Stirring device for organic fertilizer production

A mixing device and technology for organic fertilizers, which are applied to mixers, mixer accessories, mixers and other directions with a rotating mixing device, can solve problems such as affecting the quality of organic fertilizers, insufficient mixing, and inability to achieve the effect of turning over materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

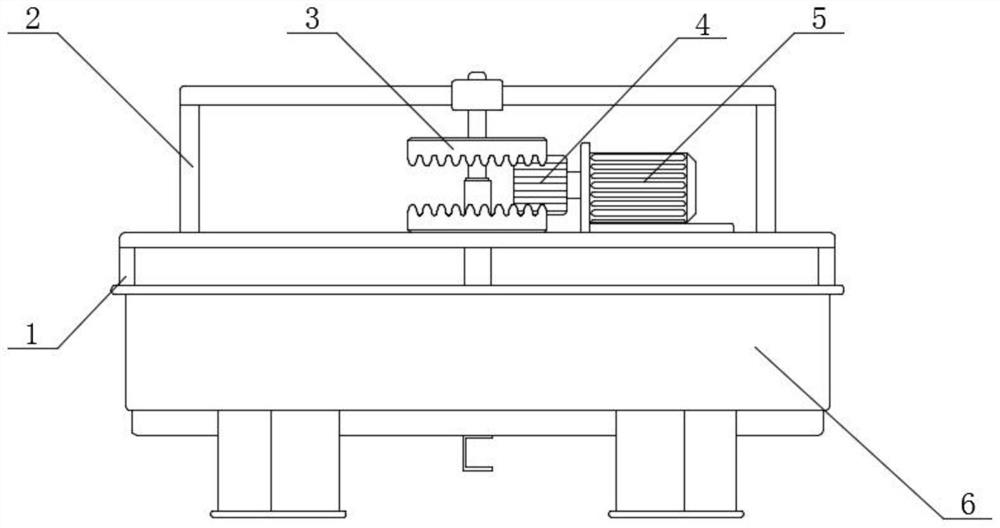

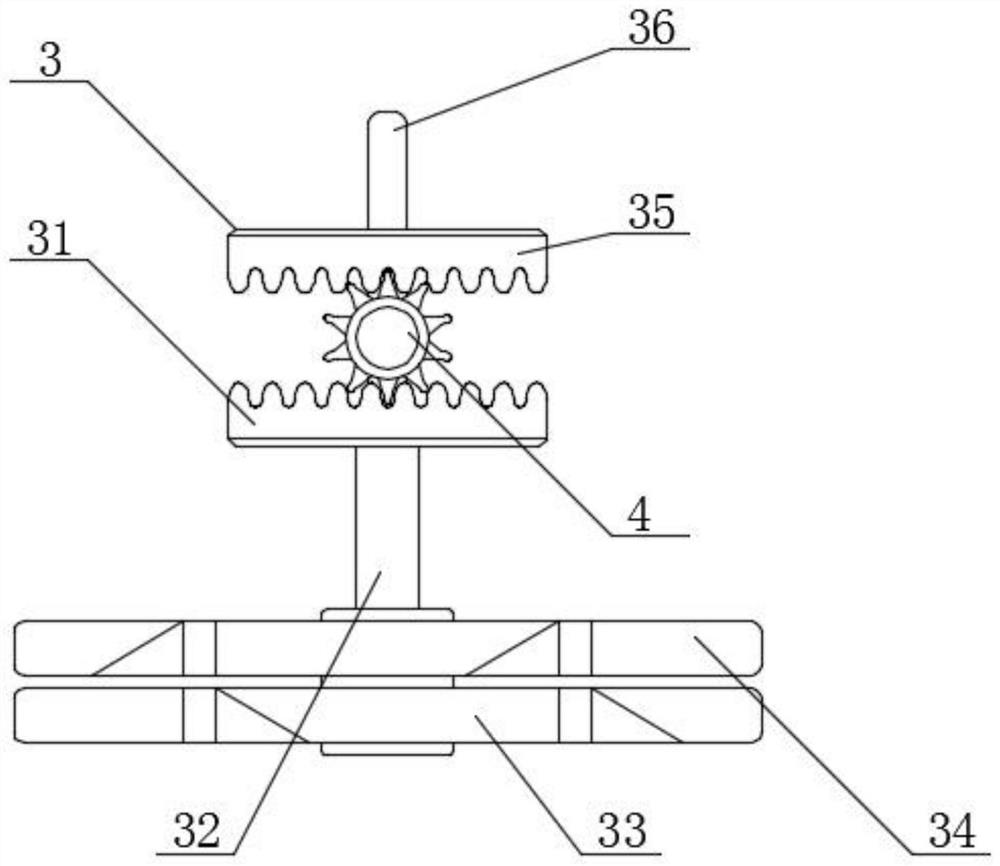

[0022] Such as Figure 1-2 As shown, a stirring device for organic fertilizer production includes a power gear 4, the surface of the power gear 4 is provided with transmission teeth, the lower end face of the power motor 5 is fixed on the surface of the support frame 1 through the motor sleeve, the support frame 1 and the fixed frame The upper end surface of 2 is provided with a bearing sleeve, and the transmission structure 3 can rotate relative to the support frame 1 and the fixed frame 2. The upper end surface of the lower rotating disk 31 and the lower end surface of the upper rotating disk 35 are provided with transmission teeth and are transmitted with the surface of the power gear 4. Teeth occlusion, the outer surface of the inner rotating column 36 is connected to the inside of the bearing sleeve on the surface of the fixed frame 2, the inner rotating column 36 can rotate relative to the outer rotating column 32, and the outer surface of the outer rotating column 32 is ...

