Intensive retarder

An intensive technology of speed reducers, which is applied to railway car body parts, track brakes, transportation and packaging, etc., can solve the problems of waste of metal resources of spare parts, unfavorable maintenance and repair work, and a large number of speed reducer parts, etc., to achieve improvement Safety performance, convenience for station renovation, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

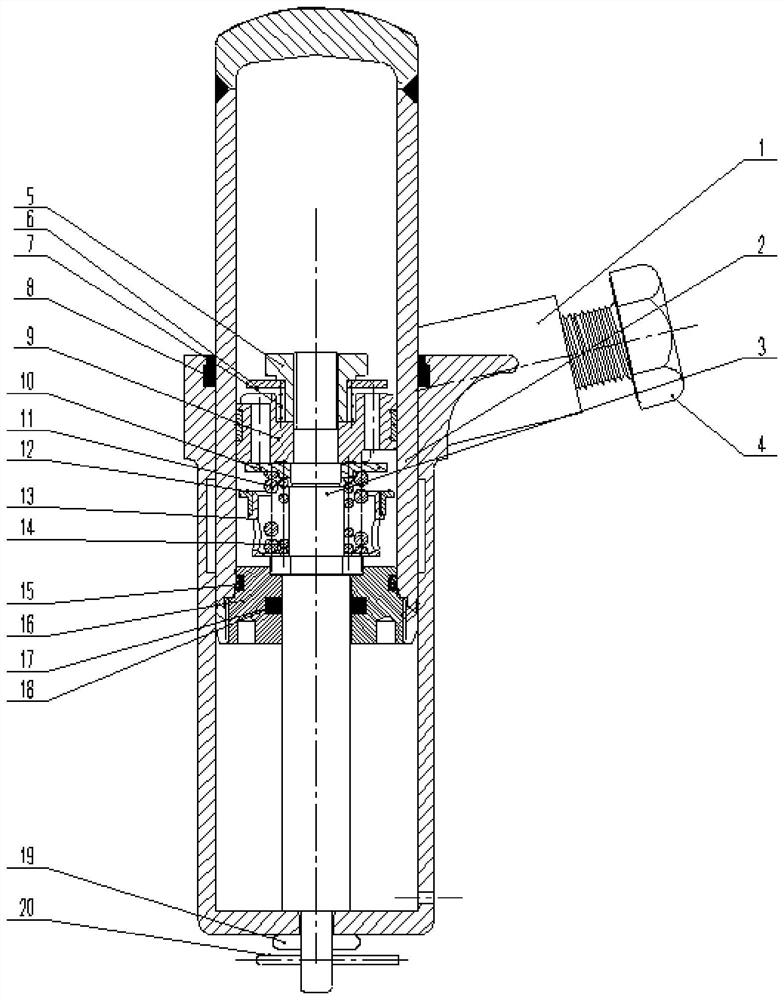

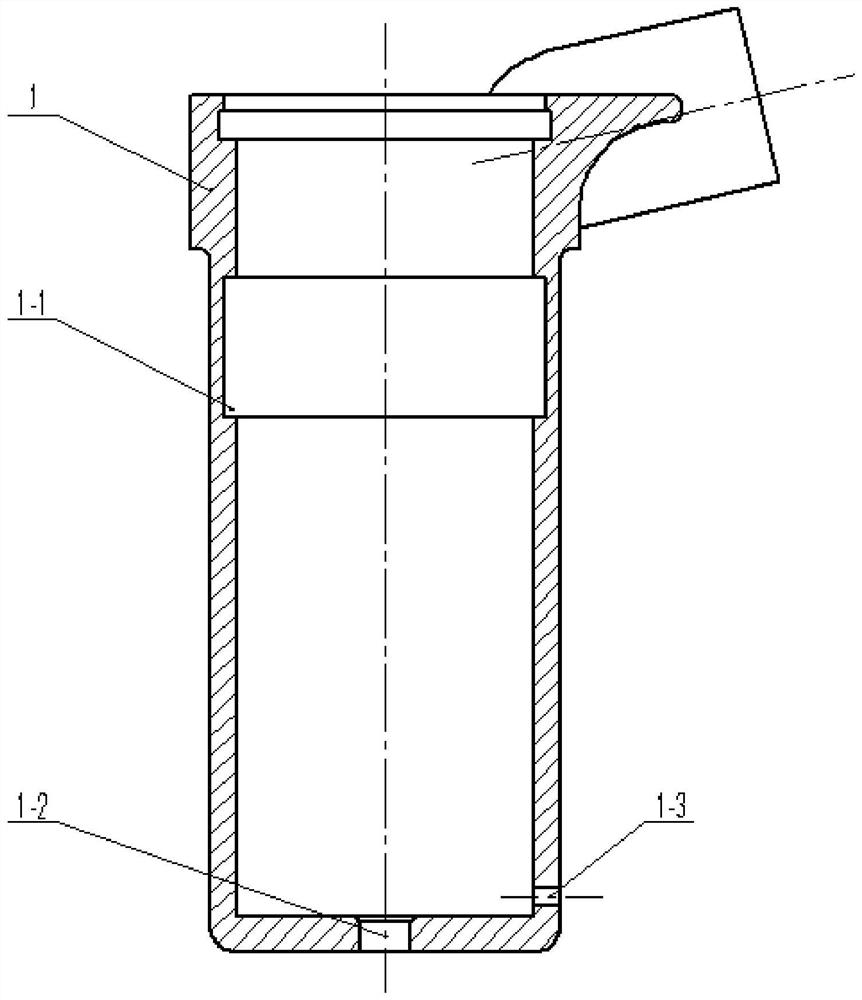

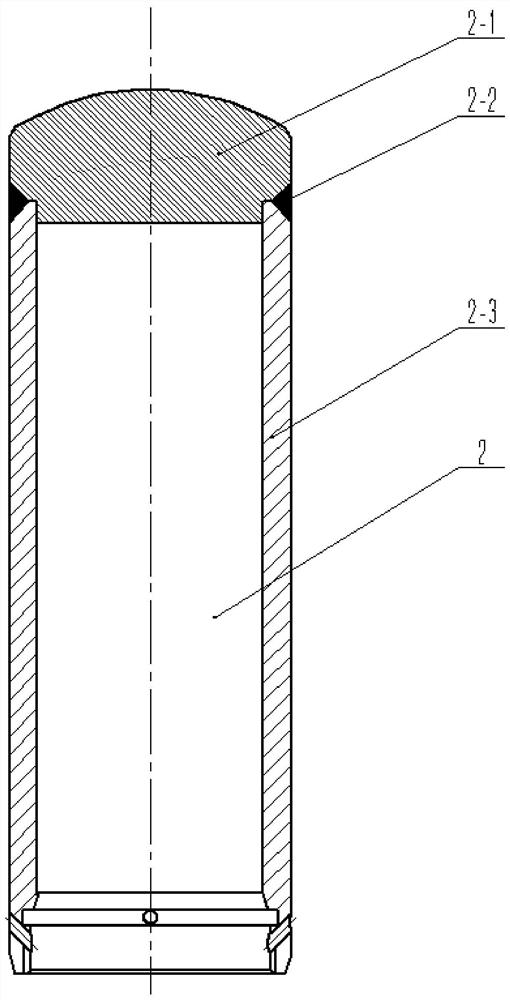

[0024]Specific implementation mode 1: CombinationFigure 1-Figure 5To explain this embodiment, an intensive retarder described in this embodiment includes a housing 1, a sliding cylinder 2, a piston rod 3, a speed valve seat 5, a speed valve plate 6, a speed valve spring 7, and a dust ring 8. , Piston 9, pressure valve plate 10, pressure valve outer spring 11, return valve plate 12, slow return valve plate bracket 13, pressure valve inner spring 14, sealing cover 16 and split pin 20; sealing cover 16 is installed on the sliding cylinder 2 At the bottom end, the piston rod 3 is inserted into the sealing cover 16, the speed valve seat 5, the piston 9, the pressure valve plate 10 and the slow return valve plate bracket 13 are sleeved on the piston rod 3 from top to bottom, and the speed valve The seat 5 is installed on the top of the piston rod 3, the speed valve plate 6 and the speed valve spring 7 are sleeved on the speed valve seat 5, the bottom end of the speed valve seat 5 is insta...

Example Embodiment

[0025]Specific implementation manner two: combinationfigure 1 To explain this embodiment, the intensive type retarder described in this embodiment also includes two hexagon head bolts 4, and each hexagon head bolt 4 is screwed and mounted on the outer side wall of the housing 1. 4 pairs of speed reducers are installed on the inner side of the rail by two hexagon head bolts. Others are the same as the first embodiment.

Example Embodiment

[0026]Specific implementation mode three: combinationfigure 1 To explain this embodiment, the intensive type retarder described in this embodiment also includes a seal 19 which is sleeved on the piston rod 3.

[0027]The seal 19 is an'O'-shaped seal ring 19, which is used to prevent the split pin 20 from breaking during the return stroke of the sliding cylinder 2 and causing the impact stop to fail. Others are the same as the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap