Steel surface rust removal device for waste steel treatment

A steel surface and steel technology, applied in the field of iron and steel surface derusting devices for waste steel treatment, can solve the problems of a large amount of rust debris, poor derusting effect, and scalding staff, etc., to achieve convenient collection and better adsorption effect Good, good rust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

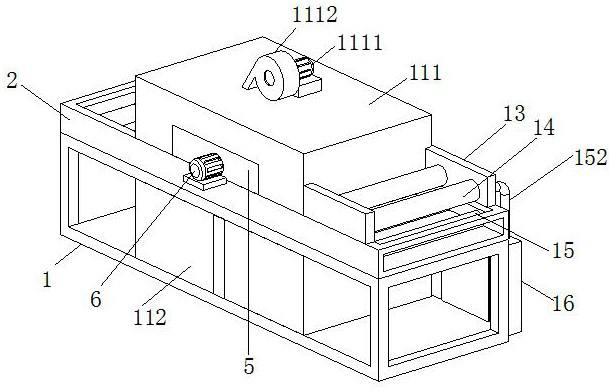

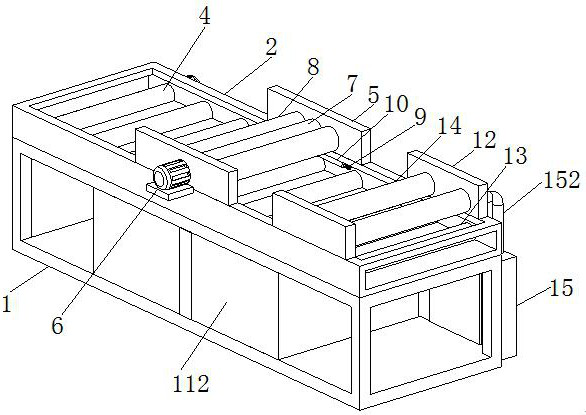

[0029] see Figure 1-Figure 3 , the present invention provides a technical solution: a steel surface derusting device for scrap iron and steel treatment, comprising a frame one 1, a dust suction device 11 and a cooling device 15, the top outer wall of the frame one 1 is fixedly connected with a frame two 2 The outer wall of one side of the frame two 2 is fixedly connected with the first motor 3, the output shaft of the first motor 3 is rotatably connected with the conveying roller 4 between the inner walls of the frame two 2, and the top outer wall of the frame two 2 is fixedly connected There is a first mounting plate 5, the number of the first mounting plate 5 is two, the outer wall of one side of the first mounting plate 5 is fixedly connected with the second motor 6, and the output shaft of the second motor 6 is fixedly connected with the first steel brush roller 7. Between the inner walls of the two first mounting plates 5 and on both sides of the first steel brush roller...

Embodiment 2

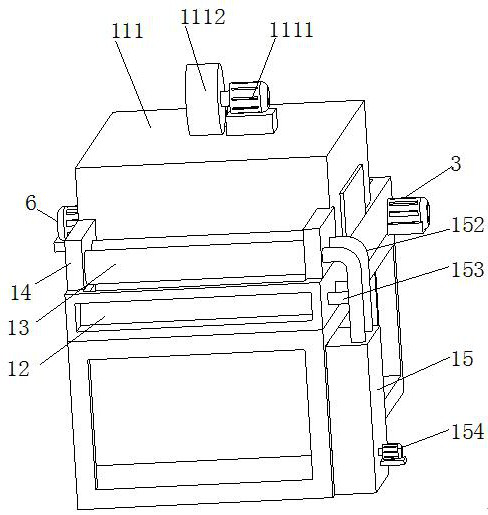

[0032] see Figure 4-Figure 6 , On the basis of Embodiment 1, the present invention provides a technical solution: the dust collection device 11 includes an upper dust collection cover 111 and a lower dust collection cover 112, the upper dust collection cover 111 is arranged on the top outer wall of the frame two 2, the lower The dust collection cover 112 is arranged on the inner wall bottom of the frame two 2, and the top outer wall of the upper dust collection cover 111 is fixedly connected with a fourth motor 1111, and the top outer wall of the upper dust collection cover 111 is fixedly installed on one side of the fourth motor 1111. Fan 1112, both sides of the inner wall of the upper dust collection hood 111 are fixedly connected with baffles 1113, the baffles 1113 are inclined, the bottom outer wall of the upper dust collection hood 111 is provided with vents, and the inner walls of both sides of the lower dust collection hood 112 are A magnetic plate 1121 is fixedly conn...

Embodiment 3

[0035] see Figure 7 , On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the top outer wall of frame 2 2 is fixedly connected with a second mounting plate 12 on one side of the first mounting plate 5, and the frame 2 A first cooling pipe 13 is rotatably connected between the inner walls of 2, a second cooling pipe 14 is rotatably connected between the inner walls of the second mounting plate 12, and the cooling device 15 includes a cooling box 151, which is fixedly connected to the frame 1 One side of the outer wall of the cooling box 151 is communicated with a first connecting pipe 152 on the top outer wall of the cooling box 151, and a second connecting pipe 153 is communicated with one side of the first connecting pipe 152. The outer wall of the cooling pipe 14 is rotatably connected, and the second connecting pipe 153 is connected to the outer wall of the first cooling pipe 13 at an end away from the first connecting pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com