A cable tightening device

A cable and wire roller technology, applied in the field of cable processing equipment, can solve the problems of inability to install and disassemble wire rollers and empty wire rollers, and inability to arrange cables, so as to achieve high efficiency, reduced labor intensity, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

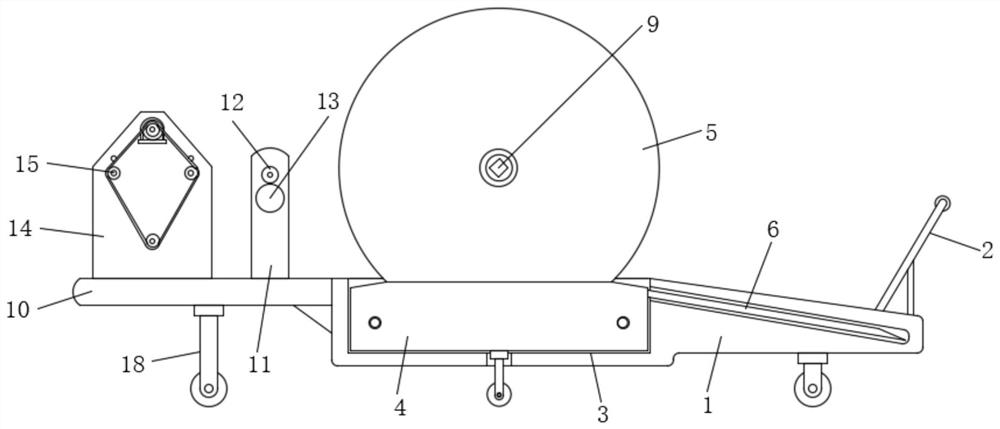

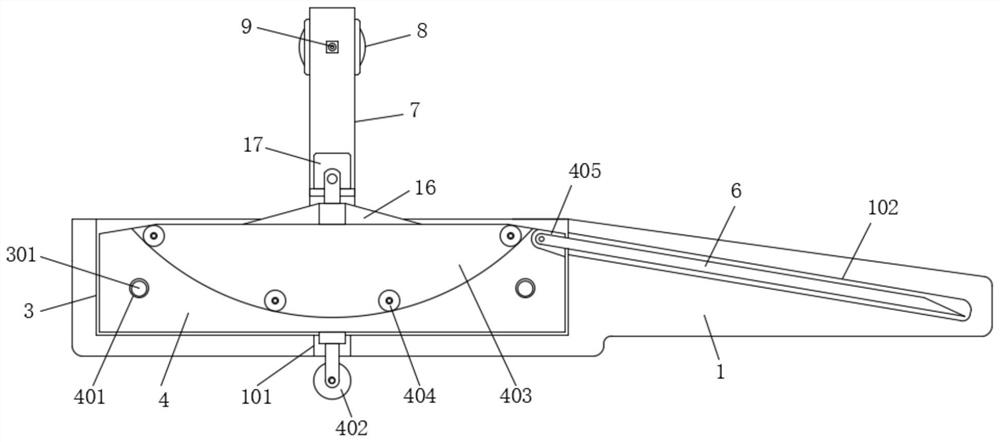

[0029] Example one, by Figure 1 to Figure 6Given, the present invention includes a base 1, a handle 2 is installed at one end of the top of the base 1, a groove 3 is installed at the other end of the top of the base 1, and a moving plate 4 is installed inside the groove 3. The moving plate 4 can be installed effectively. The top of the moving plate 4 is provided with a line roller 5, and one end of the moving plate 4 is installed with a rotating plate 6. Through the setting of the rotating plate 6, the line roller 5 can be easily moved from the moving plate 4. For assembly and disassembly, a first fixing plate 7 is installed on the top of the base 1, a first motor 8 is installed on the upper part of one side of the first fixing plate 7, and a rotating shaft 9 is installed at the output end of the first motor 8. The rotating shaft 9 and the line roller 5 One end of the base 1 is fixedly installed with a connecting plate 10, one side of the top of the connecting plate 10 is sym...

