A combined washing and drying equipment for auto parts

An auto parts and combined technology, applied in the field of parts cleaning, can solve the problems of low manual cleaning efficiency, inconvenient cleaning operations, and cumbersome processes, so as to improve the drying effect, avoid manual cleaning, and improve the cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

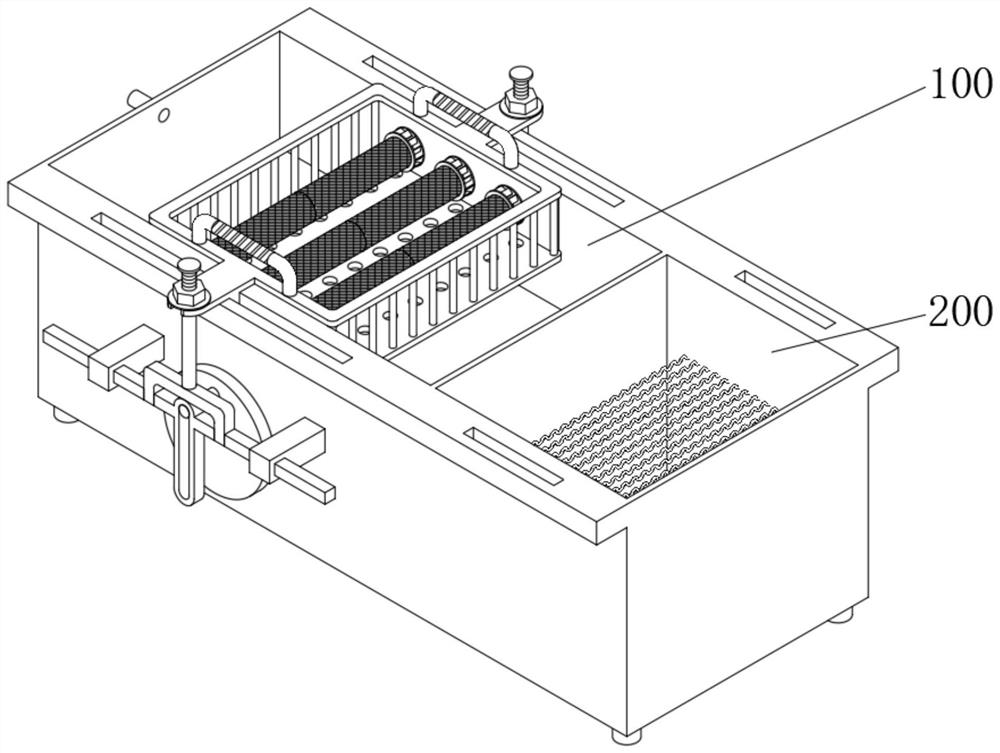

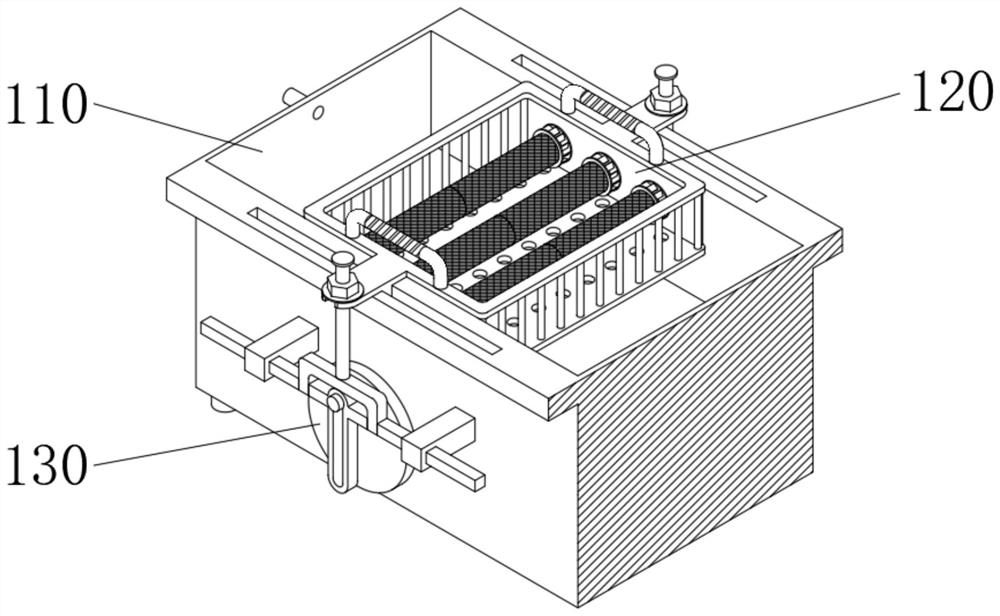

[0060] see Figure 1-Figure 12 As shown, a combined washing and drying equipment for auto parts is provided, including a cleaning structure 100 and a drying structure 200 connected to the cleaning structure 100. The cleaning structure 100 at least includes:

[0061] The base 110, the base 110 includes a cleaning pool 111, side plates 112 are provided on both sides of the cleaning pool 111, and a chute 113 is provided on the side plate 112. The chute 113 is a linear chute, which is convenient for the slider to slide. There is an interlayer 117 below 113, and the interlayer 117 and the chute 113 are integrally formed, and the structure is more stable. At the same time, the interlayer 117 is a cavity structure, and the interior can be used as an installation space for the necessary structure of the equipment;

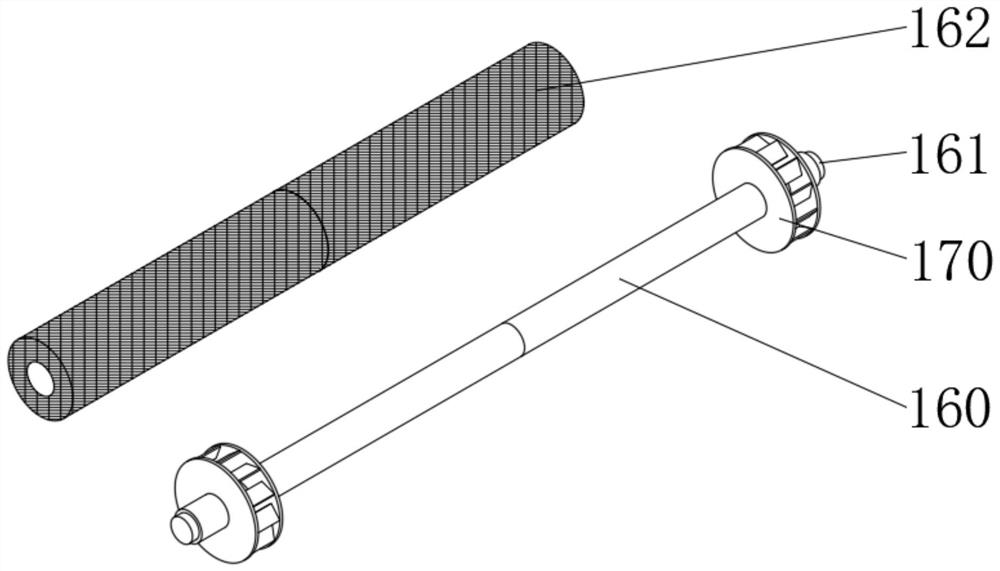

[0062] The cleaning basket 120, the cleaning basket 120 includes a bottom plate 121, which is provided with a number of through holes 125, and the two sides of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com