Device for preventing roller casting from generating shrinkage cavities

A casting and shrinkage cavity technology, applied in the field of roll castings, can solve the problems of low utilization rate of liquid metal, easy loss of temperature, inability to have plastic film, etc., and achieve the effect of stable operation and enhanced thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

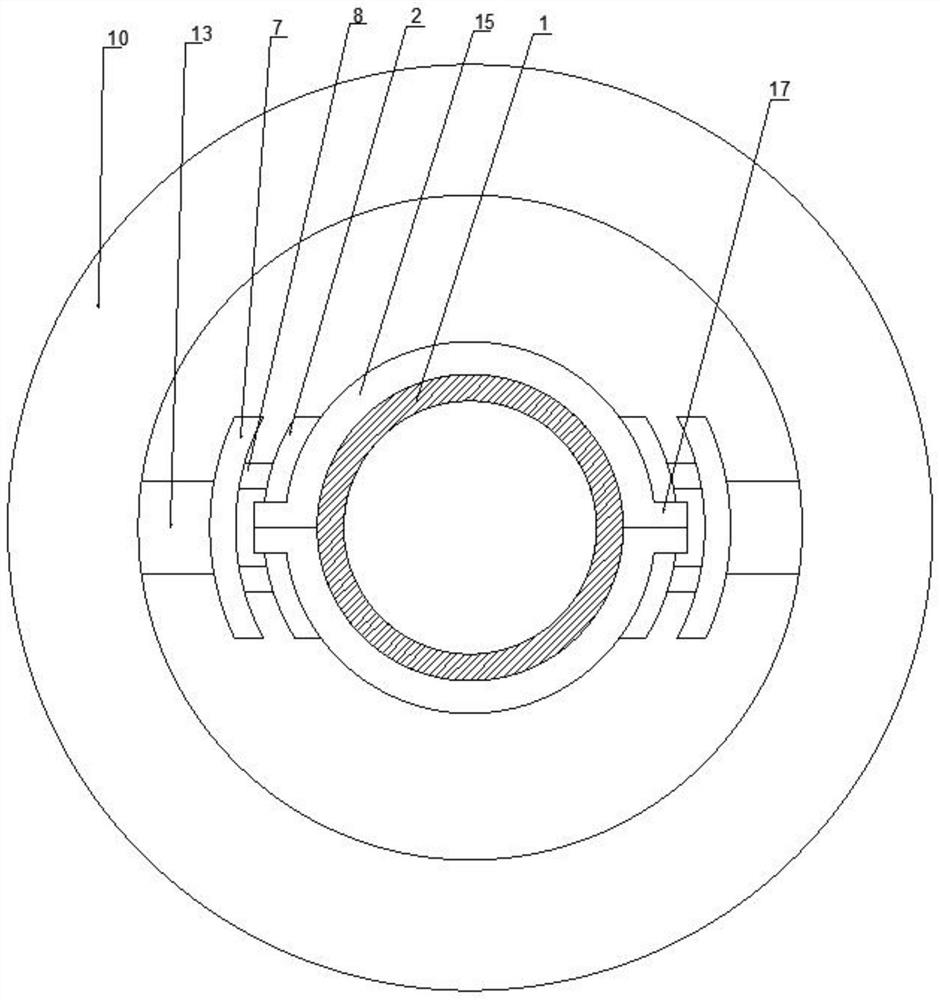

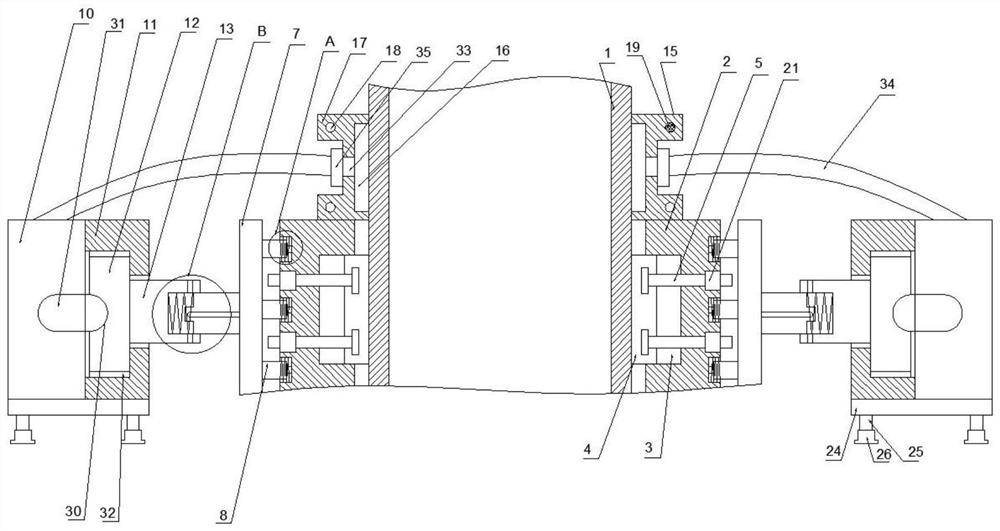

[0027] Such as Figure 1-4 As shown, the device for avoiding shrinkage cavities in roll castings according to the embodiment of the present invention includes a riser 1, and both sides of the riser 1 are provided with a tightening frame 2 matching it, and the tightening frame 2 has a The radian that matches the riser 1, and the cross-section of the tightening frame 2 is U-shaped, the inside of the tightening frame 2 is provided with a functional groove 3 that matches it, and the inside of the functional groove 3 is provided with a plastic melt Block 4, and the material of the plastic frit 4 is polypropylene material, the inside of the functional tank 3 is provided with a number of adjustment rods 5, and the inside of the tightening frame 2 is provided with a number of rods on the side away from the riser 1. Auxiliary groove 6, and the side of the tightening frame 2 away from the riser 1 is matched with the tightening plate 7, and the side of the tightening plate 7 close to the...

