Knitting thread pre-stressing device of sewing machine

A technology of sewing machines and sutures, applied in the direction of textiles and papermaking, etc., which can solve problems such as recovery of the convex part 831, inability to provide proper tension, interference with the extension of the suture 90, etc., and achieve the effect of avoiding wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055]The technical solutions of the present invention will be apparent from the embodiments of the present invention, which will be apparent from the embodiments of the present invention, and rather than all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative labor are the scope of the present invention.

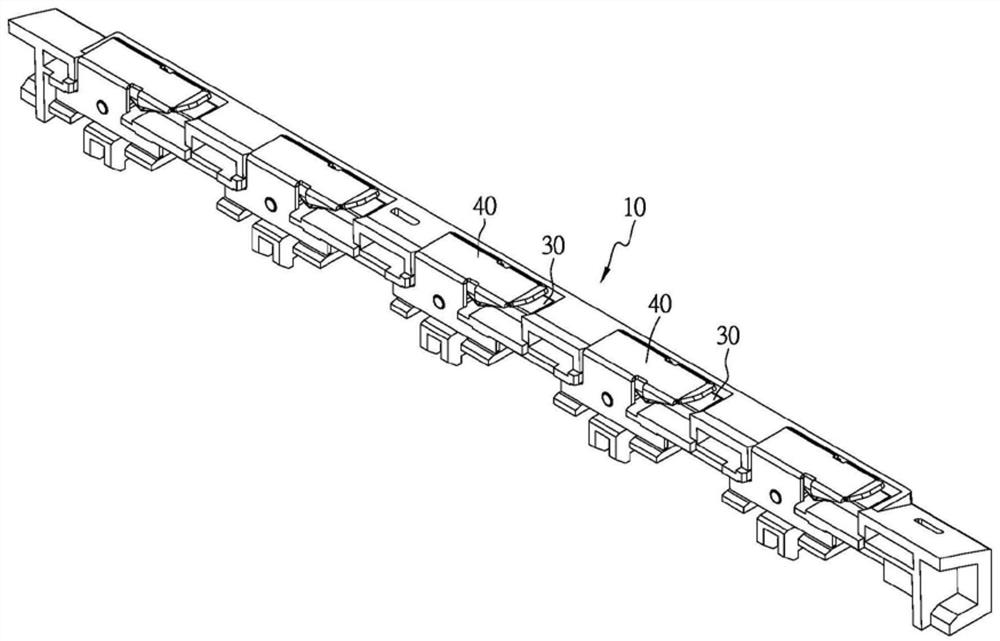

