A double vacuum disc filter

A disc filter, double vacuum technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of short service life, substandard output, long time required, etc., to prolong the service life of the equipment, The effect of reducing equipment failure rate and efficient equipment processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

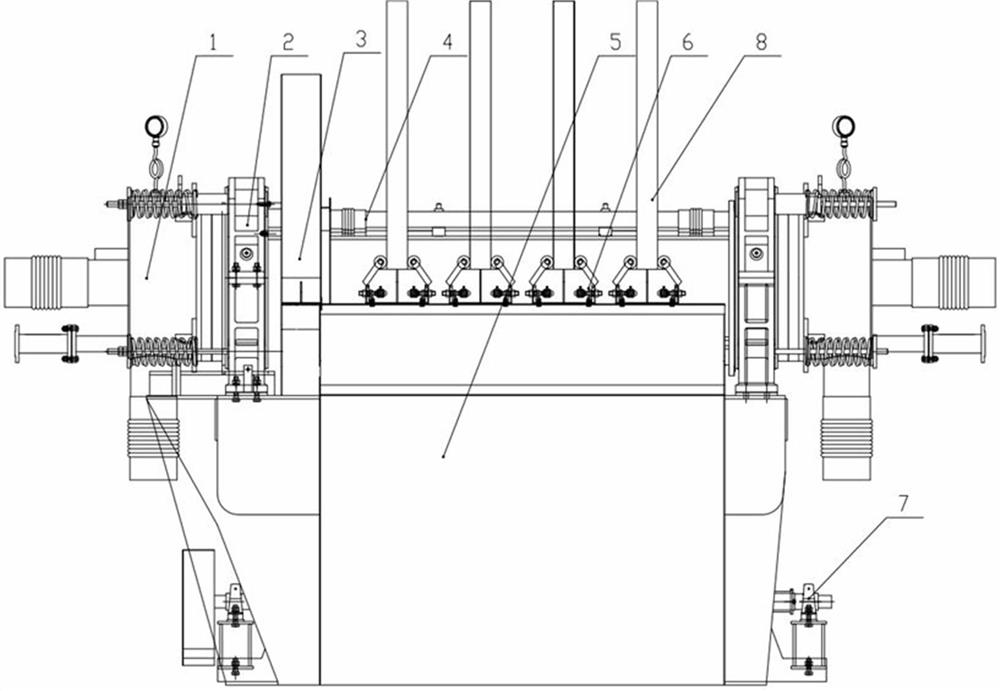

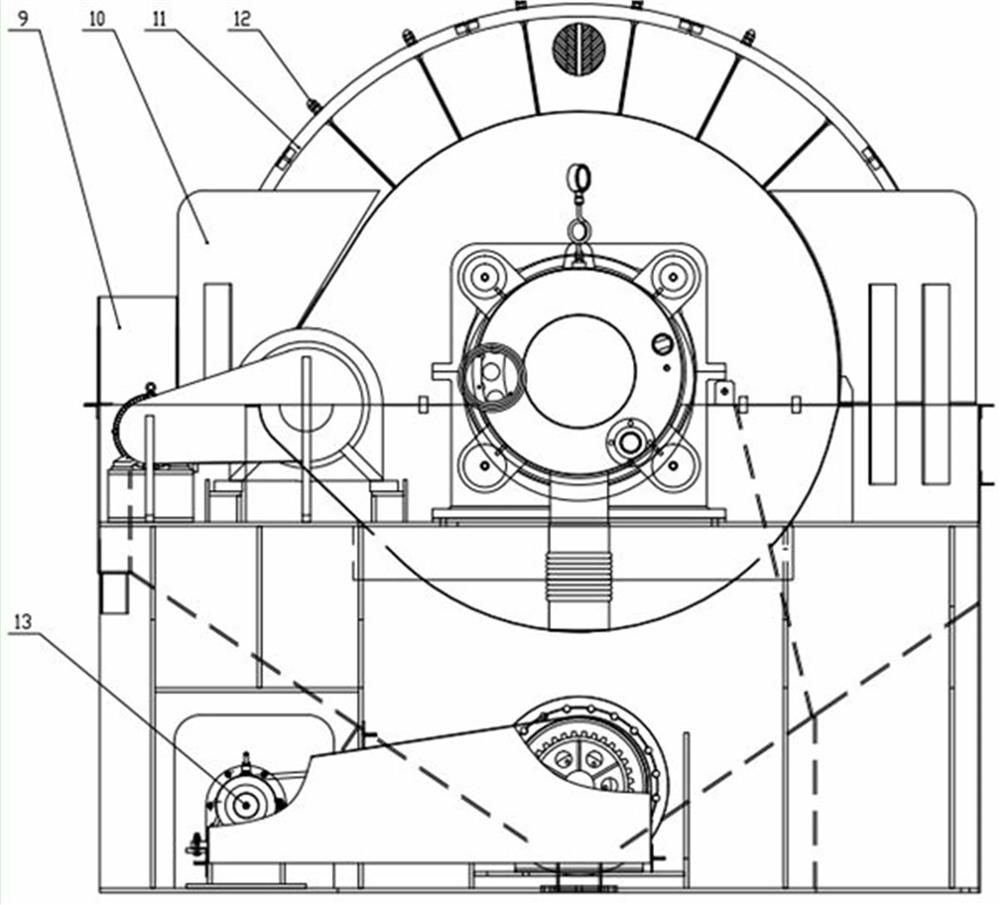

[0024] Such as Figure 1-4 As shown, the present invention includes a tank body 5 provided with an ore discharge tank, an overflow port and a discharge port, bearing blocks 2 and bearing bushes are arranged at both ends of the tank body 5, and the main shaft 4 supported between the two bearing blocks 2, the main shaft 4 It is composed of central support shaft, filtrate pipe, connecting pipe and so on.

