Patents

Literature

35results about How to "Avoid Elastic Fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

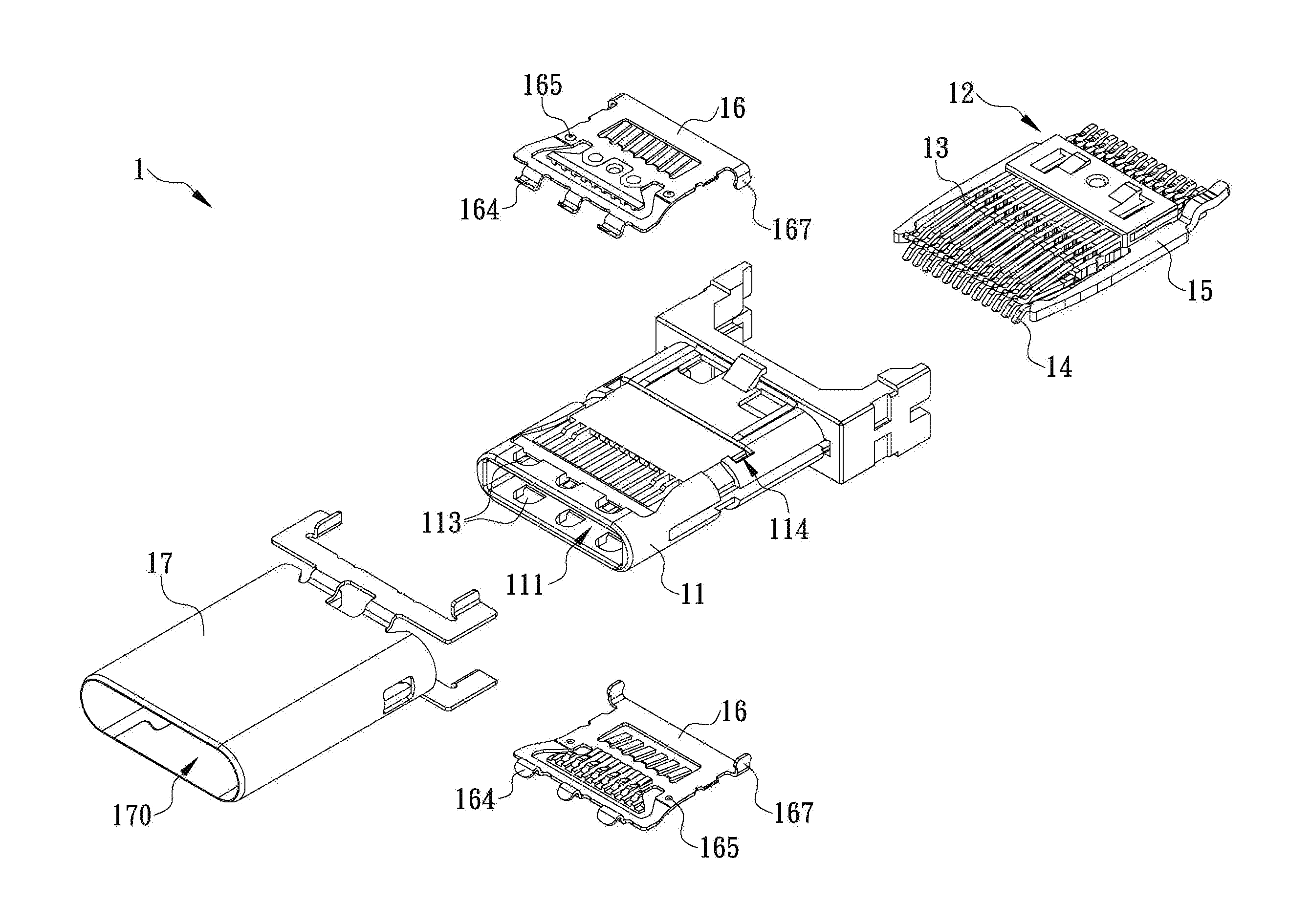

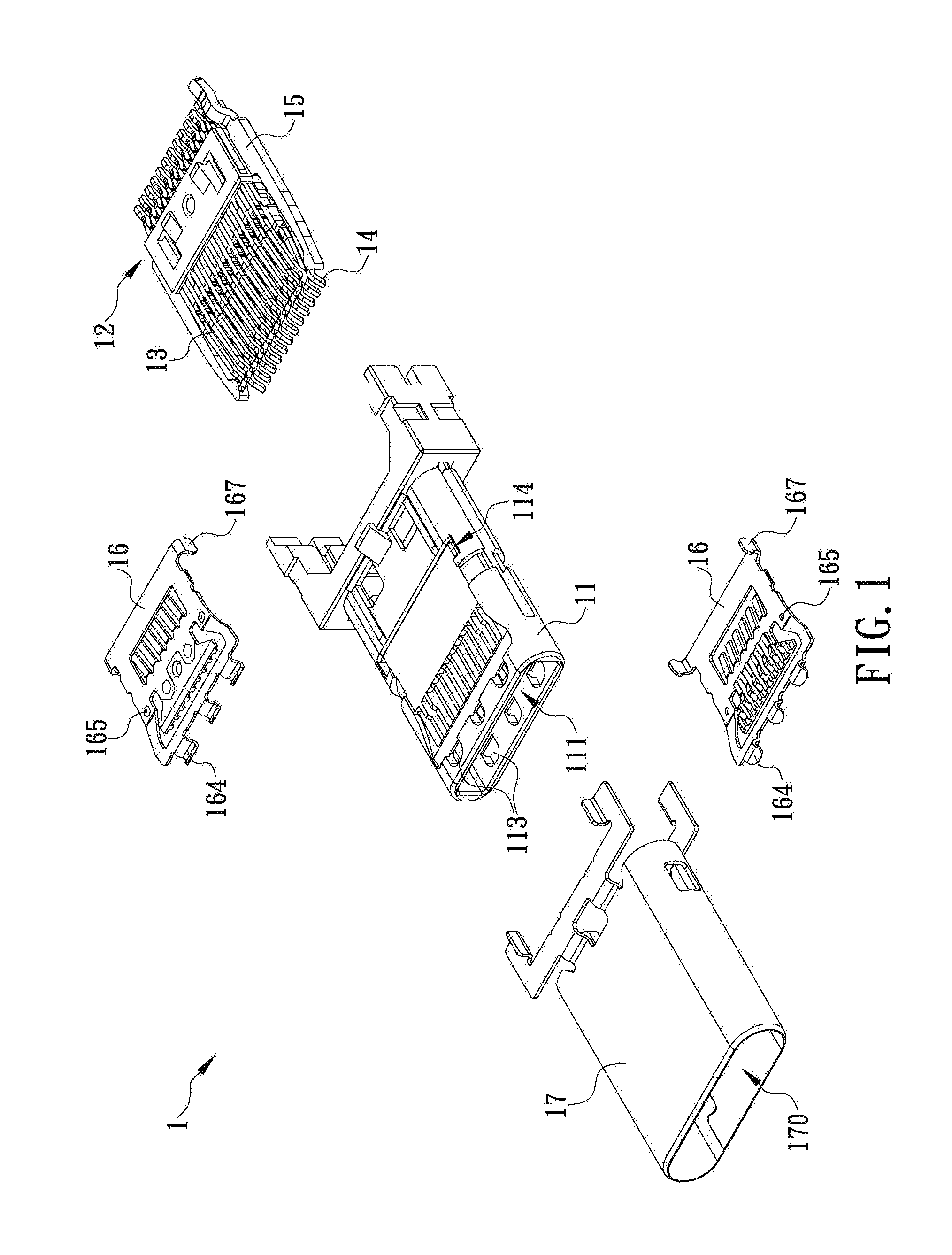

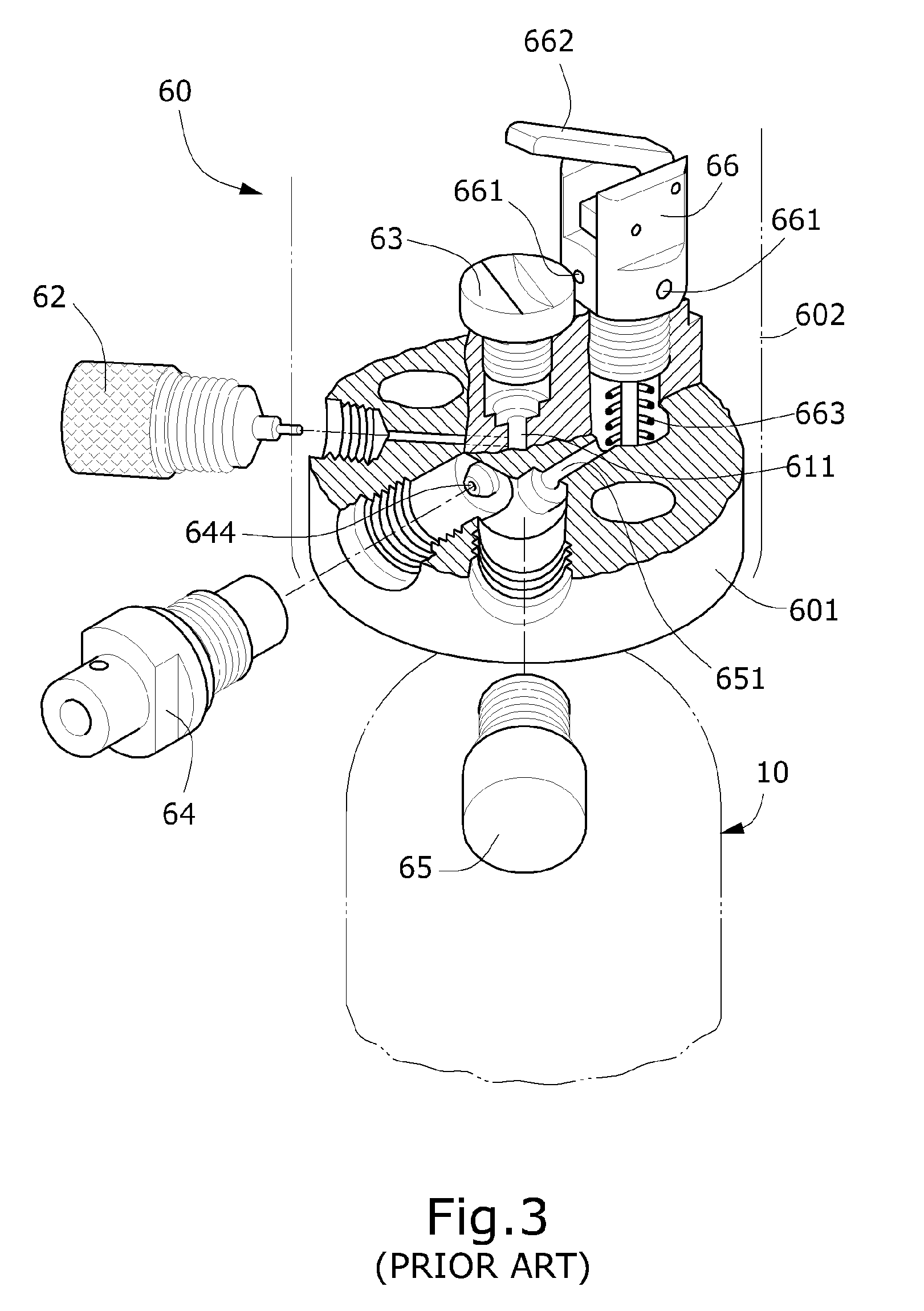

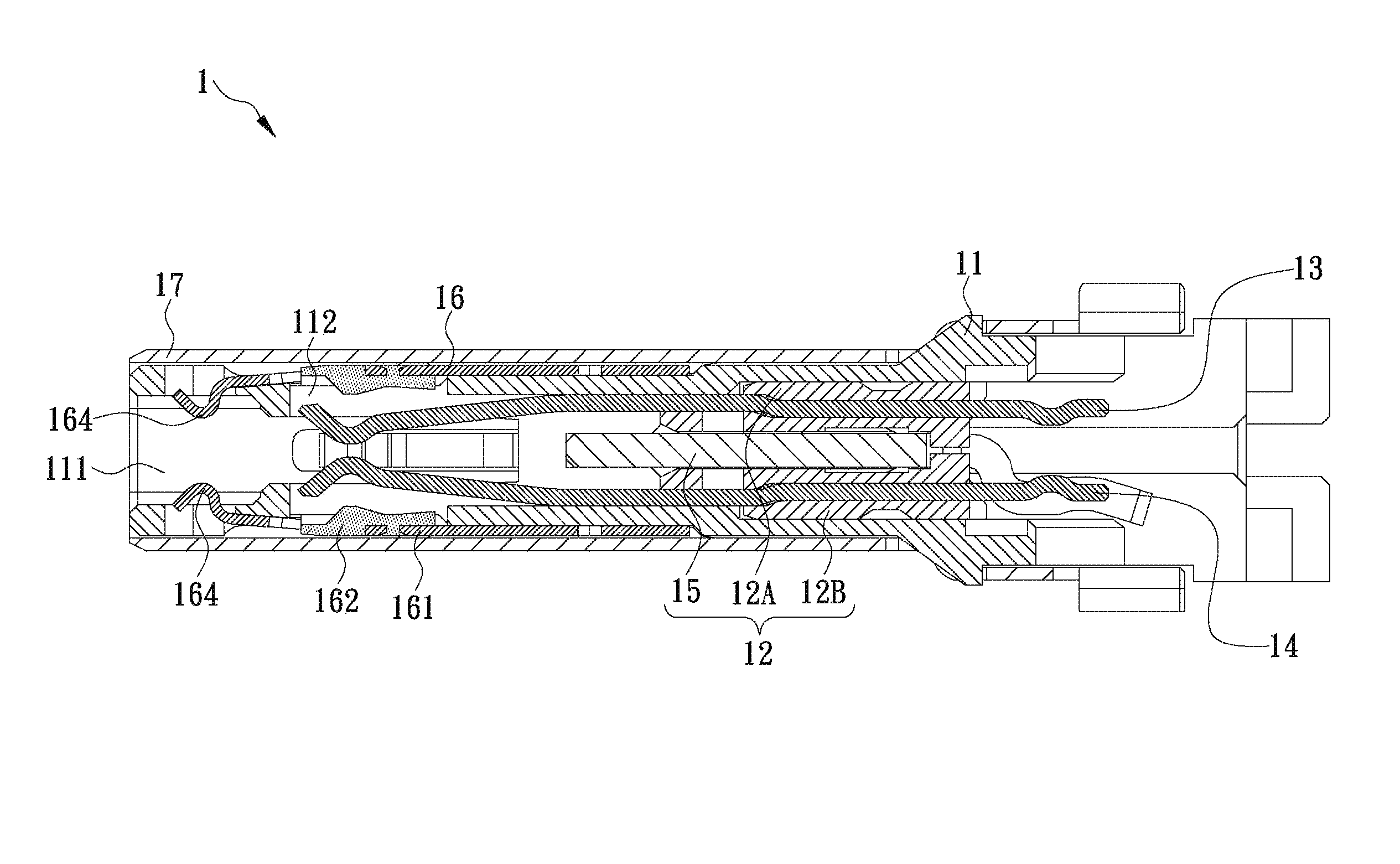

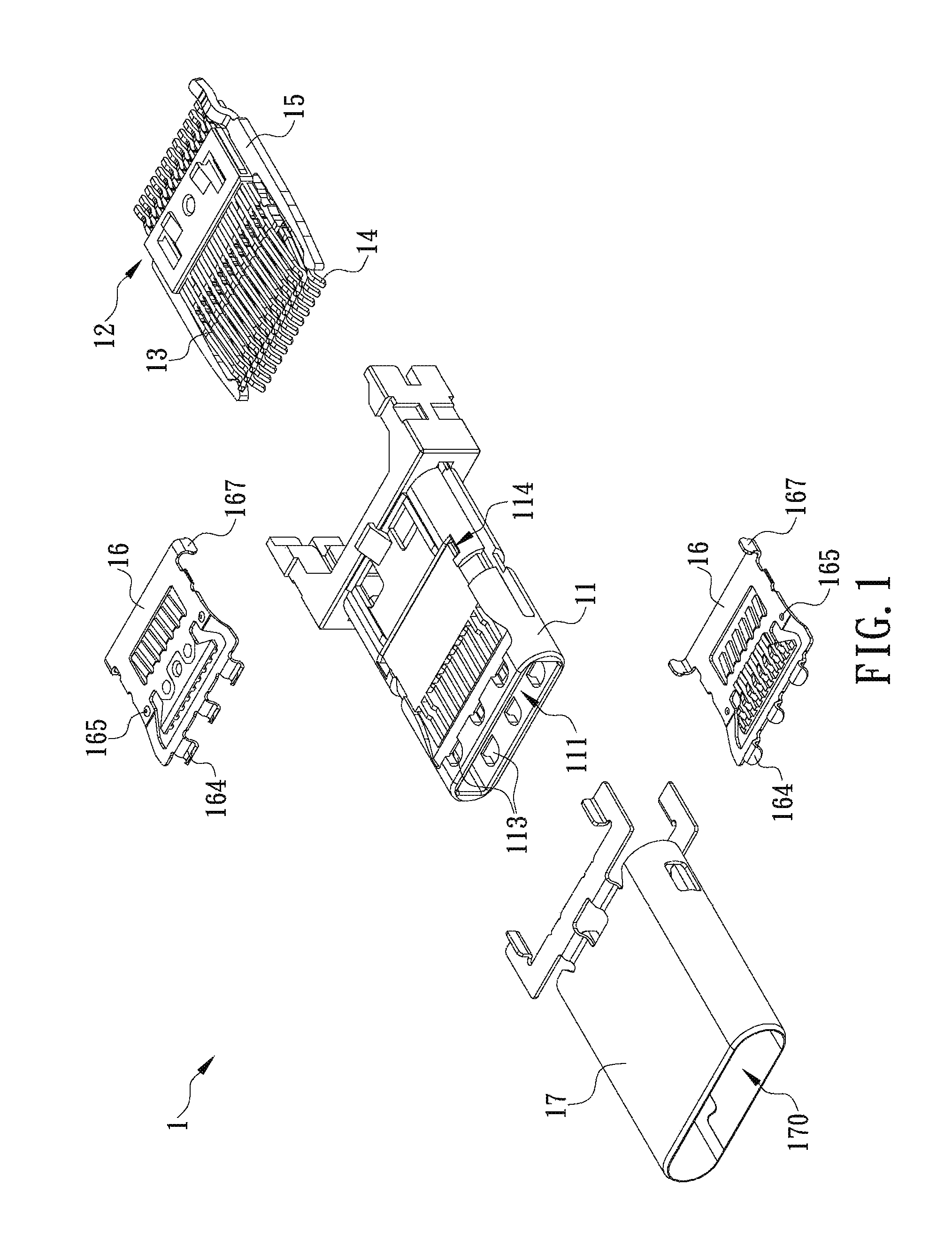

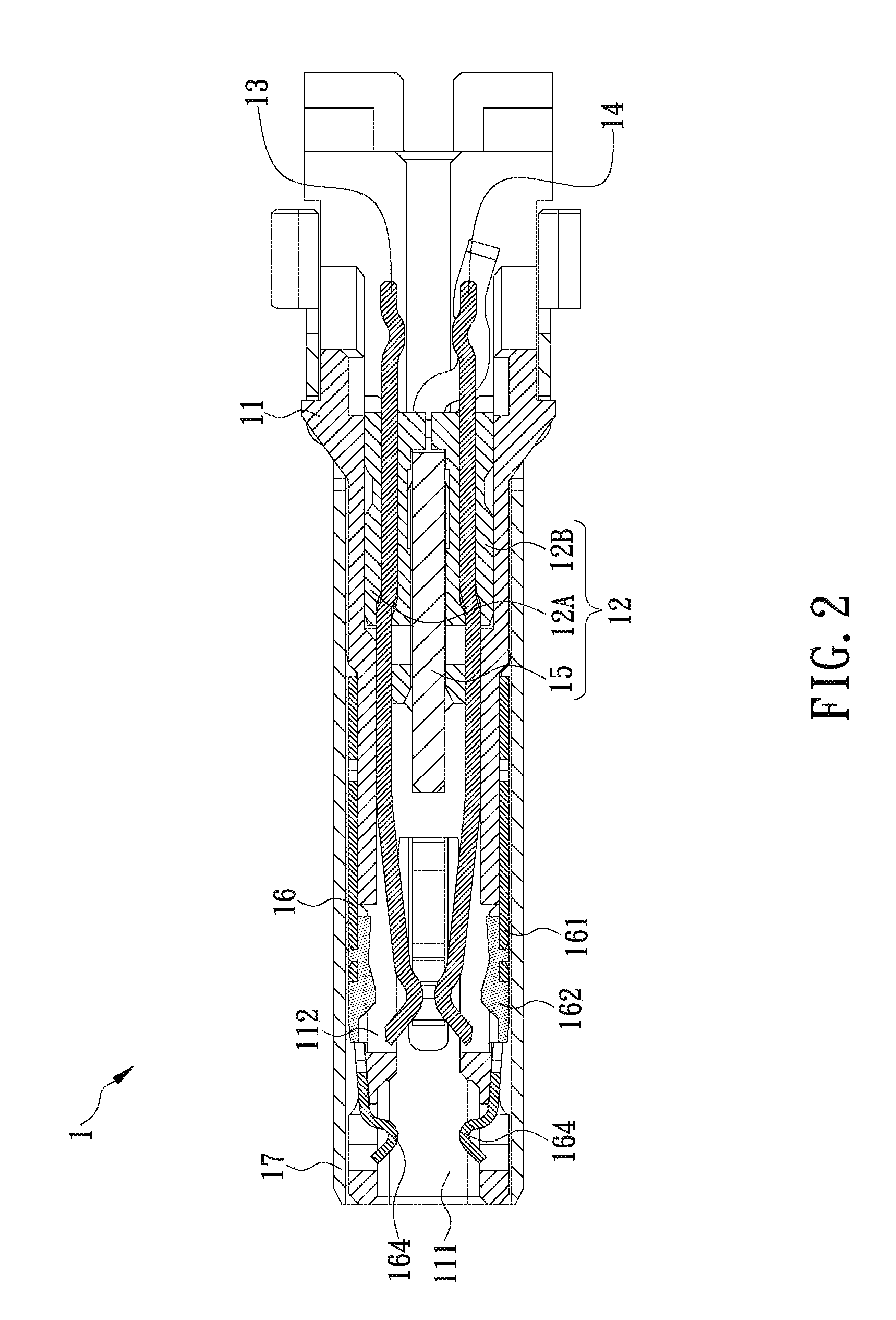

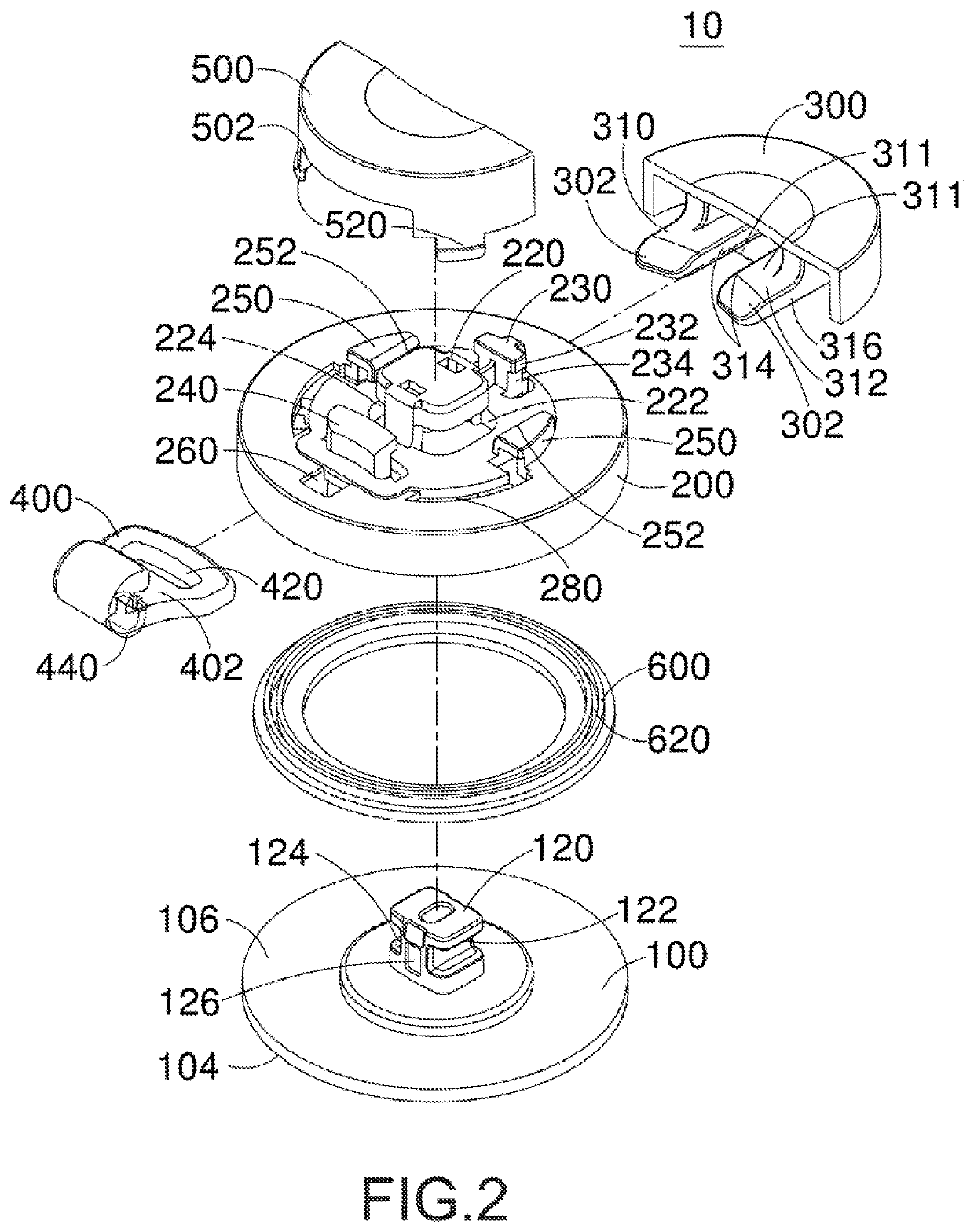

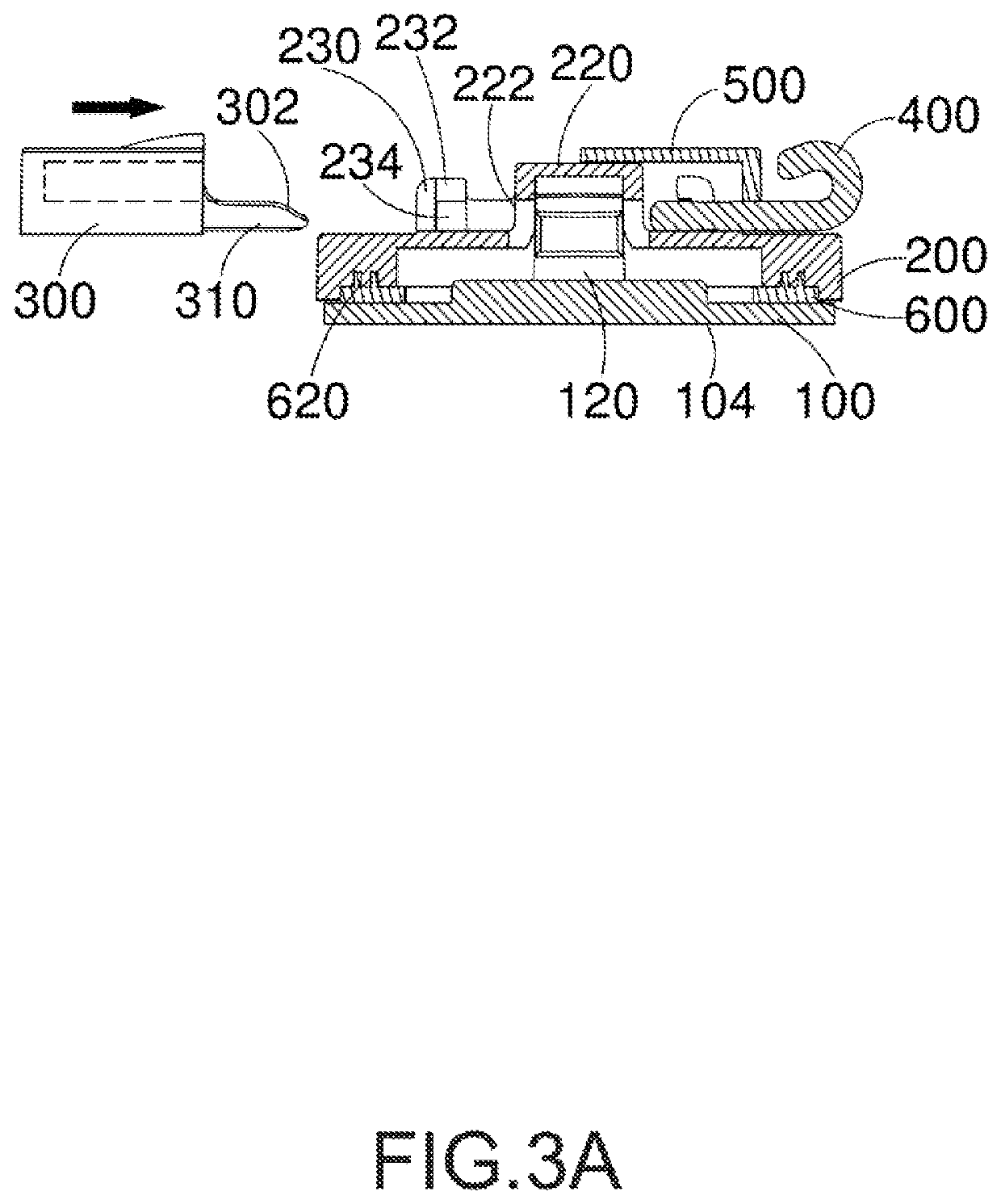

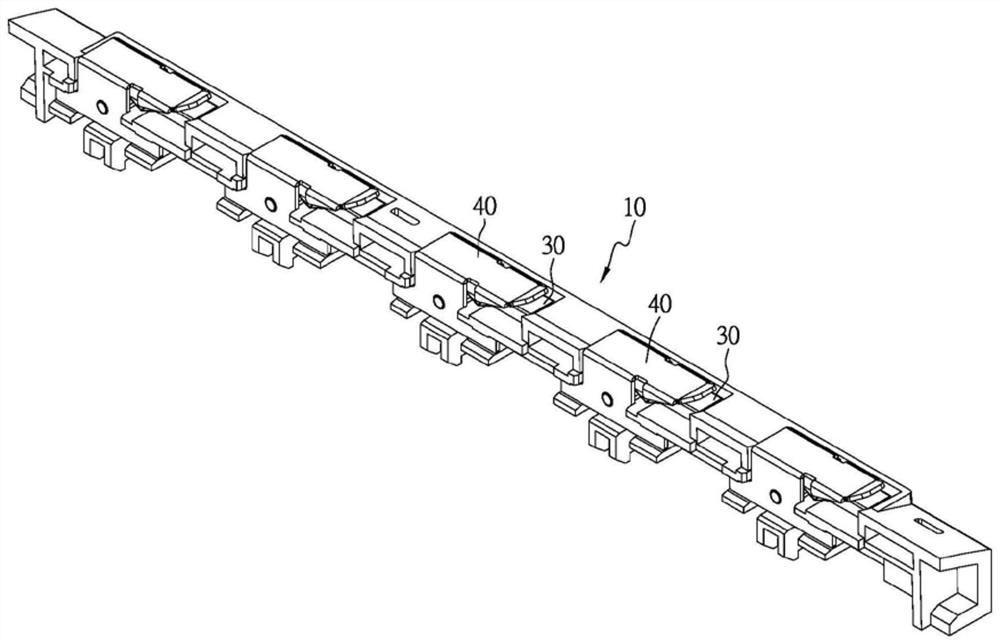

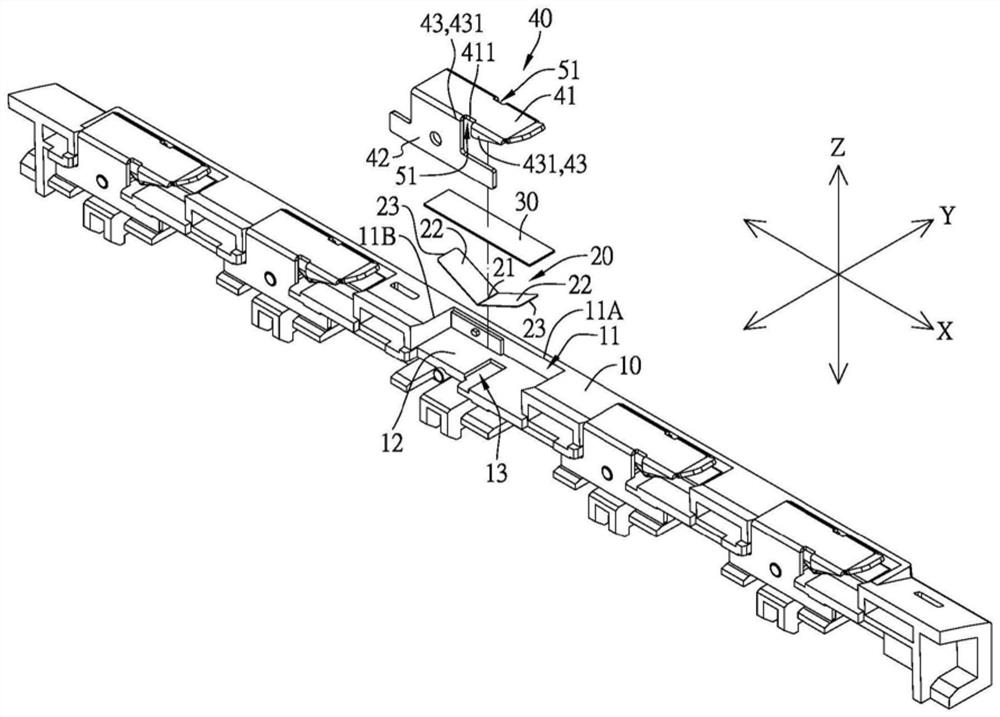

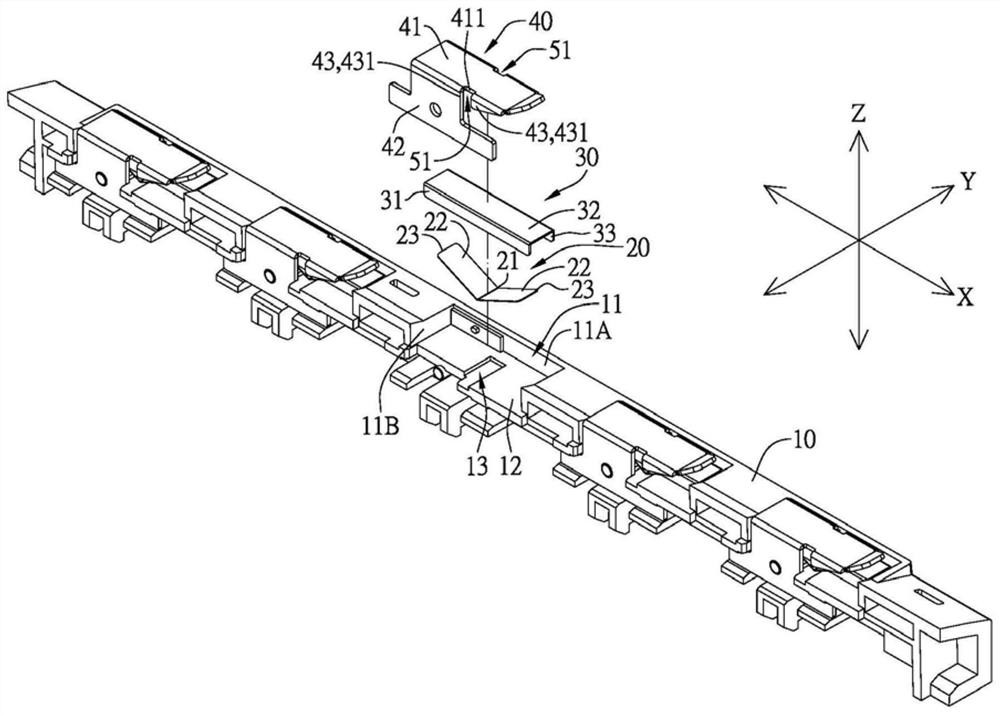

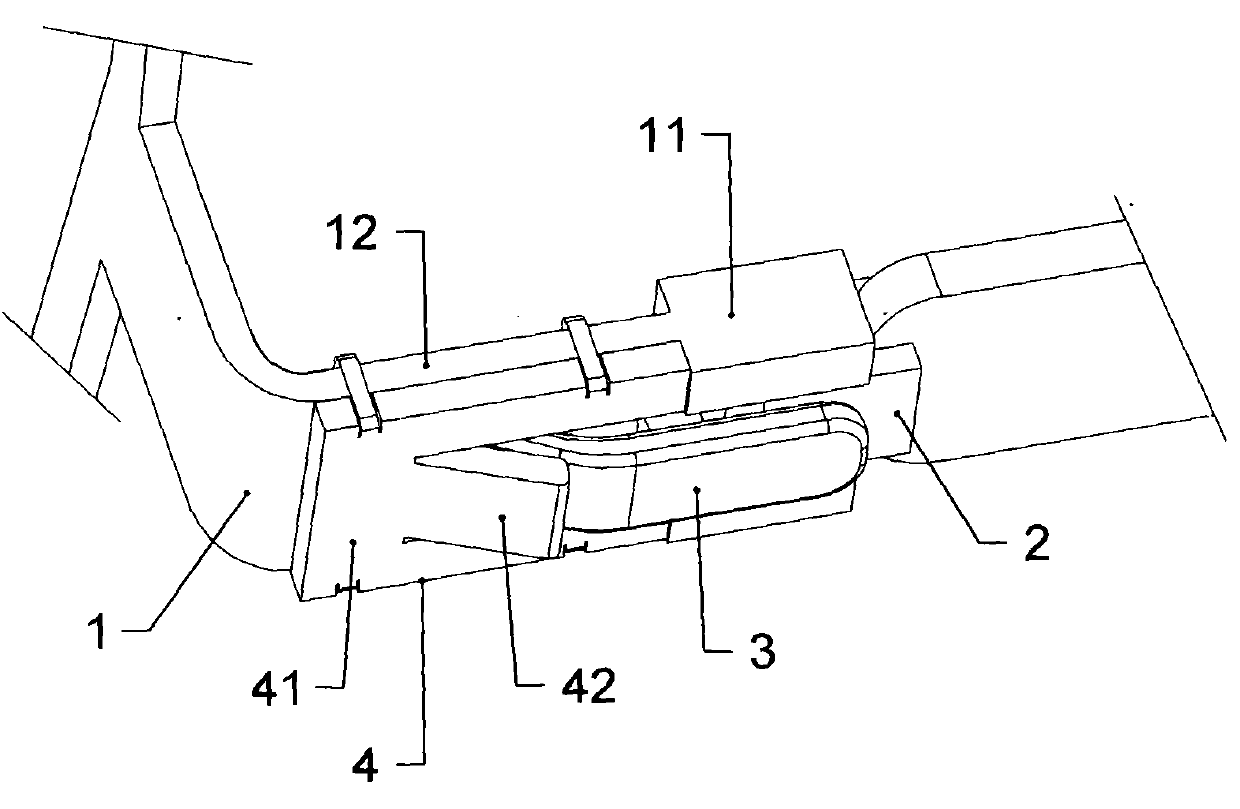

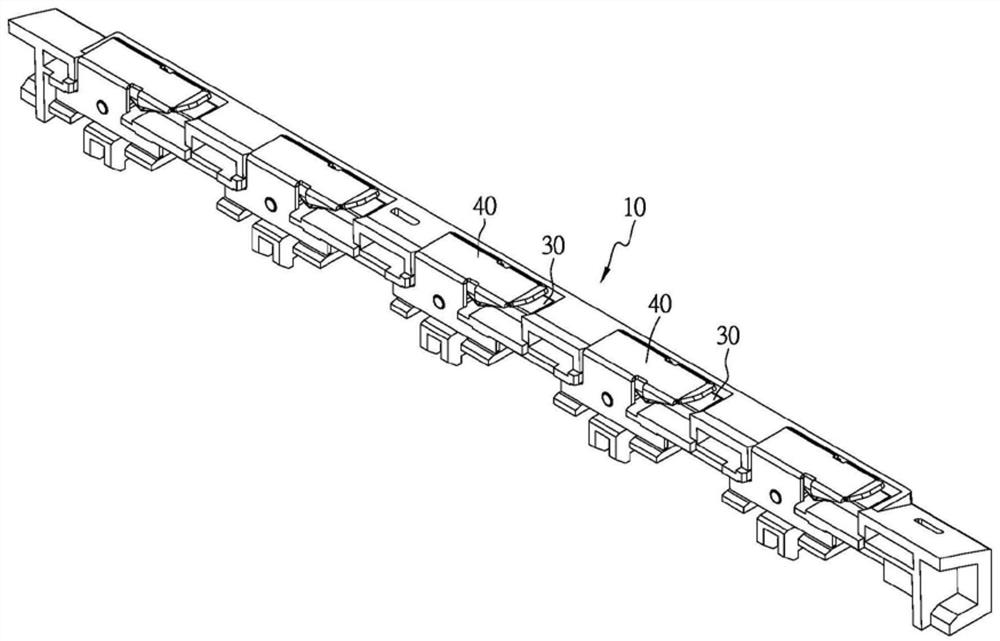

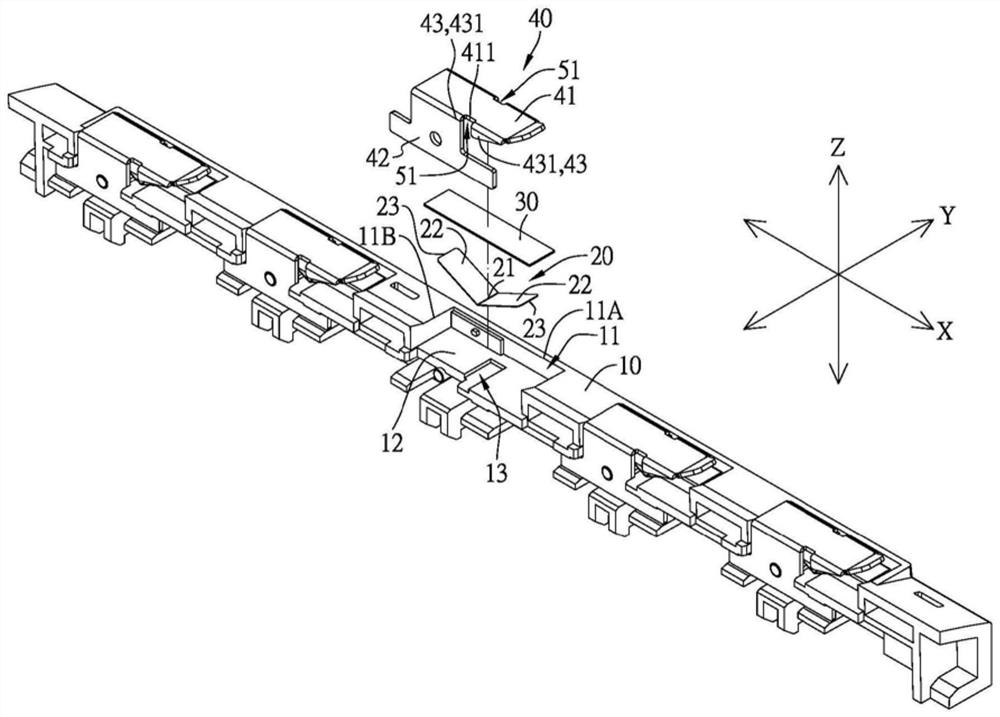

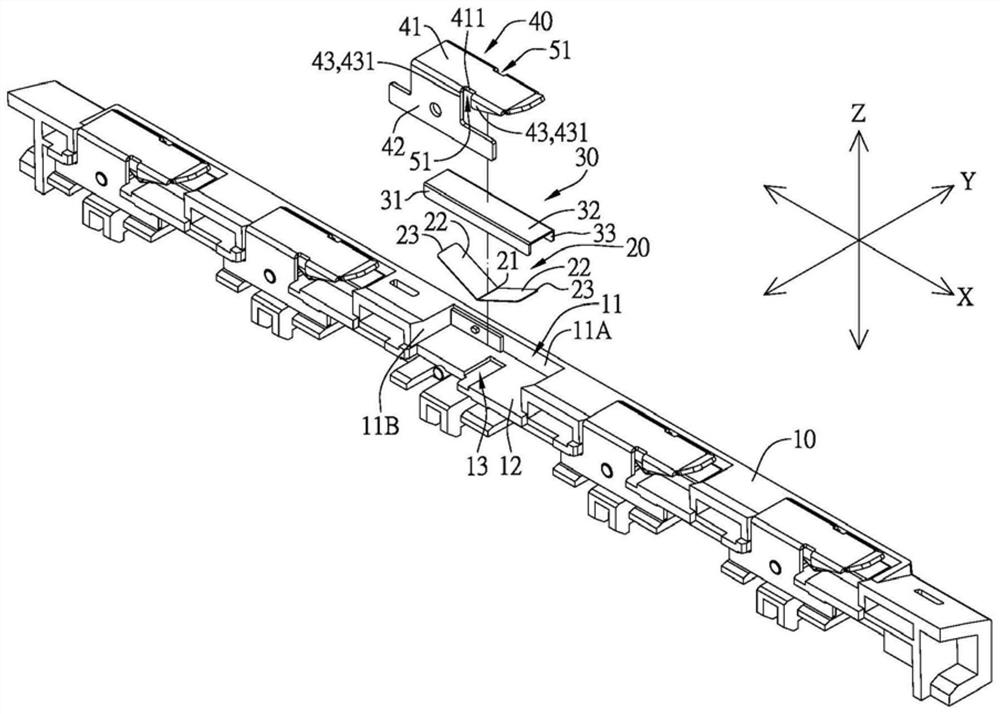

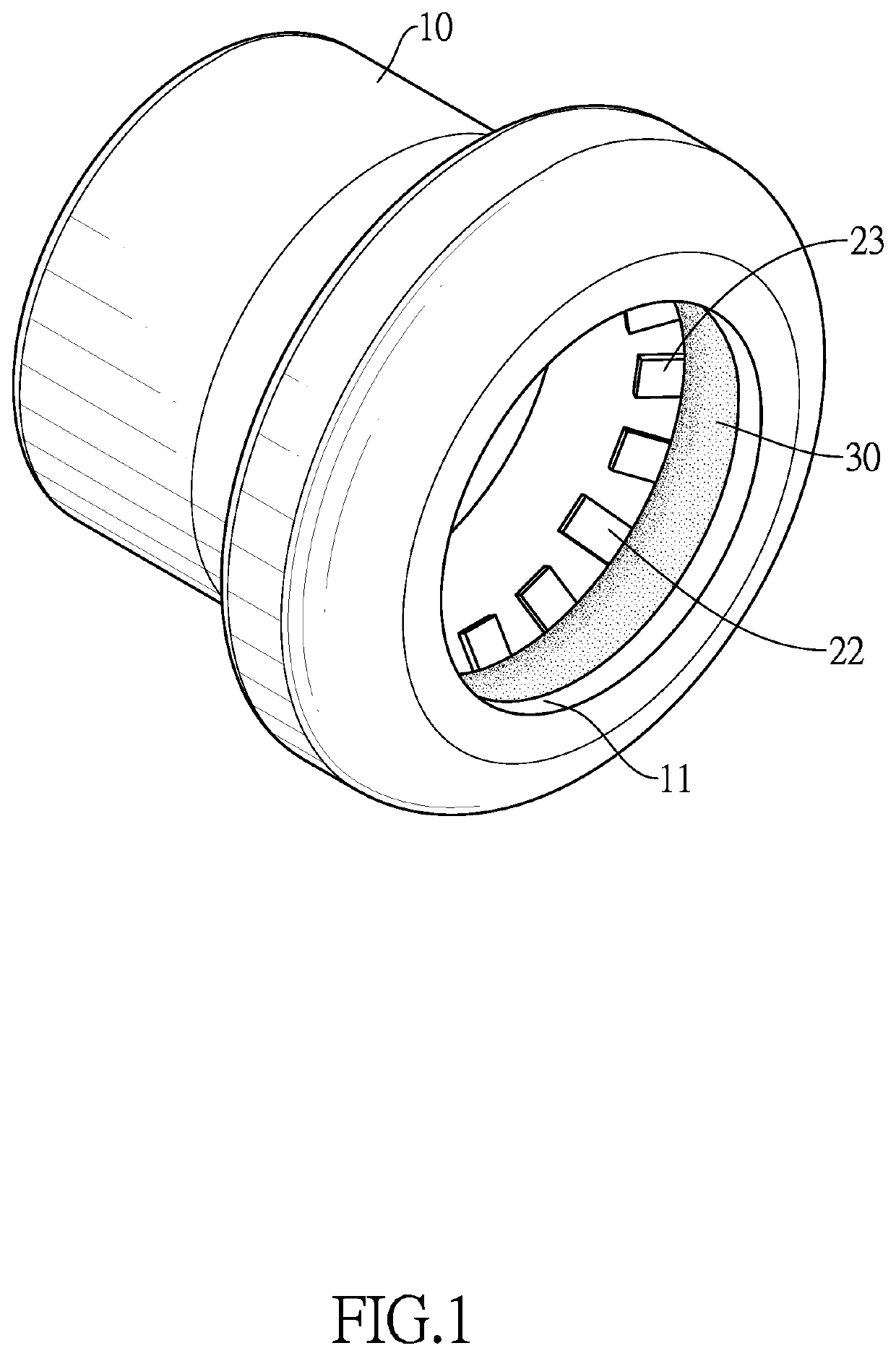

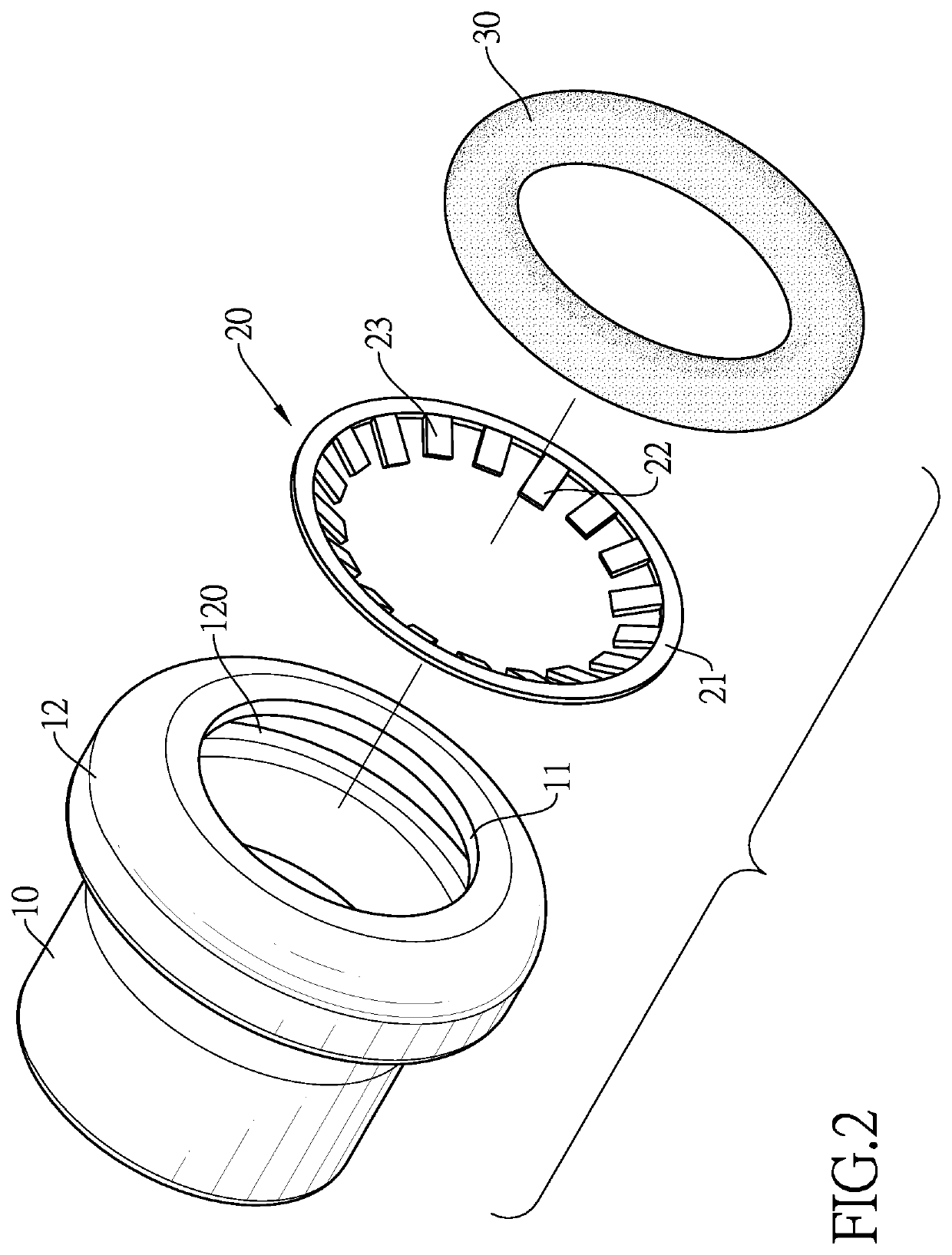

Signal connector having grounding member for pressing and preventing from short-circuit

ActiveUS20160204540A1Avoid Elastic FatigueImprove deformationElectric discharge tubesCoupling device detailsRestoring forceShort circuit

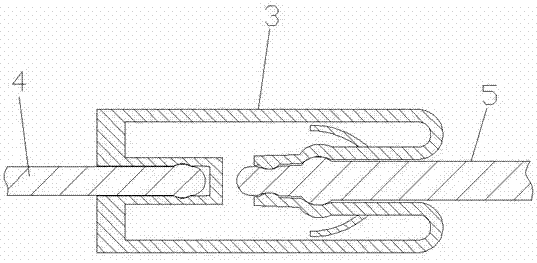

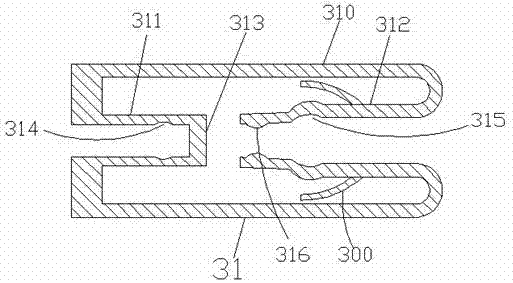

The present invention is to provide a signal connector which includes an insulating body having a plurality of through grooves cut through top and bottom surfaces thereof adjacent to a front end thereof; an insulating terminal seat mounted inside the insulating body and having a plurality of metal terminals fastened thereon and separated from each other; two metal grounding members having rear ends respectively assembled with the top and bottom surfaces of the insulating body, having pressing parts respectively formed adjacent to front ends thereof and corresponding in position to the through grooves and having insulating layers respectively covered on side surfaces thereof facing the through grooves; such that the pressing part is able to apply a restoring force on the metal terminal when the signal connector is plugged with other signal connector and the metal terminal is moved away from the insulating terminal seat through the corresponding through groove.

