Crystal ingot stripping method and crystal ingot stripping device

A crystal ingot and accommodating cavity technology, applied in laser welding equipment, electrical components, circuits, etc., can solve the problems of scattered processing procedures and inability to handle materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

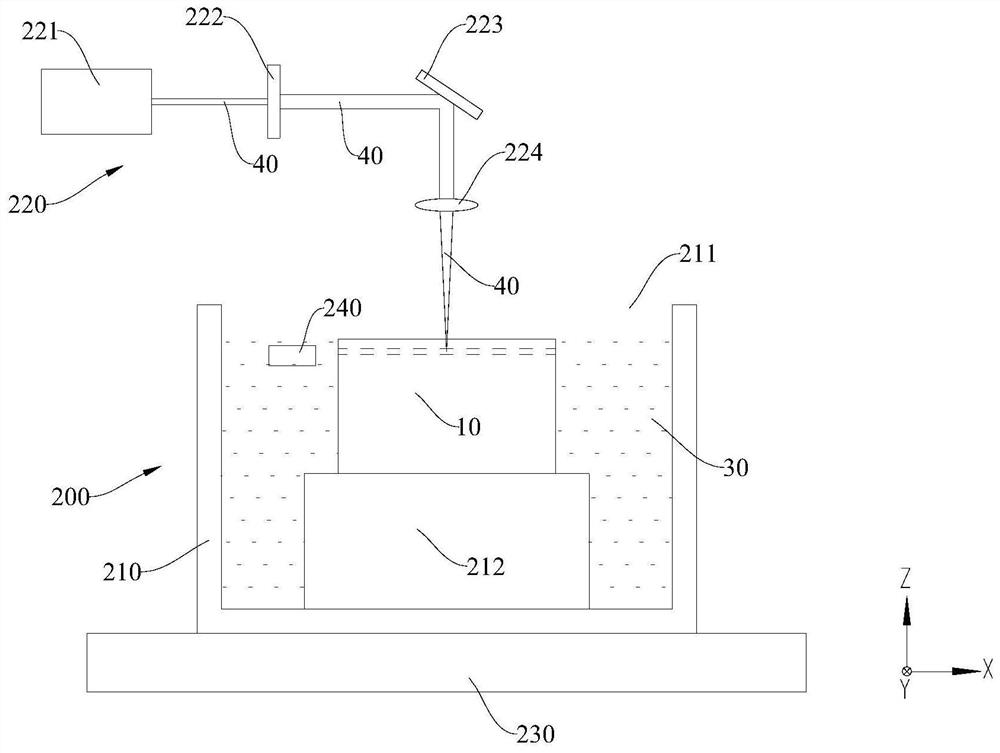

[0063] A kind of crystal ingot stripping device 200, such as image 3 As shown, it includes: a housing body 210 , a laser component 220 , a motion platform 230 and a magnetic component 240 . in:

[0064] The accommodating body 210 has an accommodating cavity 211 for accommodating the magnetorheological fluid 30 and the crystal ingot 10 , and the bottom of the accommodating cavity 211 is provided with a support platform 212 for fixing the crystal ingot 10 on the upper surface.

[0065] The laser assembly 220 is disposed above the housing body 210 , and includes a laser 221 , a beam expander 222 , a reflector 223 and a focusing mirror 224 . The laser 221 , the beam expander 222 and the reflector 223 are arranged at intervals along the horizontal direction;

[0066] The motion platform 230 is disposed at the bottom of the accommodating body 210 and is configured to be able to move along the X direction, the Y direction and the Z direction.

[0067] The magnet assembly 240 incl...

Embodiment 2

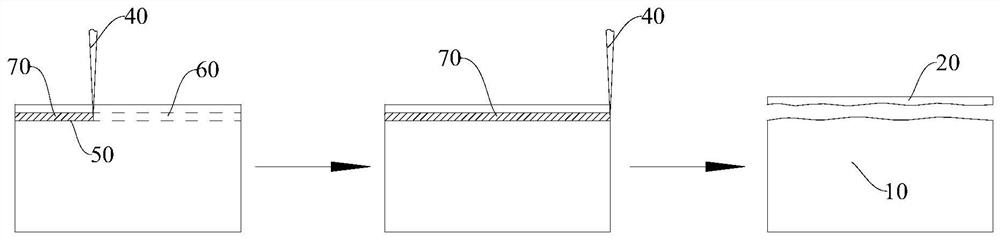

[0069] A method for stripping an ingot, carried out using the ingot stripping device 200 provided in Embodiment 1, comprising:

[0070] The silicon carbide ingot 10 to be stripped is placed on the upper surface of the supporting platform 212 , and the magnetorheological fluid 30 is filled in the accommodating cavity 211 .

[0071]According to the thickness of 350 μm of the silicon carbide wafer 20 to be peeled off, the relative height of the ingot 10 is adjusted by moving the motion platform 230 in the Z direction, so as to focus the laser beam 40 at a preset depth of 450 μm inside the silicon carbide ingot 10 . Wherein, the pulse width of the laser beam 40 is 4ns, the wavelength is 1064nm, and the power is 3W.

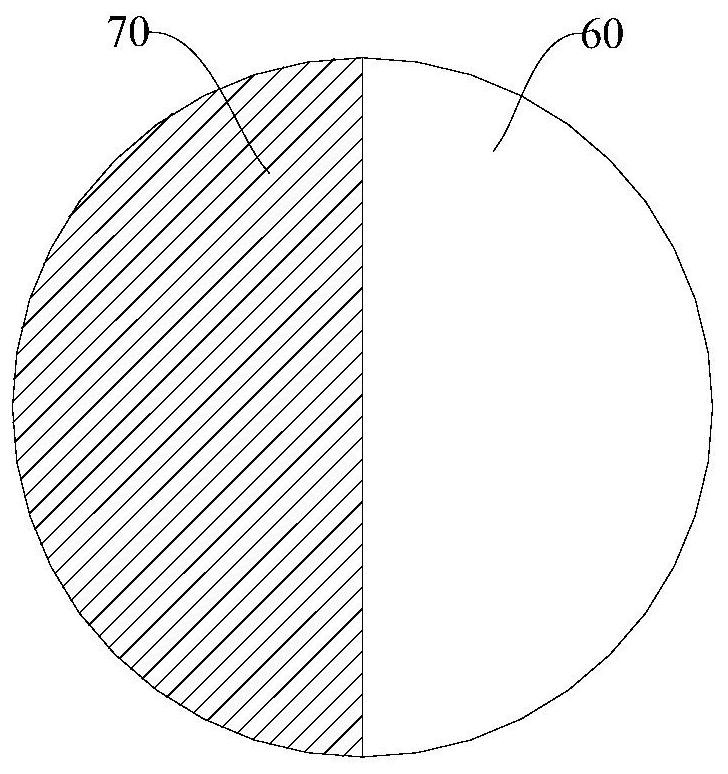

[0072] The laser beam 40 is scanned inside the ingot 10 so that a modified layer is formed inside the silicon carbide ingot 10 . Wherein, the scanning speed is 300mm / s. The scanning path is: control the motion platform 230 to move in the X direction, so that the la...

Embodiment 3

[0076] A kind of ingot stripping method, adopts the crystal ingot stripping device 200 that embodiment 1 provides to carry out, and its difference with embodiment 2 is:

[0077] The crystal ingot 10 to be peeled off is a silicon crystal ingot 10 .

[0078] The pulse width of the laser beam 40 is 10 ps, the wavelength is 1030 nm, and the power is 2 W; the scanning speed is 400 mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap