Feather removing device for poultry slaughtering

A depilation device and technology for poultry, which are applied to poultry plucking machines, poultry processing, slaughtering and other directions, can solve problems such as low depilation efficiency, and achieve the effects of improving depilation effect, improving depilation efficiency, and maintaining cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

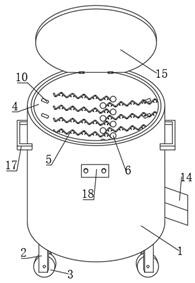

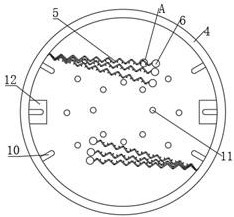

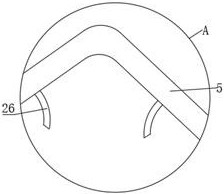

[0031] refer to Figure 1-5 A depilatory device for poultry slaughtering, comprising a box body 1, a plurality of legs 2 are symmetrically fixed on both sides of the bottom of the box body 1 by bolts, rollers 3 are fixed on the bottom of the legs 2 by bolts, and the top of the box body 1 is connected by hinges. Cover plate 15, the top of cover plate 15 is fixed with a first handle 16 by bolts, the bottom of the inner wall of box body 1 is welded with a fixed seat 7, the top of fixed seat 7 is fixed with a motor 8 by bolts, and a drum 4 is arranged above the motor 8, and the drum 4 A mounting plate 9 is welded at the bottom, and the bottom of the mounting plate 9 is fixedly connected to the output shaft of the motor 8. Both sides of the drum 4 are fixed with a plurality of springs 5 distributed up and down by bolts. The inside of the spring 5 is welded with a counterweight ball 6. The spring 5 is relatively arranged, and the interior of the spring 5 is welded with a plurality...

Embodiment 2

[0035] refer to Figure 1-7 , a hair removal device for poultry slaughter, the top of the cover plate 15 is fixed with a fan 19 by bolts, the exhaust end of the fan 19 is connected with a connecting pipe 20, the connecting pipe 20 and the cover plate 15 are fixed through, and the bottom of the connecting pipe 20 is connected with a wind pan 21, The bottom of the cover plate 15 is provided with a mesh cover 22, the cross section of the mesh cover 22 is set in the shape of a cat face, the mesh cover 22 is arranged on the periphery of the wind disk 21, the bottom of the cover plate 15 is provided with a ring groove 23, and the ring groove 23 is arranged on the periphery of the wind disk 21, Two sliders 24 are slidably connected in the ring groove 23, and the bottoms of the two sliders 24 are fixedly connected with the net cover 22 by bolts. The top of the slider 24 is provided with a plurality of circular grooves, and balls 25 are movably connected in the circular grooves. , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com