Owner:GUIMA SCI & TECH

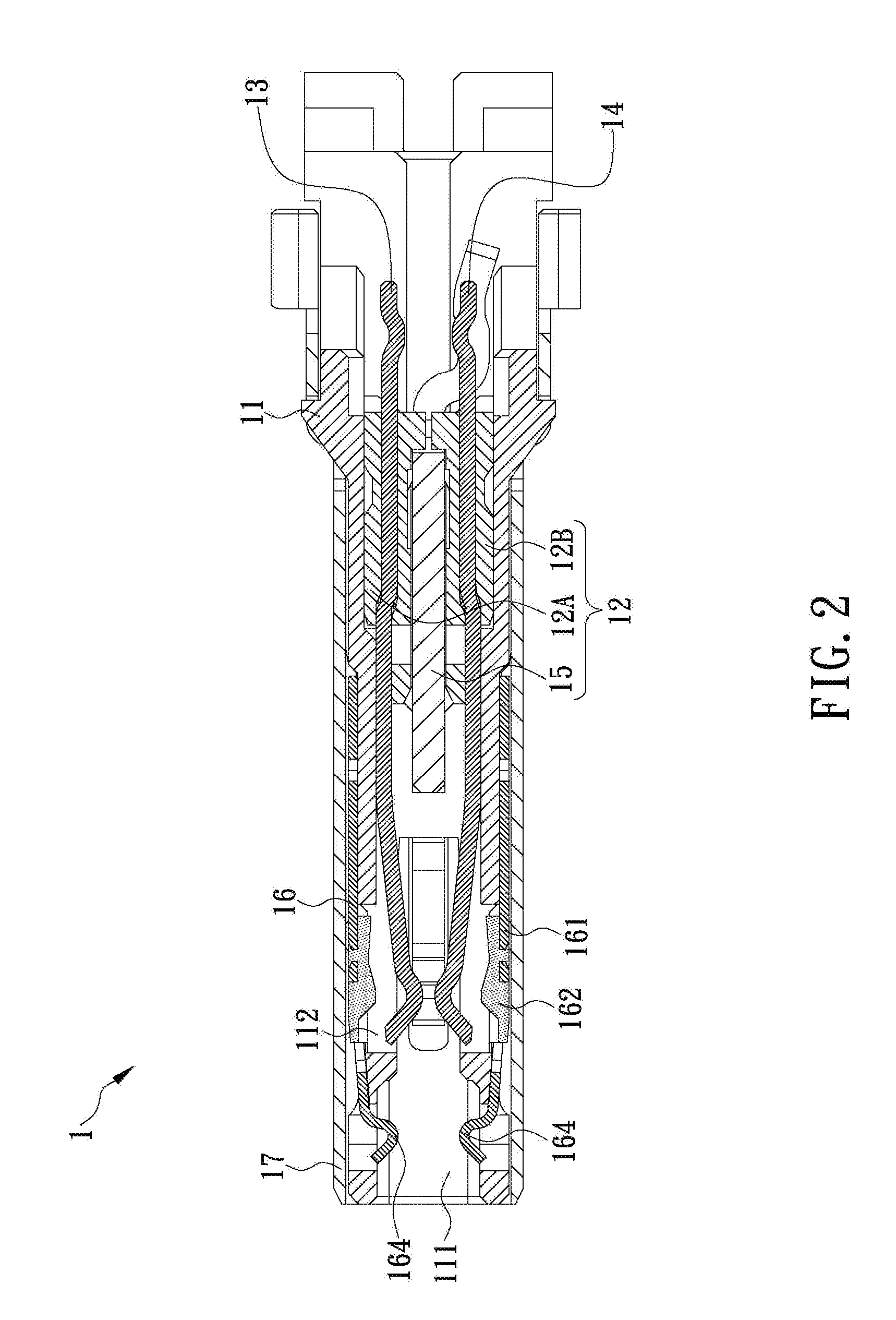

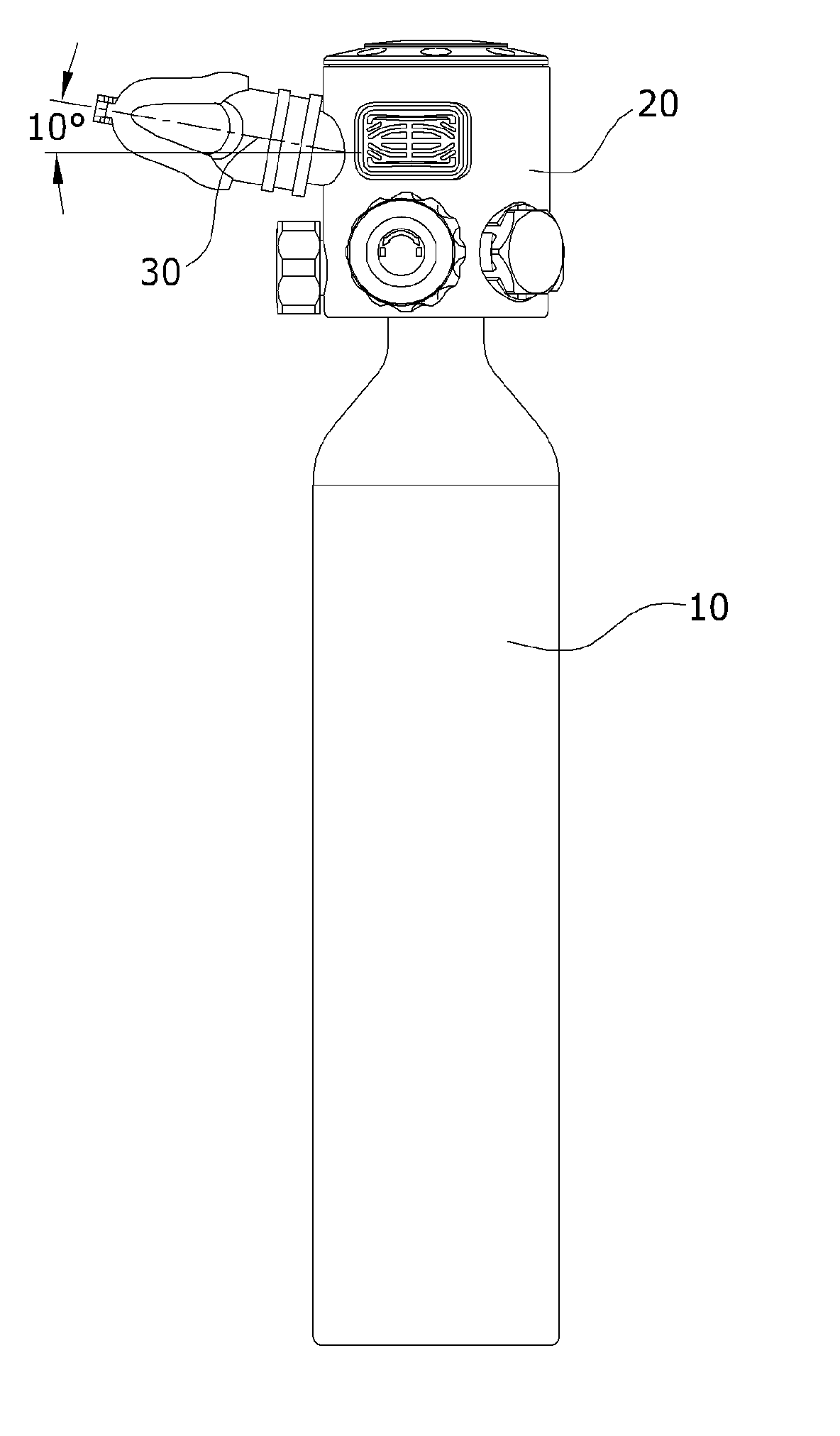

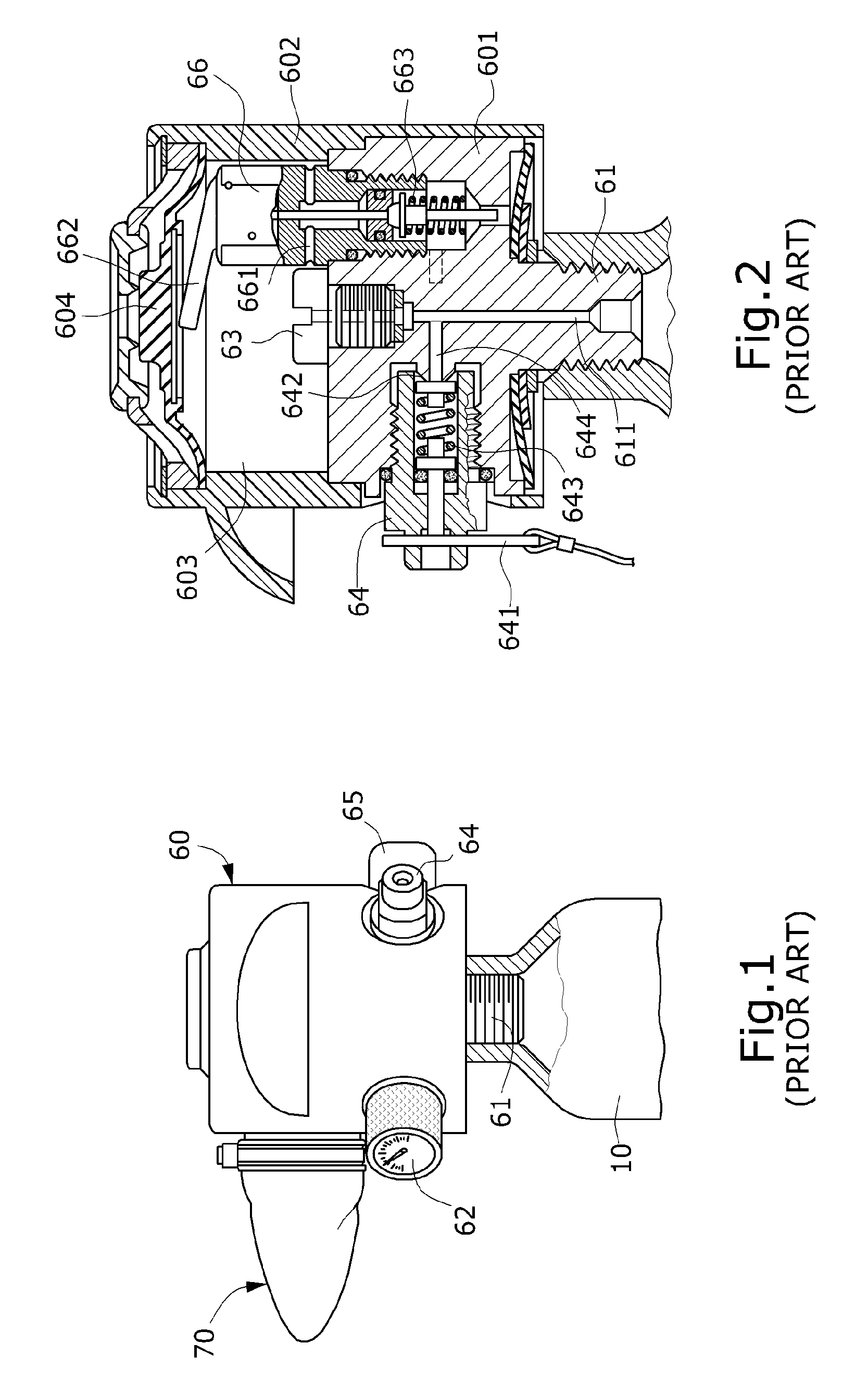

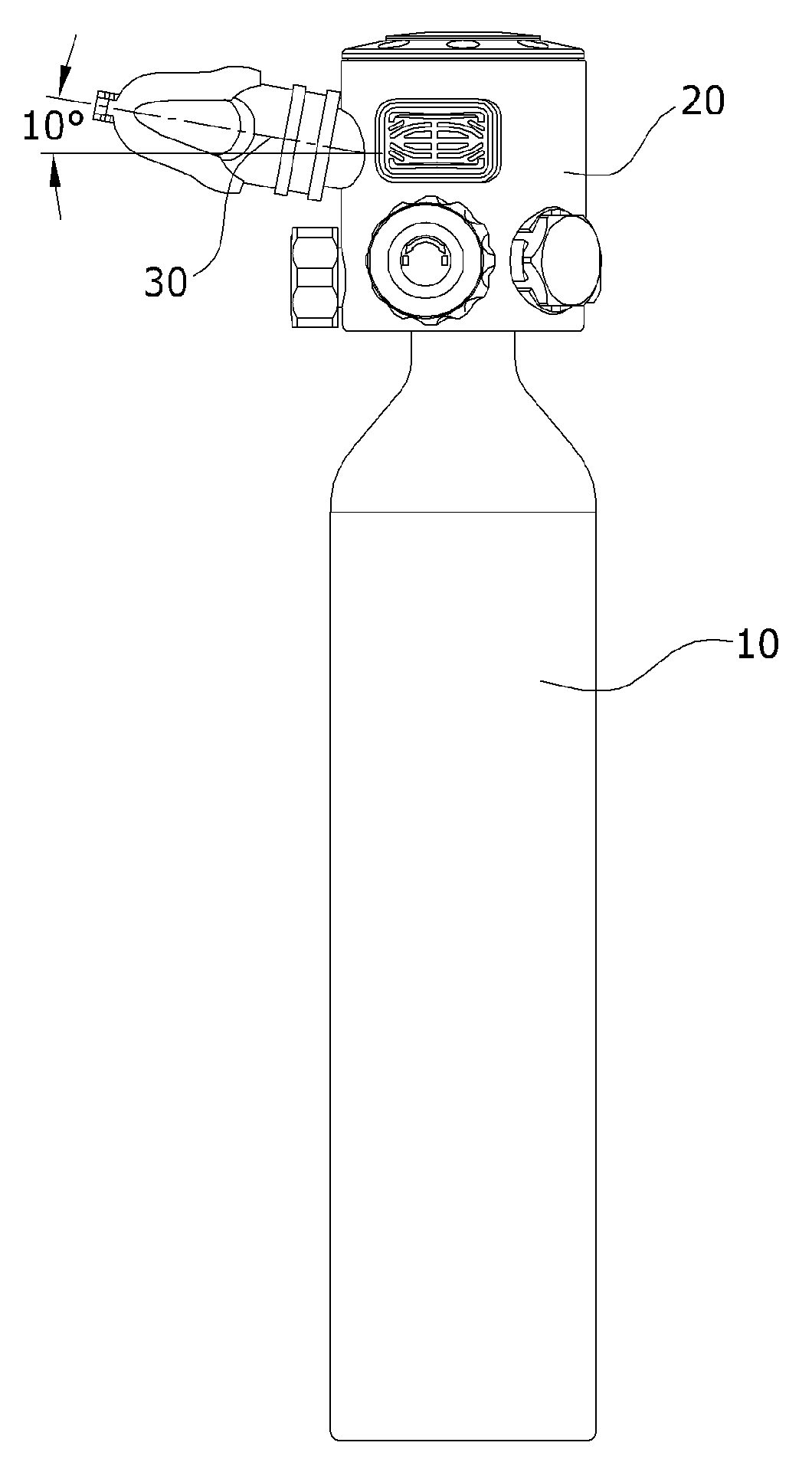

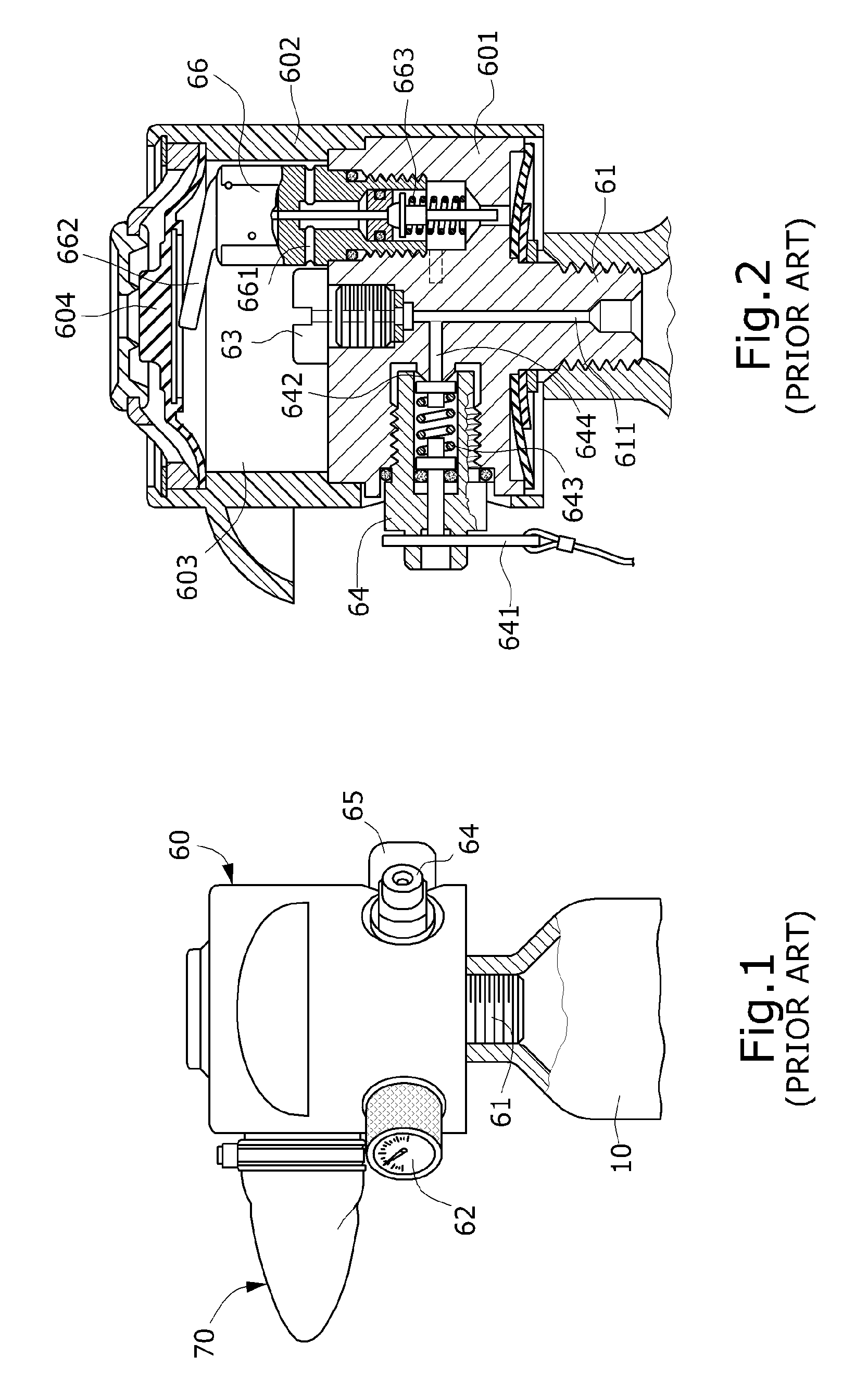

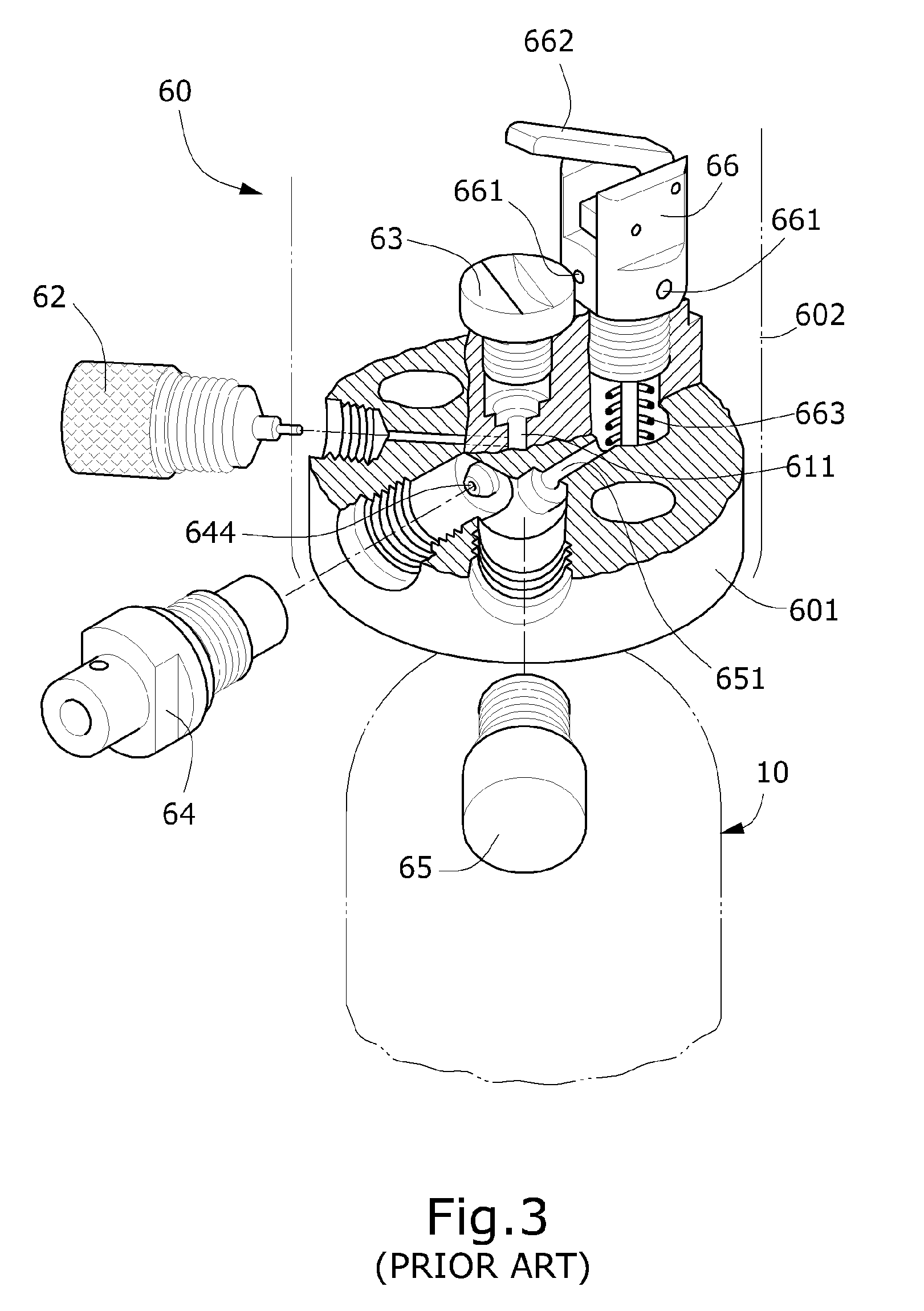

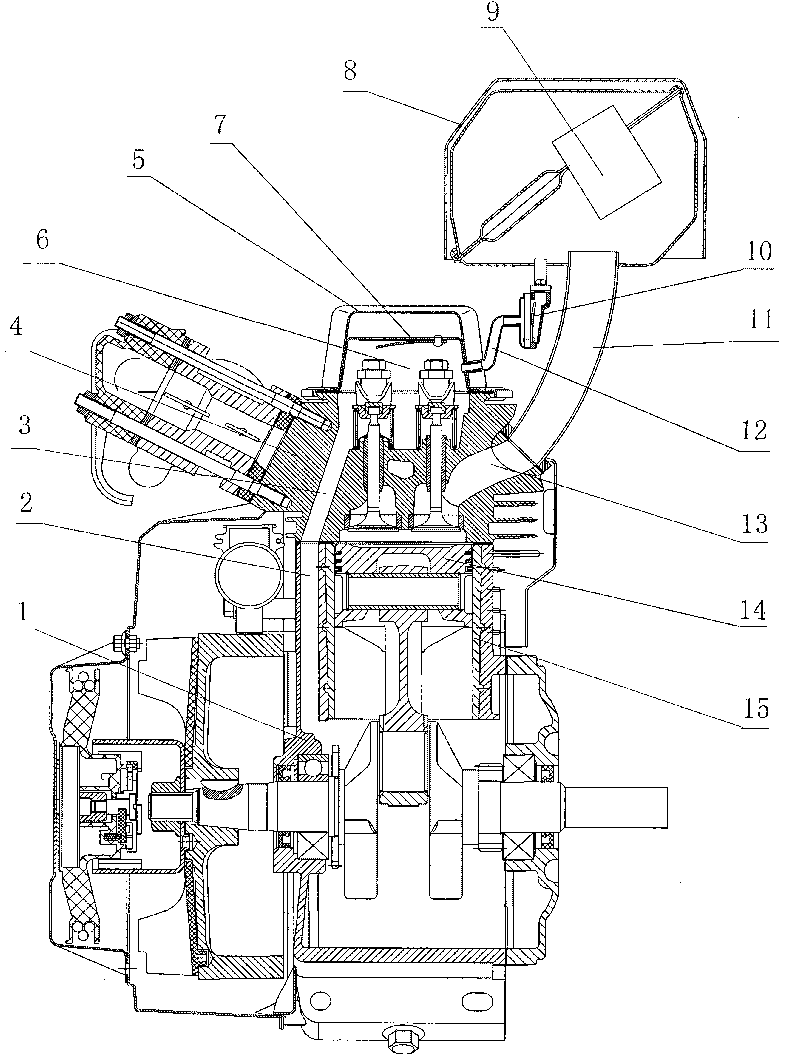

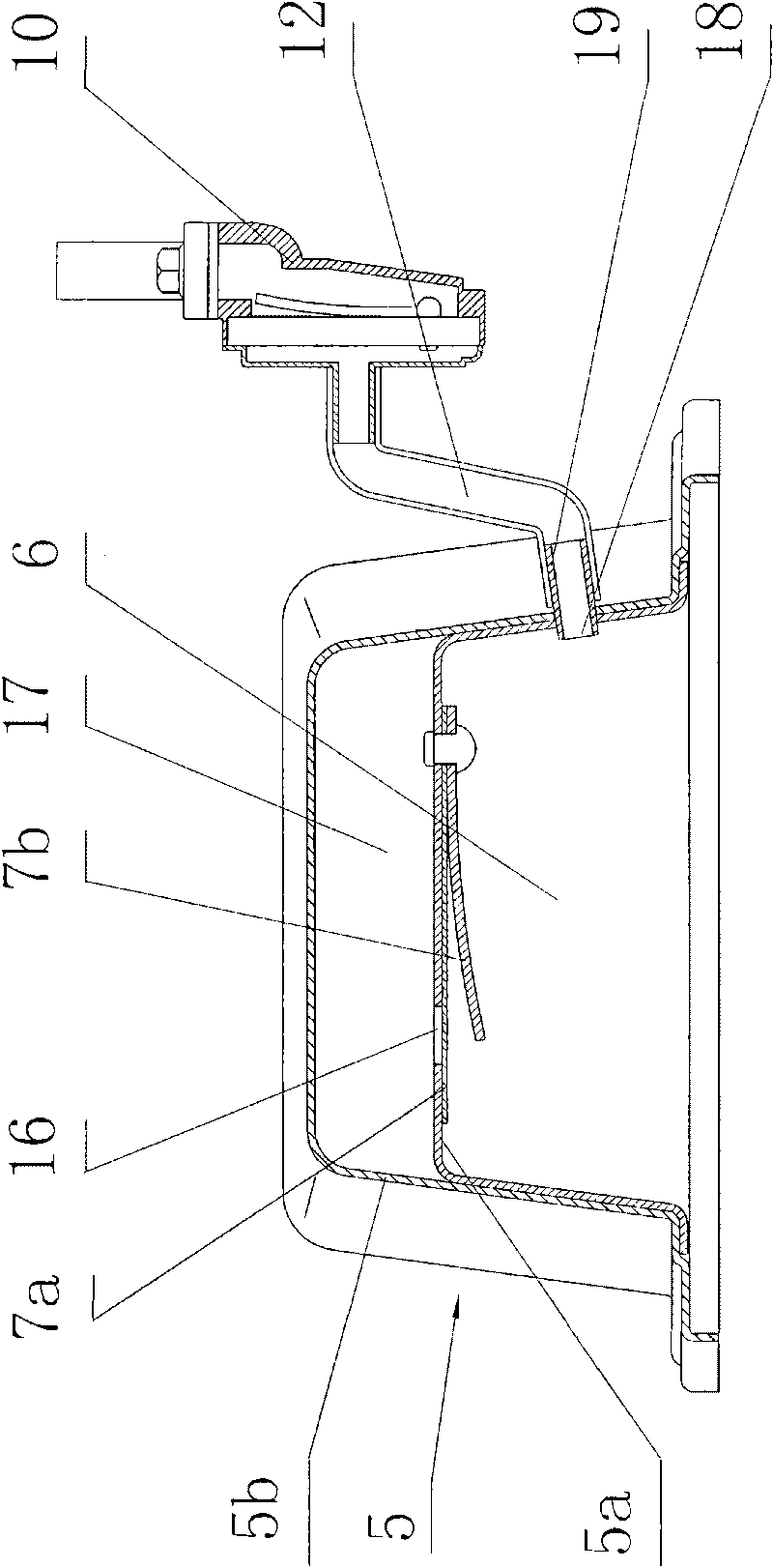

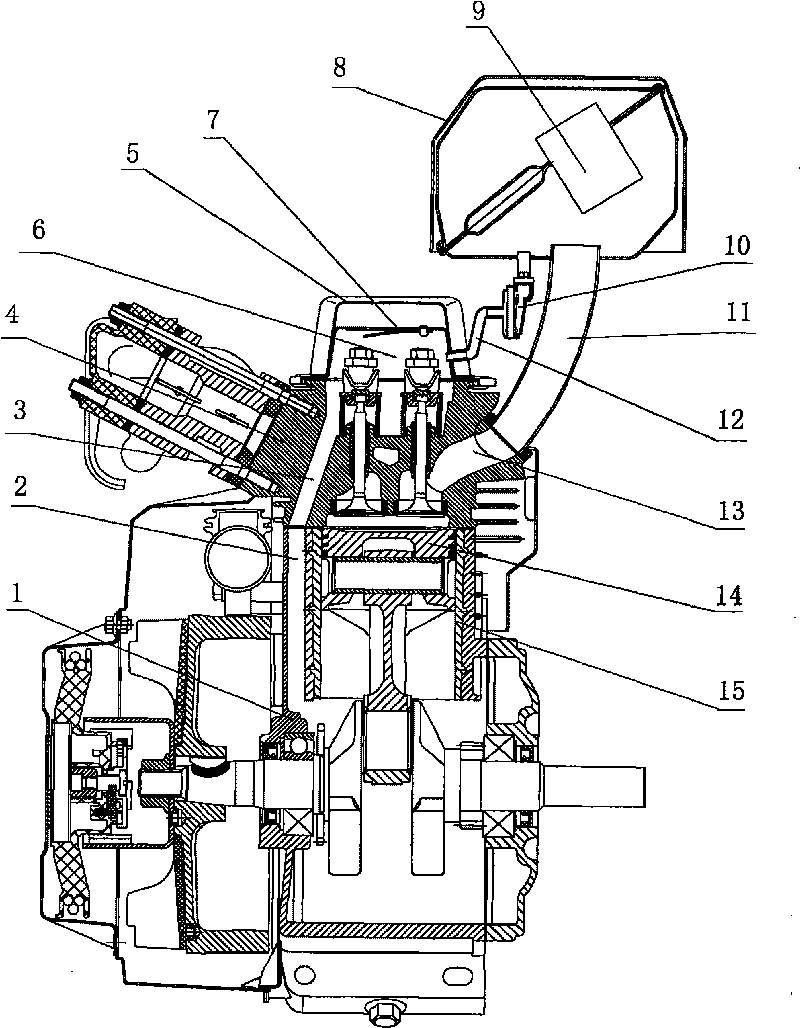

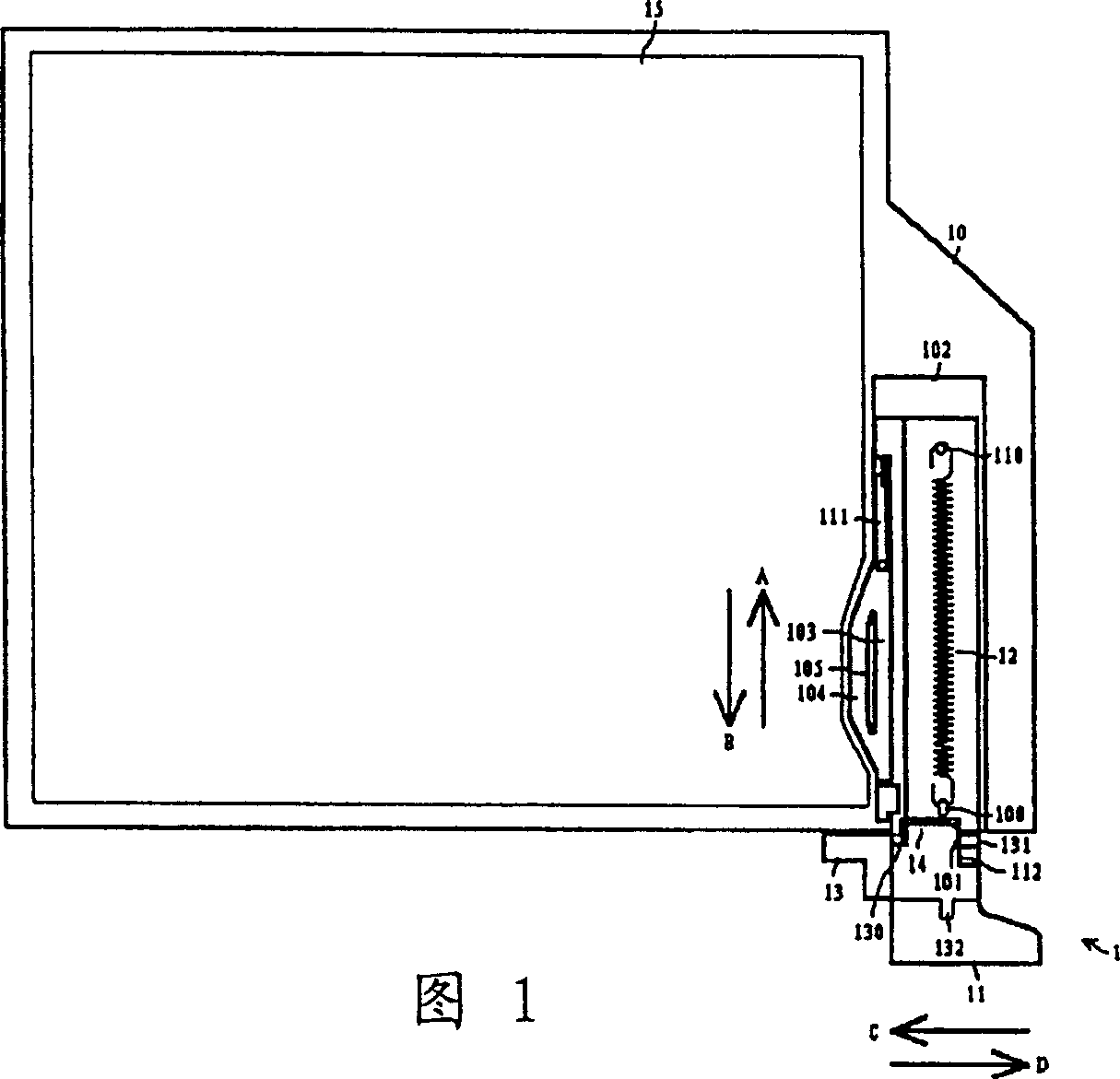

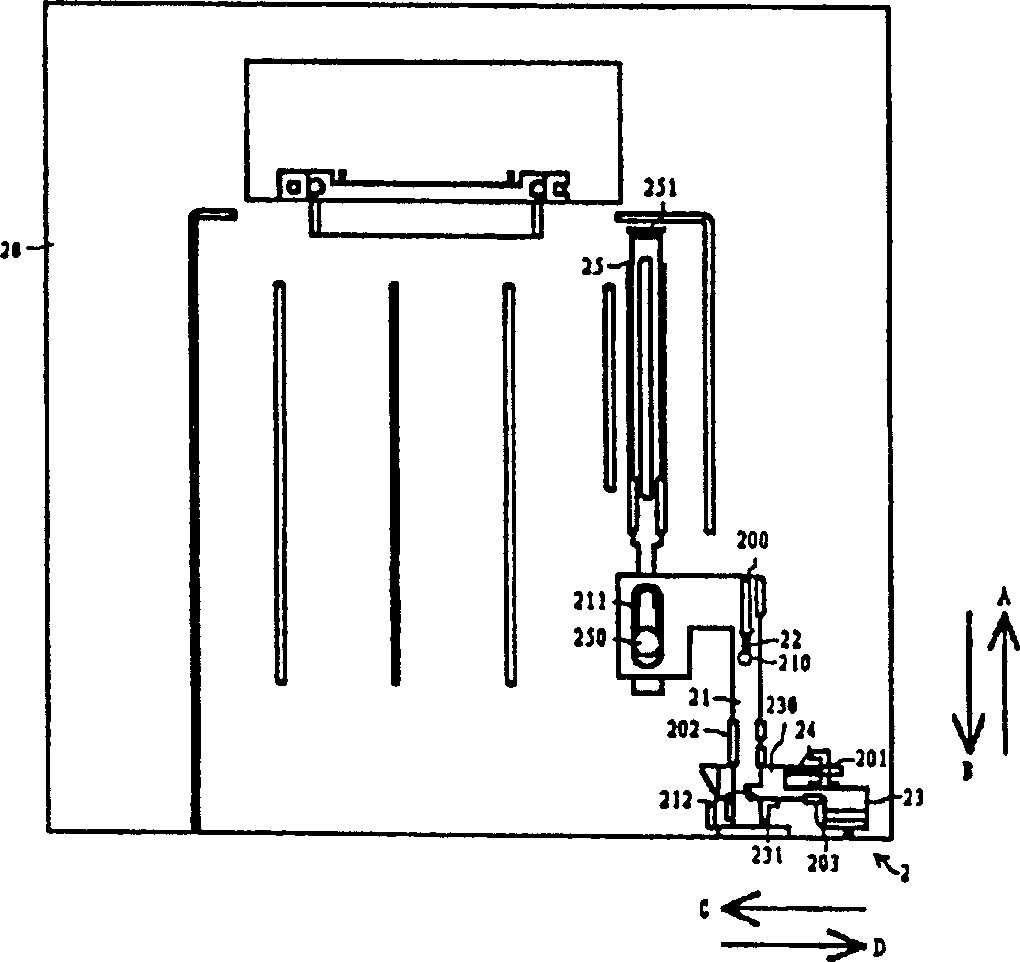

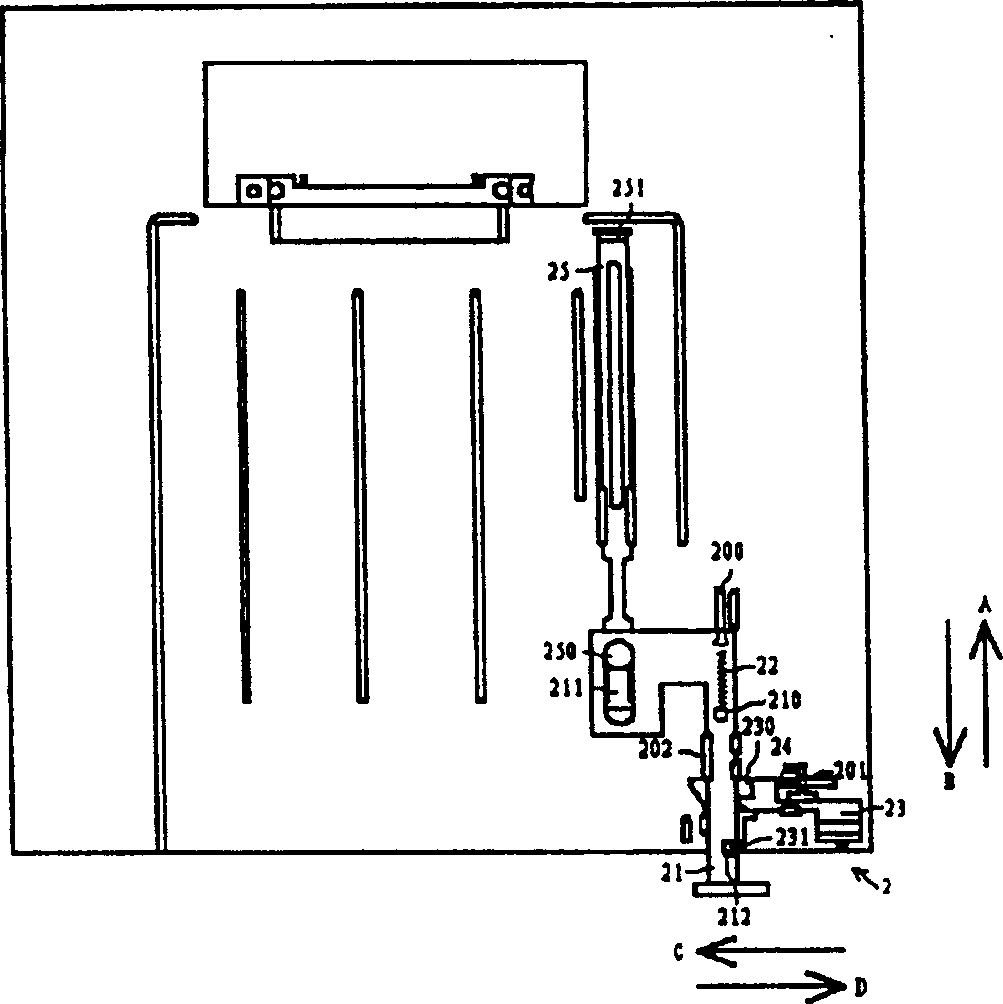

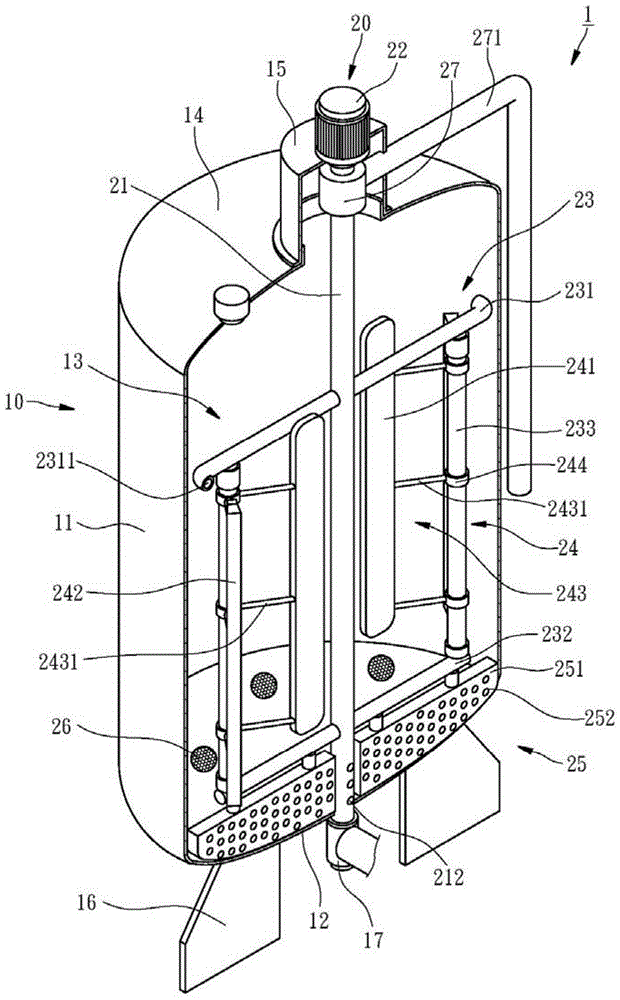

Breathing apparatus structure with two-stage reduced-pressure spare air bottle head

ActiveUS8166973B2Easy to controlEfficiently provideRespiratorsRespiratory apparatusGas cylinderEngineering

A breathing apparatus structure with a two-stage reduced-pressure spare air bottle head is provided, which includes an air bottle head mounted at an outlet end of a spare air bottle and an inhalation mouthpiece, so as to provide an air at a suitable pressure to a diver or drowning person for emergency use. The air bottle head is sequentially provided with an air bottle head switch, a high pressure reducing valve, and a low-pressure valve connected in series on an air passage thereof. Thus, an air leakage of a high-pressure air in the air bottle can be avoided when the high-pressure air is not used, and the service life of elastic elements of the low-pressure valve can also be prolonged.

Owner:PAN CHIEH CHENG

Signal connector having grounding member for pressing and preventing from short-circuit

ActiveUS9466918B2Avoid Elastic FatigueImprove deformationTwo-part coupling devicesCoupling protective earth/shielding arrangementsEngineeringRestoring force

