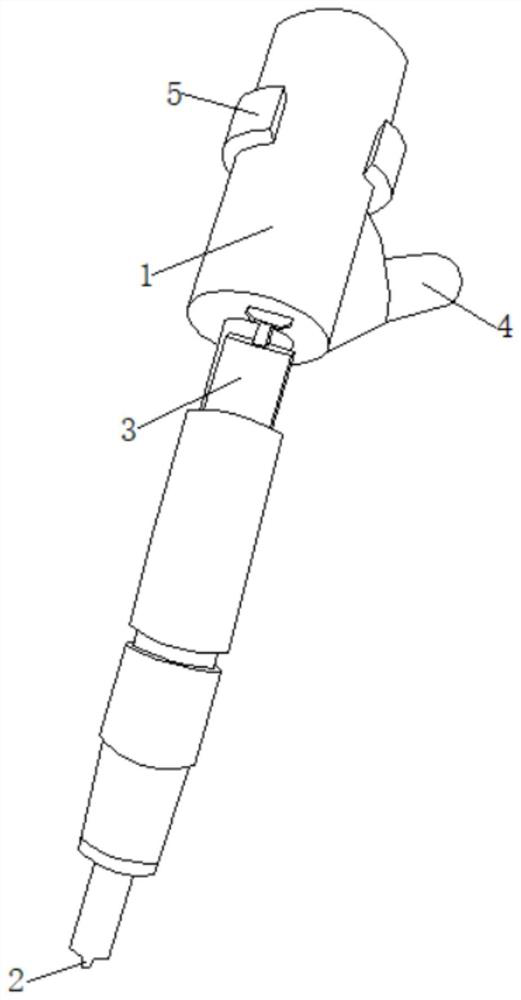

Valve rod matching high-pressure common-rail oil atomizer

A high-pressure common rail and fuel injector technology, which is applied to engine components, machines/engines, fuel injection devices, etc., can solve problems affecting service life and easy deformation, so as to achieve enhanced service life, uniform force, and avoid easy deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

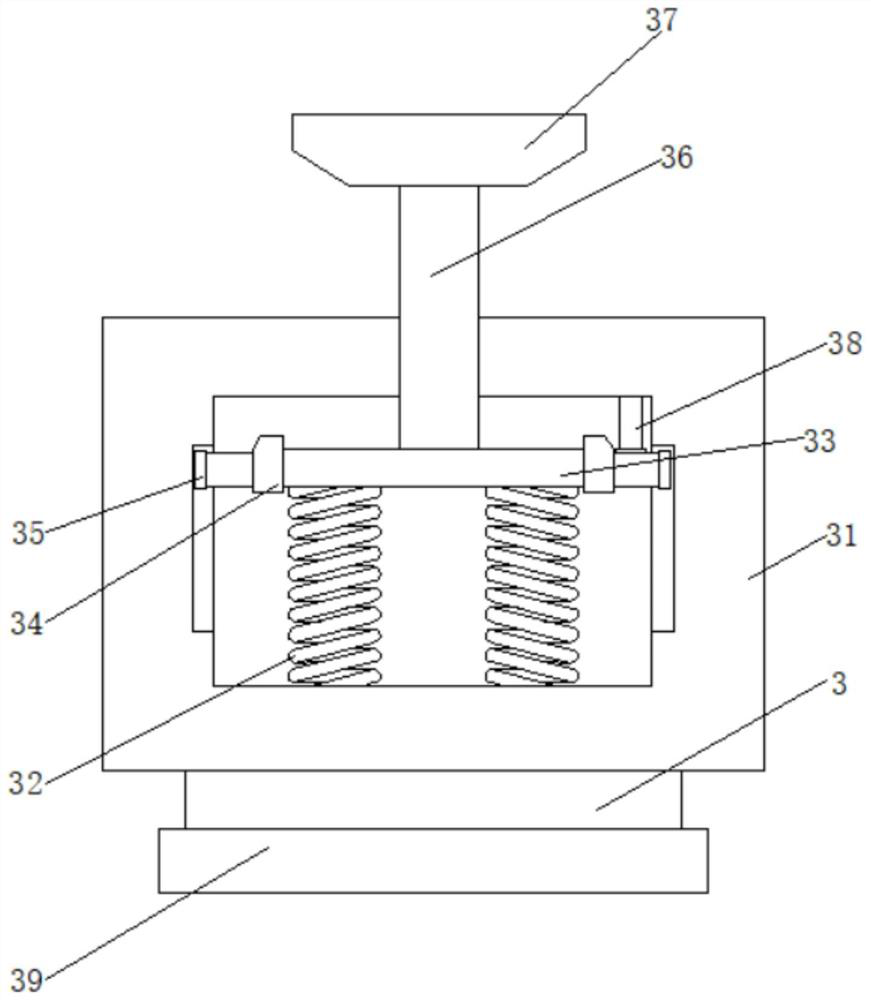

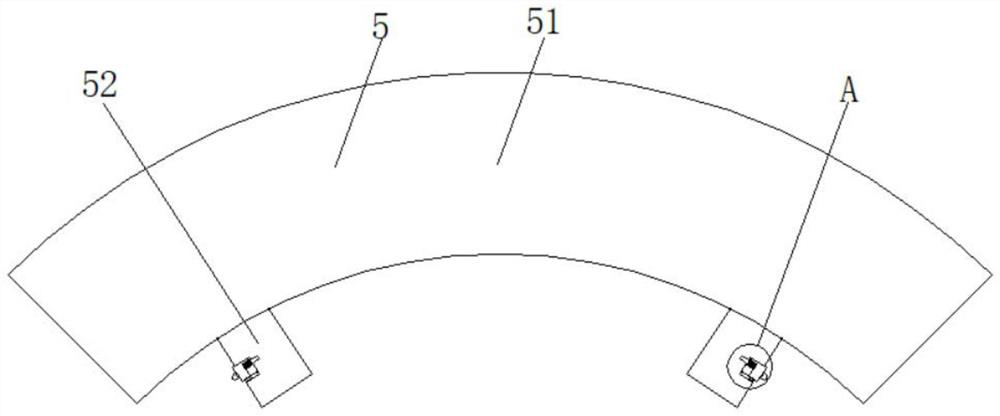

[0023] As an embodiment of the present invention, the reinforcement mechanism 5 includes a reinforcement sleeve 51, a groove block 52 is fixed on the bottom of the reinforcement sleeve 51, an extrusion spring 53 is arranged inside the groove block 52, and one end of the extrusion spring 53 is connected with a Movable block 54, the other side of movable block 54 is fixed with locking block 55, and the outside of movable block 54 is connected with limited block 56, and the outer side of movable block 54 is installed with limited post 57, can pass through the setting of reinforcing mechanism 5, the user The groove block 52 can be inserted into the interior of the main body 1 of the high-pressure common rail injector with valve stem coupling, and the elastic force is provided by the squeeze spring 53, which can push the movable block 54 outward. At this time, the movable block 54 and the outer side of the movable block 54 The locking block 55 can be snapped into the main body 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com