Recombination device for catalytic recombination of hydrogen and oxygen arising in accumulator to form water

A recombination and storage battery technology, applied in secondary batteries, electrochemical generators, battery pack components, etc., can solve the problems of flame danger, reduction of catalytic unit work efficiency, etc., and achieve the effect of simple overload protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

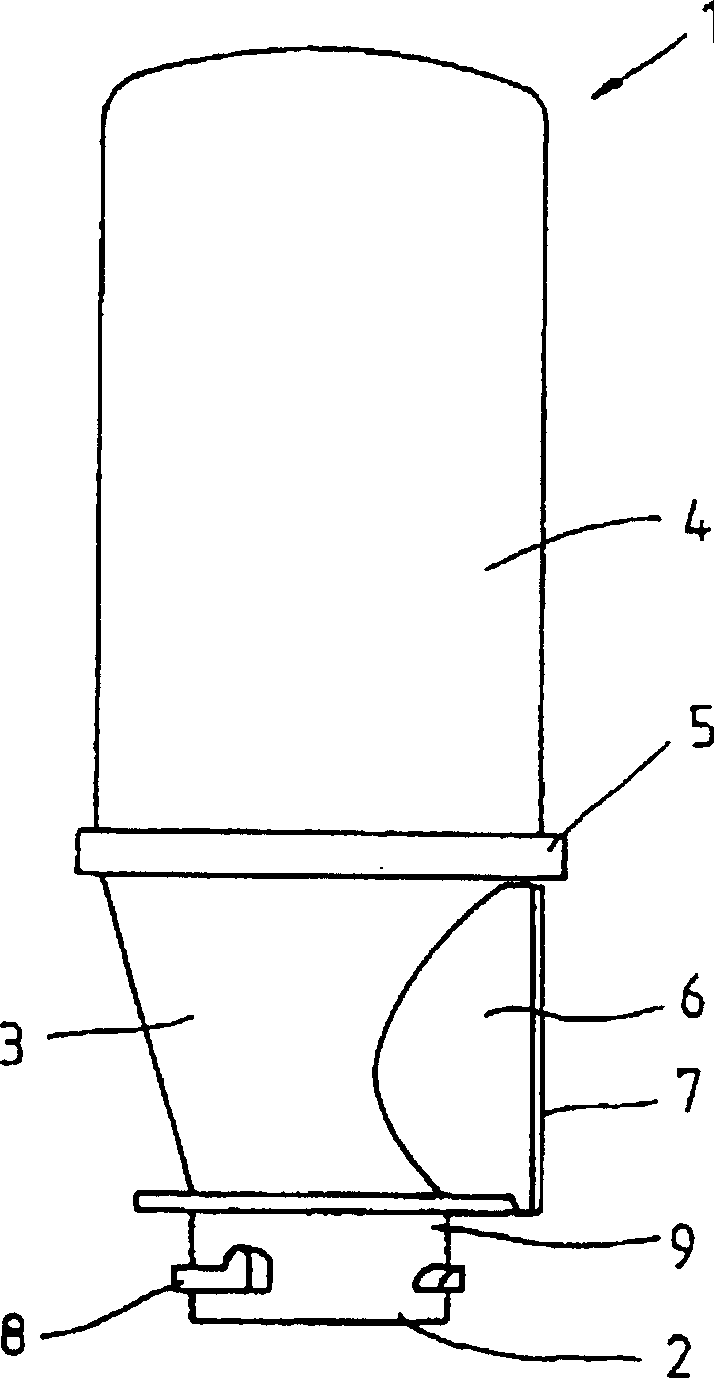

[0035] The same reference numerals represent the same components in these figures. figure 1 Shown is the outline of an embodiment according to the recombination device 1 of the present invention, and it has a connecting pipe 2, a connecting element 3, a container 4, a sealing ring 5 and a connecting tank 6, the connecting tank 6 is made of material Device 7 is closed. A key protrusion 8 is formed on the joint pipe 2 for connecting and assembling the device with a pool hole of a storage battery not shown in the figure in a clamping manner. A sealing ring area 9 provided on the key protrusion 8 serves to accommodate a sealing ring not shown in the figure.

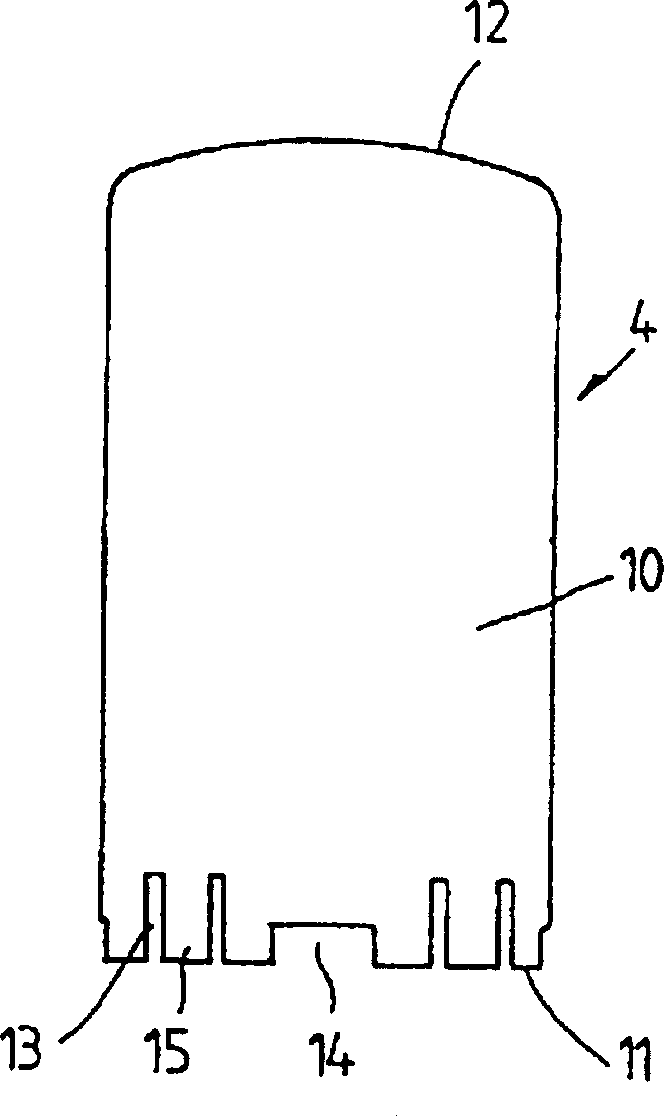

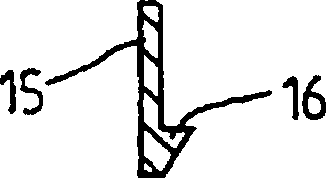

[0036] figure 2 and image 3 It is a detailed view of the container 4. The container 4 essentially consists of a thin-walled plastic cylinder 10 having an open end 11 and a closed end 12 . At the open end 11 a vertically running groove 13 emerges or emerges, so that a web 15 is formed. The container 4 is secured along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com