The present invention is to provide a signal connector which includes an insulating body having a plurality of through grooves cut through top and bottom surfaces thereof adjacent to a front end thereof; an insulating terminal seat mounted inside the insulating body and having a plurality of metal terminals fastened thereon and separated from each other; two metal grounding members having rear ends respectively assembled with the top and bottom surfaces of the insulating body, having pressing parts respectively formed adjacent to front ends thereof and corresponding in position to the through grooves and having insulating layers respectively covered on side surfaces thereof facing the through grooves; such that the pressing part is able to apply a restoring force on the metal terminal when the signal connector is plugged with other signal connector and the metal terminal is moved away from the insulating terminal seat through the corresponding through groove.

Owner:GUIMA SCI & TECH

Breathing apparatus structure with two-stage reduced-pressure spare air bottle head

A breathing apparatus structure with a two-stage reduced-pressure spare air bottle head is provided, which includes an air bottle head mounted at an outlet end of a spare air bottle and an inhalation mouthpiece, so as to provide an air at a suitable pressure to a diver or drowning person for emergency use. The air bottle head is sequentially provided with an air bottle head switch, a high pressure reducing valve, and a low-pressure valve connected in series on an air passage thereof. Thus, an air leakage of a high-pressure air in the air bottle can be avoided when the high-pressure air is not used, and the service life of elastic elements of the low-pressure valve can also be prolonge

Owner:PAN CHIEH CHENG

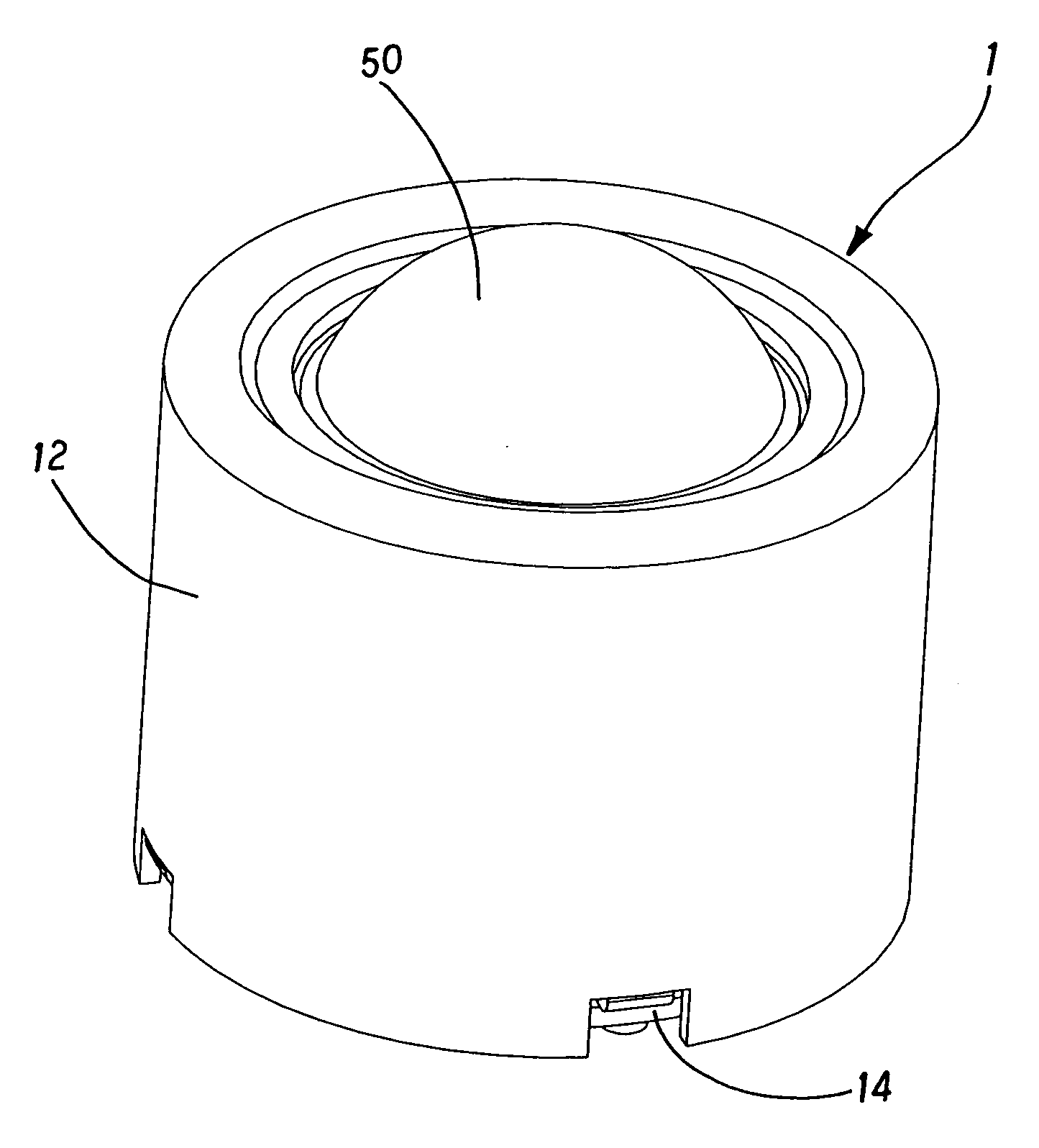

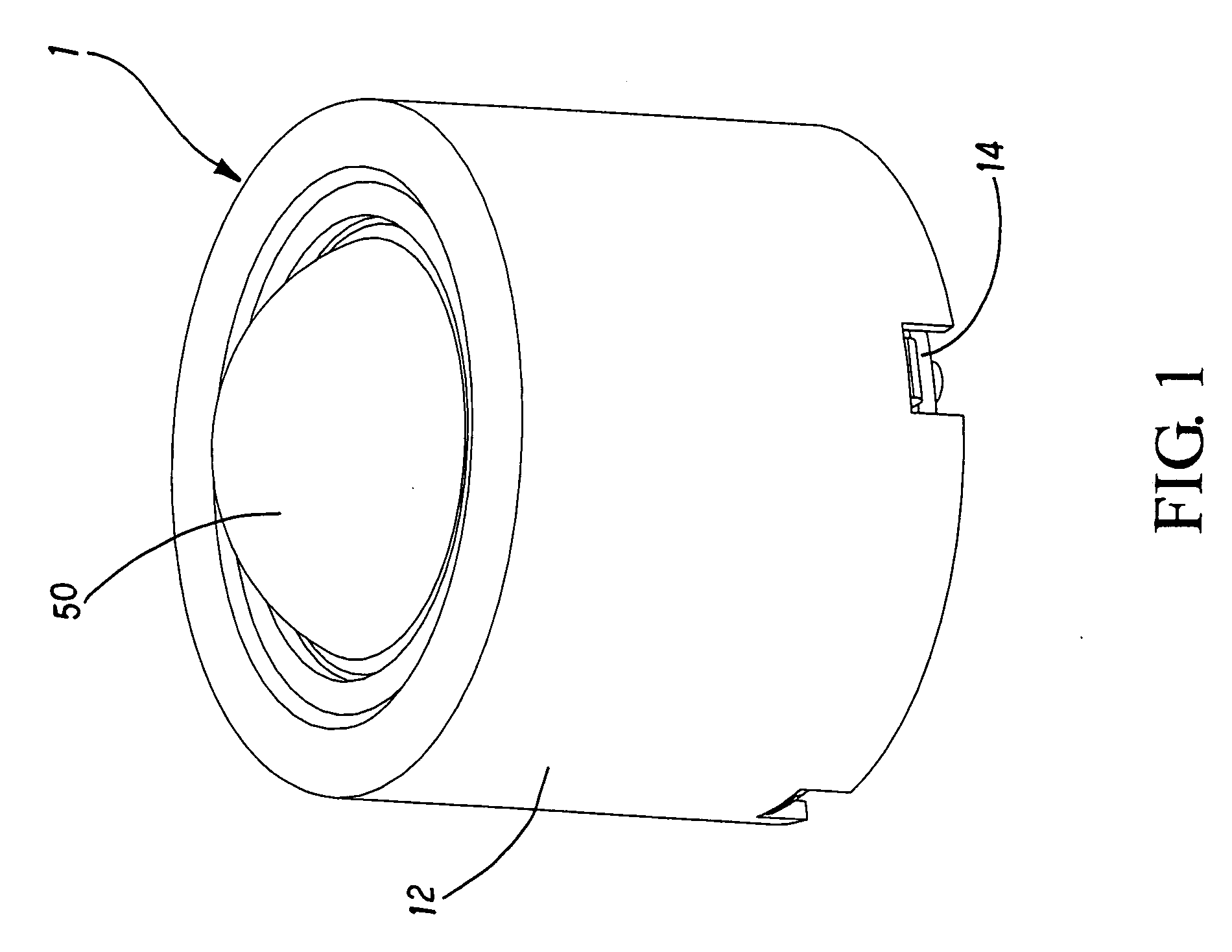

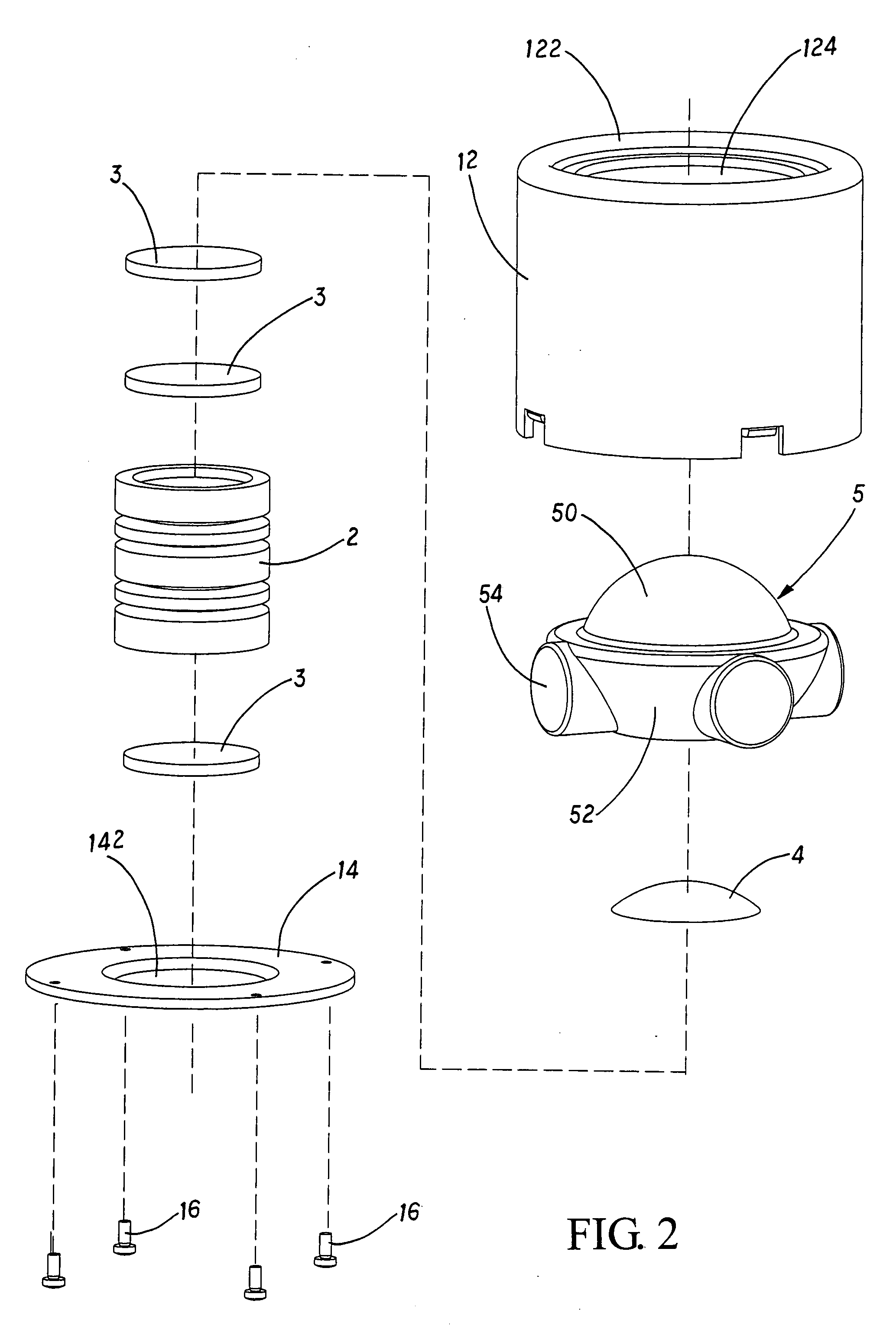

Magnetically-levitated telescopic land indicator

InactiveUS20070228852A1Avoid Elastic FatigueExtended service lifePoint-like light sourceElectric lightingEngineeringActuator