Embodiment 2

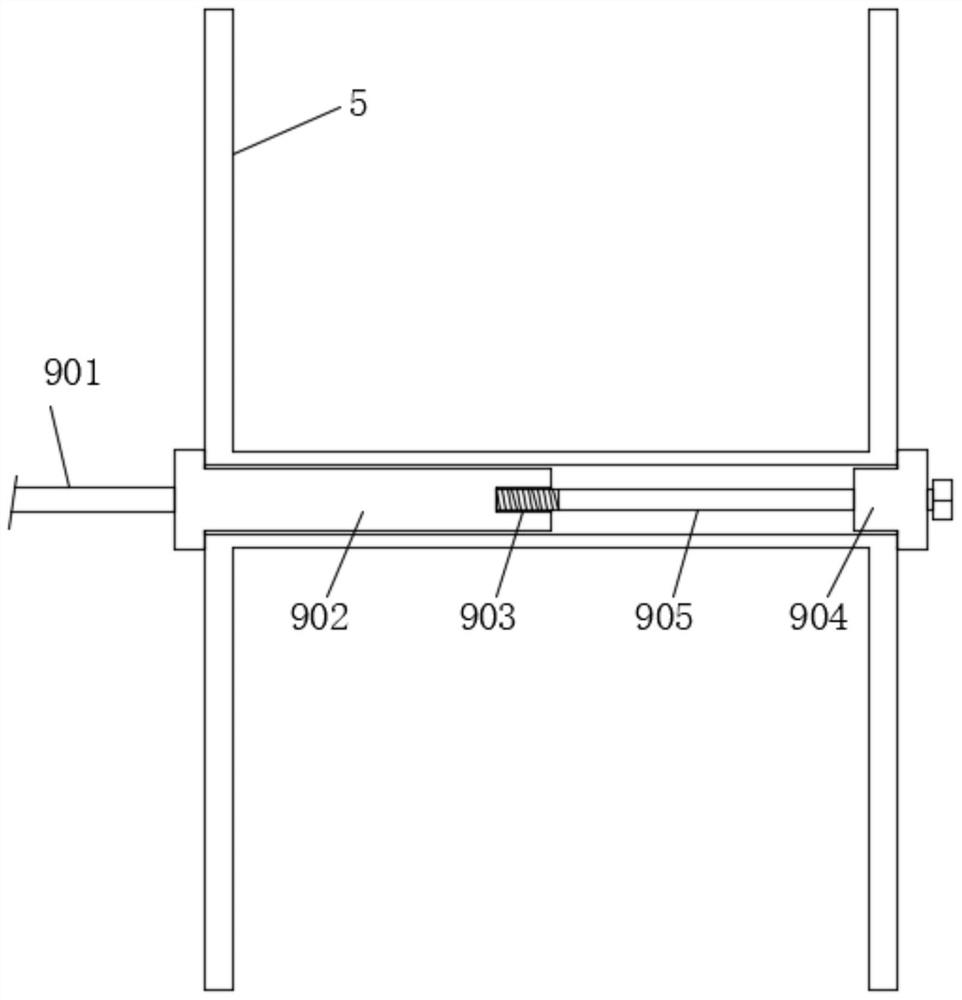

[0034] Embodiment 2, on the basis of Embodiment 1, by Figure 4 Given, the cable arrangement 12 includes a hollow sleeve 1201, an insertion rod 1202, a threading ring 1203, a disc 1204 and a tooth 1205. The hollow sleeve 1201 is movably plugged on the top of one of the second fixing plates 11, and the insertion rod 1202 It is installed on the top of the other second fixing plate 11, and the insertion rod 1202 is movably inserted into the hollow sleeve 1201. so that the cables can be arranged in an orderly manner.

Embodiment 3

[0035] Embodiment 3, on the basis of Embodiment 3, by Figure 4 Given, the cable power mechanism 13 includes a second motor 1301, a rotating rod 1302, a cylinder 1303 and a continuous cross slot 1304, the second motor 1301 is installed on the upper part of the other second fixing plate 11, and the rotating rod 1302 is rotatably installed Between the two second fixing plates 11 , a cylinder 1303 is installed at one end of the rotating rod 1302 , the other end of the rotating rod 1302 is connected to the output end of the second motor 1301 , and a continuous cross-through slot 1304 is opened at the end of the cylinder 1303 . On the surface, the bottom ends of the latching teeth 1205 are movably latched in the interior of the continuous intersecting through-grooves 1304 , so as to provide power to the cable arranging mechanism 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com