Automatic glue viscosity adjusting system

An automatic adjustment and glue technology, which is applied in the direction of control/regulation system, viscosity control, non-electric variable control, etc., can solve the problems of low glue viscosity and unstable product quality, and achieve high product quality, stable product performance, and glue viscosity. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

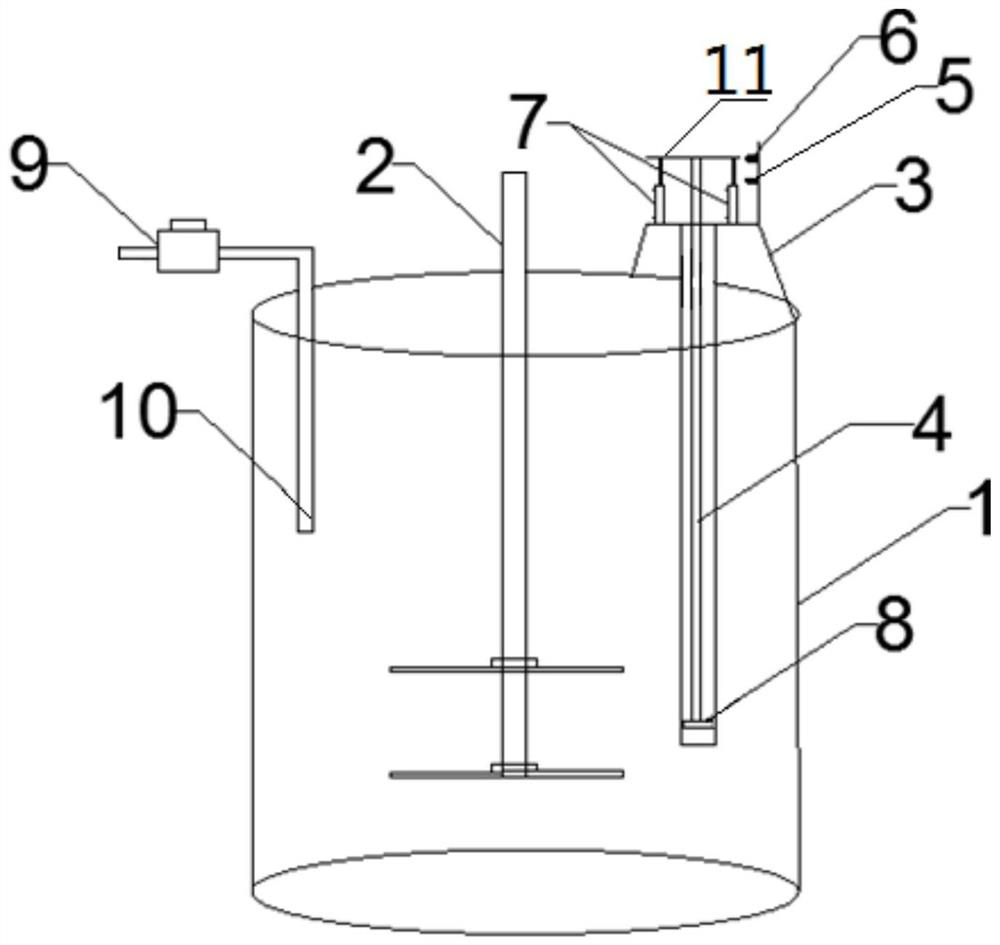

[0017] Such as figure 1 As shown, the automatic glue viscosity adjustment system of the present invention includes a viscosity detection device, a control device, and a diluent replenishing device. The viscosity detection device includes a sampling tube that extends downward into the glue in the sampling vessel. The sampling tube is provided with a sampling rod part, and the sampling rod part Including a sampling rod, the lower end of the sampling rod is provided with a sampling piston that is sealed and slidingly connected to the inner side of the lower end opening of the sampling tube, and the upper end of the sampling rod that extends out of the upper end of the sampling tube is provided with a signal trigger plate, which is connected to the sampling cylinder through transmission. The control device includes a PLC controller, a lower signal sensor, and an upper signal sensor. The lower signal sensor is located below the upper signal sensor. The sampling cylinder drives the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com