A magnetically-levitated telescopic land indicator comprises a sleeve having an end surface; the end surface having an opening; a seat combined to the sleeve so as to form an inner space for receiving other elements; a magnetic levitated telescopic cylinder installed to the downward concave portion of the seat; the magnetically-levitated telescopic cylinder being installed in an inner space between the seat and the sleeve; at least two permanent magnets being installed within the magnetically-levitated telescopic cylinder; the permanent magnets having same magnetic polarities so that the permanent magnets being repulsive to one another; and an actuator being made of strengthened transparent material; the actuator having a dome shape protrusion at an upper end; an edge portion being arranged around an edge of the protrusion, and the protrusion protruding from the opening in the end surface of the sleeve.

Owner:CHIANG TSAI JUNG

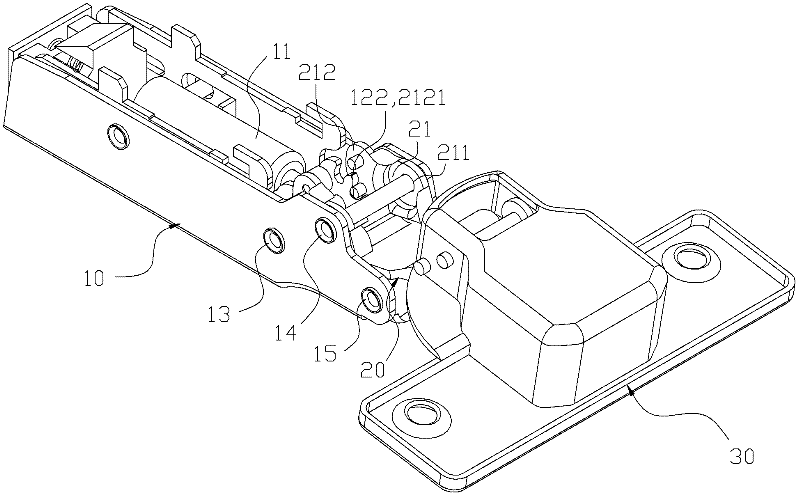

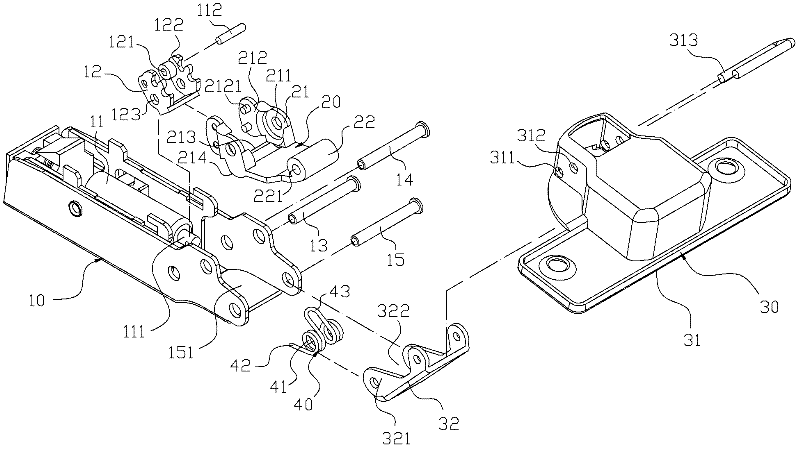

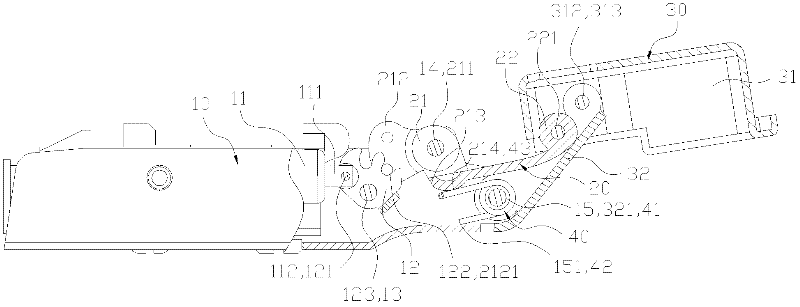

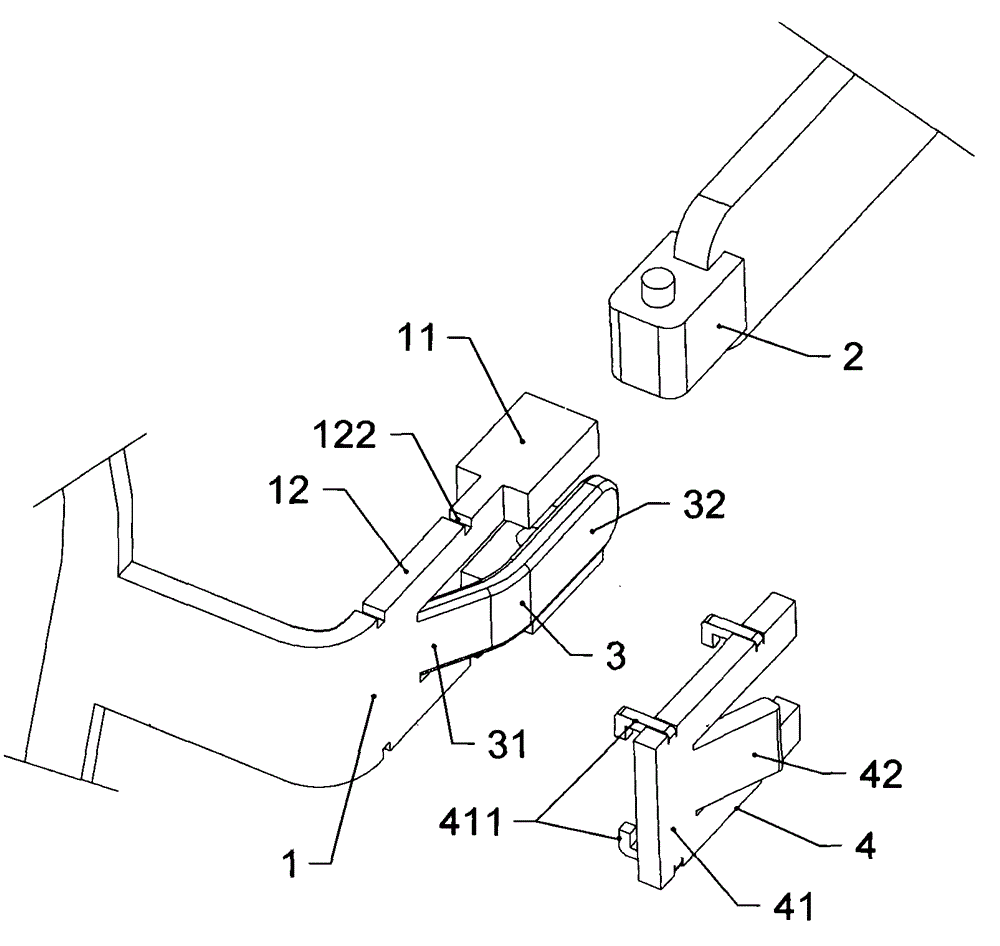

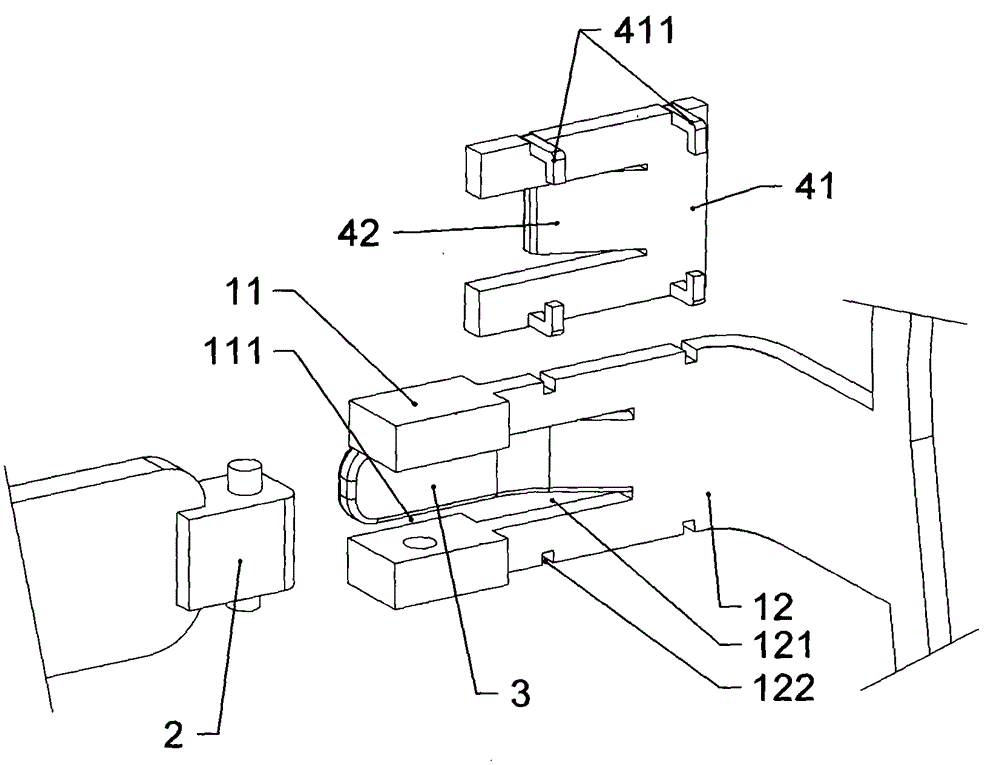

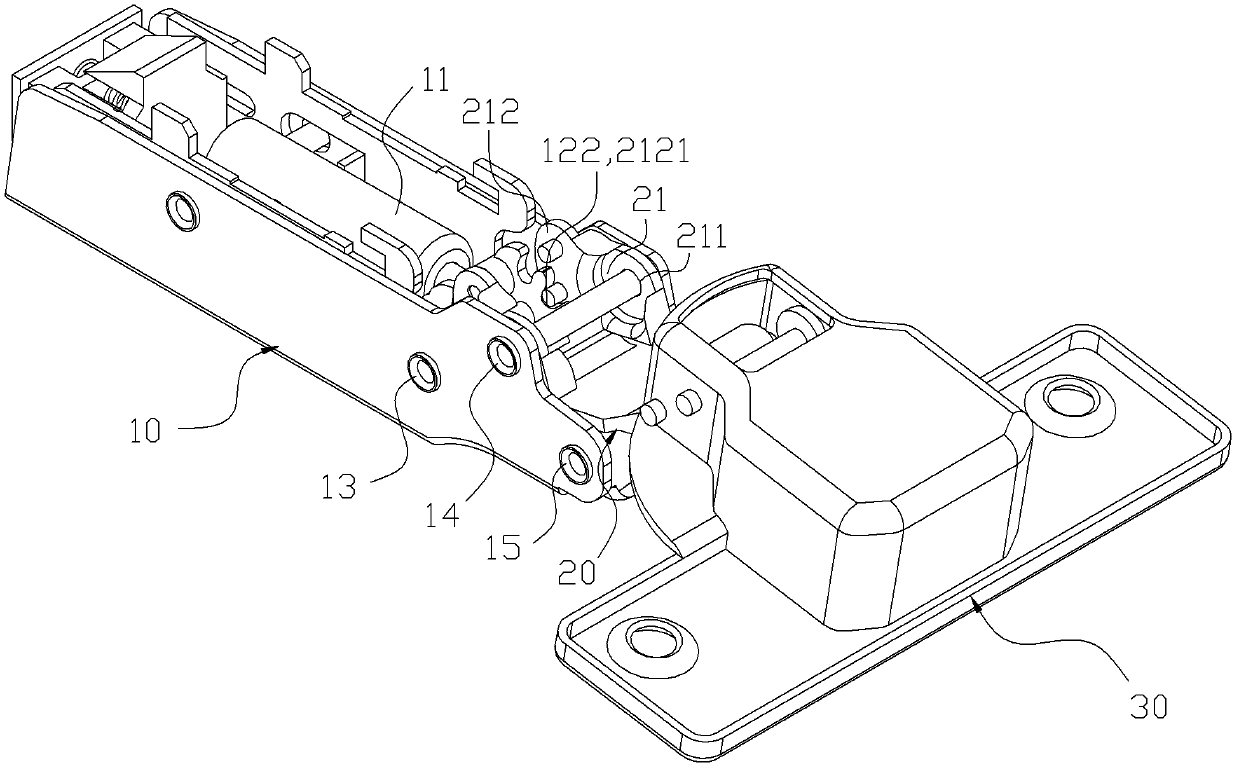

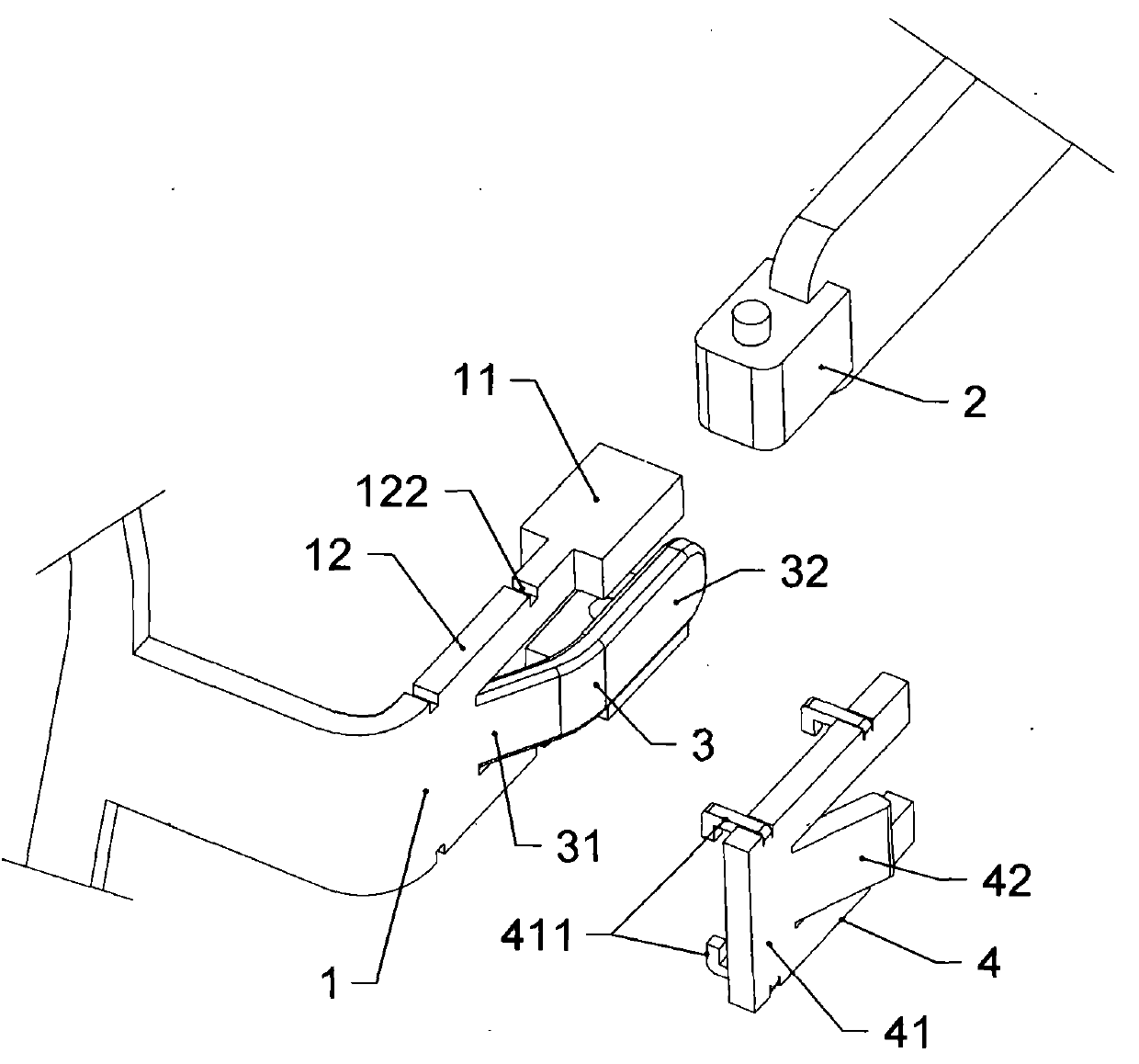

Hinge

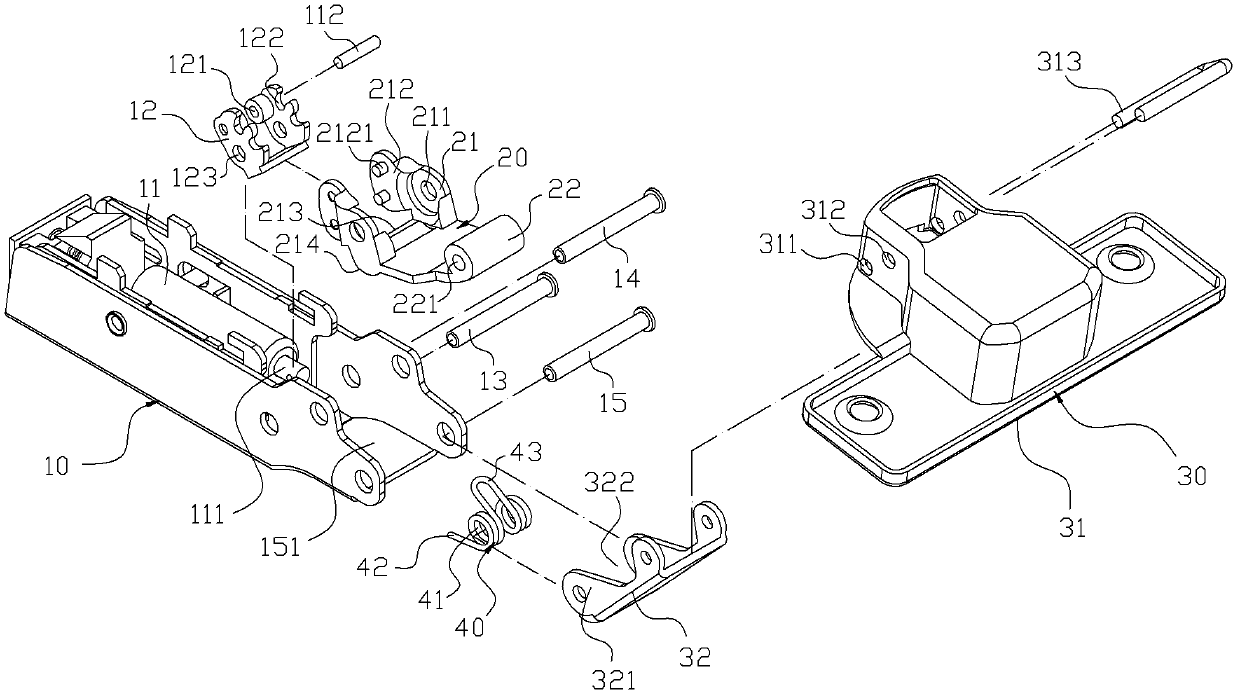

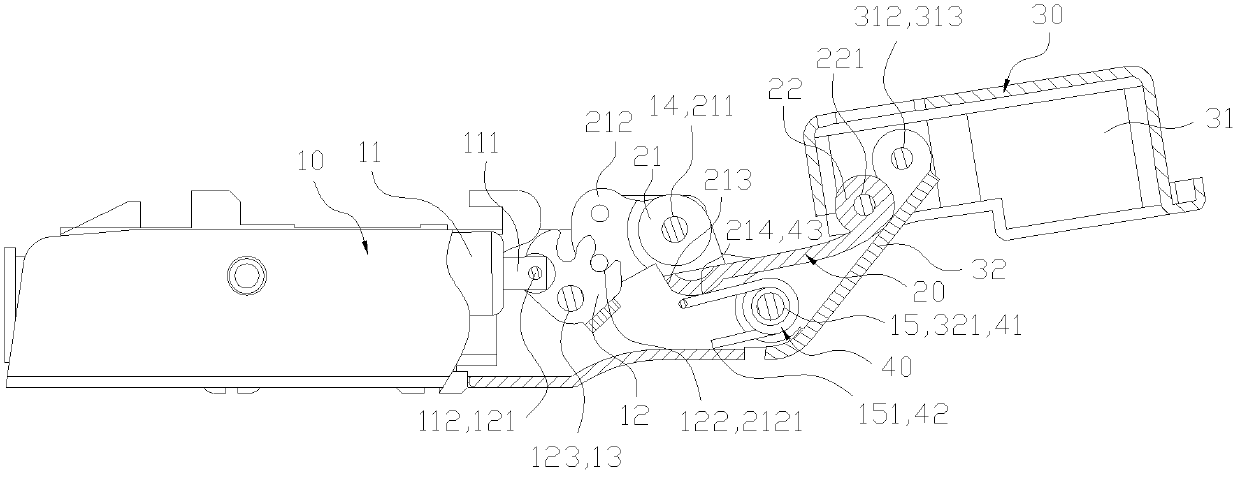

ActiveCN102373860AAvoid Elastic FatigueExtended service lifeBuilding braking devicesWing openersElastic componentCoupling

The invention discloses a hinge. The hinge comprises a hinge main body, a coupling component, a movable seat and an elastic component, wherein the coupling component is connected with a swinging block in a meshing manner, and forms a coupling relation with a buffering component of the hinge main body; the coupling component is also in pivot connection with the movable seat through a pivot connection part at one end; a rocker arm is arranged on the position, adjacent to the movable seat, of the coupling component in a pivot manner; one end of the rocker arm is arranged on a third shaft rod of the hinge main body in a pivot manner; a connecting hole of the elastic component is used for the passing of the third shaft rod of the hinge main body; two supporting ends are formed by equi-directionally extending from both sides of the connecting hole; the supporting ends are against the bottom wall surface of the hinge main body; an against end, which is located at the same side as the supporting ends, is convexly extended from the middle of the elastic component; and the against end is against the bottom surface of the coupling component. Through the structure, the hinge can generate free travel route and buffering travel route with proper angles, thus the effects of reducing the impact force and noise while opening and closing door plates are achieved.

Owner:吴枝祥

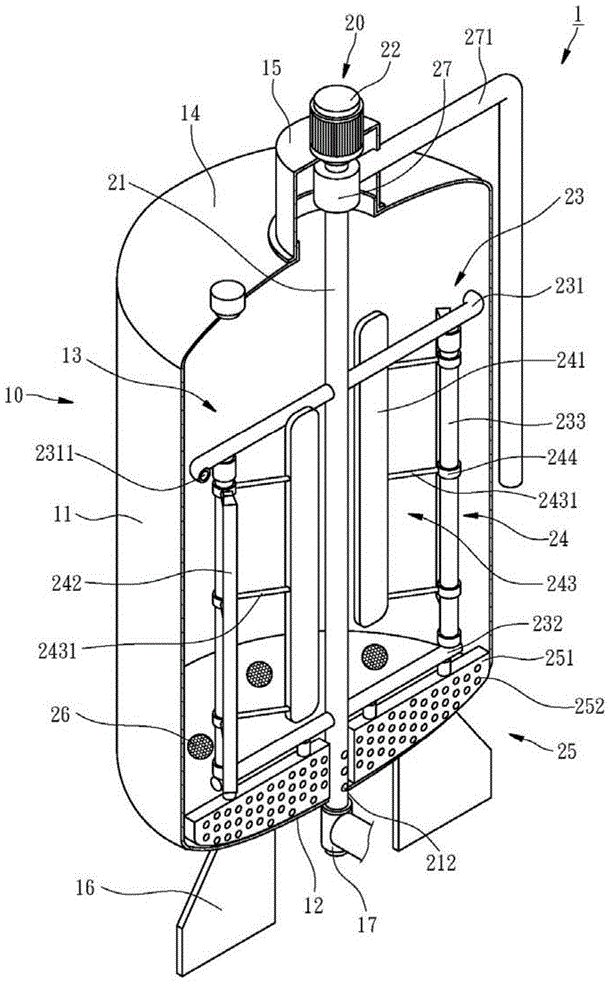

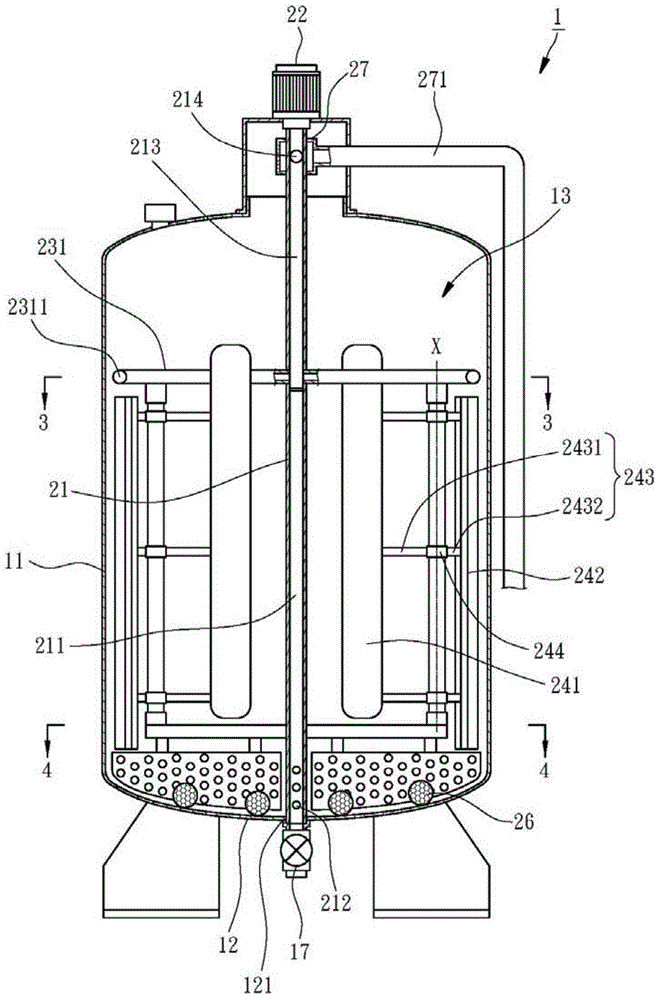

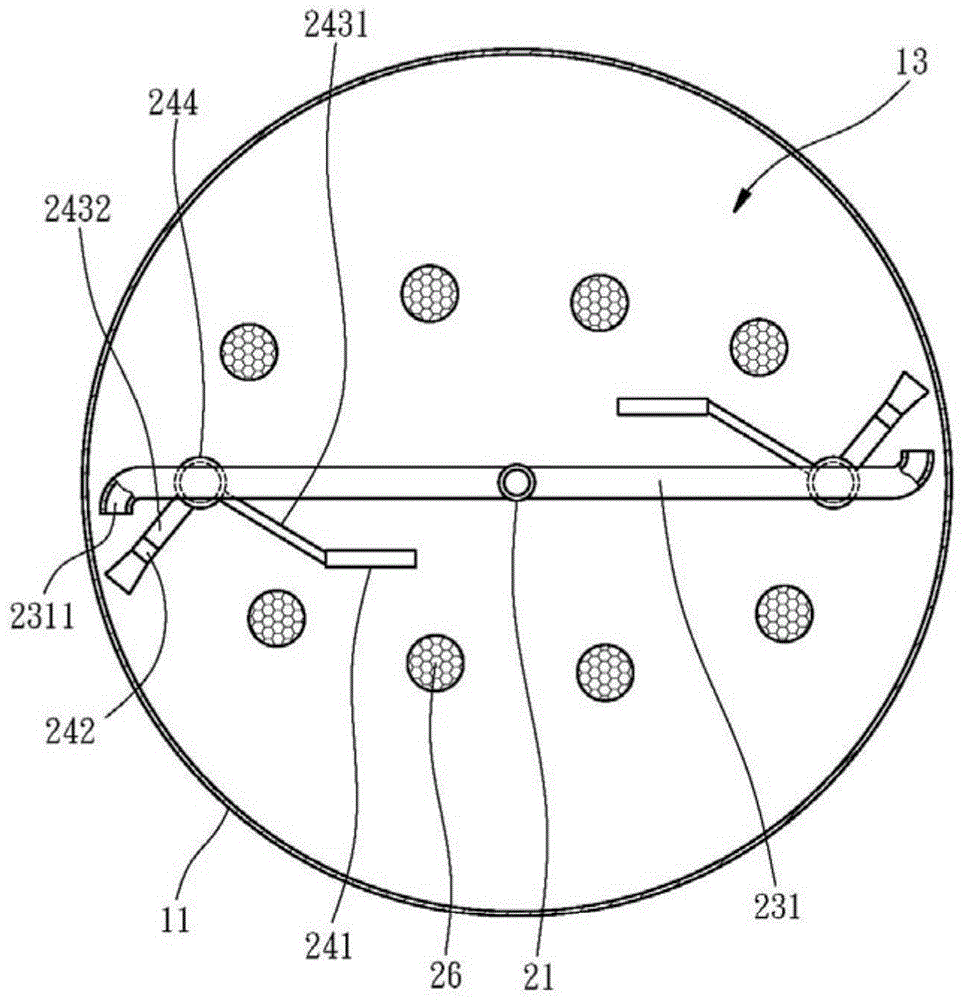

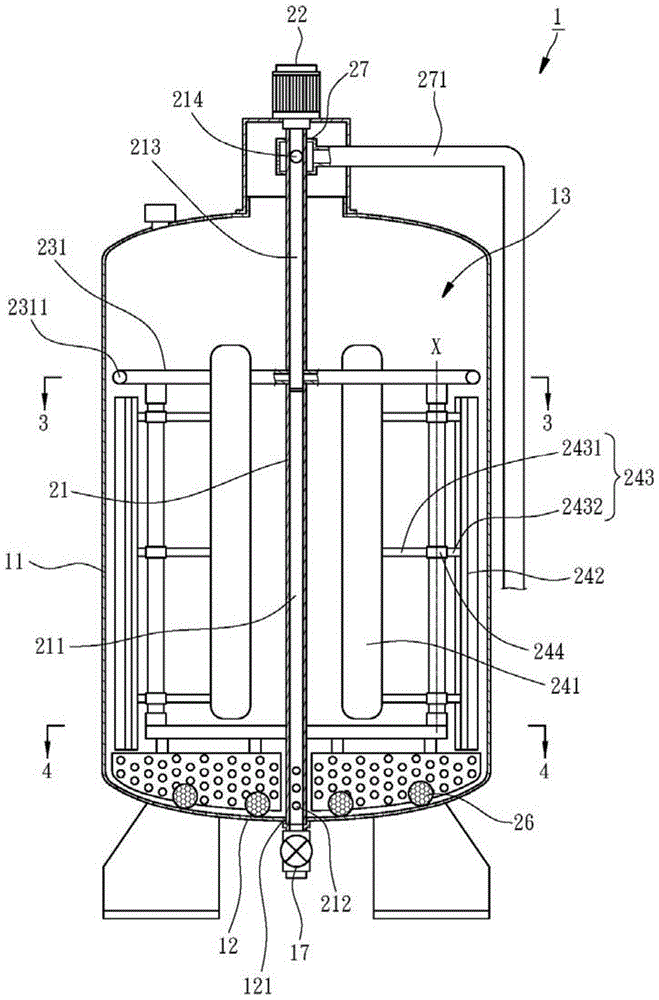

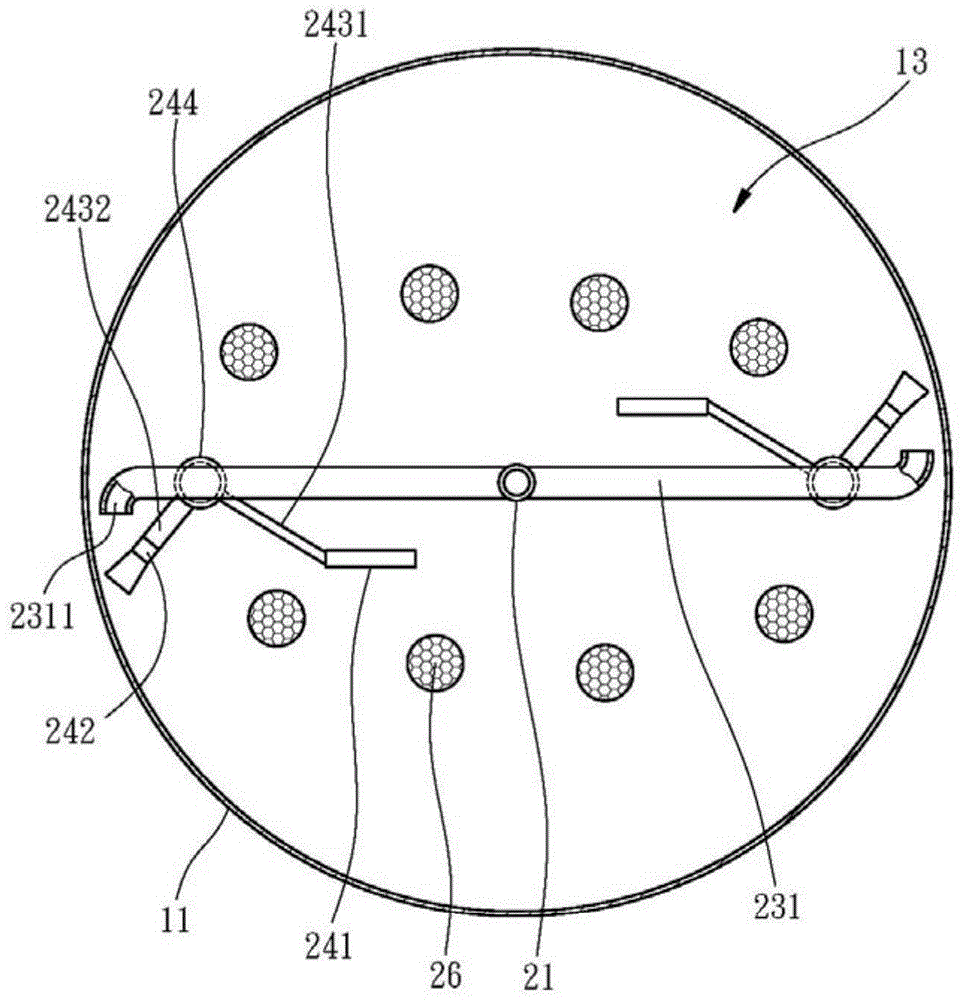

Liquid storage equipment with cleaning device

InactiveCN104631560AAvoid Elastic FatigueHollow article cleaningWater supply tanksEngineeringPendulum

The utility model relates to liquid storage equipment with a cleaning device. The liquid storage equipment with the cleaning device comprises a barrel body and the cleaning device, wherein the barrel body comprises a peripheral wall and a bottom wall arranged on the bottom edge of the peripheral wall; the peripheral wall and the bottom wall surround to form a liquid storage space; the cleaning device comprises a main shaft, a drive device, a support fixedly arranged on the main shaft, at least one cleaning element, a baffle unit and a plurality of ball brushes; the main shaft extends into the liquid storage space along the axial direction; the drive device is used for driving the main shaft to rotate; the cleaning element can be arranged on the support in a pivot pendulum way; the pivot pendulum axis of the cleaning element is parallel to the main shaft; the cleaning element is provided with a flow resistance plate, a cleaning brush and a connecting unit connected to the flow resistance plate and the cleaning brush; when the drive device does not work, the cleaning brush and the ball brushes cannot cling to the inner wall of the barrel body, so that the elastic fatigue is delayed.

