Bicycle pedal structure

A technology for bicycles and pedals, which is applied to vehicle components, rider driving, transportation and packaging, etc. It can solve problems such as high cost, troublesome processing, and pedals that cannot be used normally, and achieves simple production, low cost, and less prone to problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object and technical solutions of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

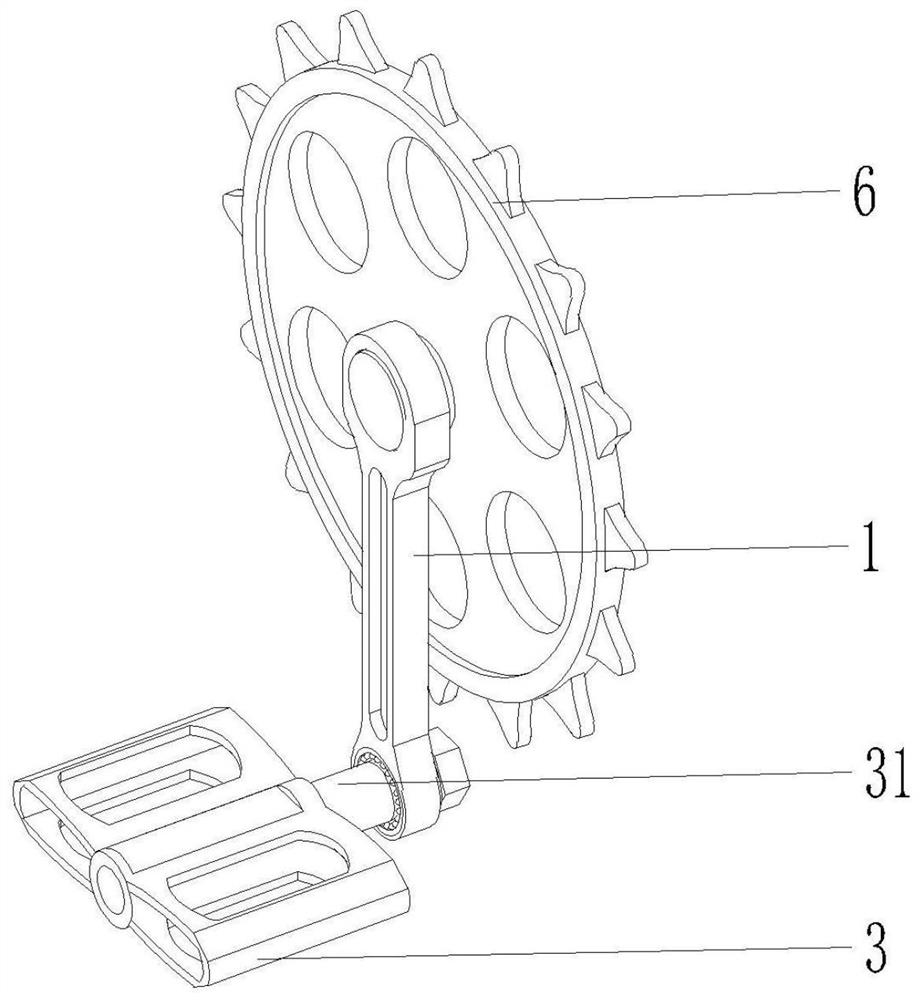

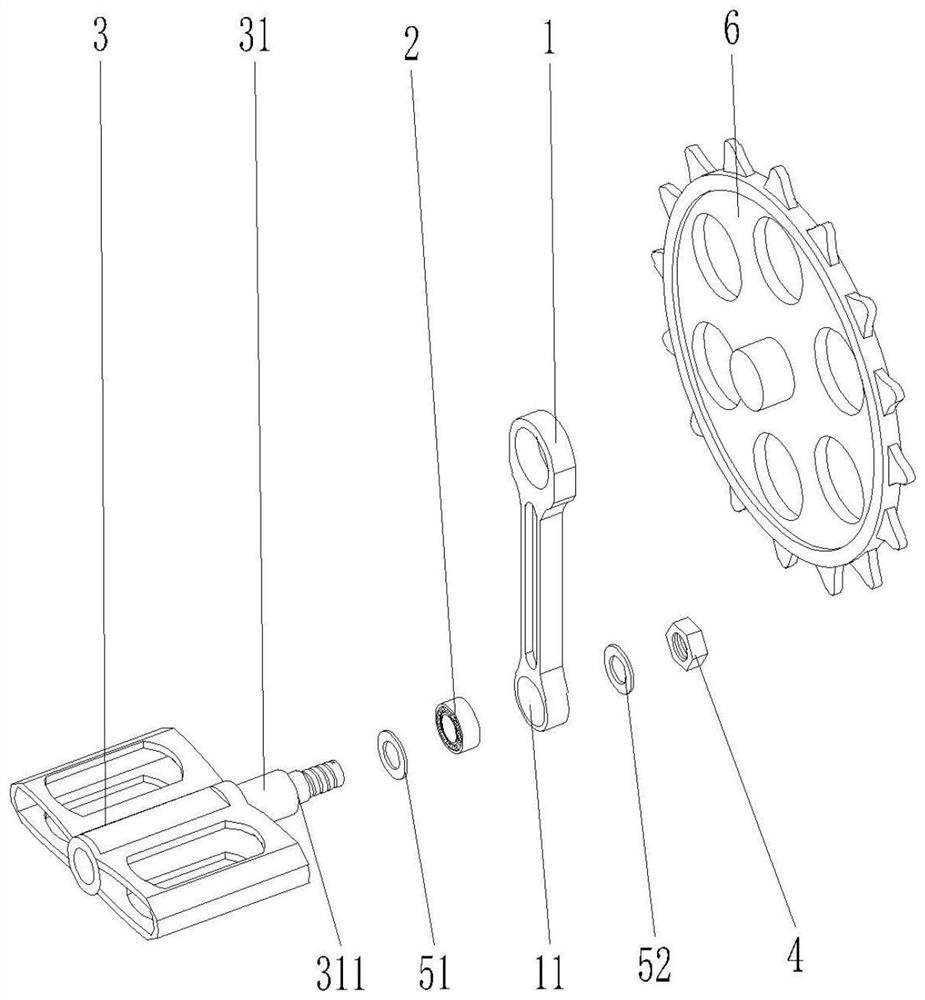

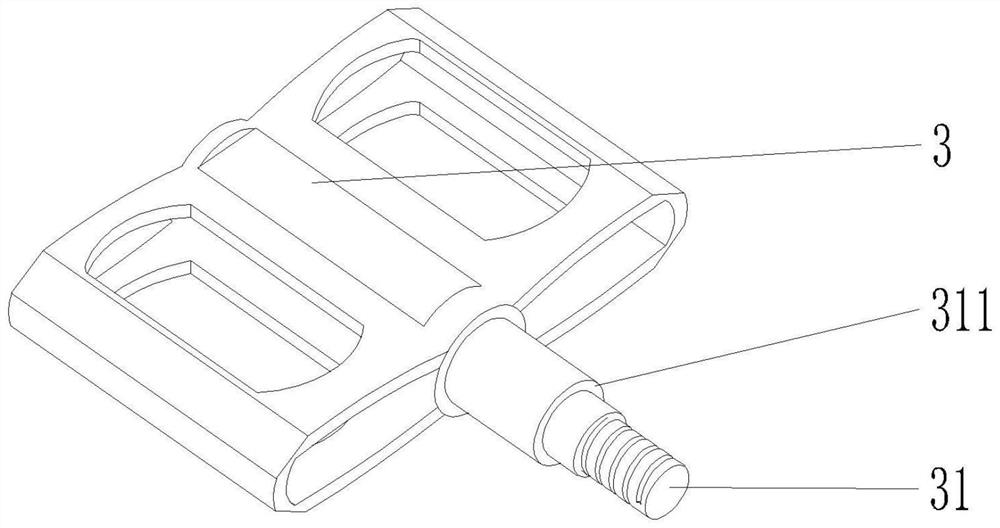

[0017] like Figure 1 ~ Figure 3 A bicycle pedal structure shown includes a crank 1; the upper end of the crank 1 is fixedly mounted on the toothed plate 6 of the bicycle, and a mounting hole is provided below the crank 1, and the mounting hole forms a bearing seat 11; the bearing 2, Installed in the bearing seat 11; the pedal structure is integrally formed, including: a pedal 3; a mandrel 31 is arranged in the middle of the pedal; the pedal 3 is installed and fixed on the bearing through the mandrel 31 2 on.

[0018] Bearing 2 can be installed in described bearing seat 11 (not shown in the figure) through end cap, and mandrel 31 and bearing 2 are interference fit, and this assembly method is more inconvenient when replacing pedal later.

[0019] Preferably, the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com