Hot-pressing waste gas collection treatment device

A technology of waste gas collection and treatment device, applied in transportation and packaging, dispersed particle filtration, dispersed particle separation, etc., can solve problems such as environmental pollution, waste gas spillage, human injury, etc., and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

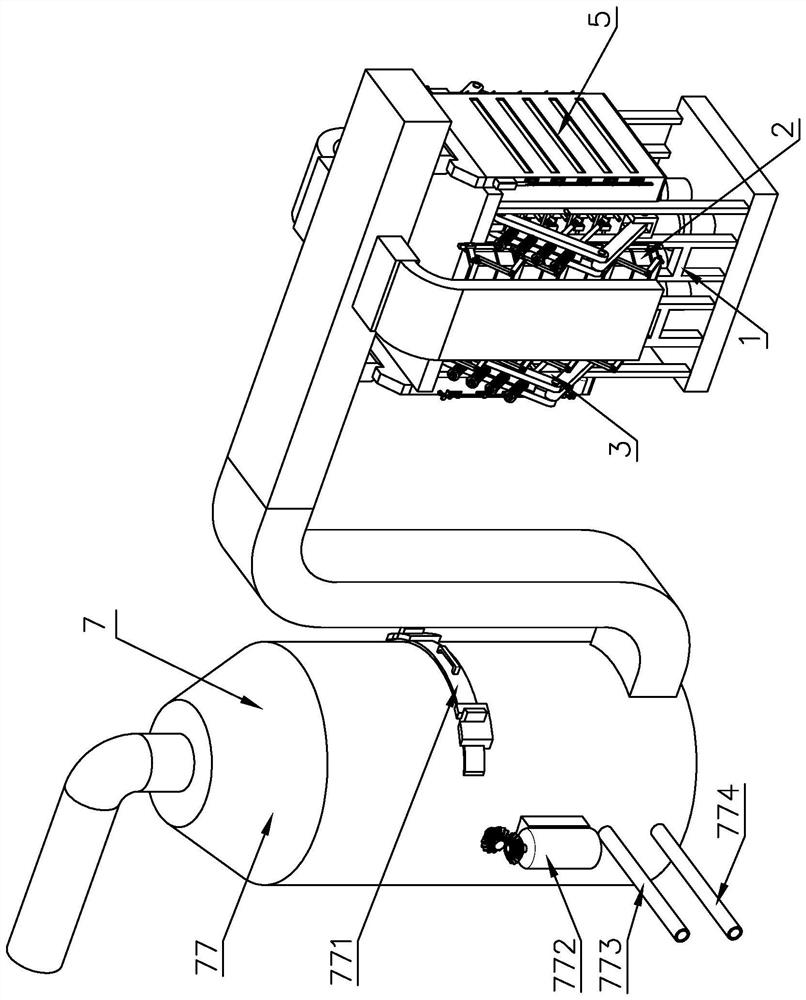

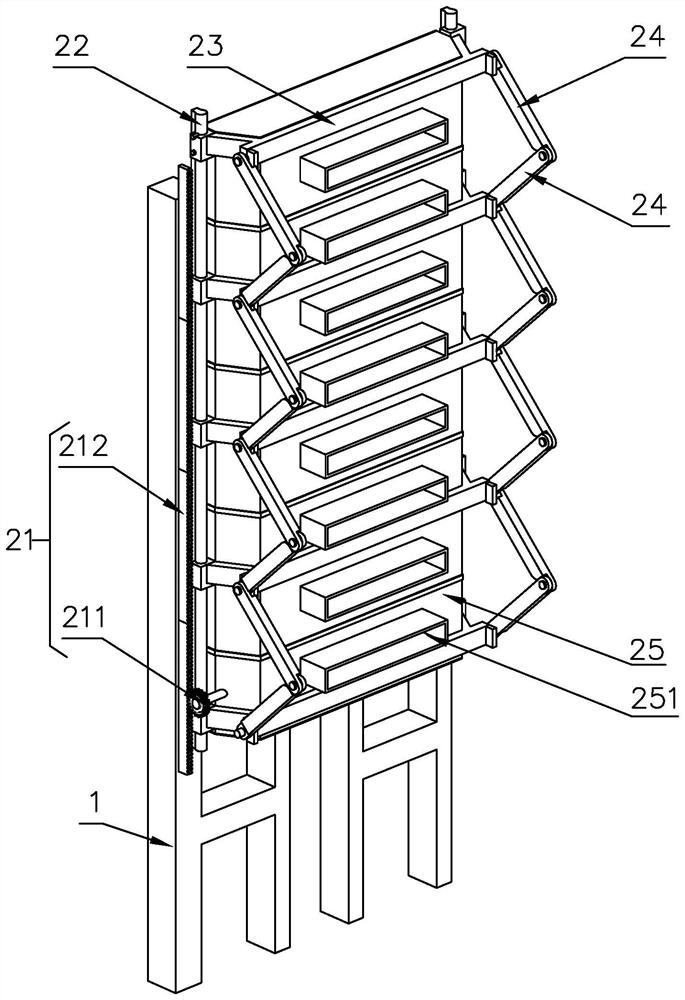

[0025] Embodiment 1: as Figure 1-5 shown;

[0026] A hot-pressed waste gas collection and treatment device, comprising a frame 1, a first waste gas collection mechanism 2, a hot press mechanism 3, a second waste gas collection mechanism 5, and a filter tower 7; the frame 1 carries the first waste gas collection mechanism 2, the second Exhaust gas collection mechanism 5 and heat press mechanism 3; the first exhaust gas collection mechanism 2 is fixed on both sides of the frame 1; the second exhaust gas collection mechanism 5 is fixed on both ends of the frame 1; the heat press mechanism 3 is fixed inside the frame 1 Surrounded by a waste gas collection mechanism 2 and a second waste gas collection mechanism 5; the top of the frame 1 is provided with a top plate 12, and the bottom is provided with a base 11; the base 11 is provided with an oil cylinder 13; the top shaft of the oil cylinder 13 is connected to the heat-pressing mechanism 3.