Owner:唐景松

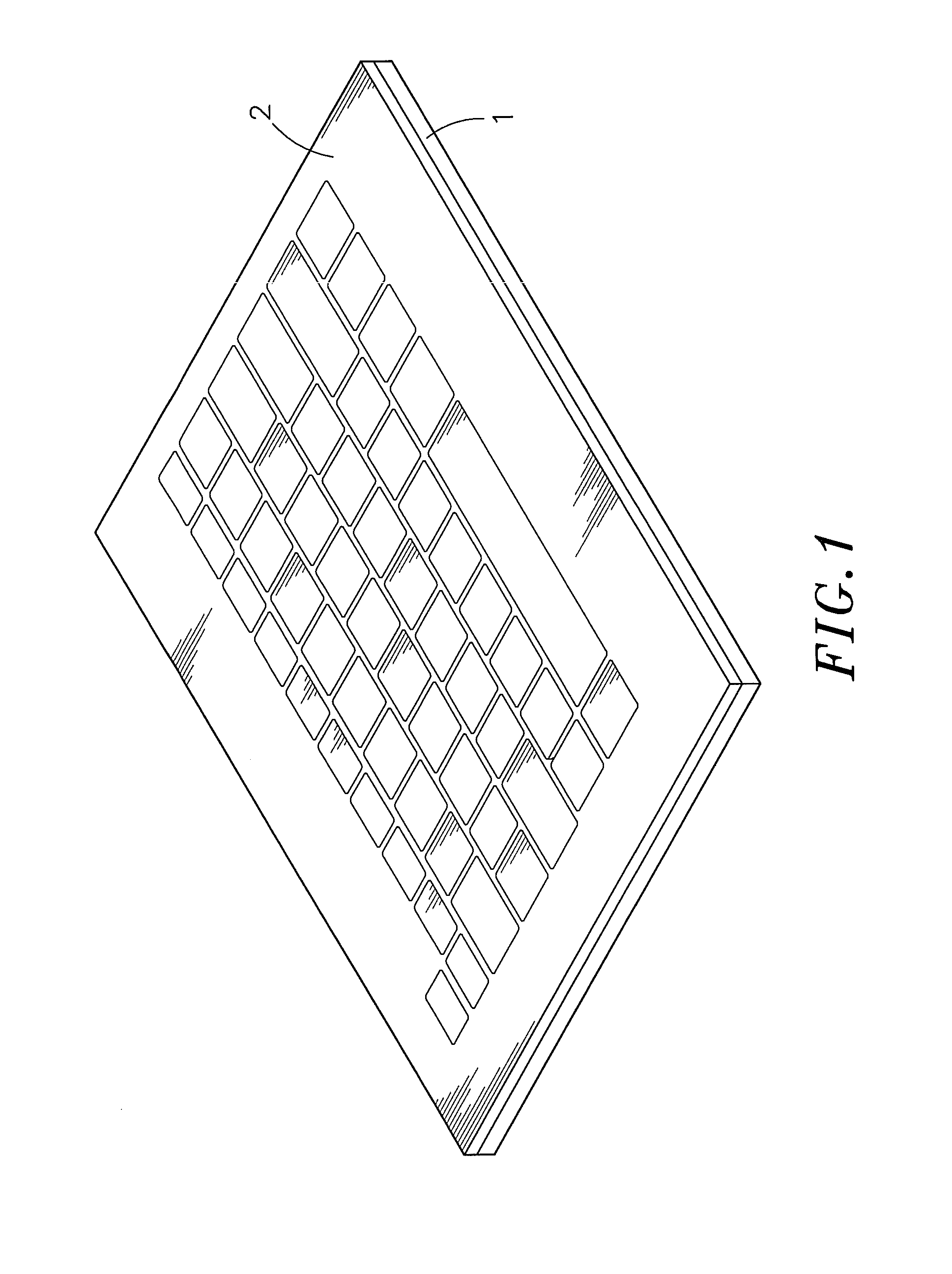

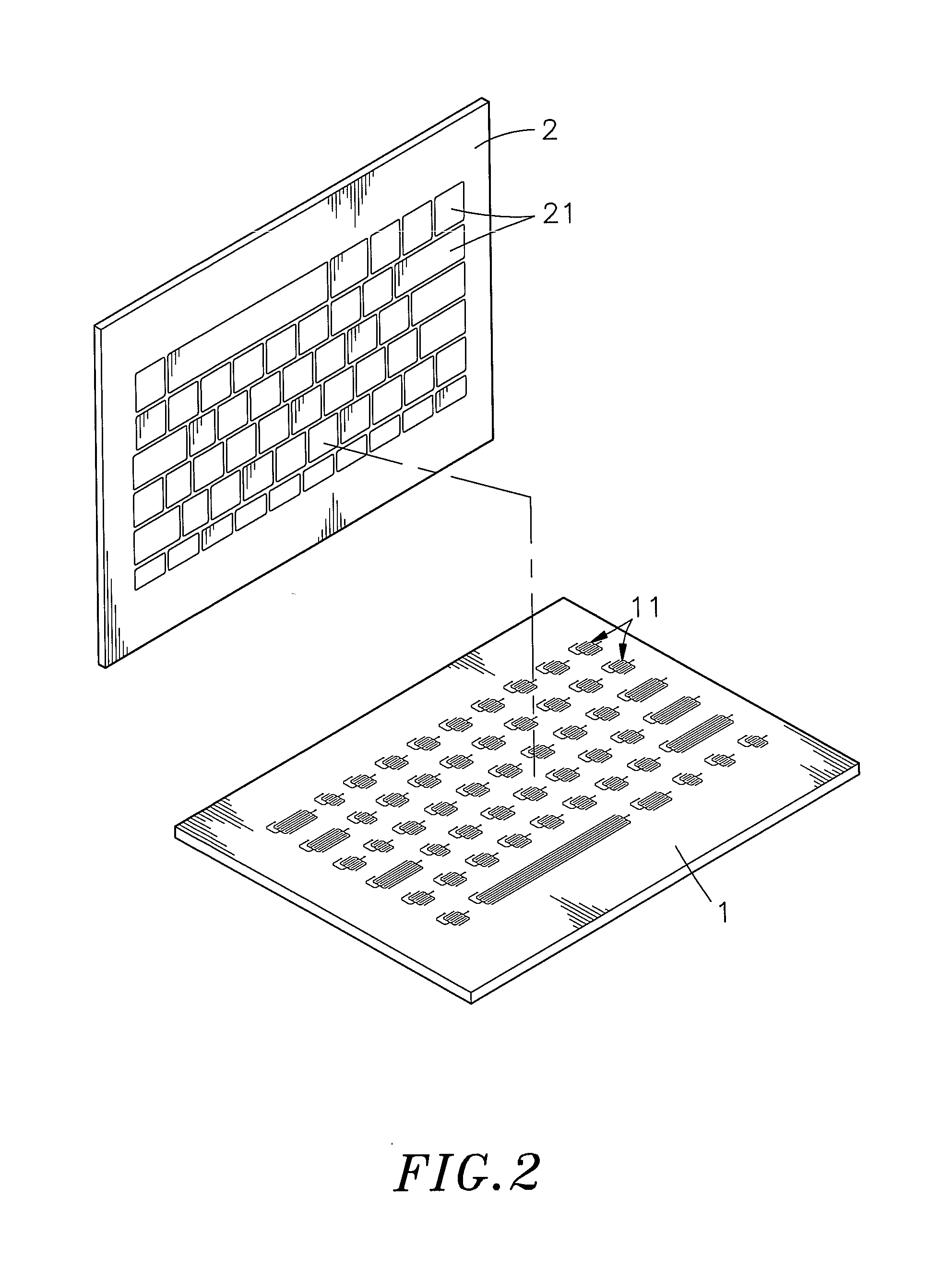

Ultra-thin computer input device

InactiveUS20140054154A1Drawback can be obviatedReduce the numberEmergency actuatorsContact surface shape/structureEngineeringInput device

An ultra-thin computer input device includes a substrate carrying a circuit layout having sets of comb-like contact portions arranged in a staggered manner, and an outer membrane arranged on the substrate and provided with conducting portions corresponding to the comb-like contact portions of the circuit layout of the substrate and electrically insulative beads located on a part of the bottom side of each conducting portion and stopped against the comb-like contact portions of the circuit layout of the substrate. Because the invention eliminates the use of metal domes, rubber domes or scissor-type linking elements, the thickness and number of component parts of the ultra-thin computer input device can be greatly reduced.

Owner:SIN MEI ELECTRONICS

Terminal structure

PendingCN107465020AAvoid Elastic FatigueLoading and unloadingCoupling contact membersEngineeringStructural engineering

The invention discloses a terminal structure. The terminal structure comprises an elastic sheet, a first current strip and a second current strip, wherein the first current strip and the second current strip are respectively inserted to two ends of the elastic sheet, the elastic sheet comprises two elastic parts, the two elastic parts are integratedly formed and are symmetrically arranged, each elastic part is provided with a body, two ends of the body are bent inwards, a first elastic edge and a second elastic edge are correspondingly formed at the two ends of the body, a tail end of the first elastic edge is bent downwards, and a connection edge is formed at the tail end of the first elastic edge. In the terminal structure, the first current strip and the second current strip are inserted into the elastic sheet, and the terminal structure is convenient to assemble and disassemble; and moreover, the elastic sheet is of a symmetric structure and is reliable in elastic force, a plurality of contact points exist among the elastic sheet, the first current strip and the second current strip, and the contact effect of the conductive terminal is effectively ensured.

Owner:镇江天旭电气有限公司

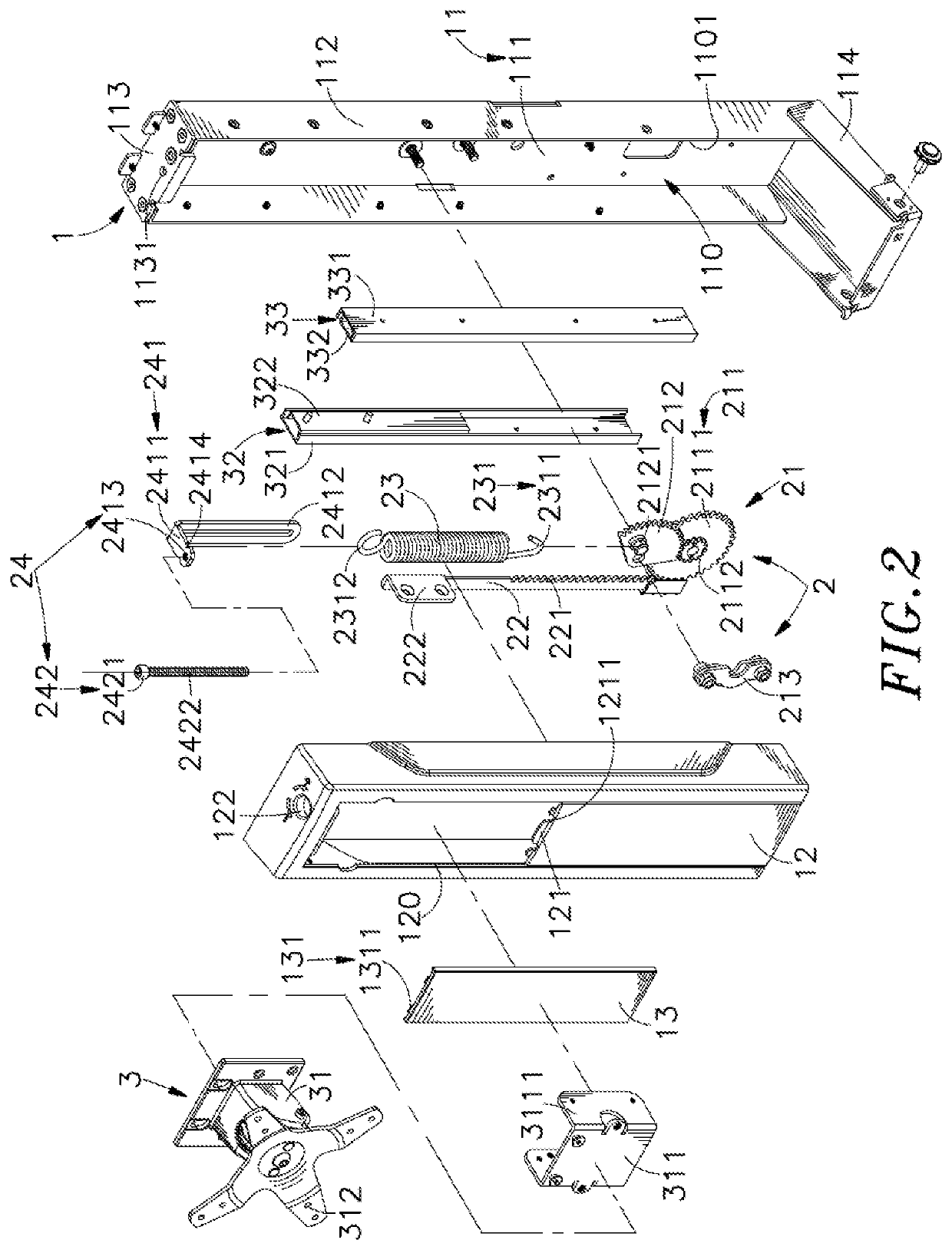

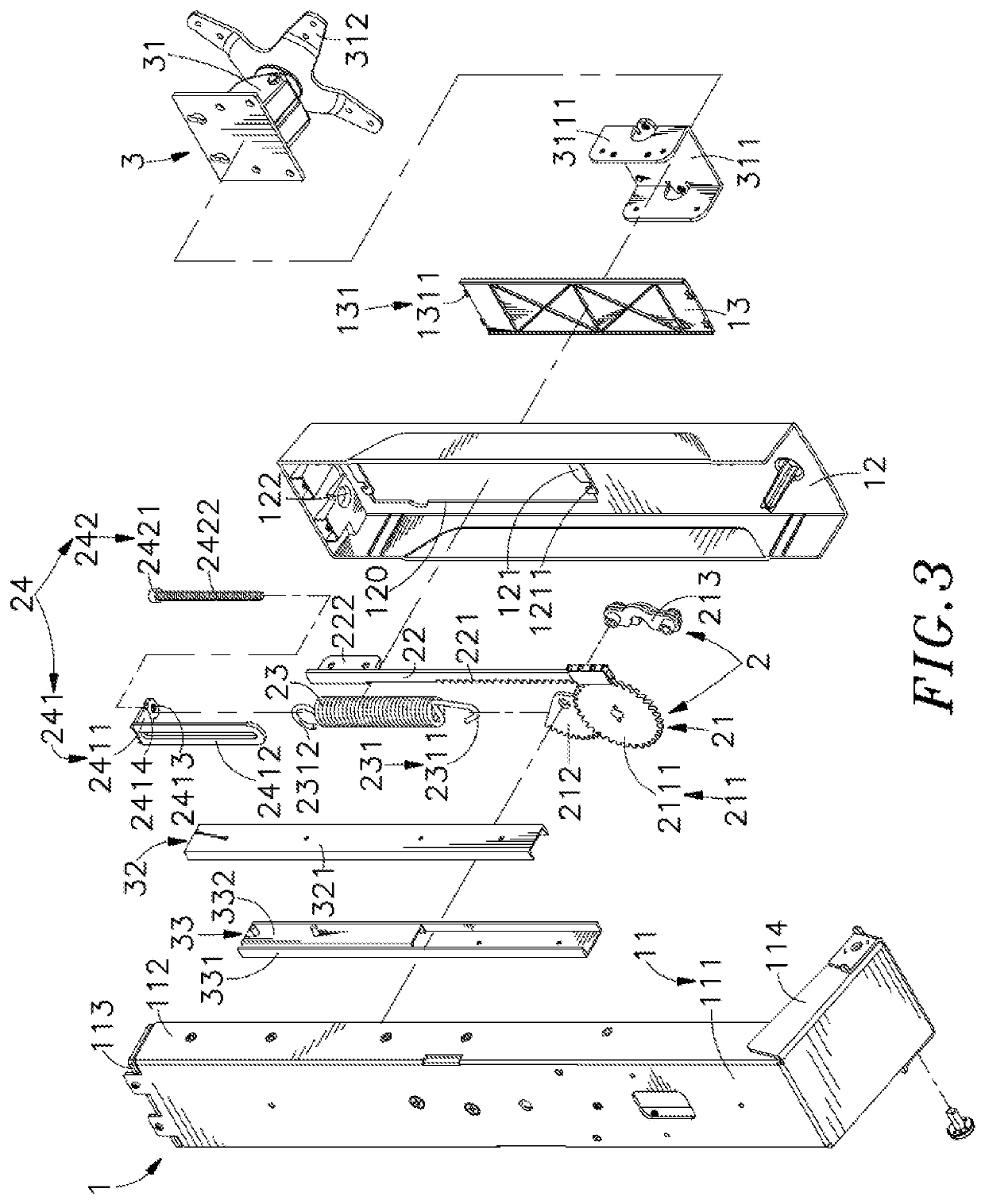

Adjustable screen lift arm

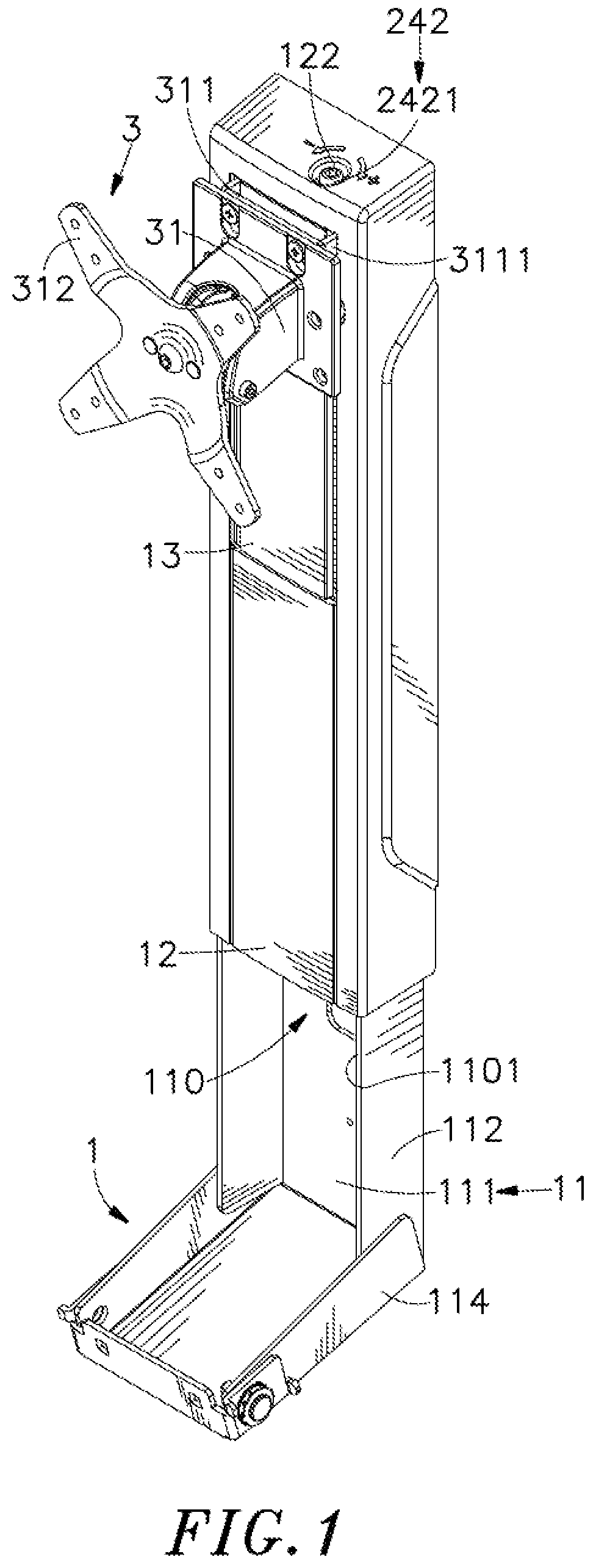

ActiveUS10550996B1Avoid Elastic FatigueExtended service lifeStands/trestlesFriction gearingsGear wheelClassical mechanics

An adjustable screen lift arm includes a support frame assembly with a frame base, a balance adjustment mechanism including a gear set consisting a drive gear and a sector-like driven gear, a gear rack meshed with the drive gear and a spring connected between the frame base and the driven gear, and a holder block assembly has a holder block body that combined with the gear rack and a first sliding rail, the other side combined with a second sliding rail. When the holder block body is moved vertically, the gear rack rotates the drive gear, causing the driven gear to stretch or compress the spring so that the arm of force is relatively changed to offset the spring force of the spring, enabling the holder block assembly to be freely adjusted to the desired elevation and then automatically positioned.

Owner:CHEN-SOURCE INC

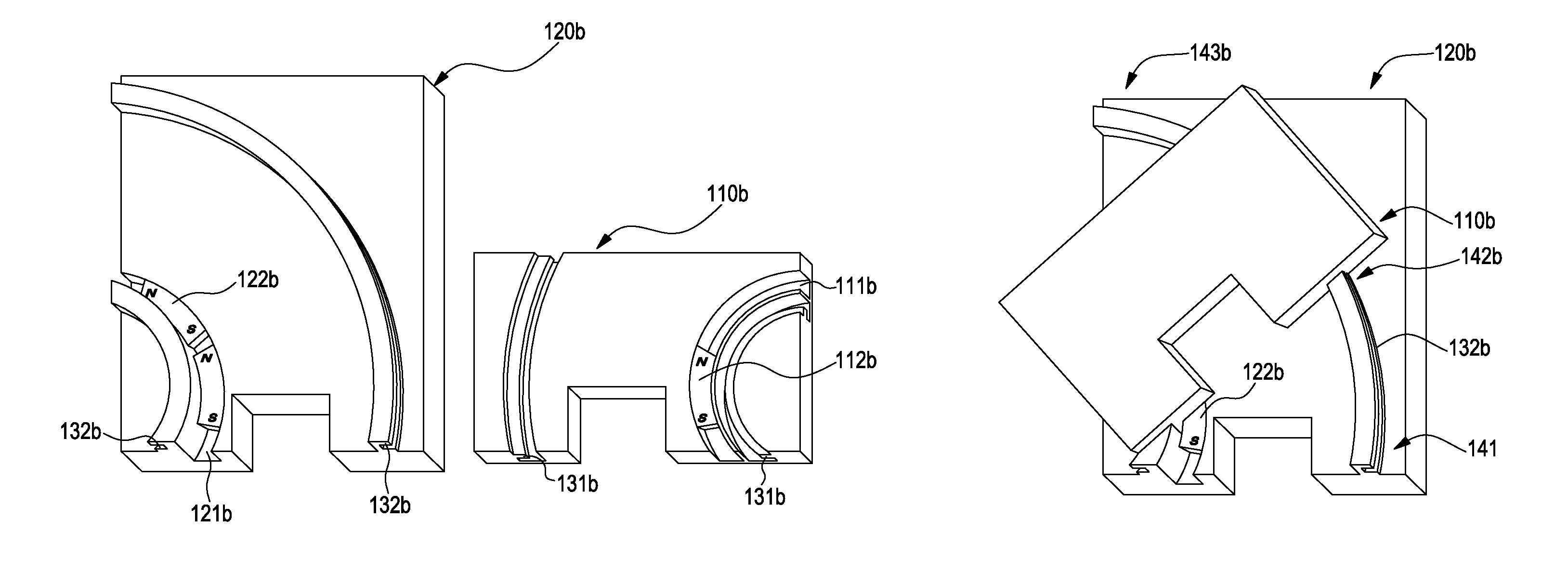

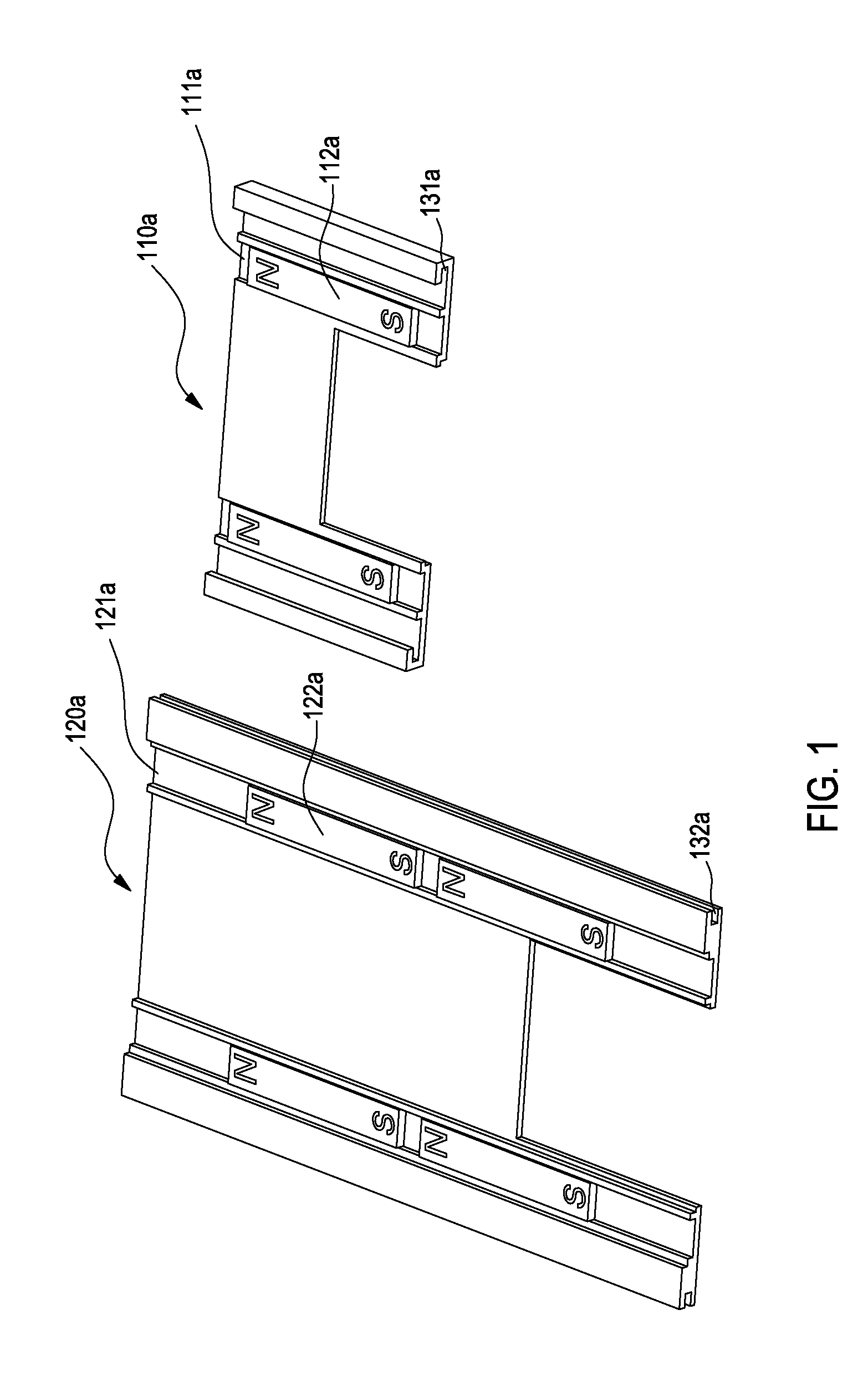

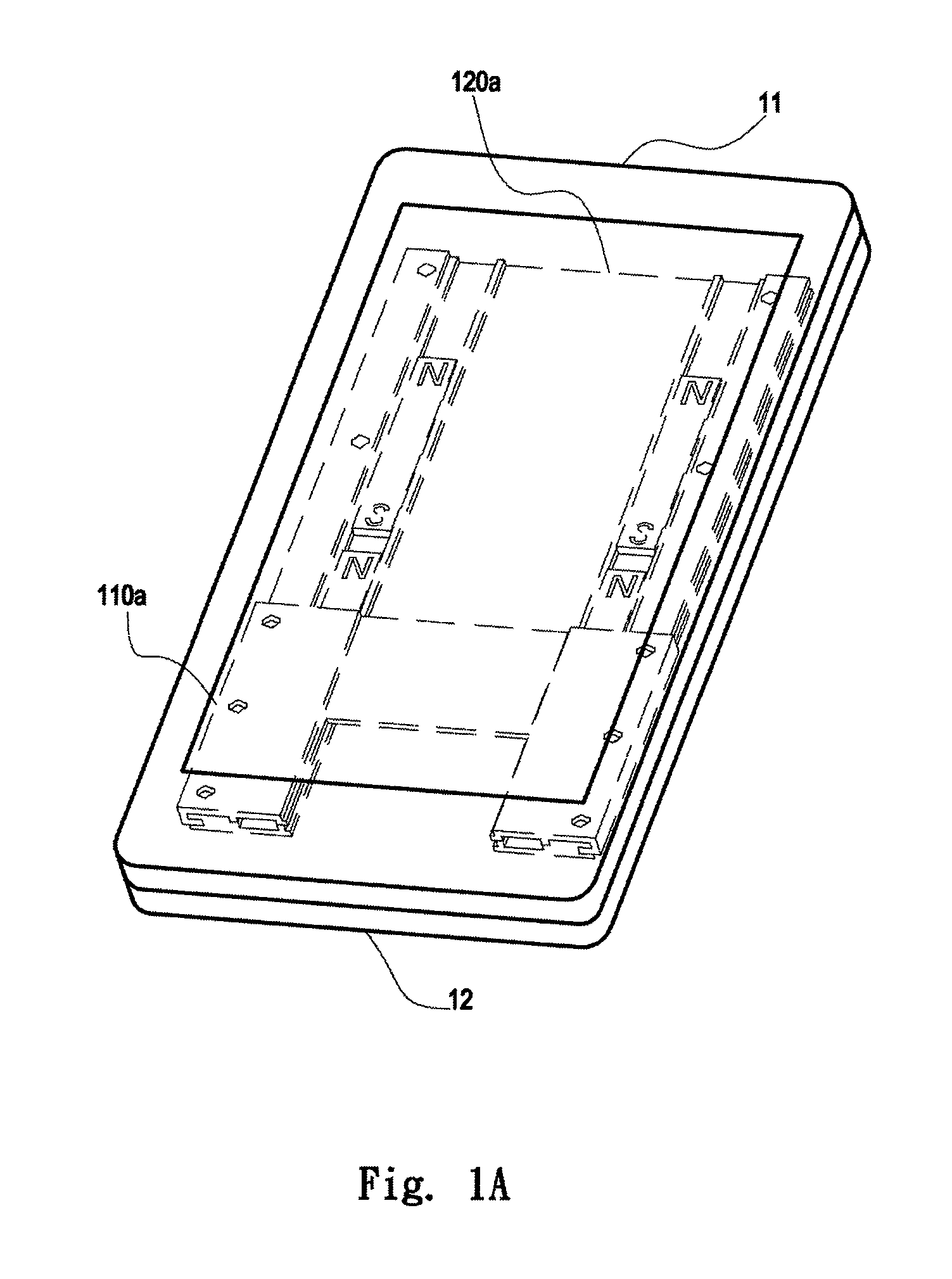

Multi-stage sliding structure of handheld device

InactiveUS8362667B2Low costIncreased durabilitySubstation equipmentSliding contact bearingsMagnetic polesHand held devices

A multi-stage sliding structure of a handheld device includes a first sliding block, a second sliding block, and an engagement structure. The first sliding block has at least one first groove for containing a first magnetic strip. The second sliding block has at least one second groove. The second groove is for containing at least two second magnetic strips which are continually spaced apart in the second groove, and the directions of magnetic poles of the second magnetic strips correspond with directions of respective magnetic poles of the first magnetic strip. The engagement structure includes two structures disposed near outer sides of the first and the second grooves respectively, and is for enabling the first and the second sliding blocks to engage with each other and slide with respect to each other.

Owner:INVENTEC APPLIANCES CORP

Double-clip glasses hinge

Owner:李建军

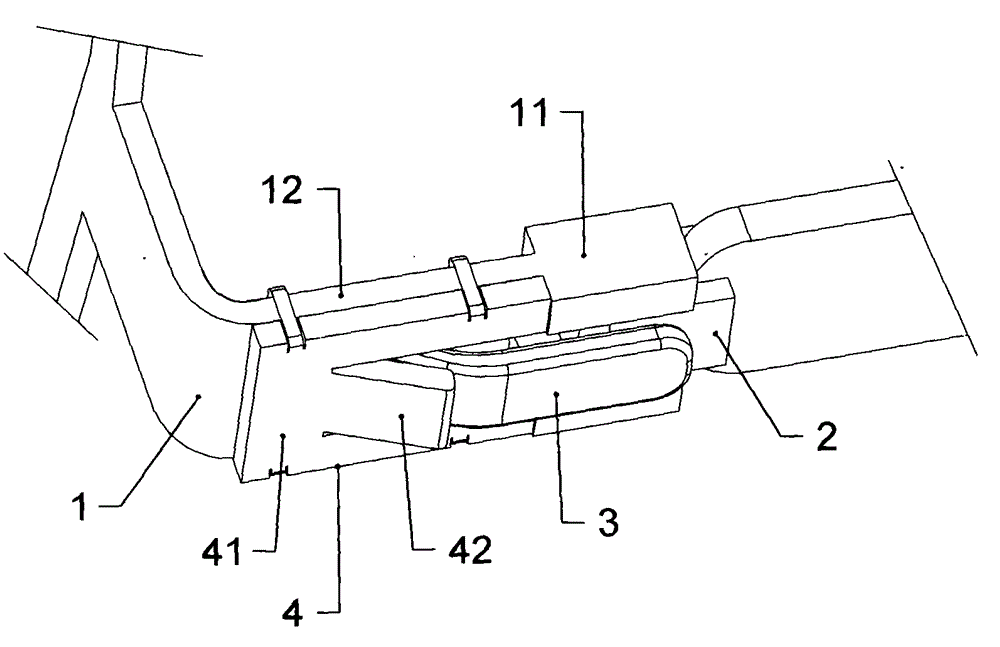

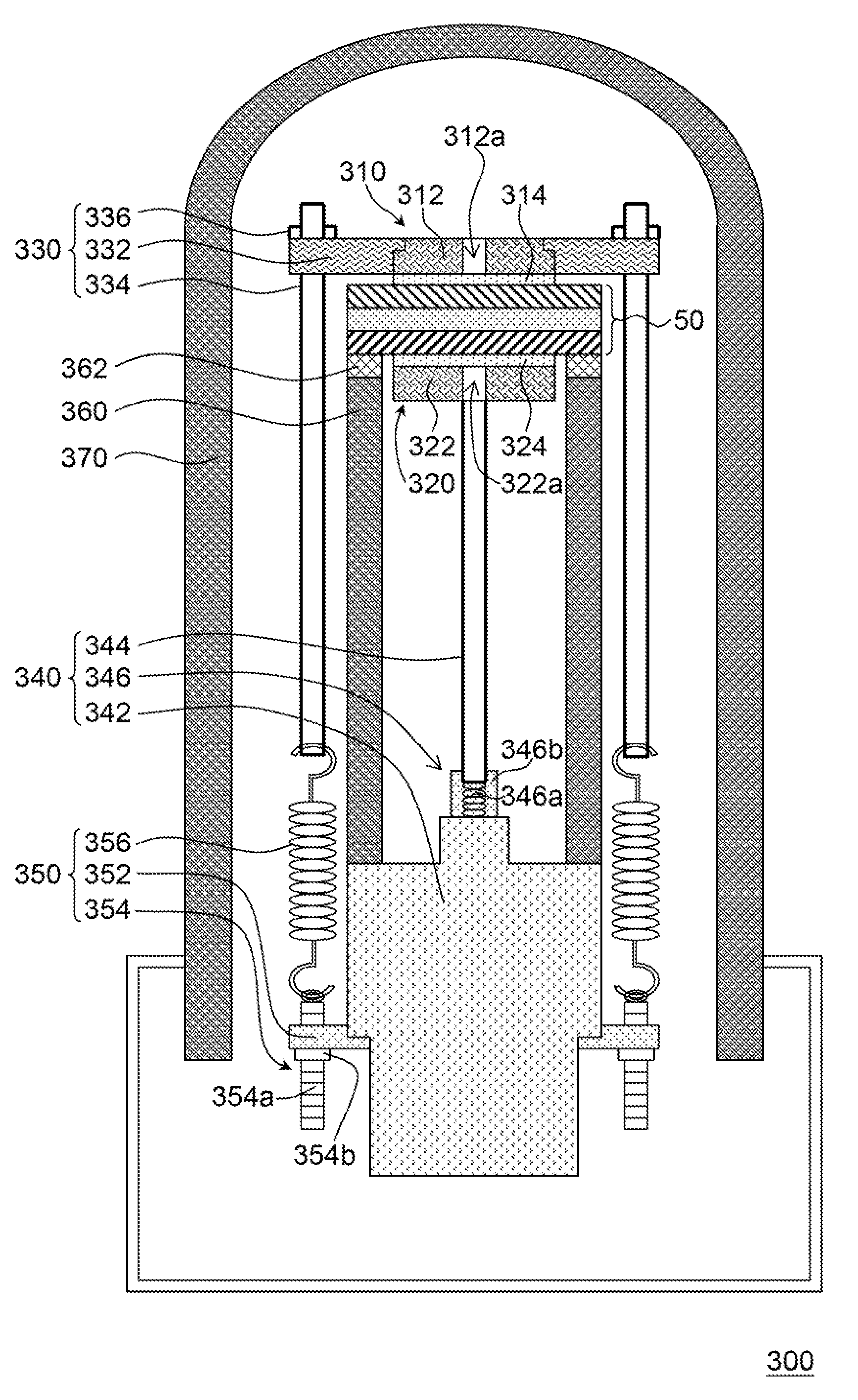

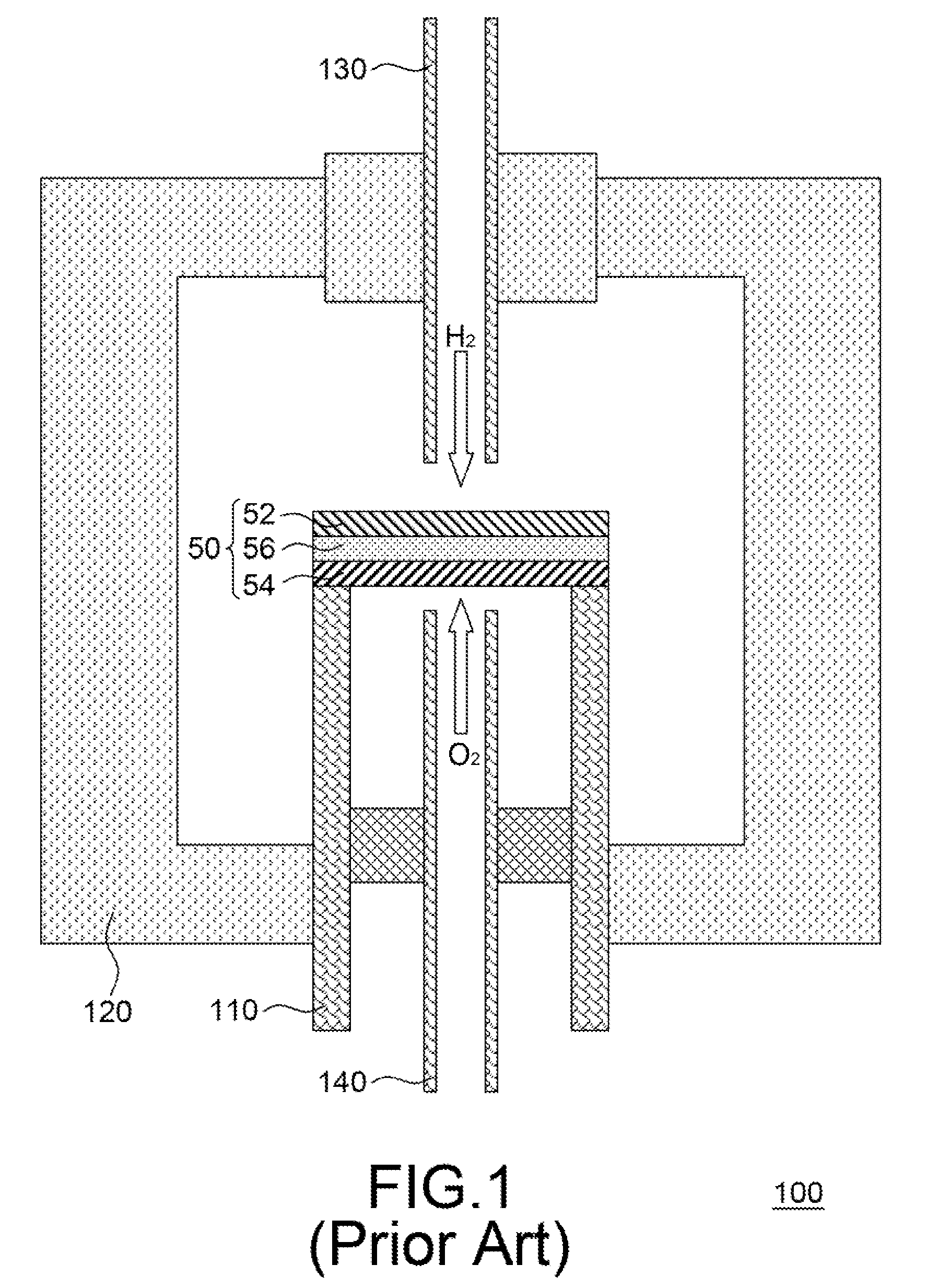

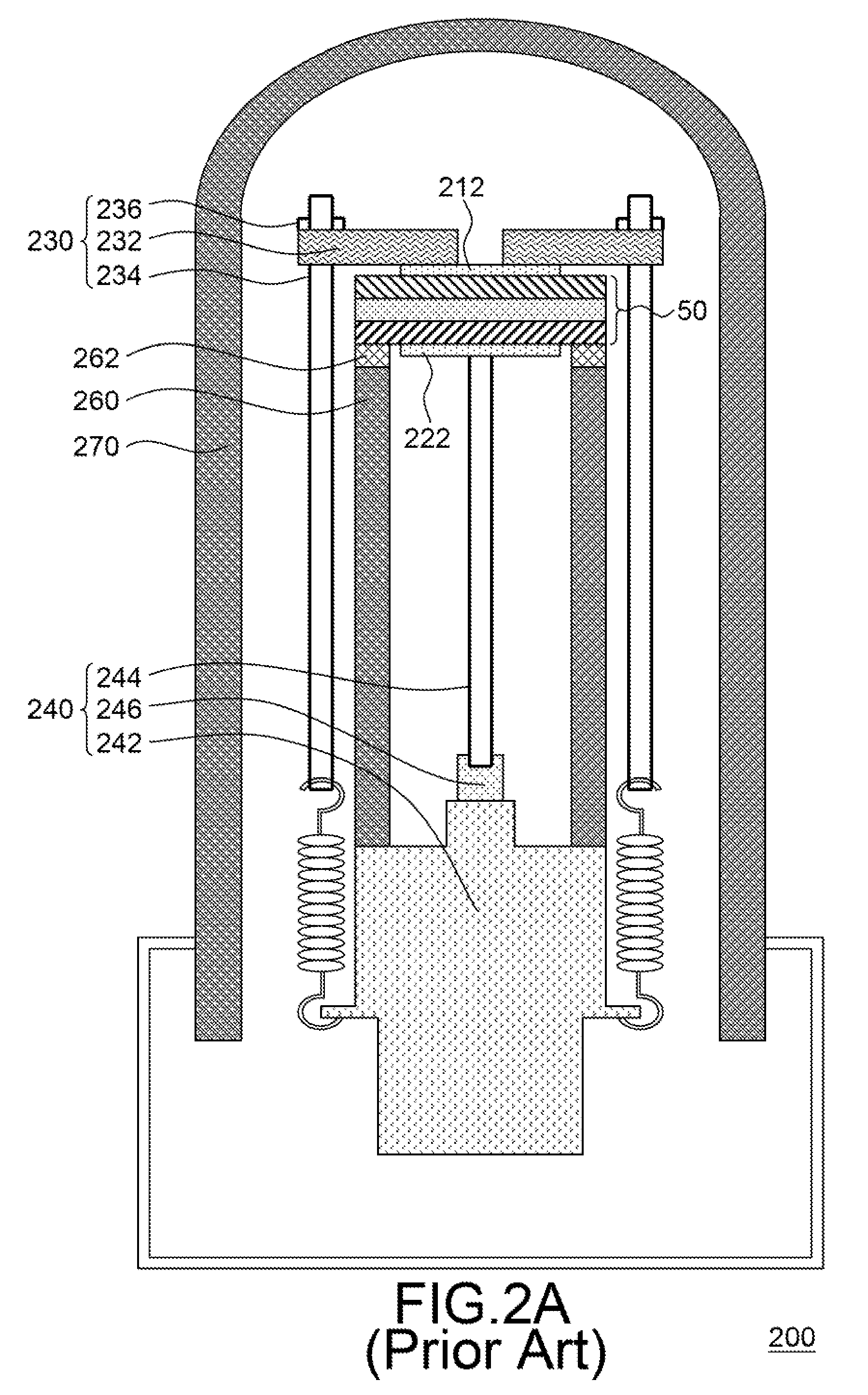

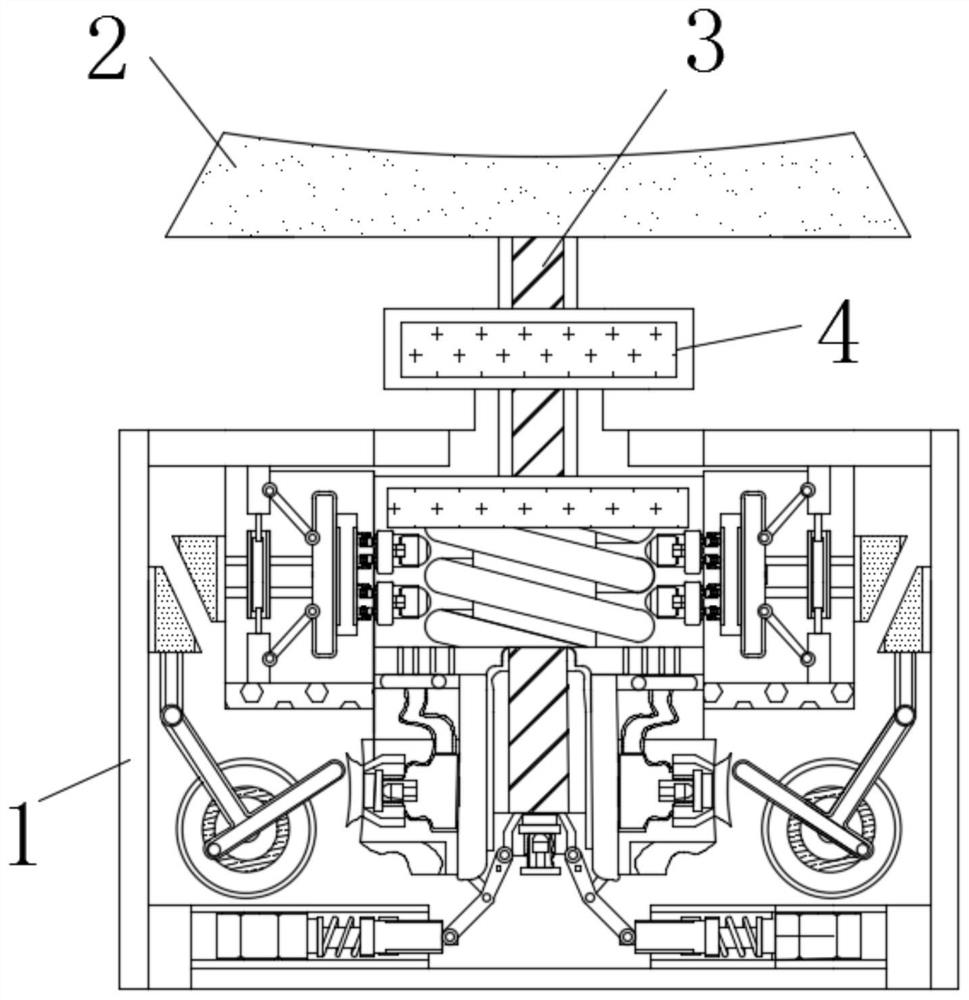

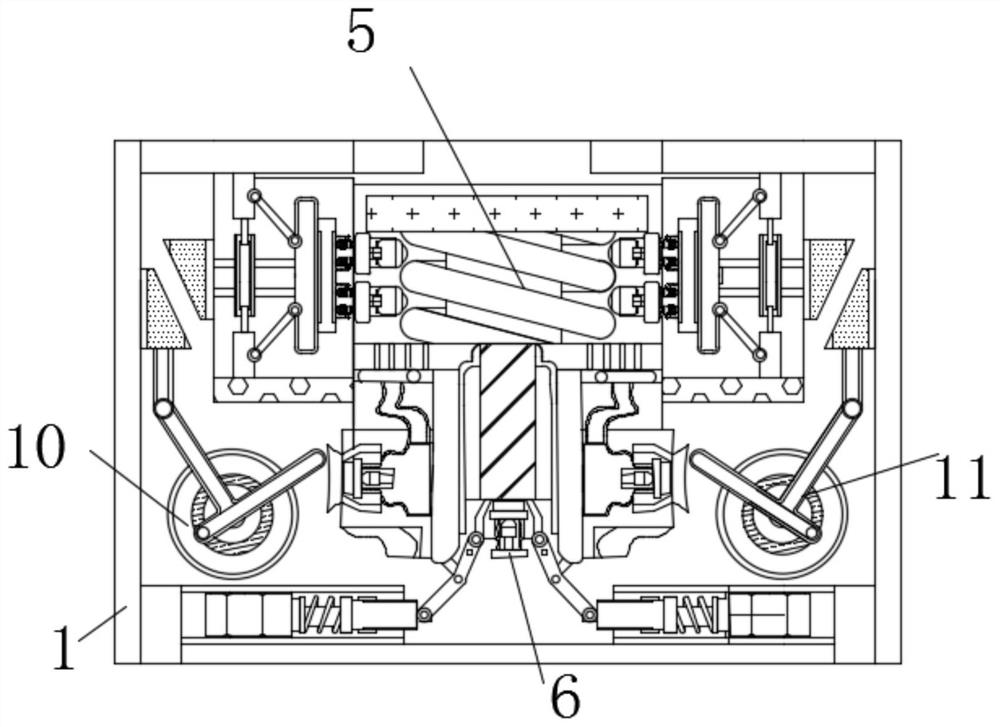

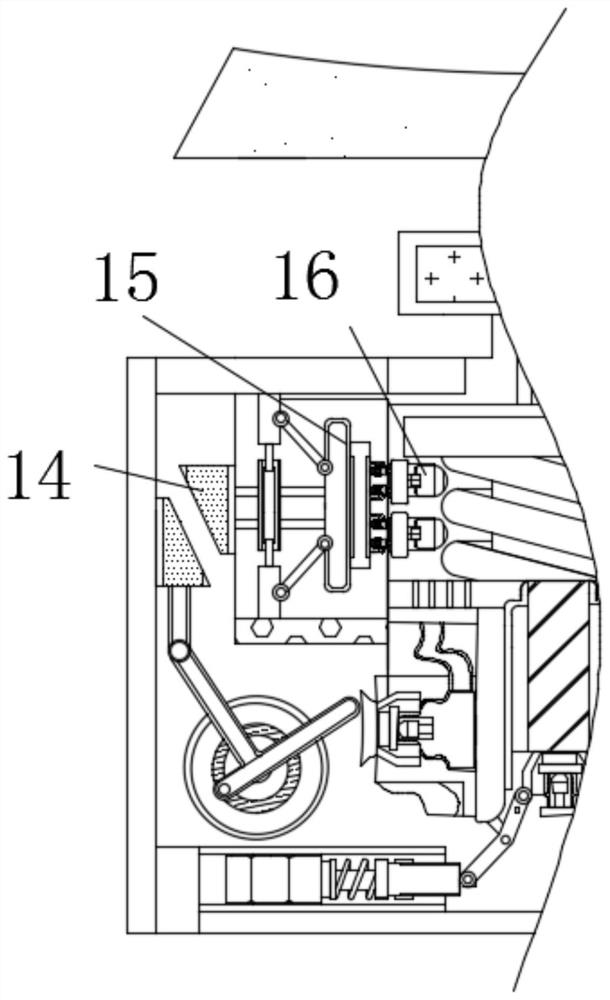

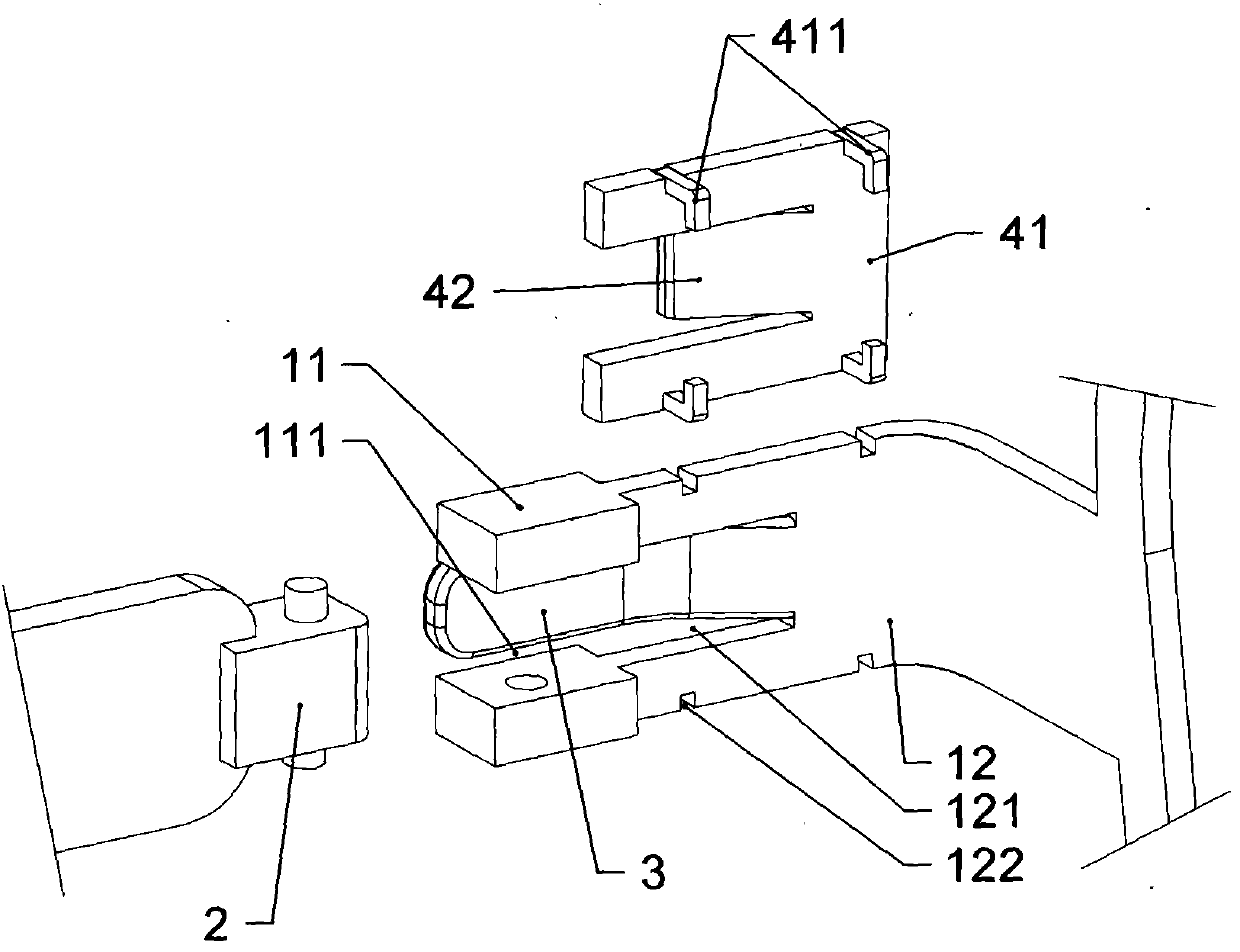

Fuel cell measurement apparatus

InactiveUS7993788B2Ease in re-using and assemblingSmooth connectionFuel cell auxillariesMaterial analysis by electric/magnetic meansElectricityFuel cells

A fuel cell measurement apparatus capable of measuring electric characteristics of a solid oxide fuel cell is provided. The fuel cell measurement apparatus comprises a first current collecting unit, a second current collecting unit, a top holding set, a bottom holding set and an adjustable elastic load set. The solid oxide fuel cell is clipped by the first current collecting unit fixed by the top holding set and the second collection unit fixed by the bottom holding set. The adjustable elastic load set is capable of adjusting the tension between the top holding set and the bottom holding set. The first (second) current collecting unit comprises a first (second) conductive mesh and a first (second) porous plate having a first (second) through hole and a first (second) gas channel communicating with each other, wherein the first (second) conductive mesh is sintered on the first (second) porous plate.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Sucktion cup

ActiveUS11391317B2Avoid Elastic FatigueStably attach onto object surfaceSuction cupsHooksSuction forceMechanical engineering

A suction cup comprises a suction cup member, a press ring, a first housing and an insertion pin. The suction cup member includes an assembly surface and a suction surface. The assembly surface includes a first protrusion having a first cut-out slot formed thereon. The press ring is pressed onto an upper outer edge of the suction cup member. The first housing is pressed onto the press ring and includes a second protrusion for mounting onto the first protrusion. One side of the second protrusion includes a first through hole corresponding to the first cut-out slot to expose the first cut-out slot. The insertion pin partially engages with the first housing and slidably engages with the first through hole and the first cut-out slot to move in the first cut-out slot and to drive the suction cup member to move upward while forming a vacuum space underneath thereof simultaneously.