Embodiment 2

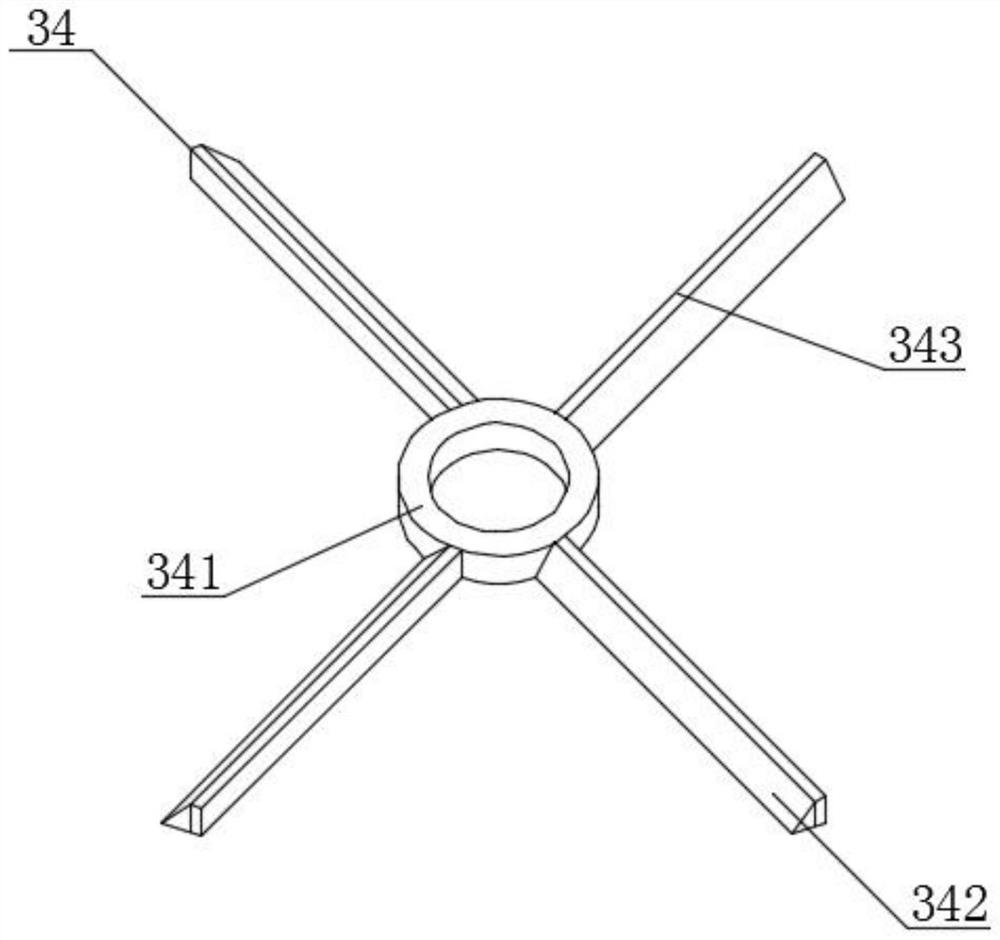

[0025] Such as Figure 1-3 As shown, a stirring device for organic fertilizer production includes a power gear 4, the surface of the power gear 4 is provided with transmission teeth, the lower end face of the power motor 5 is fixed on the surface of the support frame 1 through the motor sleeve, the support frame 1 and the fixed frame The upper end surface of 2 is provided with a bearing sleeve, the transmission structure 3 can rotate relative to the support frame 1 and the fixed frame 2, the upper end surface of the transmission ring 341 is provided with a fixing hole and the fixing hole is connected to the outer surface of the outer rotating column 32, and the supporting plate 342 The upper end surface of the upper end and the lifting plate 343 form an angle of 45 degrees.

[0026] The transmission ring 341 can be well connected to the surface of the outer rotating column 32, the outer rotating column 32 drives the transmission ring 341 to rotate, the rotation of the transmis...

Embodiment 3

[0028] Such as Figure 1-4 As shown, a stirring device for organic fertilizer production includes a power gear 4, the surface of the power gear 4 is provided with transmission teeth, the lower end face of the power motor 5 is fixed on the surface of the support frame 1 through the motor sleeve, the support frame 1 and the fixed frame The upper end surface of 2 is provided with a bearing sleeve, the transmission structure 3 can rotate relative to the support frame 1 and the fixed frame 2, the inner surface of the fixed rubber block 64 is provided with a sliding groove and the pulling baffle 61 can move left and right inside the sliding groove, and the pulling baffle Plate 61 is a thin iron sheet with strong bending performance.

[0029] The position of the pull baffle 61 can be well limited by fixing the rubber block 64, the pull protrusion 63 pulls upwards, and the upward movement of the pull protrusion 63 drives the pull baffle 61 to move, and the pull baffle 61 moves inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com