[0025] The filter plate device 8 is assembled on the connecting pipe of the main shaft 4 by the compression of the gland 11 and the long screw rod 12 through the nut. The positioning ear plate 15 of the distribution head 1 is positioned on the outer main shaft 4 of the bearing blocks 2 on both sides through a compression spring.

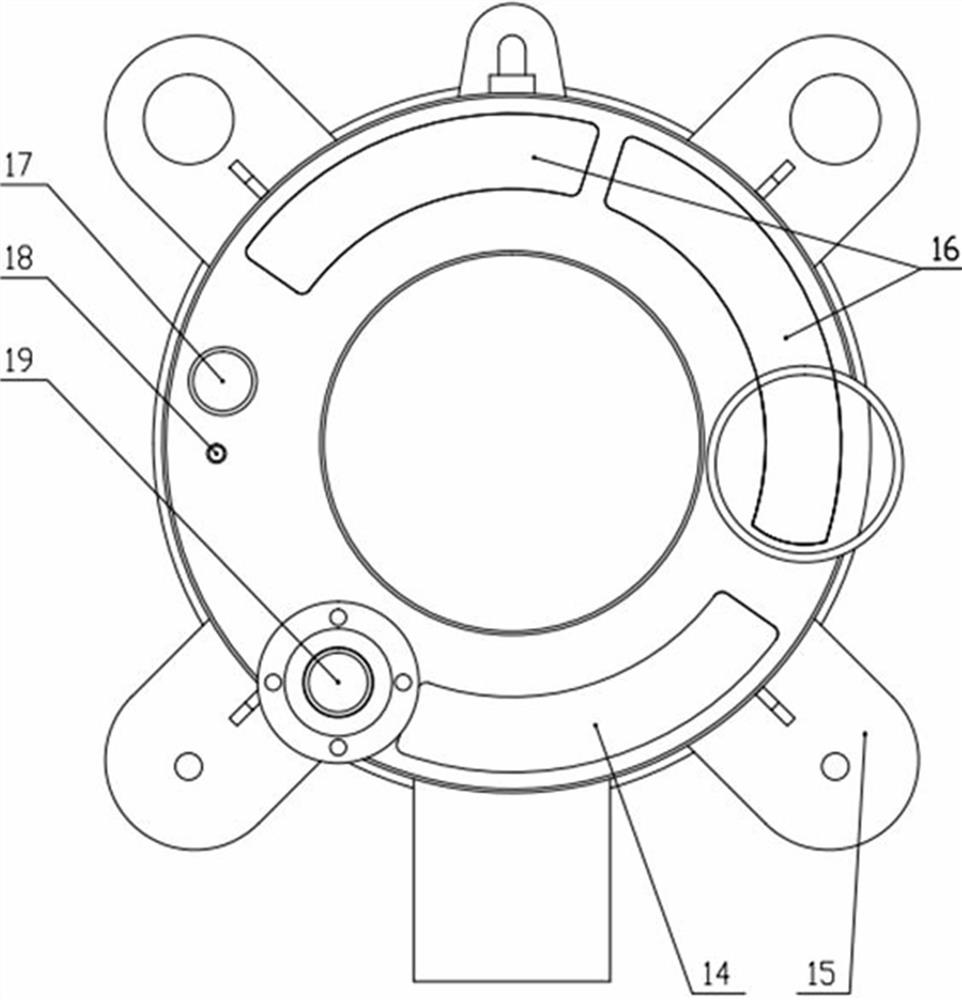

[0026] Such as image 3 As shown, the distribution head 1 has three independent chambers, namely: the distribution head adsorption area 14 , the distribution head dehydration area 16 , and the distribution head blowback area 17 . Wherein, beside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com