Battery housing for at least one battery cell and motor vehicle

A technology for battery casings and battery cells, applied in electric vehicles, batteries, battery pack components, etc., can solve problems such as fire protection restrictions, increase manufacturing steps, and single cell ignition, and achieve improved fire protection design or safety design, reduce The effect of fire prevention measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

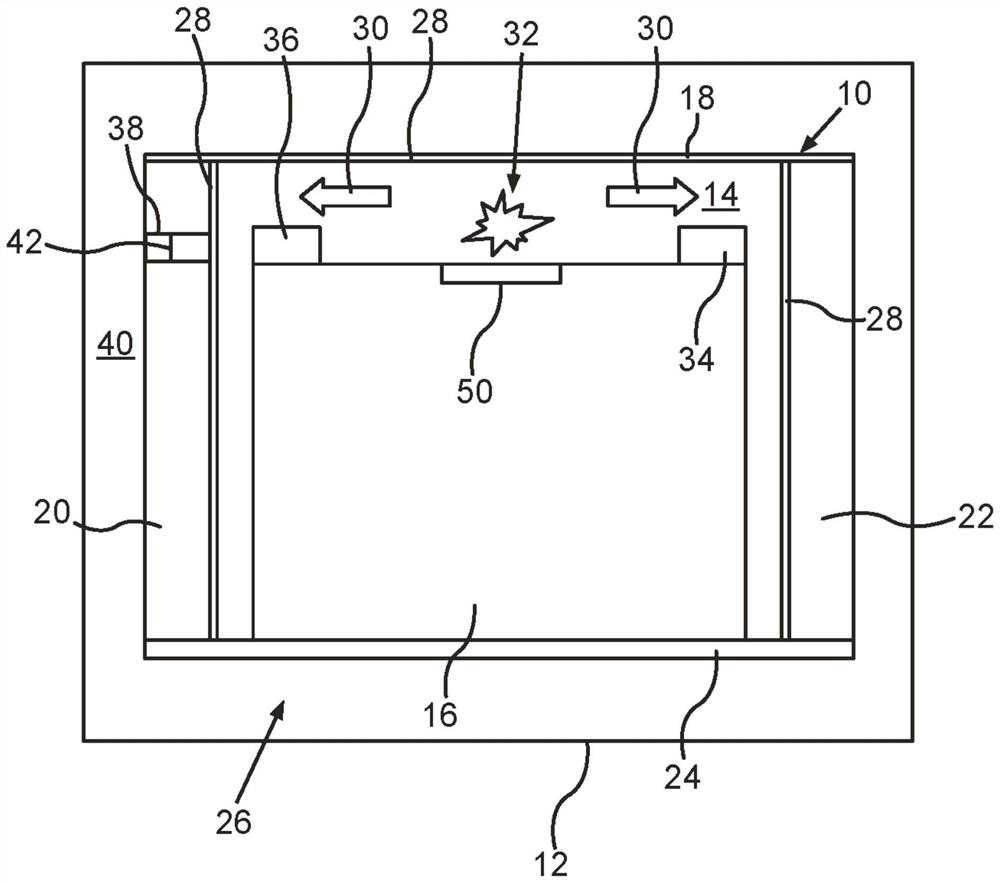

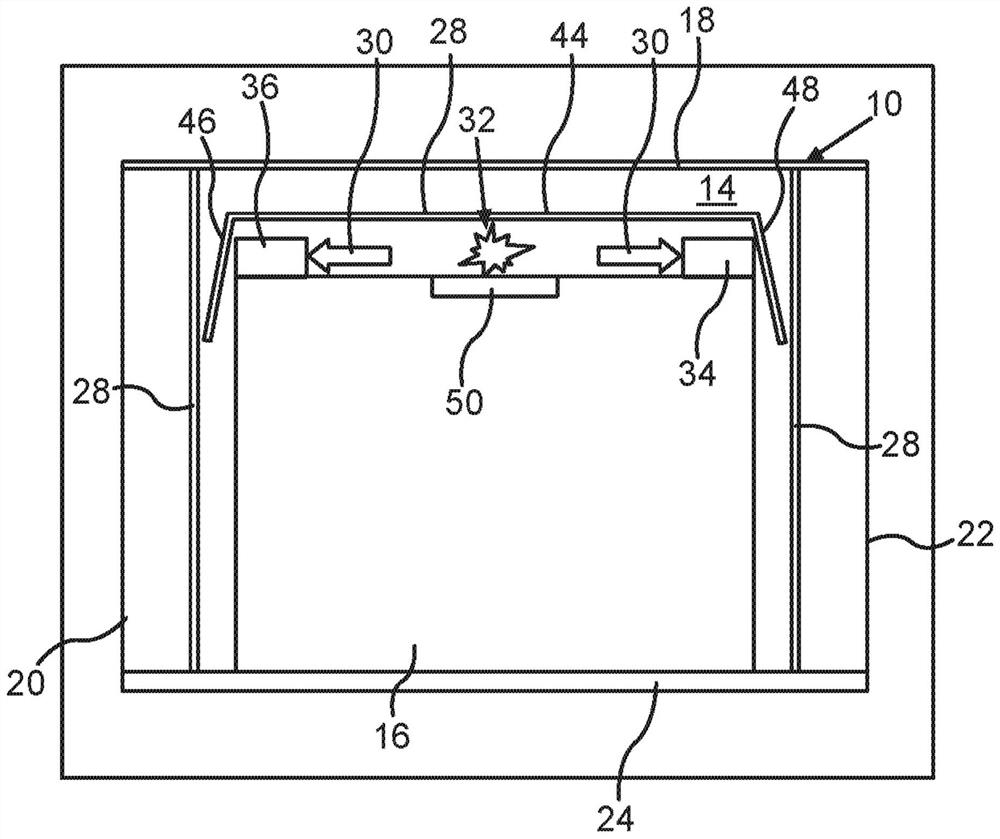

[0029] figure 1 One embodiment of the battery housing 10 is shown in a schematic side view. In the present exemplary embodiment, the battery housing 10 is in particular designed purely schematically in the purely schematically shown motor vehicle 12 . The battery housing 10 has an interior space 14 . In particular, battery cells 16 can be arranged in this interior space 14 . In the present exemplary embodiment, the battery cells 16 are arranged in the interior space 14 .

[0030] In the present exemplary embodiment, the battery housing 10 has in particular a cover element 18 , a first side element 20 and a second side element 22 . Furthermore, the battery housing 10 has a base element 24 .

[0031] The battery housing 10 is designed as at least one battery cell 16 for an electrical energy store 26 of an at least partially electrically operated motor vehicle 12 . In particular, electrical energy store 26 may be formed from a plurality of battery cells 16 . For this purpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com