[0027] The first exhaust gas collec...

Embodiment 2

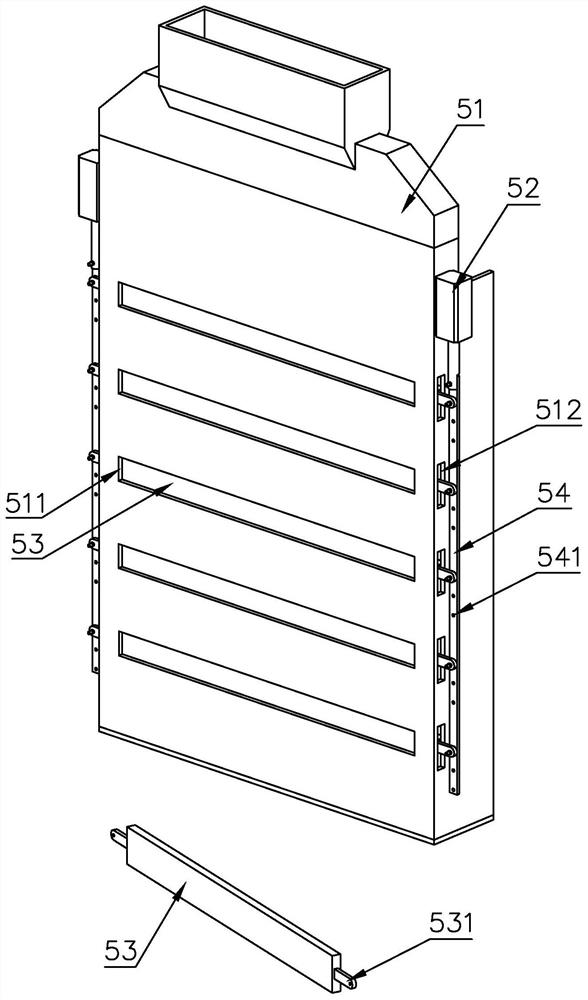

[0033] Embodiment 2: as Figure 6 Shown, compared with embodiment 1, the difference is:

[0034] The two ends of the sealing plate 53 are provided with connecting arms II 532; the two sides of the cover plate 51 are respectively provided with a set of first lead screws 56 and bevel gears are arranged at both ends, and the first lead screws 56 pass through the connecting arms II 532 Threads are connected to each other; the top of the cover plate 51 is provided with a second lead screw 57 and both ends are provided with bevel gears and are meshed with the bevel gears at one end of the first lead screw 56; one end of one group of first lead screws 56 is provided with a motor I55 is fixed on the cover plate 51; the shaft end of the motor I55 is provided with a bevel gear meshing with the bevel gear at one end of the first lead screw 56; the power provided by the motor I55 drives the sealing plate 53 to move up and down along the first lead screw 56 to realize the feeding port 511 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com