Shearing mechanism for automatic wiring of intelligent parking lot control barrier gate

A technology of parking lot control and shearing mechanism, which is applied in metal processing, coating and other directions, can solve the problems of automatic conveying of casings, unable to realize automatic processing and wiring of coding casing systems, etc., to improve efficiency and save manpower and material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

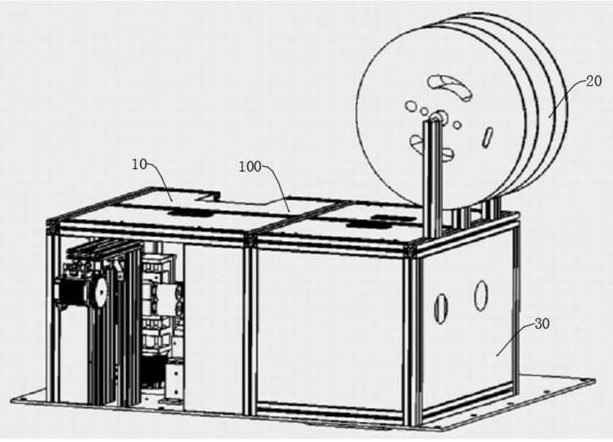

[0029] see Figure 1-5 , in the illustration: this embodiment is a preferred implementation of this technical solution, a cutting mechanism for automatic wiring of intelligent parking lot control gates; including wiring coded casing assembly 100 and line number pipe plate 20, The cable to be wired is wound inside the wire number tube coil 20 , and a protective cover 30 is arranged outside the wiring code casing assembly 100 , and the wire number tube coil 20 is installed above the protective cover 30 , and the Each mechanism inside the wiring code casing assembly 100 is installed inside the protective cover 30;

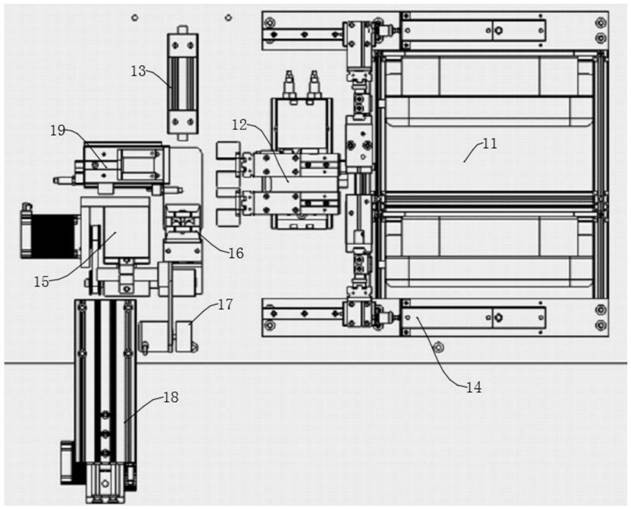

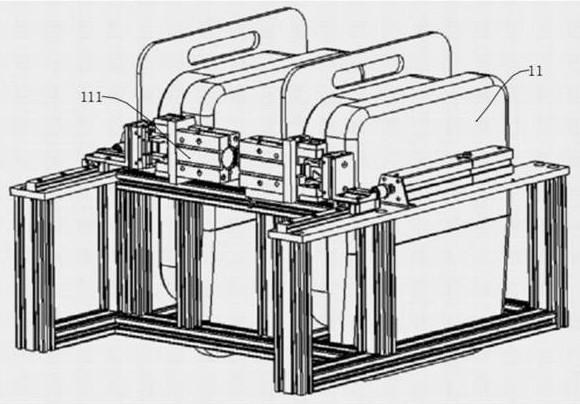

[0030] Such as figure 2 As shown, the wiring coding casing assembly 100 includes a printing mechanism 11, a casing grabbing mechanism 12, a wire feeding mechanism 15, a cutting mechanism 16 and a heat shrinking mechanism 19, and the two sides of the printing mechanism 11 are installed There is a transmission mechanism 14. The transmission mechanism 14 includes a do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com