Diaphragm valve and method for manufacturing diaphragm valve

一种膜片阀、阀壳体的技术,应用在隔膜阀、阀的操作/释放装置、隔膜等方向,能够解决支承单元不能够运动地固定阀壳体等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

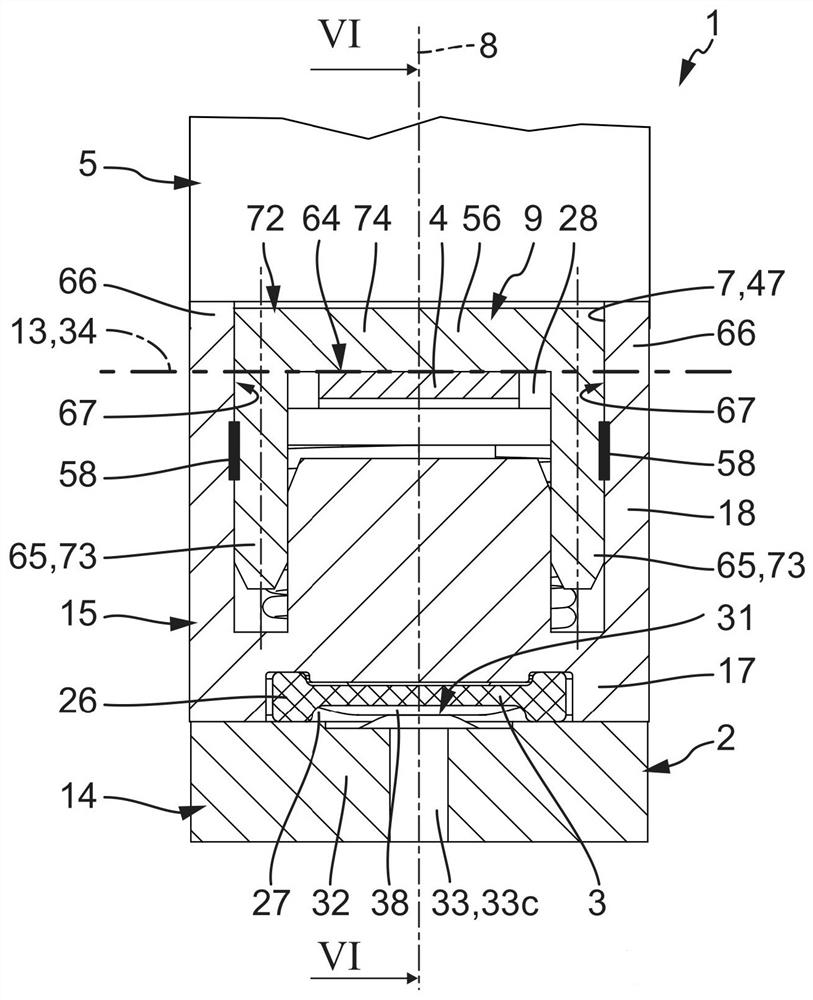

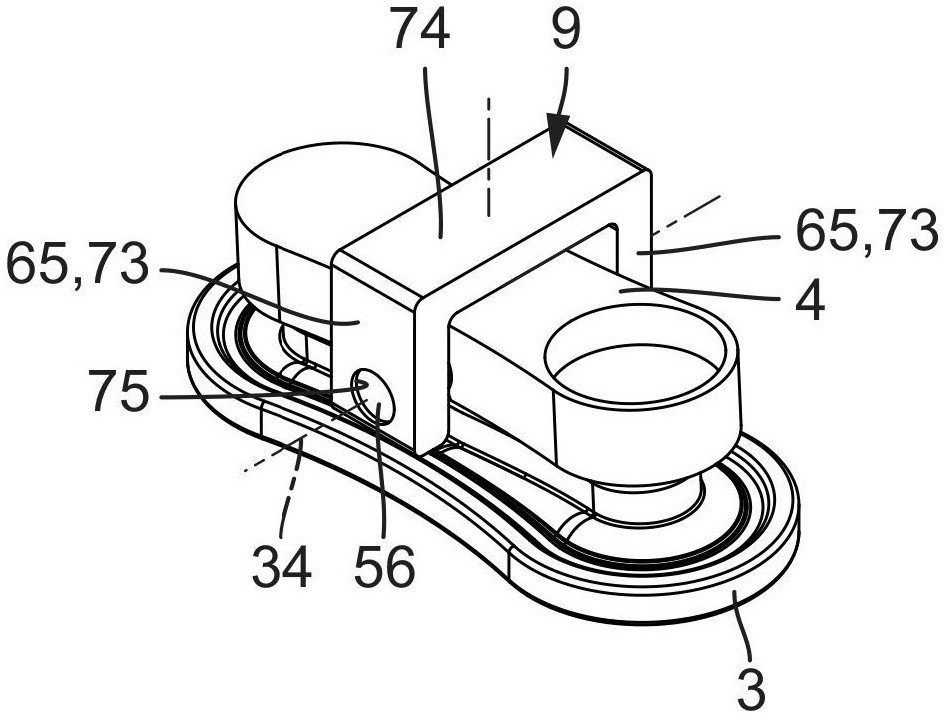

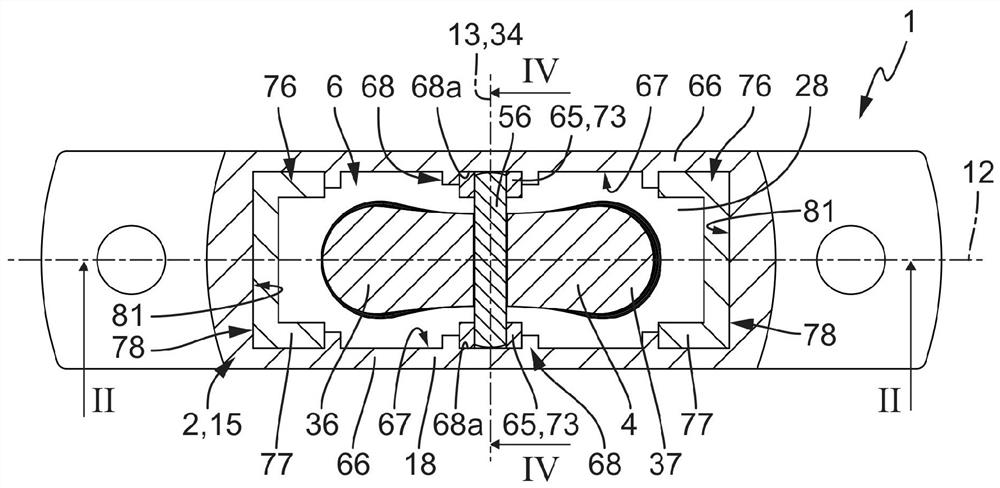

[0041] The diaphragm valve identified in its entirety with the reference number 1 has a valve housing 2 , a control diaphragm 3 acting as a valve element, a switching rocker 4 for actuating the control diaphragm 3 and a switching rocker for actuating 4 of the drive mechanism 5 as a basic component.

[0042] Furthermore, the diaphragm valve 1 has a bearing unit 9 , by means of which the switching rocker 4 is supported so as to be pivotable with respect to the valve housing 2 .

[0043] The valve housing 2 delimits a housing interior 6 in which the control membrane 3 , the bearing unit 9 and the switching rocker 4 are accommodated. The housing interior 6 has an interior opening 7 which is closed by a drive mechanism 5 which is arranged on the valve housing 2 .

[0044] The valve housing 2 has an imaginary vertical axis 8 which simultaneously delimits the vertical axis of the entire diaphragm valve 1 . The axial direction of the vertical axis 8 is referred to as the height dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com