Waste gas sampling monitoring device in factory environment

A monitoring device and exhaust gas technology, which is applied in the direction of measuring devices, analyzing gas mixtures, and the structural details of gas analyzers. The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

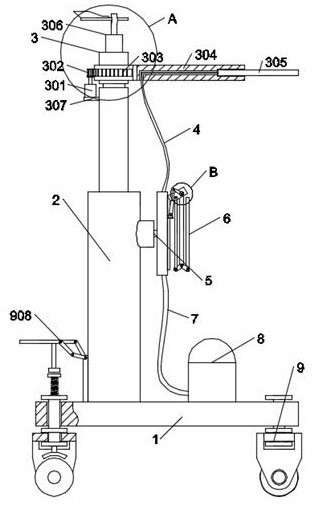

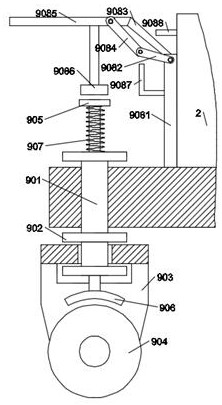

[0023] Such as figure 1 and figure 2 As shown, in the embodiment of the present invention, an exhaust gas sampling and monitoring device in a factory environment includes an installation base plate 1 on which a first telescopic rod 2 is fixed, and the upper end of the first telescopic rod 2 is connected to an exhaust gas A detection module 3, the exhaust gas detection module 3 is connected with a first wire 4, the first wire 4 is connected with a control cabinet 5, the upper end of the control cabinet 5 is connected with a stretching device 6, and the stretching device 6 and the control cabinet 5 Both are fixed on the lower half of the first telescopic rod 2, and the control cabinet 5 is also connected with a second wire 7, and the second wire 7 is connected with an alarm flashing light 8, and the alarm flashing light 8 is fixed on the first telescopic rod 2 On the installation base plate 1 on the right side, the lower ends of the four corners of the installation base plate ...

Embodiment 2

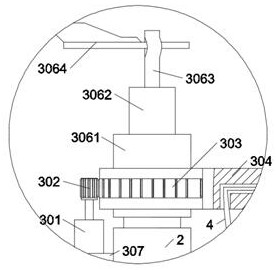

[0026] Such as figure 1 and figure 2 As shown, in the embodiment of the present invention, the exhaust gas detection module 3 includes a motor 301, the motor 301 is fixed on the bracket 307 at the upper end of the first telescopic rod 2, the motor 301 is connected with a gear 302, and the gear 302 The incomplete gear 303 is meshed, the toothless end of the incomplete gear 303 is connected with a long rod 304, and the end of the long rod 304 is connected with a high-precision thermal probe 305, which is located at the lower end of the incomplete gear 303 and is connected to the At the end of the first telescopic rod 2, a wind vane 306 is connected to the upper end of the incomplete gear 303.

[0027] In the embodiment of the present invention, the high-precision thermal probe 305 generates an electromotive force with the change of the exhaust gas, and the electromotive force generates a current that is transmitted to the control cabinet 5 through the first wire 4; the rotatio...

Embodiment 3

[0029] Such as figure 1 and figure 2 As shown, in the embodiment of the present invention, the wind vane 306 includes a base 3061, a cylindrical boss 3062 is fixed on the upper end of the base 3061, and a rotating column 3063 is rotatably connected to the cylindrical boss 3062, and the rotating column The upper end of 3063 is horizontally connected with weathervane 3064.

[0030] In the embodiment of the present invention, the wind vane 3064 is affected by the wind to change its direction, the cylindrical boss 3062 and the rotating column 3063 rotate relatively, and the wind vane 3064 is driven by the wind to rotate the rotating column 3063 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com