Setting machine lampblack purification system

A technology of purification system and engine oil, which is applied in the field of setting machines, can solve the problems of reduced working efficiency of the device and reduced service life of the lampblack pipe, and achieve the effect of improving the adjustable ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

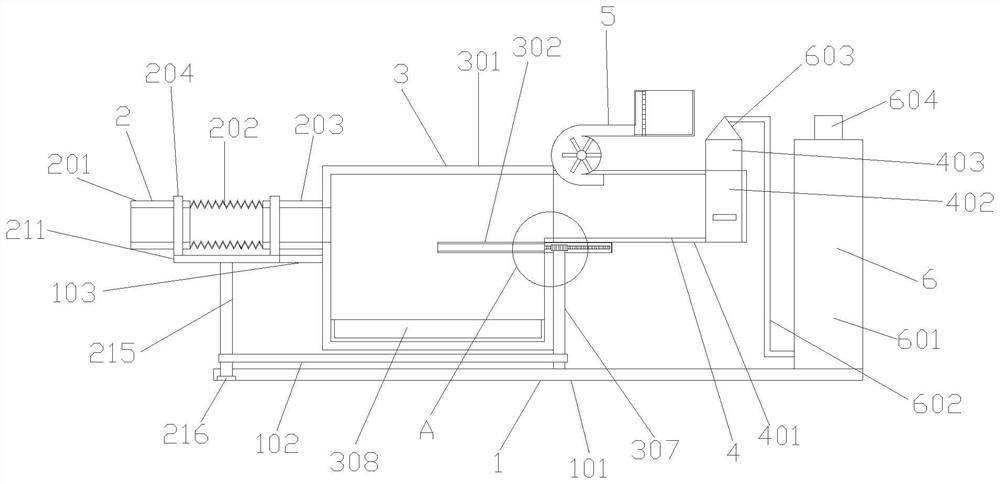

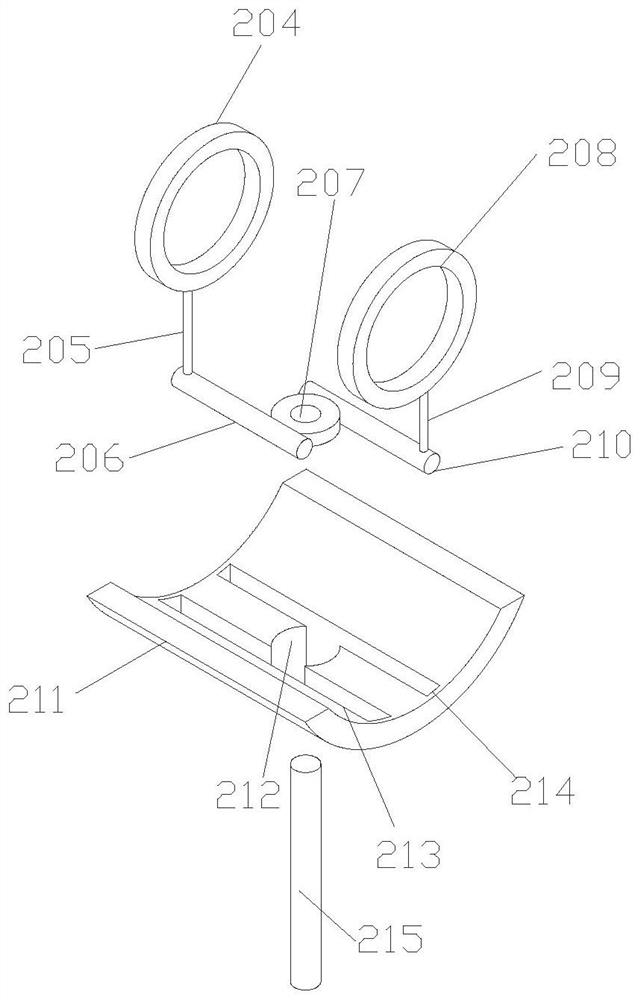

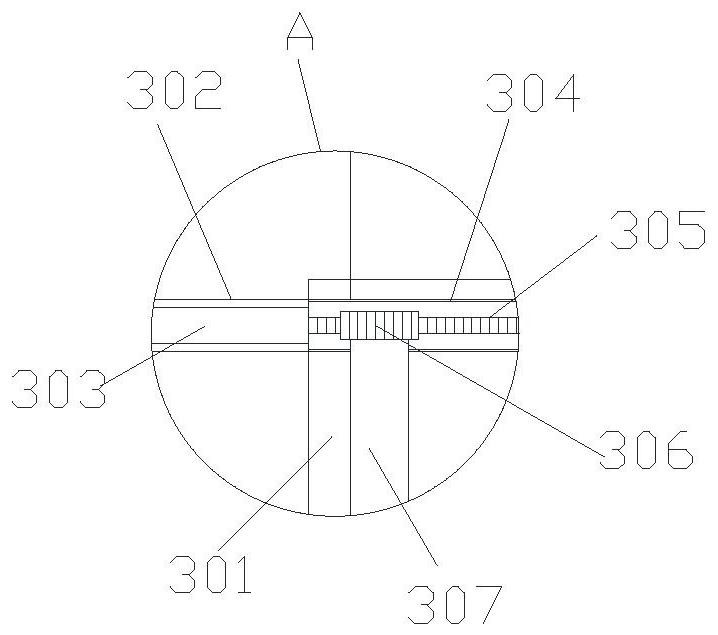

[0026] Embodiment: a kind of oil fume purification system of stereotypes machine, such as Figure 1-Figure 5As shown, the present invention provides a technical solution: a cooking fume purification system for a stereotyped machine, including an accessory device 1, the accessory device 1 includes a base 101, and an inlet device 2 is arranged above the left end of the base 101, and the inlet device 2 includes an inlet pipe 1 201 , the left end of the inlet pipe 201 is fixedly connected to the oil outlet of the setting machine, the right end of the inlet pipe 201 is fixedly connected with a bellows 202, the right end of the bellows 202 is fixedly connected with an inlet pipe 203, and the right end of the inlet pipe 201 The outer side of the port is fixedly sleeved with a collar-204, the lower end of the collar-204 is fixedly connected with a vertical post-205, and the lower end of the vertical post-205 is fixedly connected with a gear post-206, and the front right end of the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com