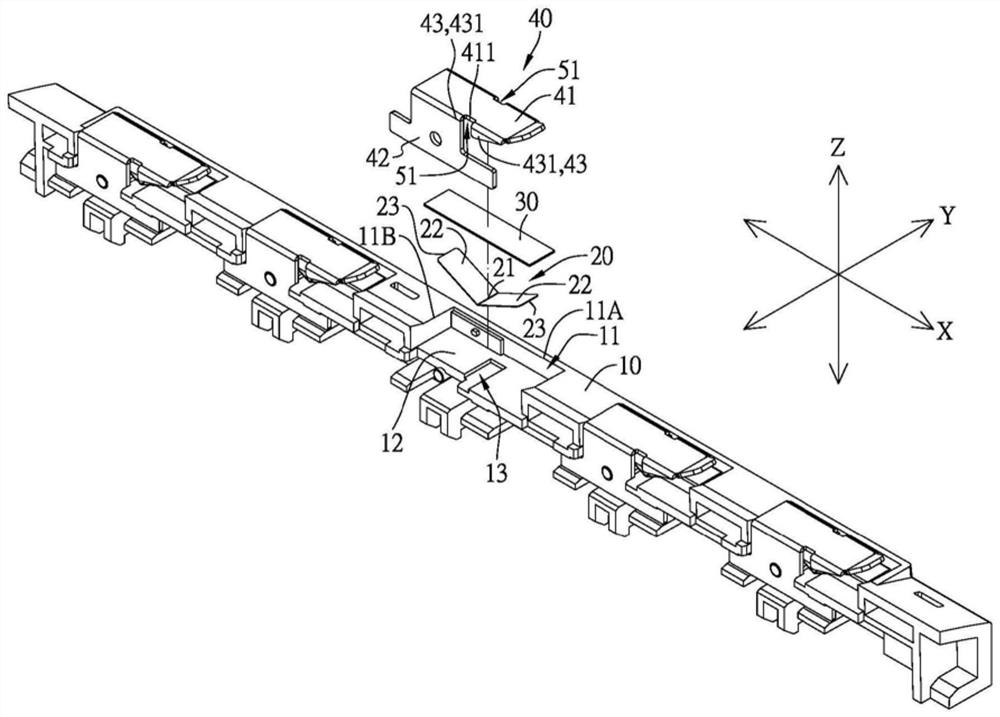

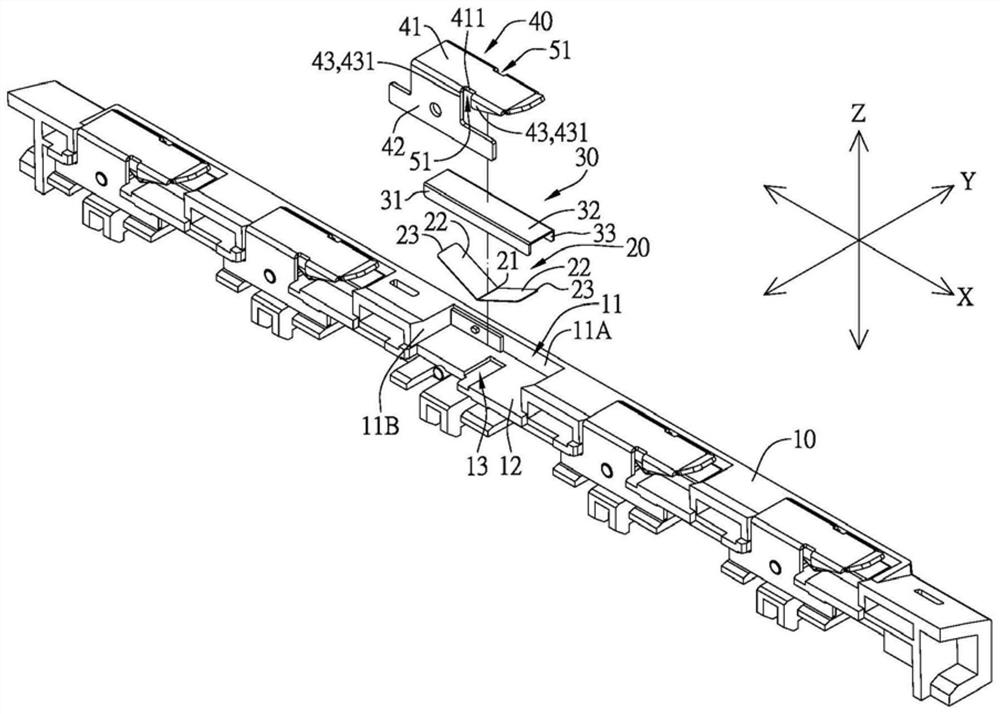

[0056]The present invention provides a sewing machine's weaving line prefix device, such asFigure 1 to 10As shown, including:

[0057]The conductor 10 has at least one accompaniment groove 11, the accommodating groove 11 has a groove bottom 12, preferably, the lead seat 10 opens a plurality of accommodating grooves 11 along the longitudinal direction, and each accommodating groove 11 is a rectangular tank body. The accommodational groove 11 has a long side 11a along the longitudinal X, defining the lateral Y, the vertical direction is lateral Y, and the accommodating groove 11 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com