Owner:FREE FREEUSA INC +1

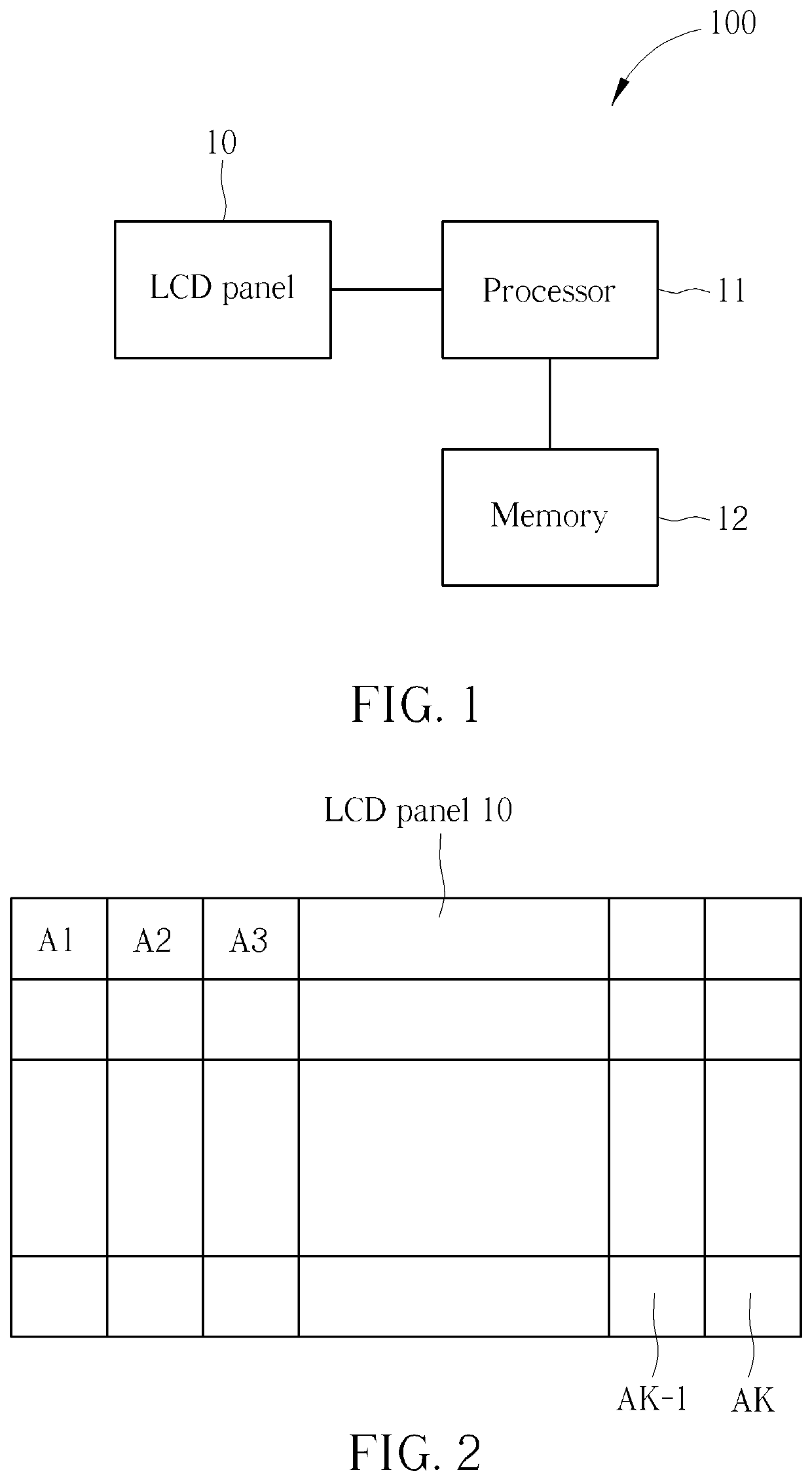

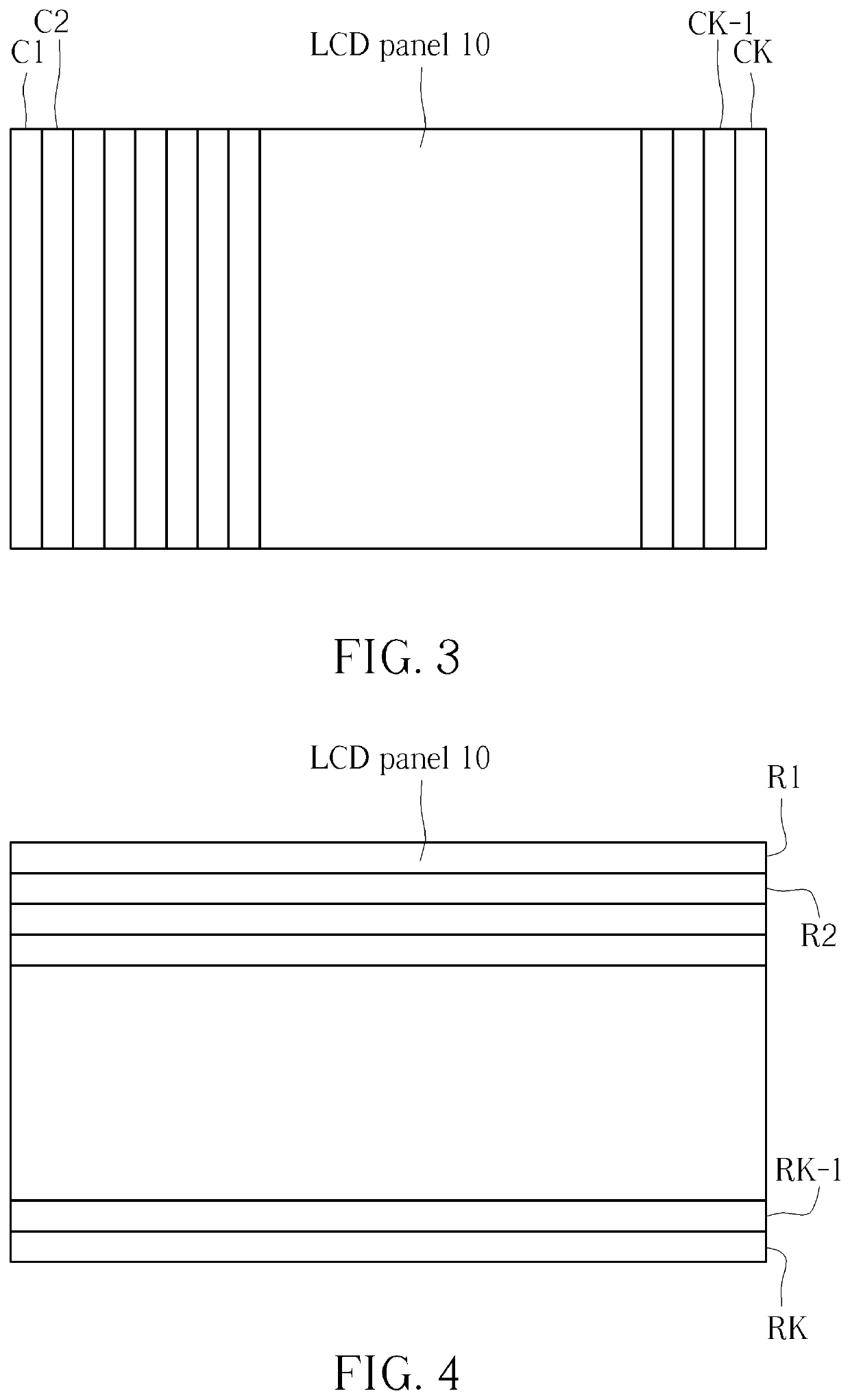

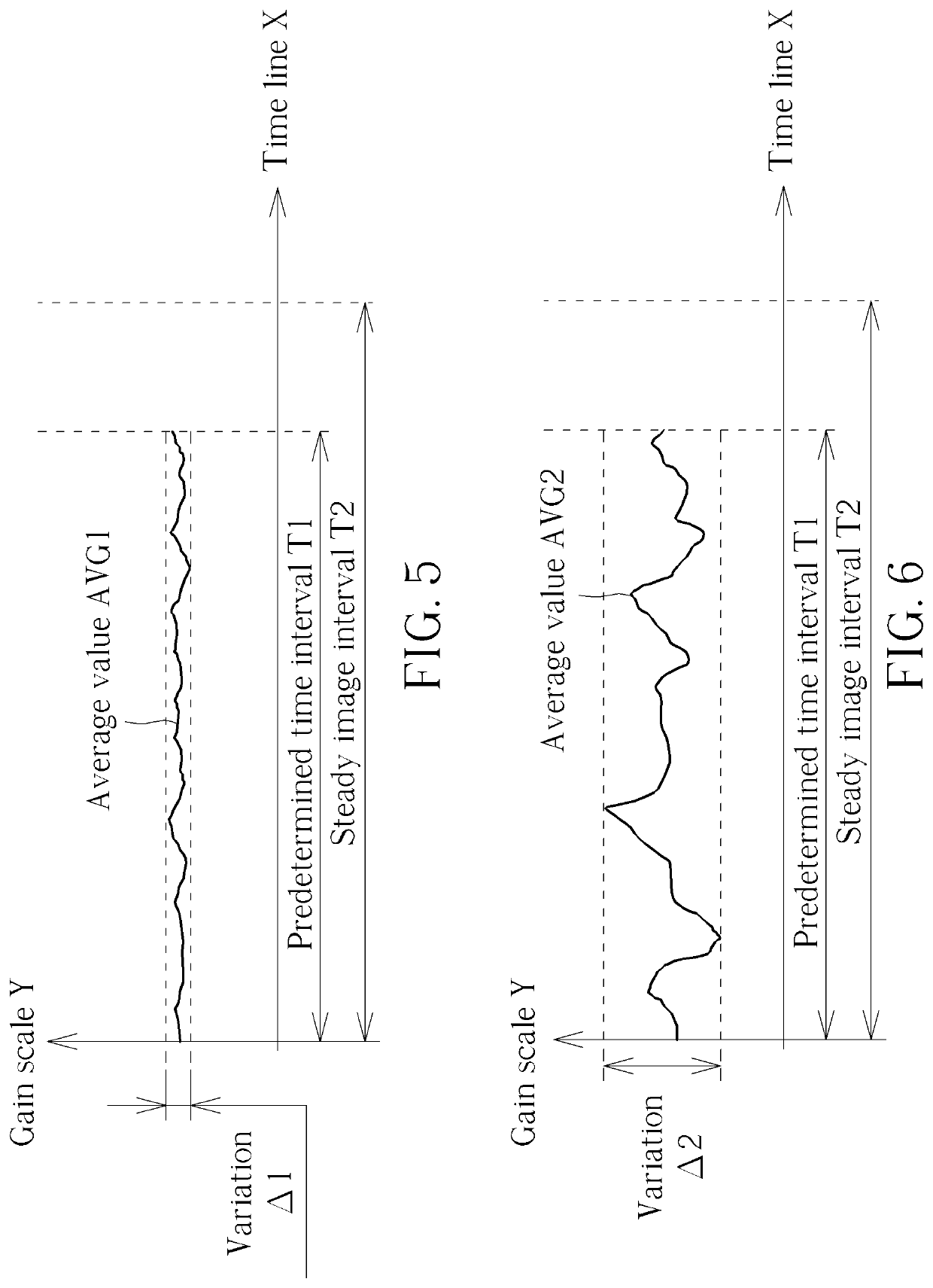

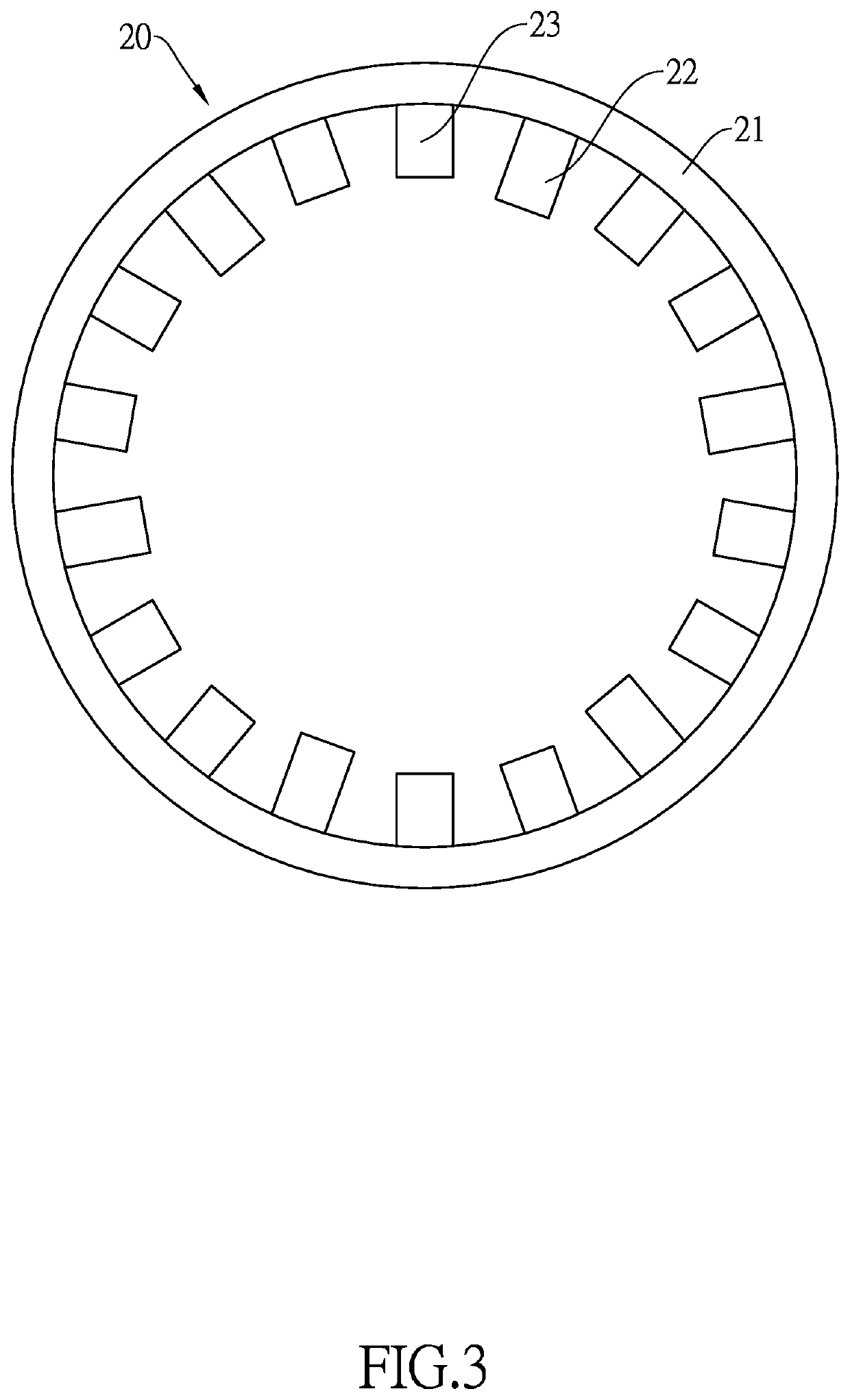

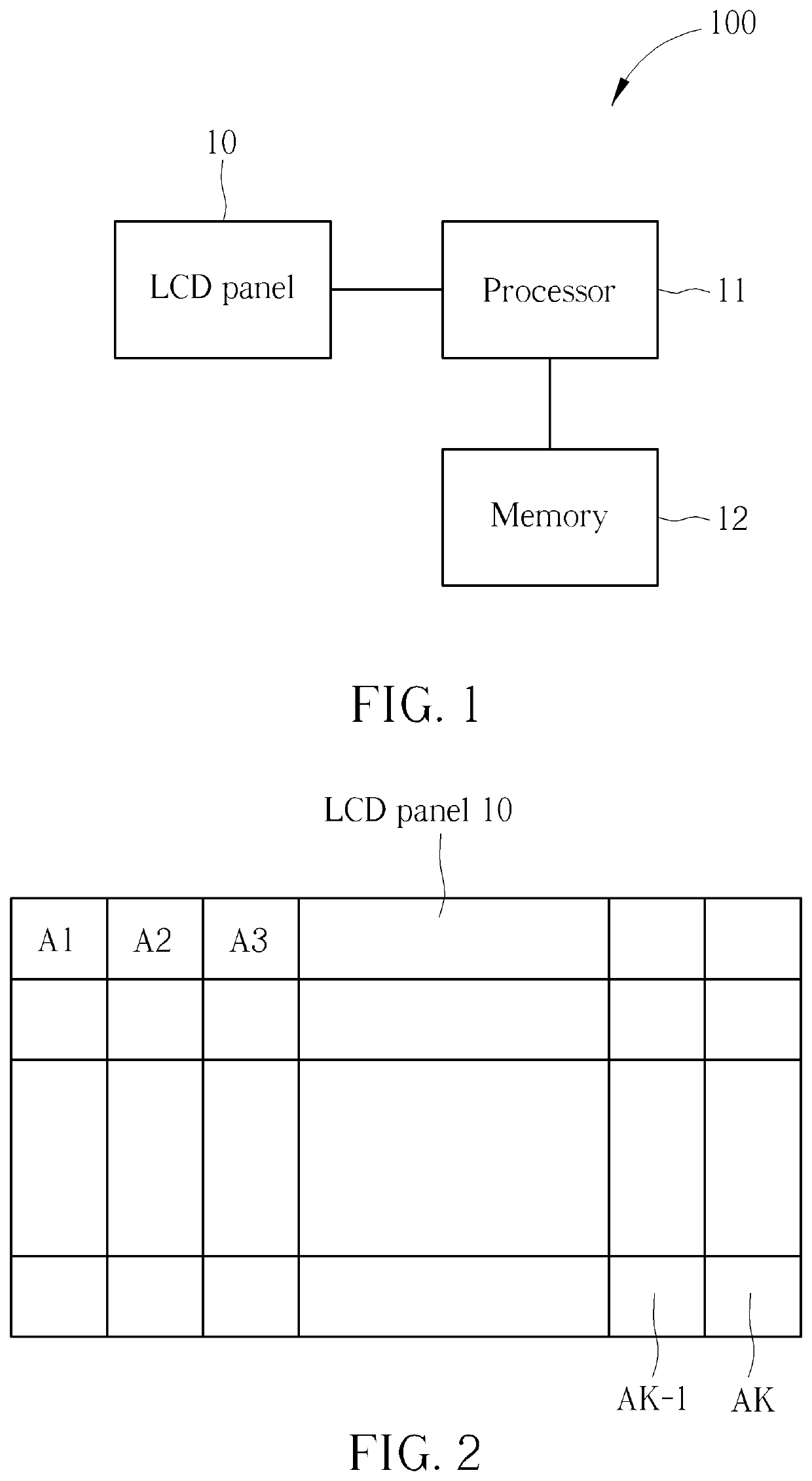

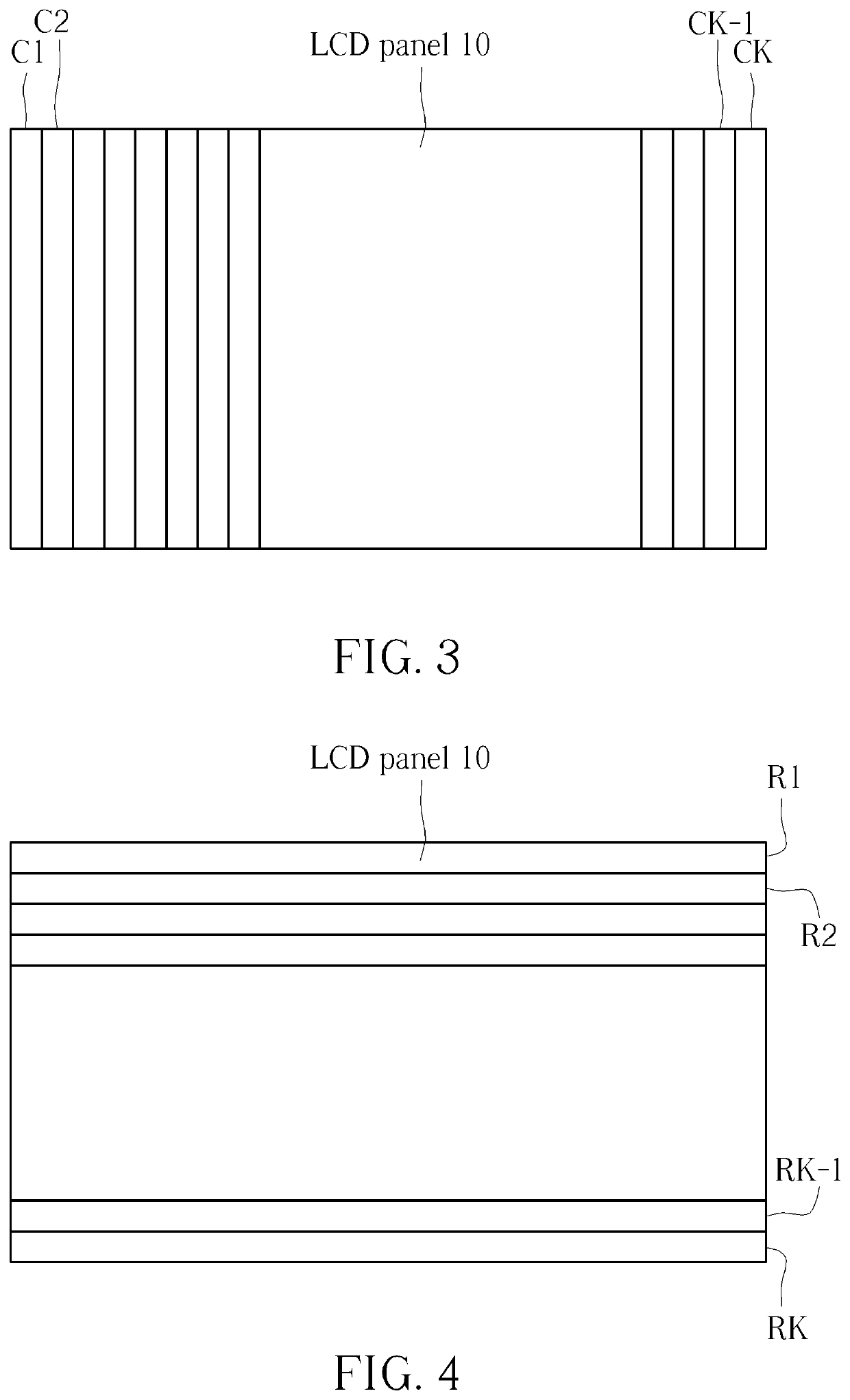

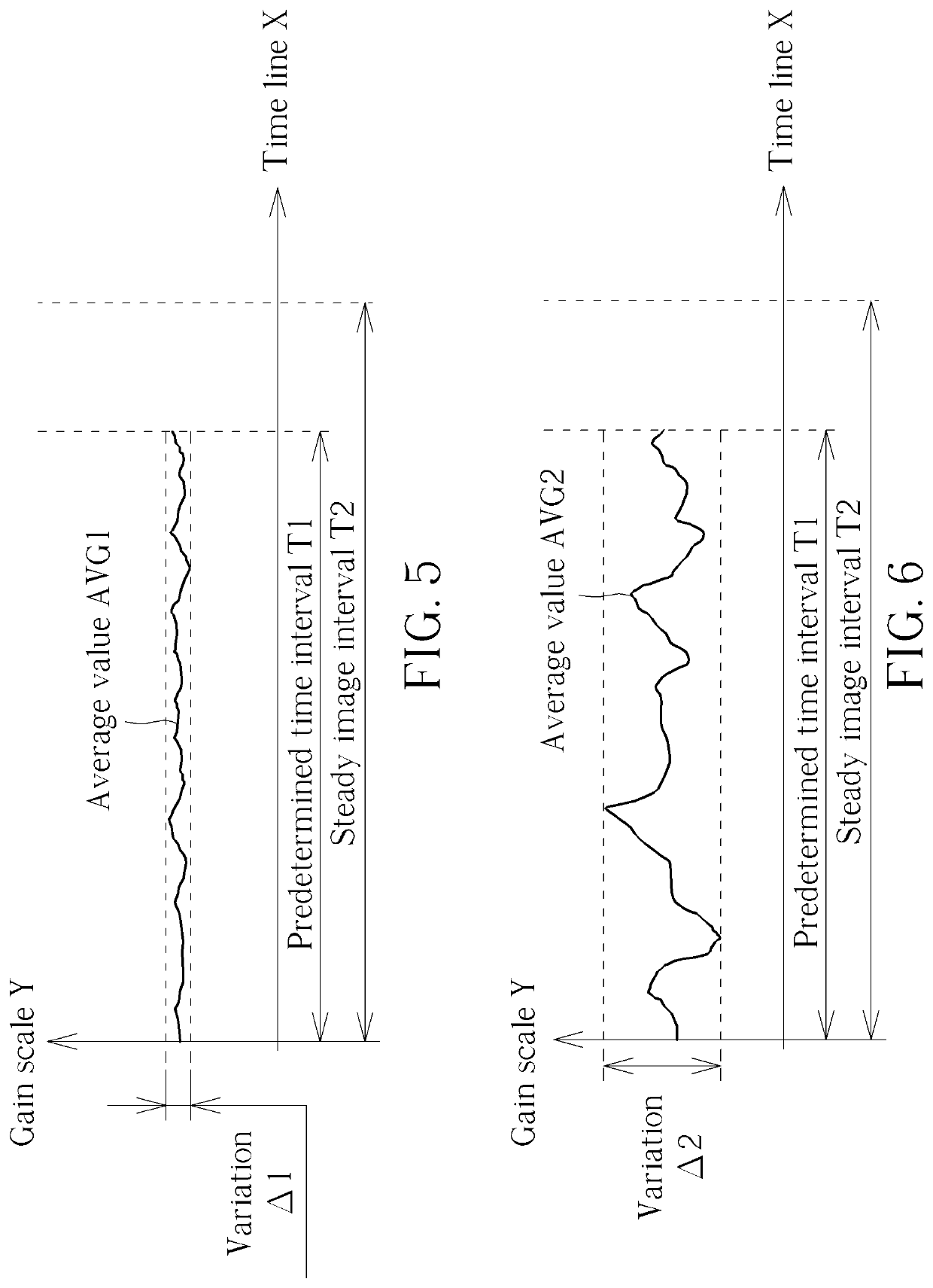

Method for avoiding an image sticking effect and display system capable of dynamically rotating pixel molecules

ActiveUS10705386B2Inhibition effectAvoid Elastic FatigueStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

A method for avoiding an image sticking effect includes acquiring a color tone status of an image during a predetermined time interval according to an input signal of a liquid crystal display panel, rotating pixel molecules of at least one region of a plurality of regions of the image by using a pixel inversion process when the color tone status is maintained at a steady state, and after the pixel molecules of the at least one region of the image are rotated, suspending the pixel inversion process of the image when the color tone status is changed from the steady state to an unstable state.

Owner:BENQ INTELLIGENT TECH SHANGHAICO LTD +1

Thread pretension device for sewing machine

The invention provides a prestressing device for sewing thread of a sewing machine, which comprises a guide wire seat, a preforce supply part, a propping part and a top cover. The part is made of elastic material, and the pre-force supply part is arranged in the accommodating groove. The pre-force supply part has a reversing part. The abutting part and the reversing part are set at the bottom of the groove, the abutting part is set on the pre-force supply part, the two abutting parts are abutted against the abutting part; the top cover is set on the abutting part, and the top cover is combined with the wire seat and located On the abutting member, a threading space is formed between the top cover and the abutting member, and the threading space is provided for the weaving suture to pass through; thus, the present invention mainly consists of making the pre-force supply member made of elastic material, and the form It is roughly V-shaped, so that the change of elastic force is relatively small, and it can provide appropriate line pressure.

Owner:曾贤长

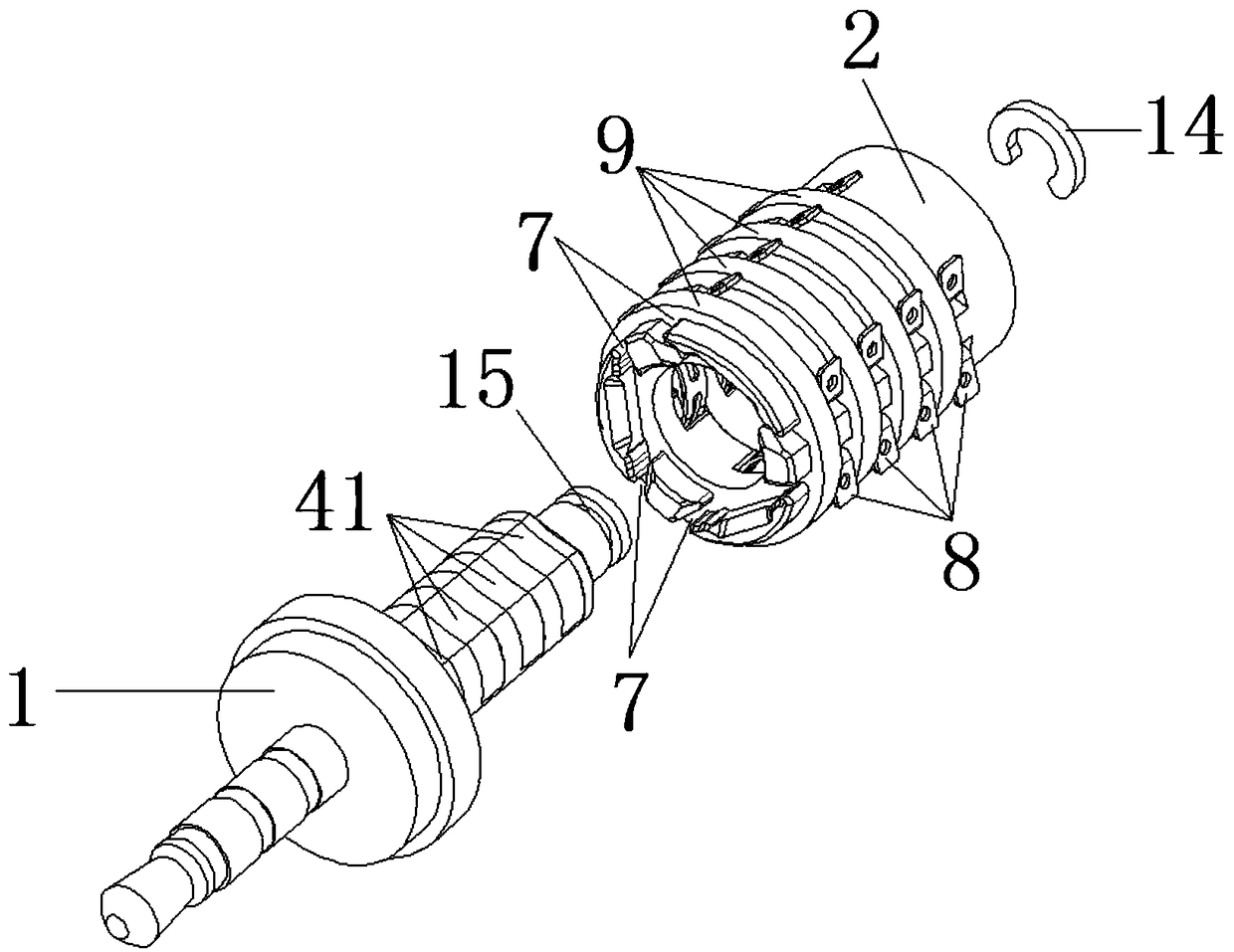

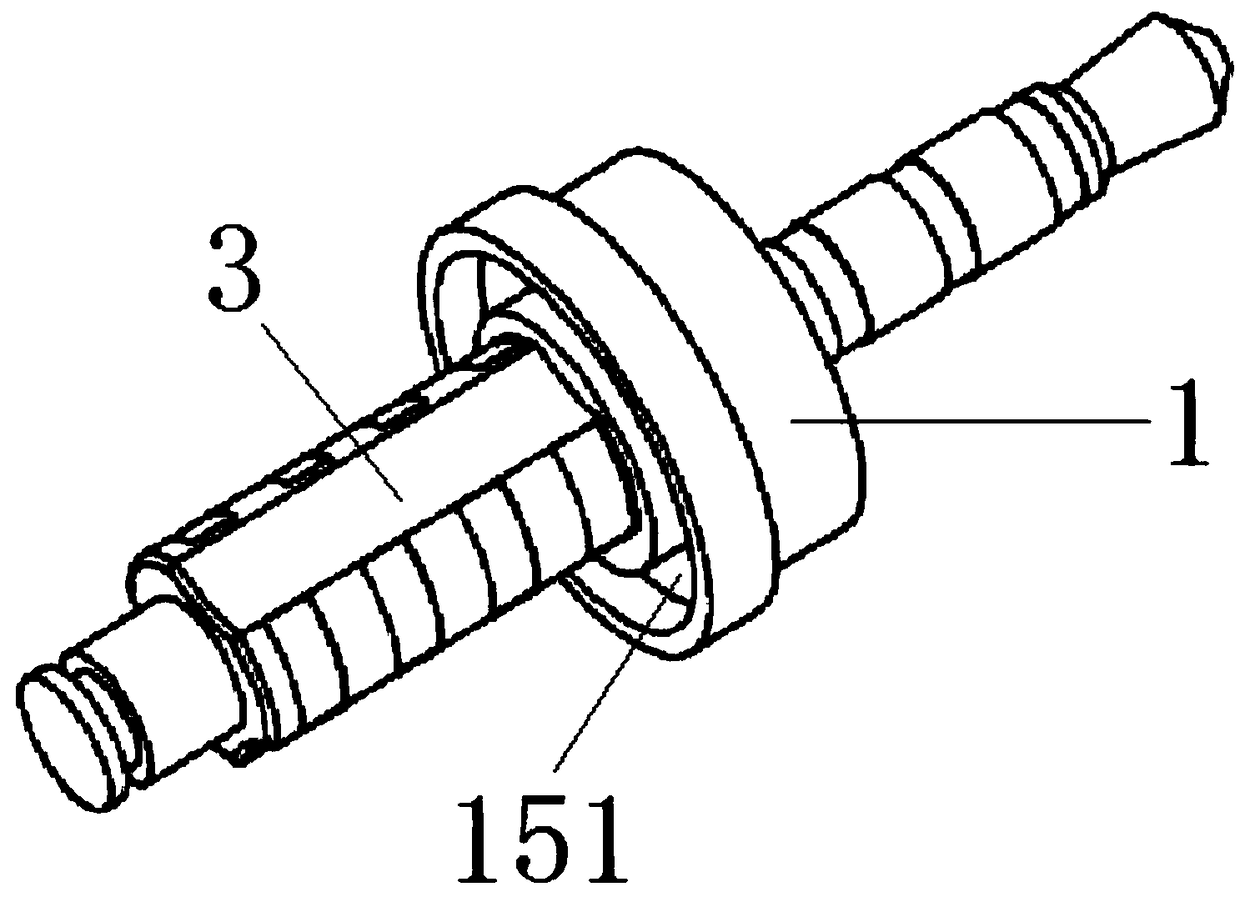

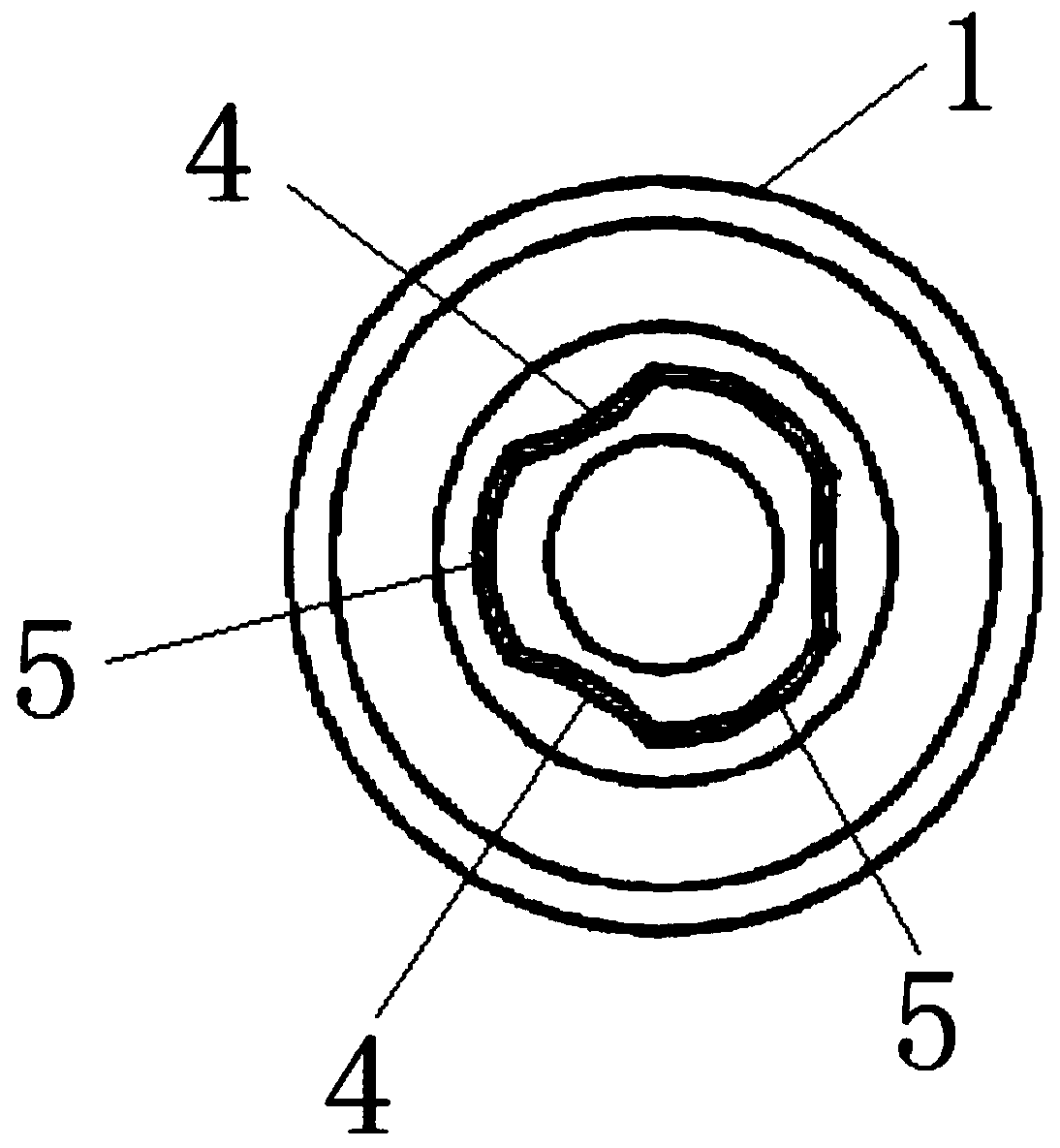

A rotary three-section balancing head earphone wire

ActiveCN109038009APrevent disengagementAvoid Elastic FatigueClimate change adaptationCoupling contact membersSound qualityEngineering

The invention discloses a rotary three-section balancing head earphone wire, which comprises a male plug, a female plug, a C-shaped clamp spring and an earphone connecting wire. The male plug is provided with an insertion part, a first circular groove, a concave surface, four contact parts, an insulating layer, an arc convex surface and a second circular groove. The plug-in part of the male plug of the invention can be rotated in three sections in the female plug. When the male plug rotates for one section, the earphone connected with the earphone connecting wire can play a sound effect. Whenthe male plug rotates for three sections, the earphone can play three different sound effects respectively. The earphone has the advantages of fast audio transmission speed and high sound quality definition. And the male plug can be easily disassembled or assembled with the female plug through the C-shaped card spring, The utility model has the advantages of high assembling efficiency and convenient assembling, and solves the problems that the male and female plugs in the headphone cable are integrally formed, and the utility model has the advantages of single use, the male plugs can not be rotated, the audio transmission speed is slow, the sound quality effect is poor, and only one sound effect can be played, and the like.

Owner:张万祥

Hinge

ActiveCN102373860BAvoid Elastic FatigueExtended service lifeBuilding braking devicesWing openersElastic componentCoupling

The invention discloses a hinge. The hinge comprises a hinge main body, a coupling component, a movable seat and an elastic component, wherein the coupling component is connected with a swinging block in a meshing manner, and forms a coupling relation with a buffering component of the hinge main body; the coupling component is also in pivot connection with the movable seat through a pivot connection part at one end; a rocker arm is arranged on the position, adjacent to the movable seat, of the coupling component in a pivot manner; one end of the rocker arm is arranged on a third shaft rod of the hinge main body in a pivot manner; a connecting hole of the elastic component is used for the passing of the third shaft rod of the hinge main body; two supporting ends are formed by equi-directionally extending from both sides of the connecting hole; the supporting ends are against the bottom wall surface of the hinge main body; an against end, which is located at the same side as the supporting ends, is convexly extended from the middle of the elastic component; and the against end is against the bottom surface of the coupling component. Through the structure, the hinge can generate free travel route and buffering travel route with proper angles, thus the effects of reducing the impact force and noise while opening and closing door plates are achieved.

Owner:吴枝祥

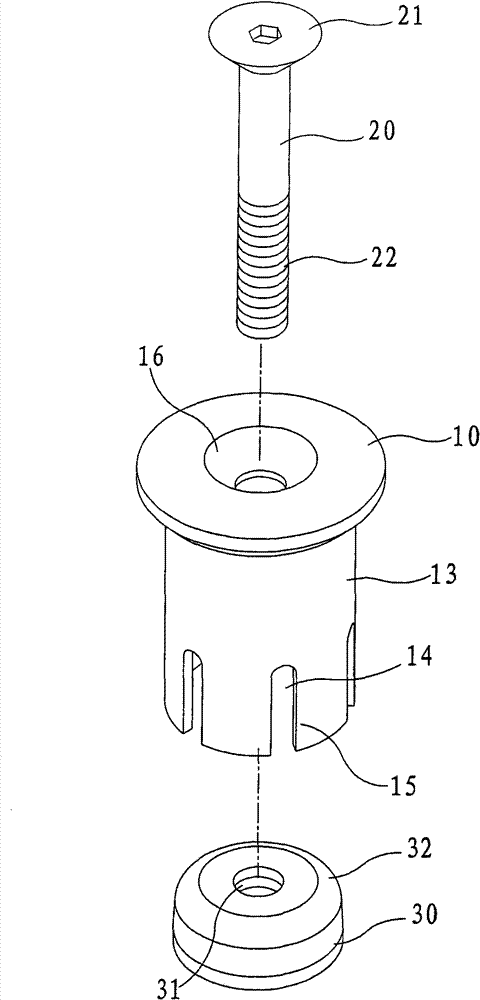

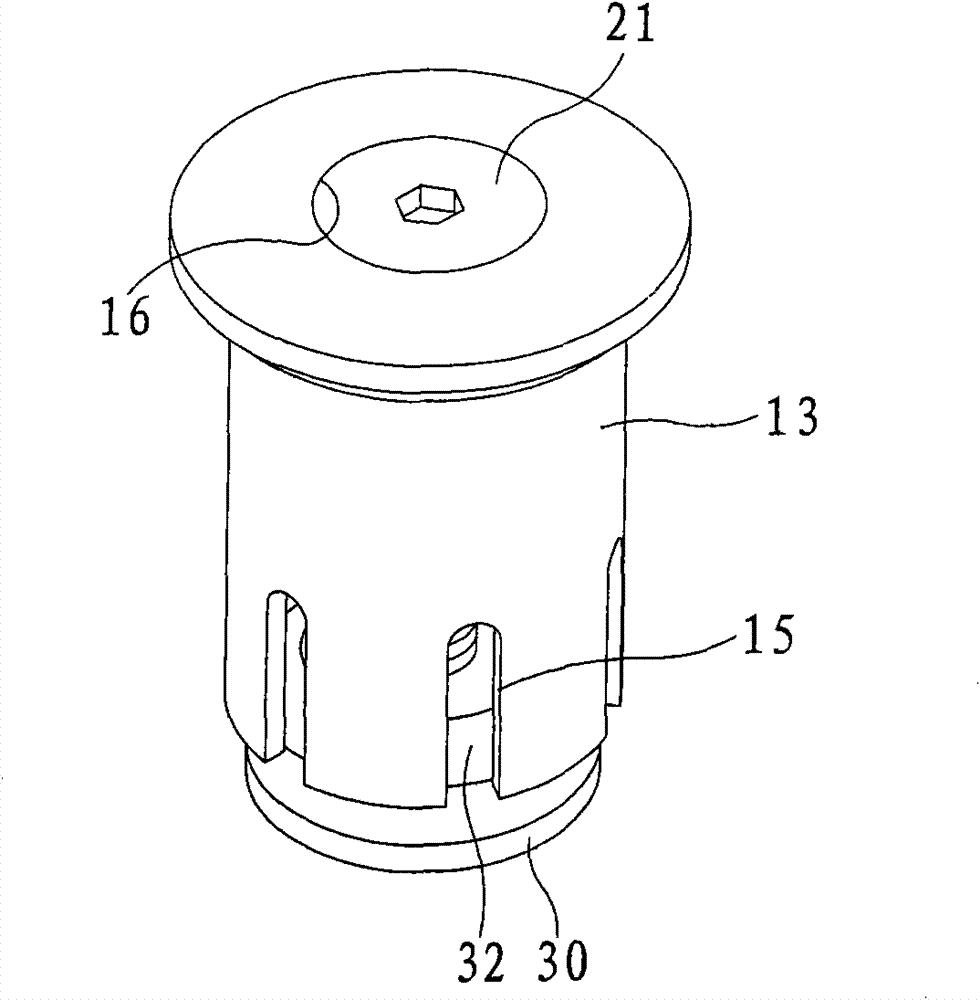

Riser upper cover and manufacturing method thereof

ActiveCN102059315BWon't happenGood precisionSteering deviceEngine componentsEngineeringMechanical property

The invention discloses an integrally molded riser upper cover. A lower half part of a cover body is provided with a sleeve with a smaller diameter; the top of the sleeve is provided with an expanded annular pressing shoulder, and a cylinder body extends downwards from the bottom surface of the sleeve, and is provided with a downward through counter bore; and a screw head hole coaxially communicated with the counter bore passes through the cover body, and a splitting groove is formed on the cylinder body so as to form a compression part. The manufacturing method comprises the following steps of: A, preparing metal bars in preset shapes and with preset weight; B, cold forging the counter hole in the center of the bottom surface of each bar; C, continuously cold forging to gradually mold the diameter and depth of the counter bore so as to form the downwards through cylinder body, and cold forging the compression part in turn on the cylinder body; D, shaping the counter bore and the compression part, forming a necking auxiliary hole concavely on the top of the counter bore, and molding the sleeve and the annular pressing shoulder; and E, cold forging the screw head hole which covers the auxiliary hole and coaxially passes through to the counter hole on the top of the cover body. The invention has the characteristics of high precision, mechanical properties and assembly strength, and low production cost.

Owner:张世杰 +1

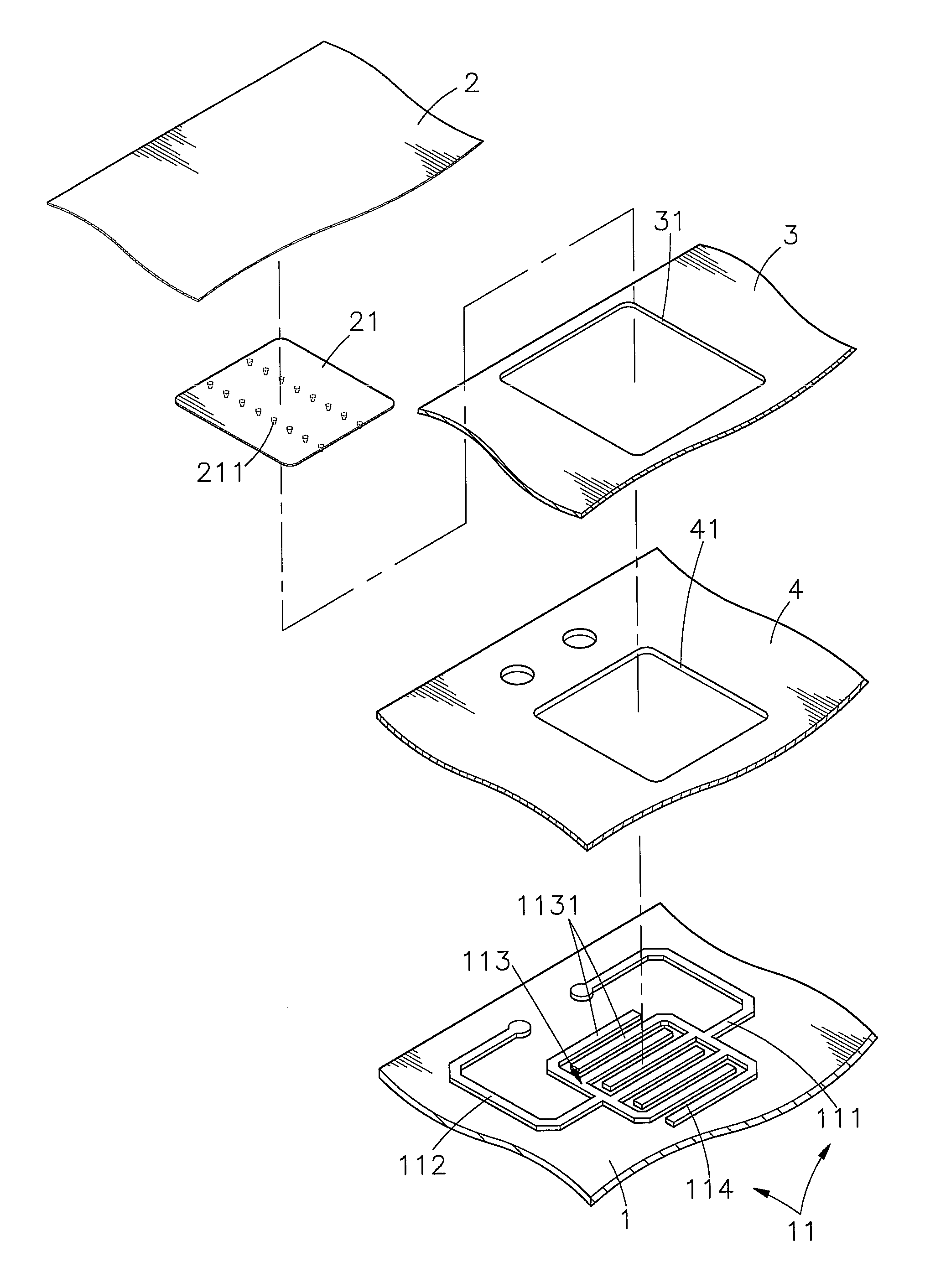

Software development device for assisting in eliminating elastic fatigue through layering

InactiveCN112509839AAvoid Elastic FatigueAvoid affecting work efficiencyElectric switchesSoftware developmentCoil spring

The invention relates to the technical field of software development, and provides a software development device for eliminating elastic fatigue by using layering assistance, which comprises a key box, a key is movably connected to the outer wall of the key box, a push rod is fixedly connected to the outer wall of the key, and a partition plate is fixedly connected to the position, away from the key, of the push rod. According to the software development device for eliminating elastic fatigue through layering assistance, a keyboard is manually used for pressing keys, the keys and the push rodjointly act to enable the partition plate to move, the partition plate controls the highest height and the lowest height of the keys, the partition plate moves in the key box to compress a spiral spring, and the spiral spring is extruded multiple times to cause elastic fatigue and lose elasticity; and at the moment, the partition plate drives a connecting block to move, the connecting block and alinkage rod are jointly matched to enable the sliding block to move, the sliding block drives a rotating wheel to rotate through teeth on the outer wall of the sliding block, and when the key rebounds, the rotating wheel and a turning rod act to enable a second inclined block to move inwards, a layering block moves and is inserted into a gap of the spiral spring to extrude auxiliary reset to prevent elastic fatigue.

Owner:广州单凌舫科技有限公司

A double shrapnel type glasses hinge

Owner:李建军

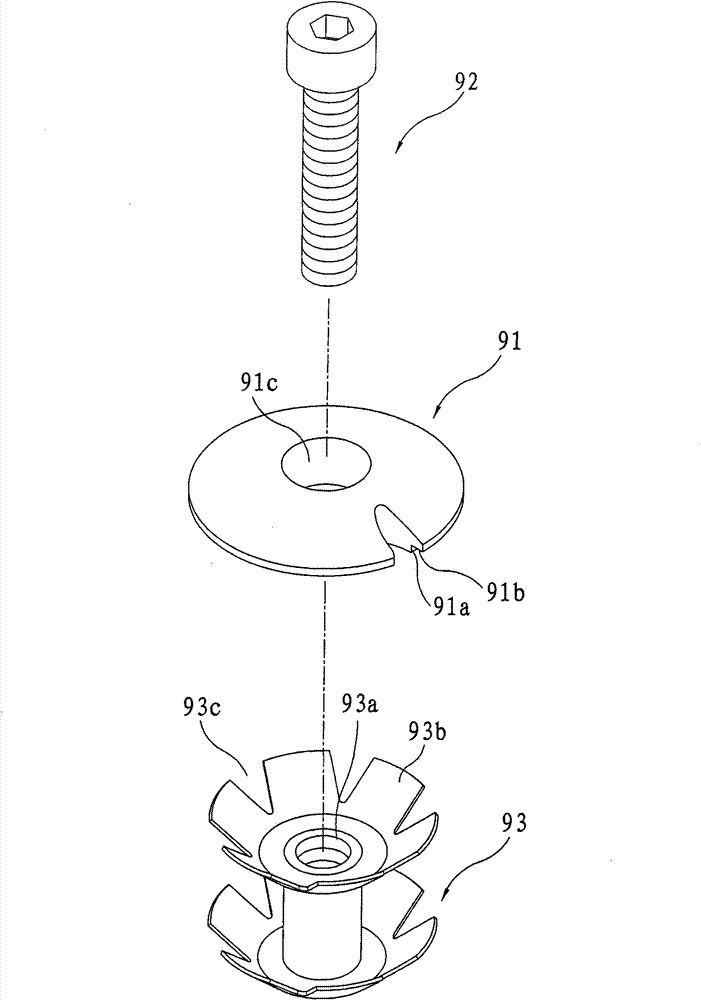

Anti-electromagnetic interference shrapnel

ActiveCN103153034BImprove the protective effectFasten the connectionMagnetic/electric field screeningElectromagnetic interferenceBiomedical engineering

The invention provides an electromagnetic interference prevention spring plate which comprises a cap body portion, a cap brim portion and elastic rubber, wherein the cap body portion is in a shell-shaped structure, the surface of the structure is provided with weave-shaped creases and a protruding arc face, the cap body portion is hollow, a containing space is arranged inside the cap body portion, the elastic rubber is fixed in the containing space, the top end of the containing space protrudes out of a plane where the edge of the cap body portion is located, and the edge of the cap body portion is externally connected with the cap brim portion. According to the electromagnetic interference prevention spring plate, the elastic rubber is arranged inside the cap body portion, not only is elasticity increased and is connection between adjacent components firm, but also materials can be prevented from producing elastic fatigue and service life is prolonged; and meanwhile, an arc-shaped surface outside the cap body portion is provided with the weave-shaped creases to increase a specific surface area, and therefore the radiation protection area of the electromagnetic interference prevention spring plate is increased. Therefore, the electromagnetic interference prevention spring plate has good protection effects on electromagnetic interference.

Owner:HWA 1 PRECISION MACHINERY KUNSHAN

General-purpose engine with low exhaust gas emission

InactiveCN101705856AReduce pollutionEmission of pollution acceleratedInternal combustion piston enginesExhaust apparatusChemical reactionPositive pressure

The invention relates to a general-purpose engine with low exhaust gas emission, comprising a general-purpose engine case body, a cylinder head and a cylinder cover, wherein a cavity between the cylinder head and the cylinder cover is a rocker arm chamber; a muffler is communicated with an exhaust port of the cylinder head through an exhaust pipe; a crankcase cavity of the case body is communicated with the rocker arm chamber at the upper end of the cylinder head through an air duct; the cylinder cover is provided with an air inlet hole for communicating the outside with the rocker arm chamber; a one-way valve which is opened at negative pressure is arranged at the air inlet hole; and the cylinder cover is also provided with an air outlet which is communicated with the muffler through a one-way valve which is opened at positive pressure. Fresh air can be sucked into the rocker arm chamber for storage by the negative pressure formed in a crankcase when a piston of the engine reciprocates and the stored fresh air can be forced to be sent to the muffler by the positive pressure formed in the crankcase when the piston of the engine reciprocates, thus HC, CO and NOx in high-temperature exhaust gas exhausted from the engine can undergo fully chemical reaction with sufficient oxygen in the muffler and then can be exhausted, and the exhaust gas emission of the general-purpose engine can be effectively reduced.

Owner:LONCIN MOTOR

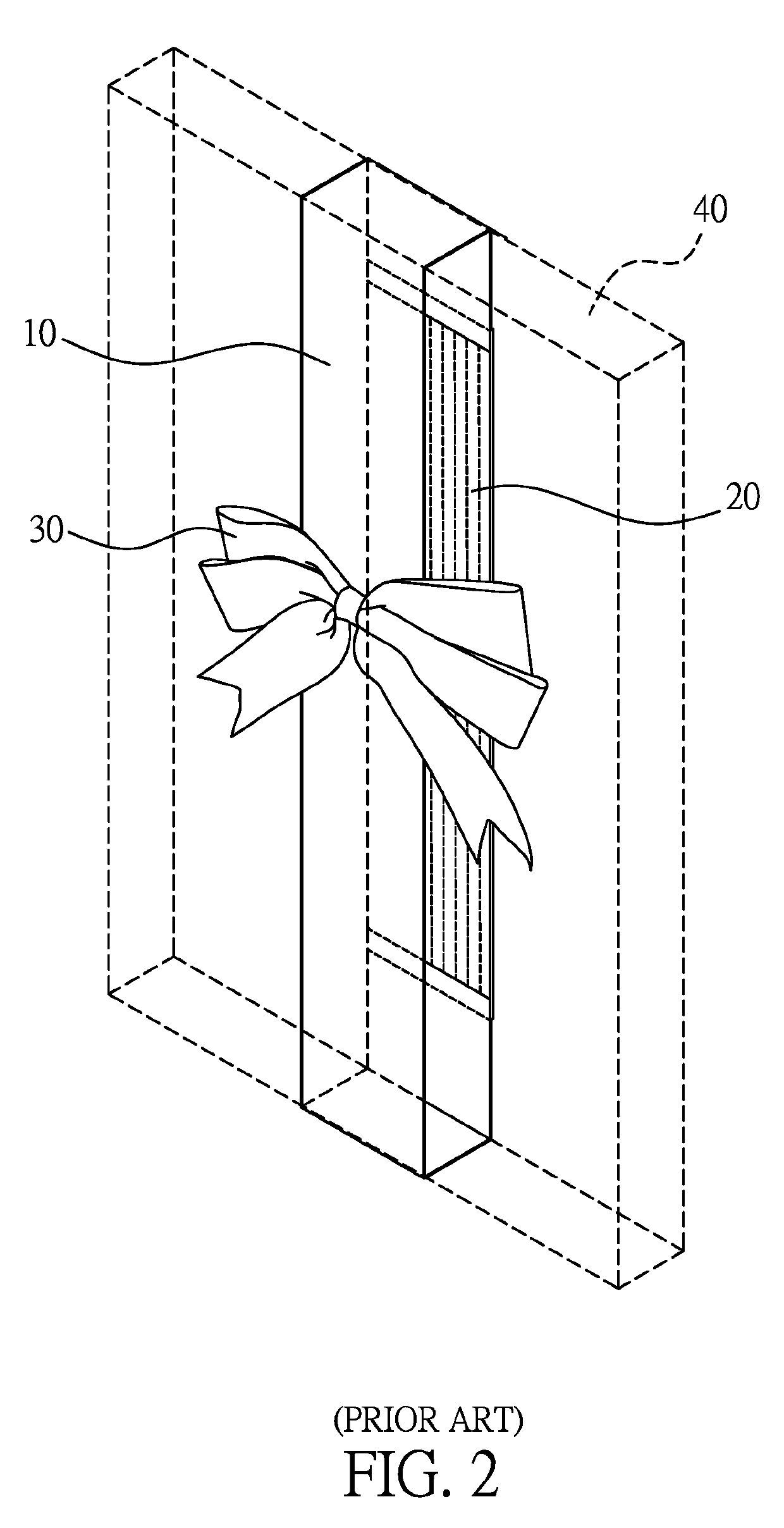

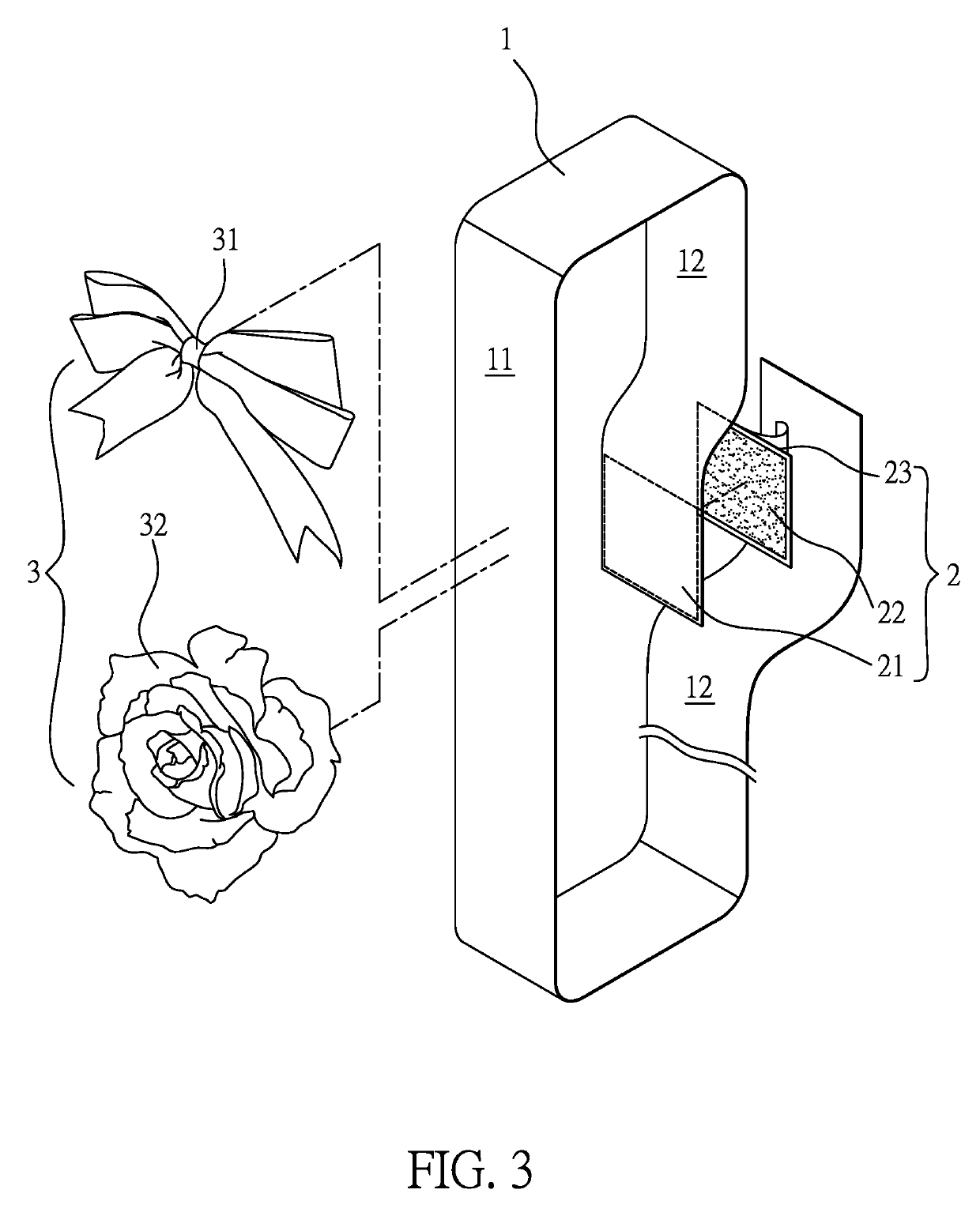

Decoration ribbon

InactiveUS20190316282A1Compact effectAvoid Elastic FatigueOrnamental textile articlesArtificial flowers and garlandsFiberEngineering

A decoration ribbon comprises a ribbon member formed with a first surface and a second surface, a first fastening band and at least one decorative object; the first surface or the second surface at one end of the ribbon member is disposed with a first fibriform pile fabric structure or a first micro-fibriform loop fabric structure of the first fastening band; the second surface or the first surface at another end of the ribbon member is disposed with the first micro-fibriform loop fabric structure or the first fibriform pile fabric structure of the first fastening band, and the at least one decorative object is combined on the first surface of the ribbon member; when the first fibriform pile fabric structure is adhered and fastened with the first micro-fibriform loop fabric structure, the ribbon member is formed as an annular member for wrapping a plate to be decorated.

Owner:KUAN HUO FENG HSIA

Draw-off gear of computer modular

InactiveCN1180330CAvoid Elastic FatigueReduce processing costsDigital data processing detailsEngineeringMechanical engineering

The invented set for pulling computer module out possesses the first pull rod with the first elastic cell being pin jointed and the second pull rod with the second elastic cell being pin jointed. The elastic force of the second elastic cell makes the second pull rod embed to the first pull rod with the first elastic cell being compressed. With being pushed, the second pull rod exits the position where the first pull rod is embedded and the elastic force of the first elastic cell pushes the first pull rod away. The invented set is positioned on the bearing slot. Pushing the second pull rod makes the first pull rod be parked on back side of the bearing slot and the first pull rod hooks the module and brings the module out for a section of displacement. Then, pulling the first pull rod takes the module out.

Owner:WISTRON CORP +1

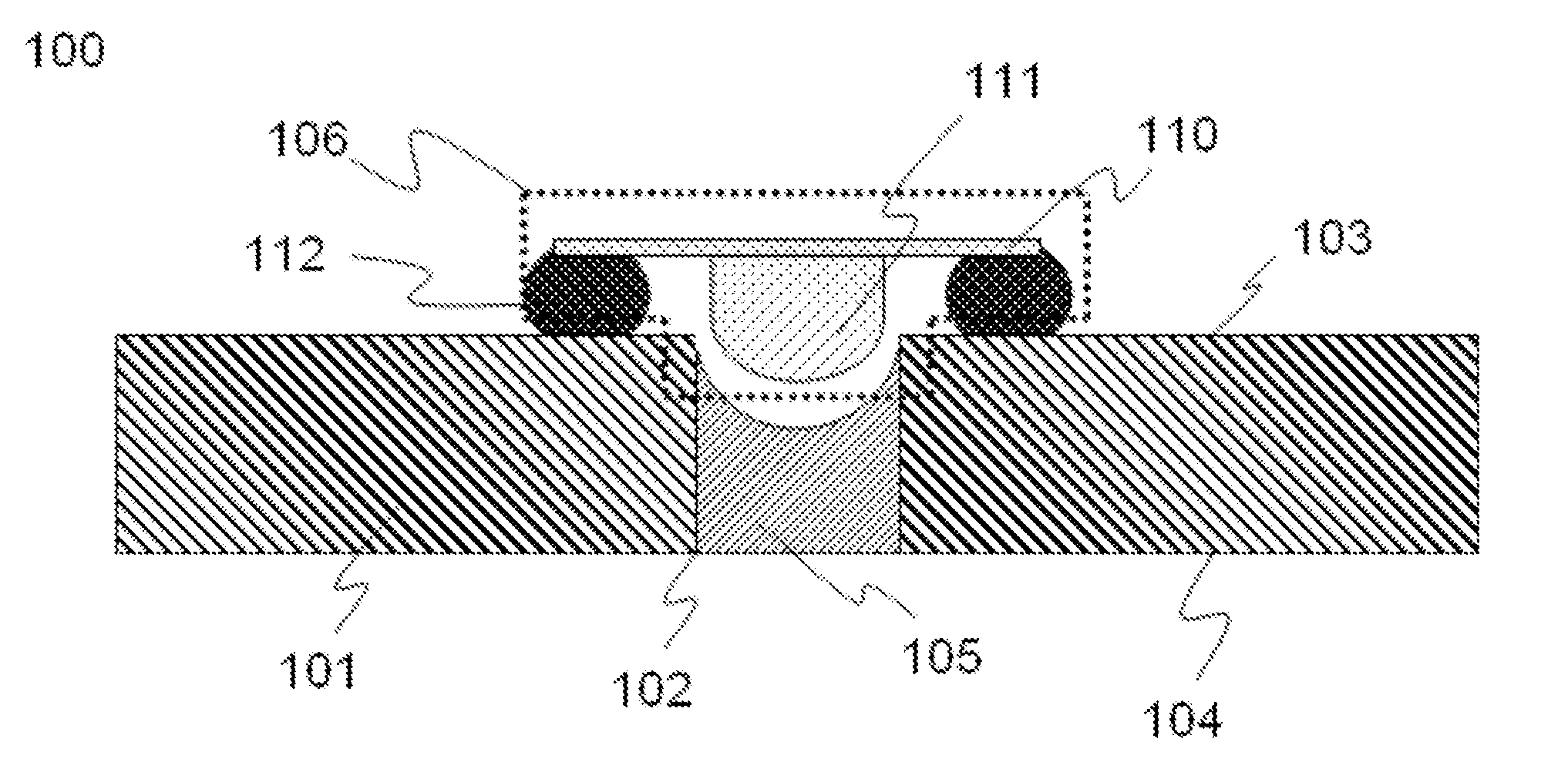

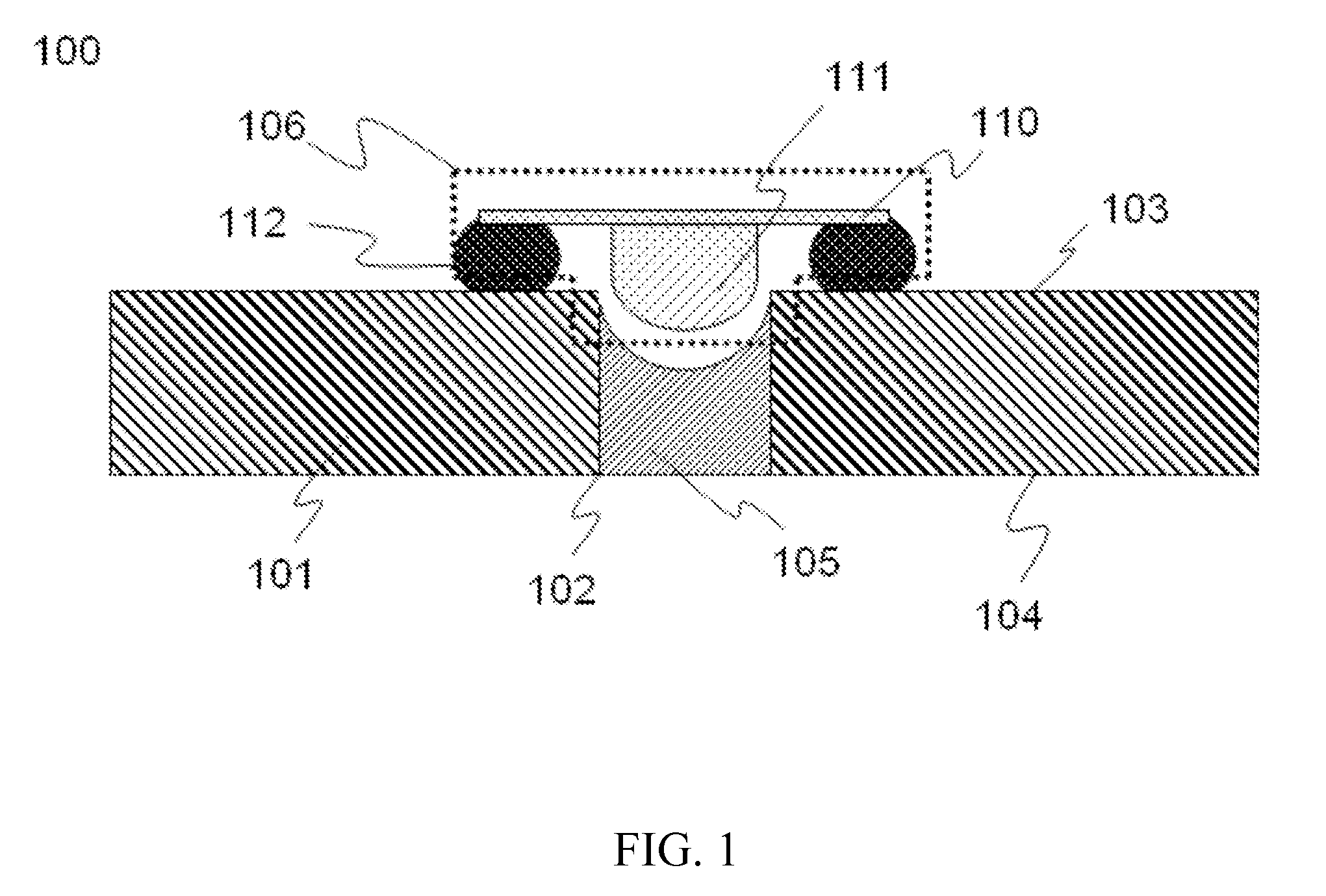

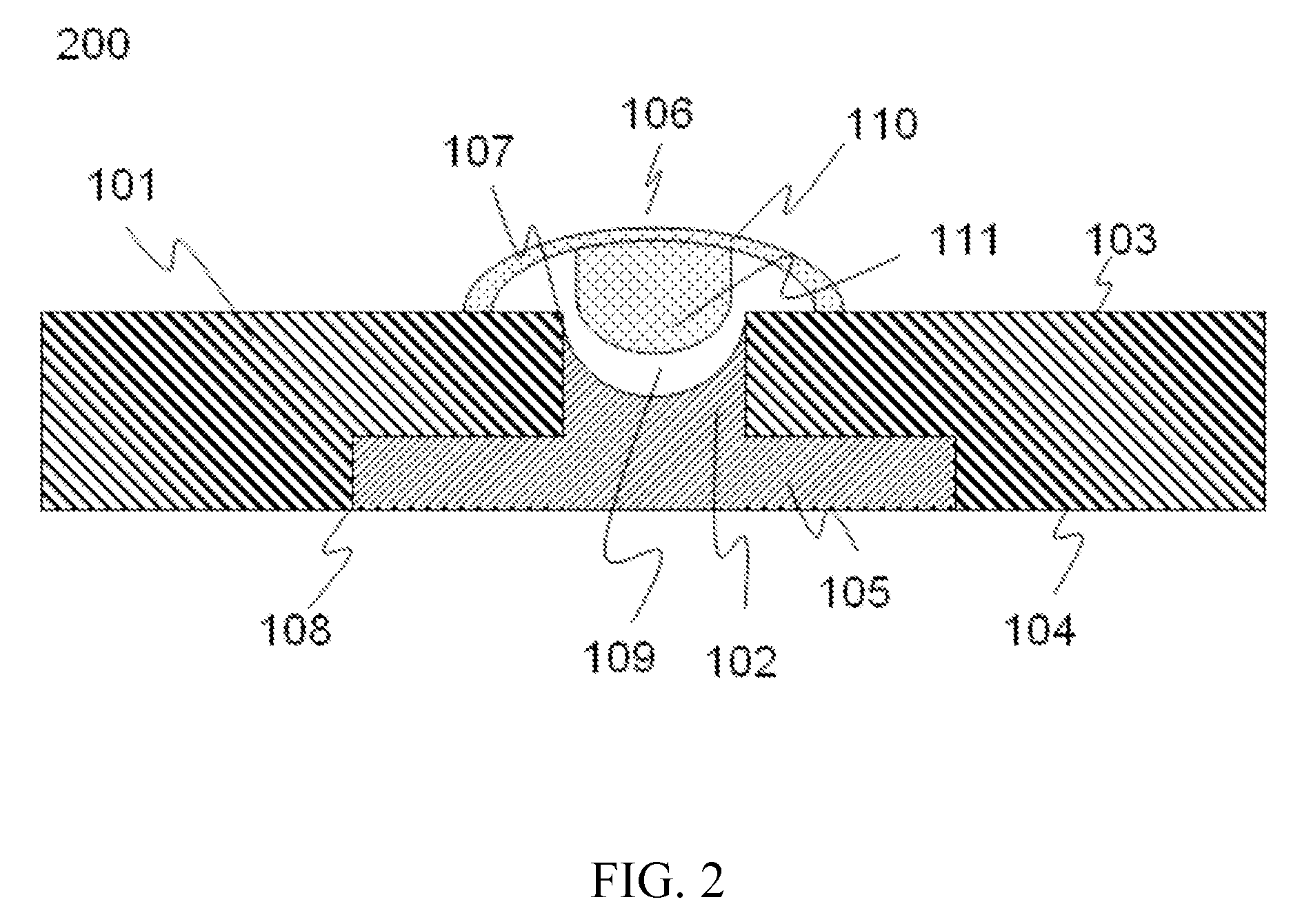

Micro electronic component structure

ActiveUS9161446B2Simple structureEasy to manufacturePrinted circuit assemblingFinal product manufactureEngineeringConductive materials

Owner:KING YUAN ELECTRONICS

Knitting thread pre-stressing device of sewing machine

ActiveCN112391749AAvoid knotsReduce the amount of variationTextiles and paperEngineeringSewing machine

The invention provides a knitting thread pre-stressing device of a sewing machine. The knitting thread pre-stressing device of the sewing machine comprises a thread guide seat, a pre-stressing supplypiece, a propping piece and a top cover, wherein the thread guide seat is provided with at least one accommodating groove; the accommodating groove is provided with a groove bottom; the pre-stressingsupply piece is made of an elastic material, is arranged in the accommodating groove and is provided with a reversing part; two sides of the reversing part are respectively connected with extending parts; the ends, connected with the reversing part, of the two extending parts are provided with abutting parts respectively; the reversing part is arranged at the groove bottom; the propping piece is arranged on the pre-stressing supply piece; the two abutting parts abut against the propping piece; and the top cover is arranged on the propping piece, is combined with the thread guide seat and is positioned on the propping piece, so that a threading space is formed between the top cover and the propping piece, and a knitting thread can pass through the threading space; Therefore, the pre-stressing supply piece is mainly made of the elastic material and is approximately V-shaped, so that the variation of the elastic force is relatively small, and proper linear pressure can be provided.

Owner:曾贤长

Liquid storage equipment with cleaning device

InactiveCN104631560BAvoid Elastic FatigueHollow article cleaningWater supply tanksEngineeringPendulum

The utility model relates to liquid storage equipment with a cleaning device. The liquid storage equipment with the cleaning device comprises a barrel body and the cleaning device, wherein the barrel body comprises a peripheral wall and a bottom wall arranged on the bottom edge of the peripheral wall; the peripheral wall and the bottom wall surround to form a liquid storage space; the cleaning device comprises a main shaft, a drive device, a support fixedly arranged on the main shaft, at least one cleaning element, a baffle unit and a plurality of ball brushes; the main shaft extends into the liquid storage space along the axial direction; the drive device is used for driving the main shaft to rotate; the cleaning element can be arranged on the support in a pivot pendulum way; the pivot pendulum axis of the cleaning element is parallel to the main shaft; the cleaning element is provided with a flow resistance plate, a cleaning brush and a connecting unit connected to the flow resistance plate and the cleaning brush; when the drive device does not work, the cleaning brush and the ball brushes cannot cling to the inner wall of the barrel body, so that the elastic fatigue is delayed.

Owner:唐景松

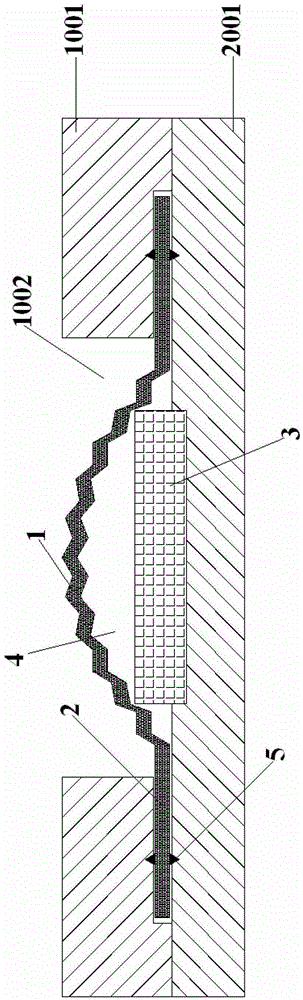

Tube connector

ActiveUS11460133B2Avoid Elastic FatigueGood fixabilitySleeve/socket jointsFlanged jointsMechanical engineeringPhysics

A tube connector has a main body, a restricting element, and a sealing ring. The main body has a mounting segment extending outwardly and transversely to form an inner annular space to accommodate the restricting element and the sealing ring. When the tube body is inserted, the tube body will be engaged and positioned by teeth of the restricting element. The sealing ring and the restricting element abut each other to maintain the sealing from the sealing ring. The changes of the pressure from the fluid transporting in the tube body will move the tube body and the main body relatively to and fro, and thus the abutting force against the sealing ring will increase or decrease accordingly, which maintains the elasticity of the sealing ring to maintain the sealing after a long time of use, thereby avoiding elastic fatigue and prolonging the lifespan.

Owner:KUO HSIN CHENG +1

Method for Avoiding an Image Sticking Effect and Display System Capable of Dynamically Rotating Pixel Molecules

ActiveUS20200073160A1Avoid effectInhibition effectStatic indicating devicesNon-linear opticsPhysicsComputer vision

A method for avoiding an image sticking effect includes acquiring a color tone status of an image during a predetermined time interval according to an input signal of a liquid crystal display panel, rotating pixel molecules of at least one region of a plurality of regions of the image by using a pixel inversion process when the color tone status is maintained at a steady state, and after the pixel molecules of the at least one region of the image are rotated, suspending the pixel inversion process of the image when the color tone status is changed from the steady state to an unstable state.

Owner:BENQ INTELLIGENT TECH SHANGHAICO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com