Embodiment 2

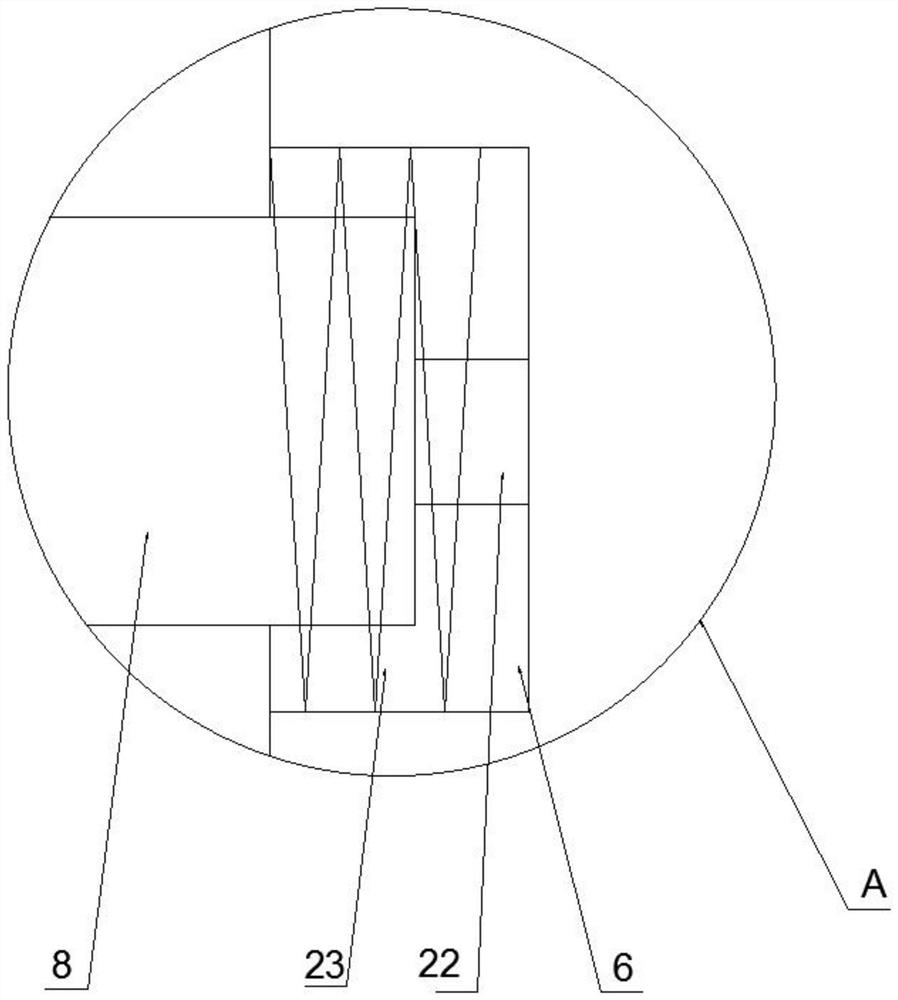

[0031] Such as Figure 1-4 As shown, the side of the heating jacket 15 away from the riser 1 is symmetrically provided with a locking extension piece 17, and the inside of the locking extension piece 17 is provided with a locking hole 18, and the inside of the locking hole 18 There is a locking pin rod 19 matched with the locking extension piece 17, the outer wall of the central connecting rod 9 is provided with a plurality of strip grooves 20, and the inner wall of the strip groove 20 is provided with matching A threaded strip, a connecting pad is provided between the adjusting rod 5 and the plastic frit 4, the connecting pad is made of nylon plastic material, and a matching sleeve 21 is provided between the adjusting rod 5 and the tightening frame 2, A positioning pin 22 is provided between the connecting positioning rod 8 and the auxiliary groove 6, and the outer wall of the connecting positioning rod 8 is provided with a spring 23 matched with the auxiliary groove 6. The p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap