An electronic container for storing electronic devices

An electronic container and electronic device technology, applied in the field of electronic container, can solve the problems of high self-weight unfavorable for high-floor installation, inability to realize dense storage of materials, low space utilization rate, etc., to save movement space, stable transmission, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing.

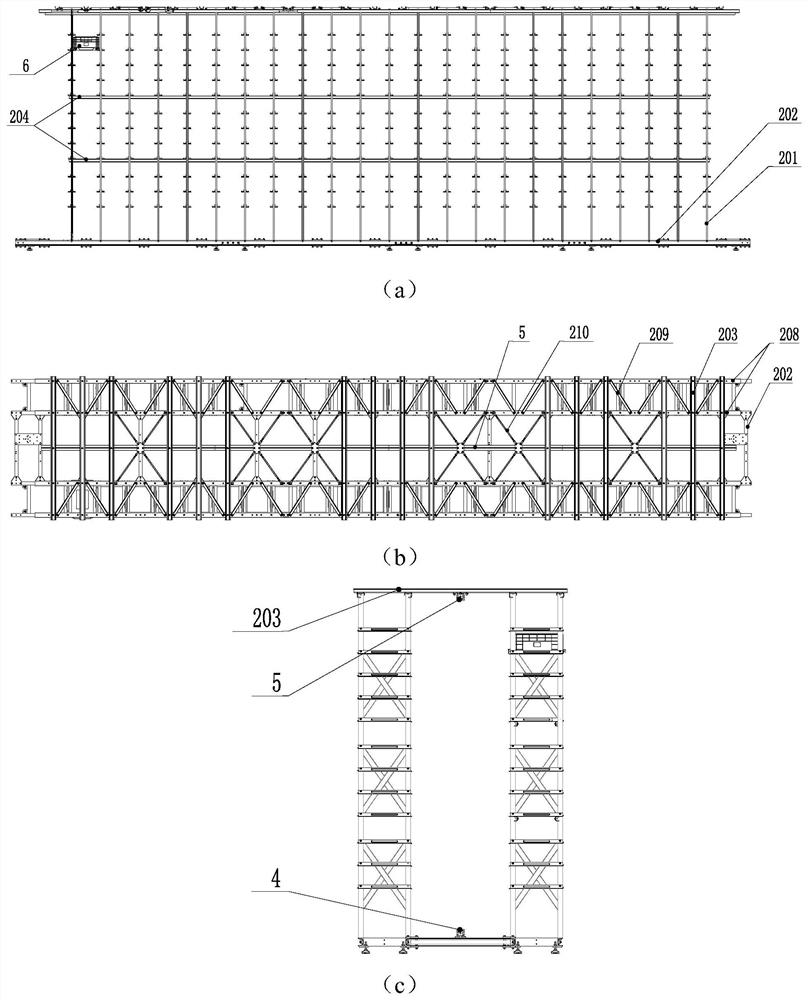

[0050] The electronic container provided by the present invention includes a stacker, a three-dimensional shelf, a sky rail 5, a ground rail 4, a material box 6 and a container shell.

[0051] 1. Stacker

[0052] The stacker among the present invention is a kind of light stacker, and this stacker runs in the roadway in the middle part of the three-dimensional shelf along the sky rail 5 and the ground rail 4, and is used for taking and putting material boxes.

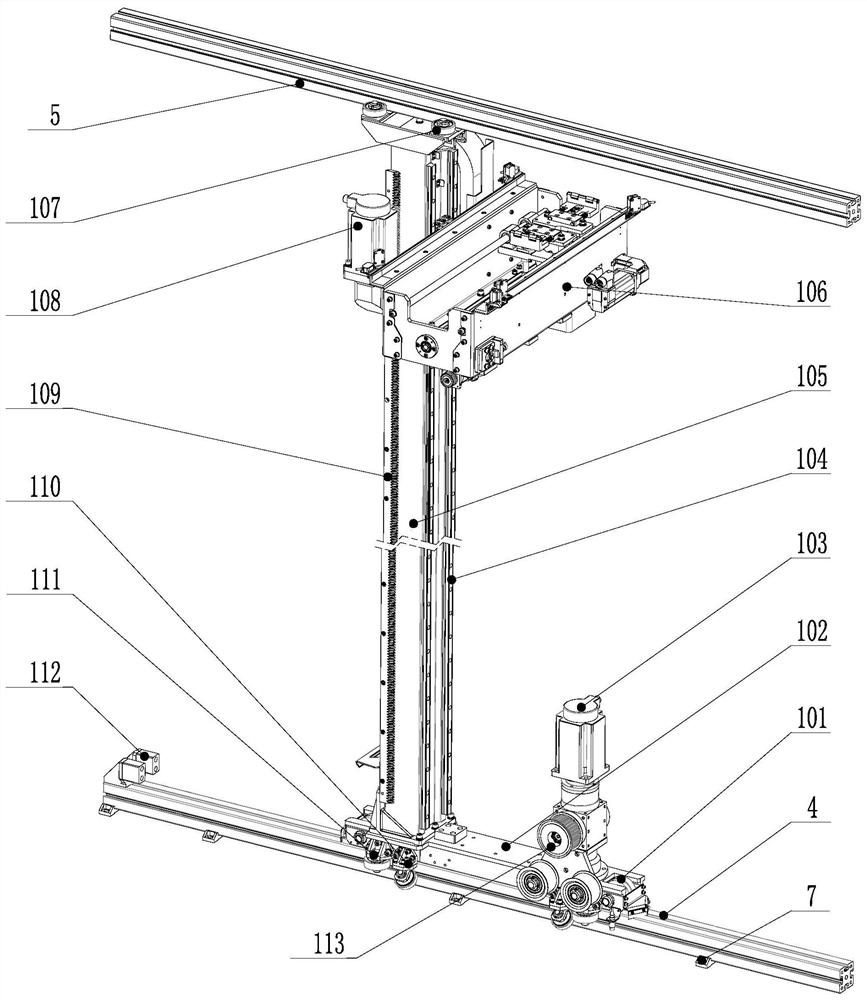

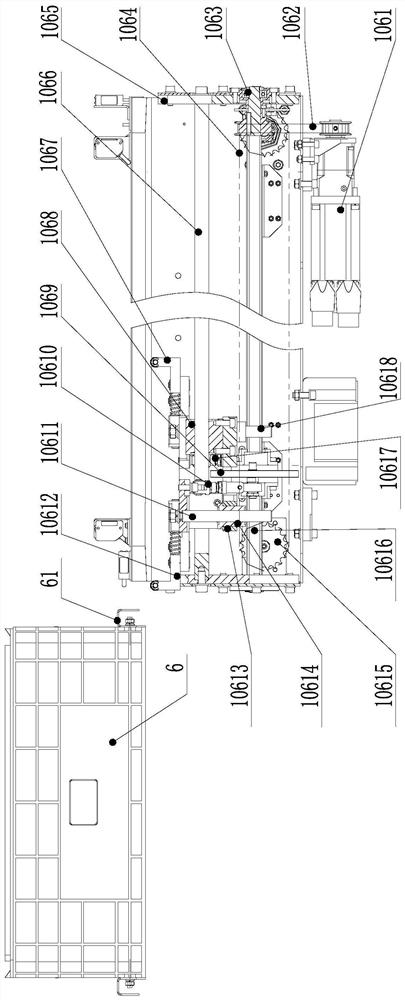

[0053] Such as figure 1 , 5 As shown, the stacker includes a horizontal walking unit, a vertical lifting unit and a box-taking mechanism 106;

[0054] The horizontal walking unit comprises a walking base 102, a horizontal drive servo motor 103, a synchronous belt transmission mechanism and two walking support wheels 101 arranged on the walking base 102; the synchronous belt 114 in the synchronous belt transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com