General-purpose engine with low exhaust gas emission

A general-purpose engine and exhaust gas emission technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of less secondary air supply, short duration of negative pressure, and long duration of positive pressure, etc., to save money, The effect of reducing emission pollution and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

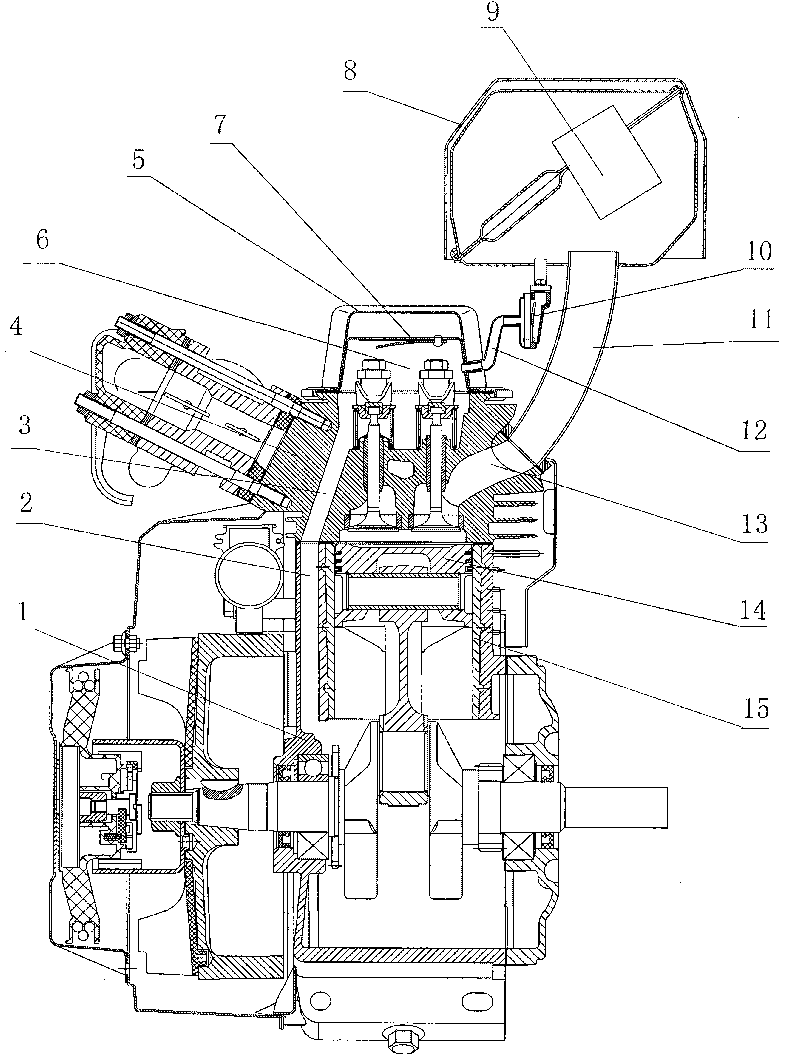

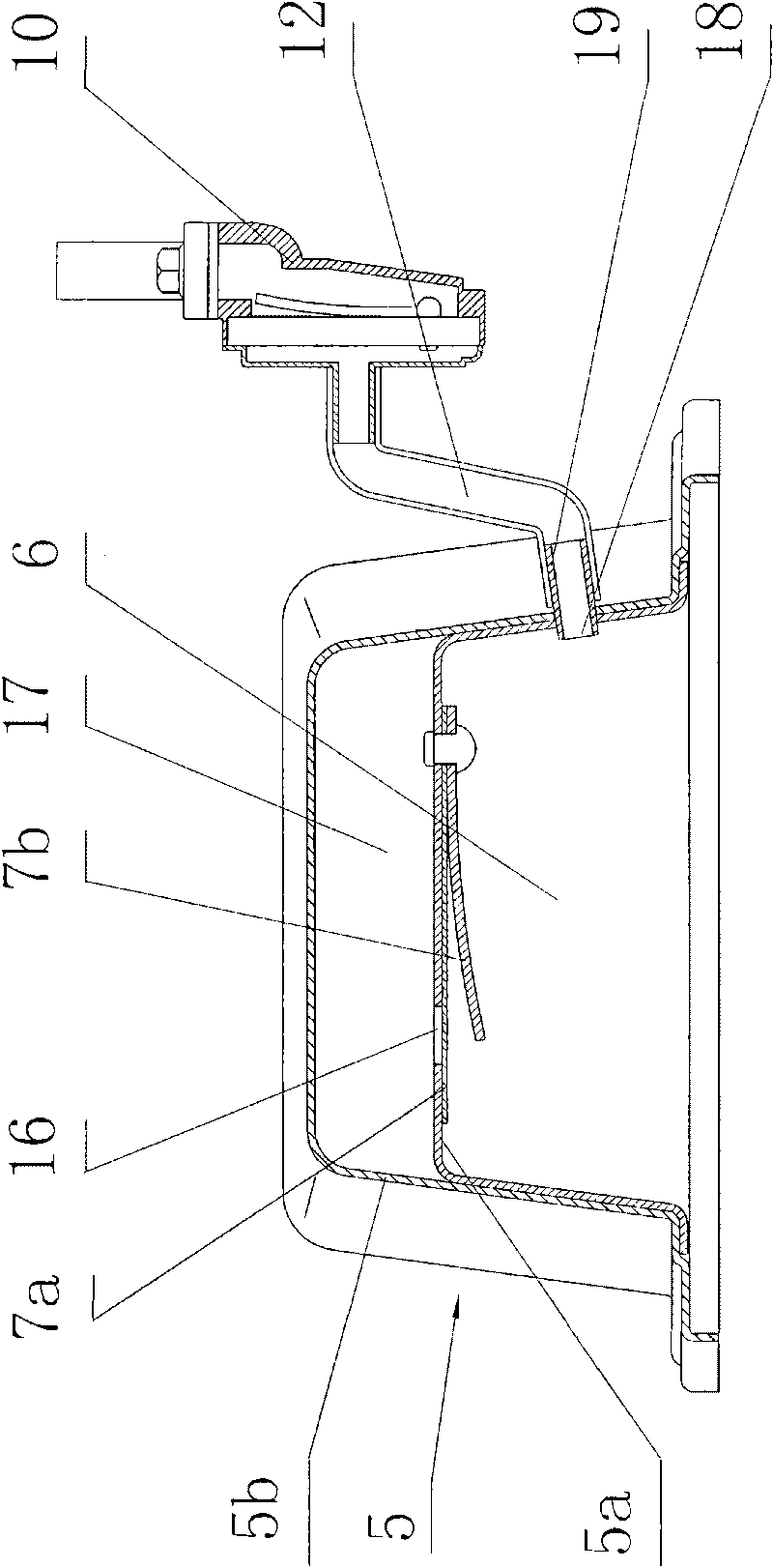

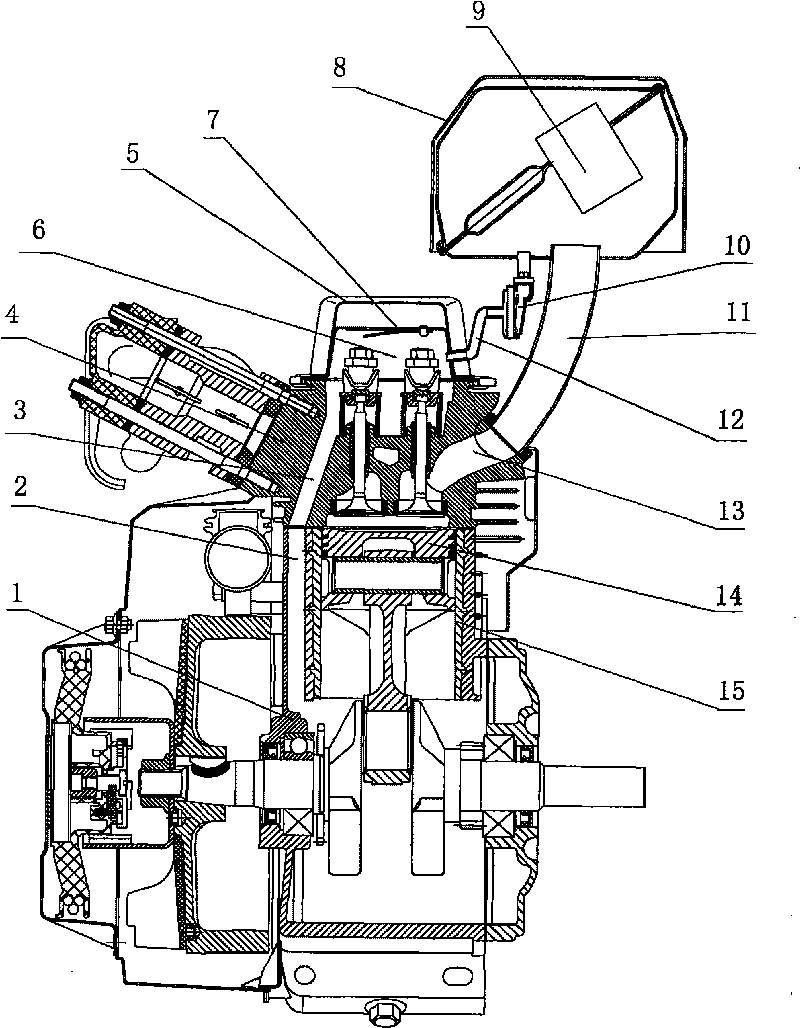

[0020] see figure 1 , figure 2, a kind of embodiment of the general-purpose engine of low exhaust gas emission, comprise the general-purpose engine case body that has cylinder 15 and crankcase 1, cylinder head 4 is assembled on the cylinder 15 upper end of case body, seals with gasket between cylinder head and case body , the cylinder head cover 5 is assembled on the upper end of the cylinder head 4, the cylinder head cover and the cylinder head are sealed with a gasket, the cavity between the cylinder head 4 and the cylinder head cover 5 is the rocker chamber 6, the cylinder head cover 5, the cylinder The head 4 and the box body are fastened and connected by mounting bolts. The muffler 8 communicates with the exhaust port 13 of the cylinder head through the exhaust pipe 11. The inner cavity of the crankcase 1 of the box body is connected to the rocker arm at the upper end of the cylinder head 4 through the air passage. Chamber 6 communicates, and the air channel of this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com