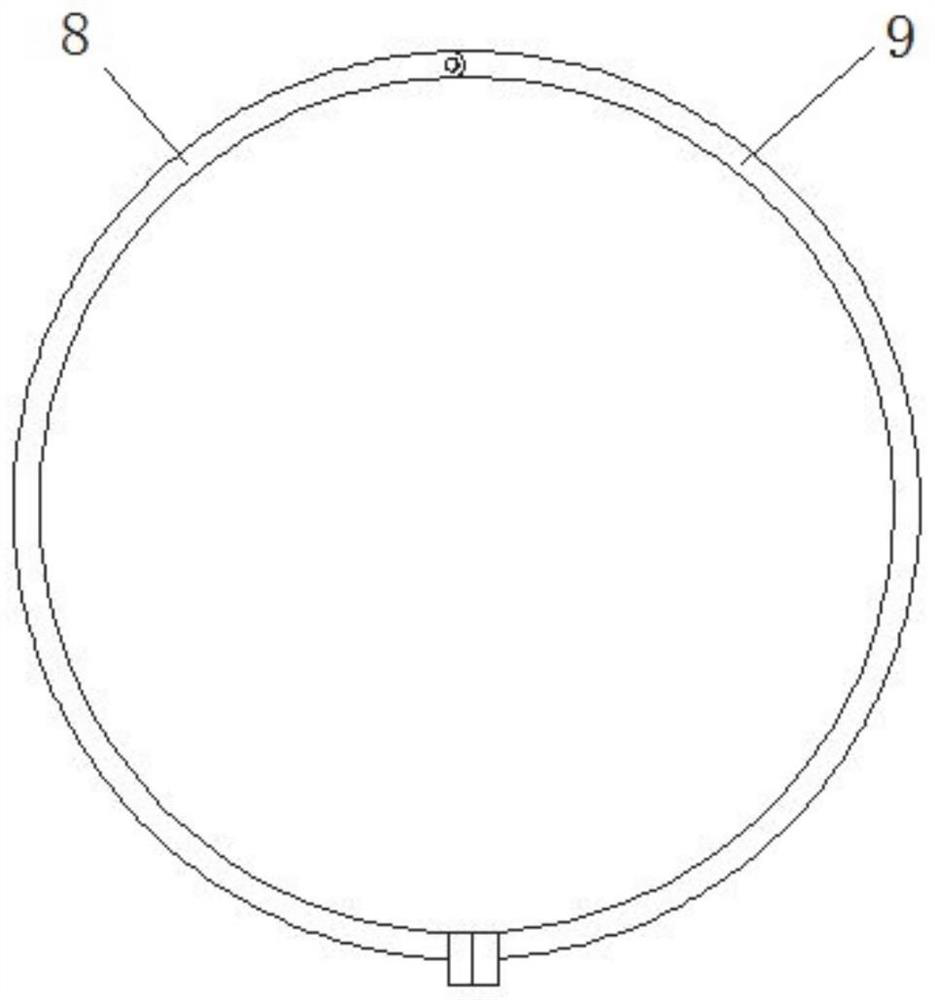

[0036] Further, the buoyant body 1 and the cable fixing member 3 are connected through a connecting piece, and the connecting piece only needs to be able to realize the detachable connection between the buoyant body 1 and the cable f...

Embodiment 2

[0040] This embodiment provides a surface cable laying system, such as figure 1 As shown, it includes several cable laying devices connected in series, and the cable laying device can adopt the structure described in Embodiment 1; a plurality of cable laying devices are arranged at intervals of set distances.

[0041] The buoys 1 are connected by a stay wire 3 , and the connecting piece can move along the stay wire 3 to adjust the distance between adjacent cable laying devices. Further, the connecting piece is connected to the pull wire 3 through a sliding device, and the sliding device is equipped with a locking device. When the locking device is opened, the connecting piece can move along the pulling wire 3. When the locking device is closed, the position of the cable laying device is fixed.

[0042] In this embodiment, the sliding device may be a slider, and the locking device may be a lock nut; of course, in other embodiments, the sliding device and the locking device may ...

Embodiment 3

[0049] This embodiment provides a method for using a surface cable laying system, using the laying system described in Embodiment 2, including:

[0050] Step 1: Predetermine the distance between adjacent cable laying devices, and connect each cable laying device.

[0051] Step 2: Pass the cables through the cable holder one by one.

[0052] Step 3: The water level detection sensor detects the water level information and transmits it to the controller. When the set water level is exceeded, the controller controls the alarm to alarm.

[0053]Step 4: The operator enters the transfer ship, and the controller controls the transfer ship to move to the alarm position.

[0054] Step 5: The operator adjusts the distance between adjacent cable laying devices to restore the water level below the set value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com