A paint bucket automatic sealing device

An automatic sealing and paint bucket technology, applied in the direction of flanged bottle caps, etc., can solve the problems of poor sealing and low efficiency of manual sealing, and achieve the effect of improving efficiency and sealing tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

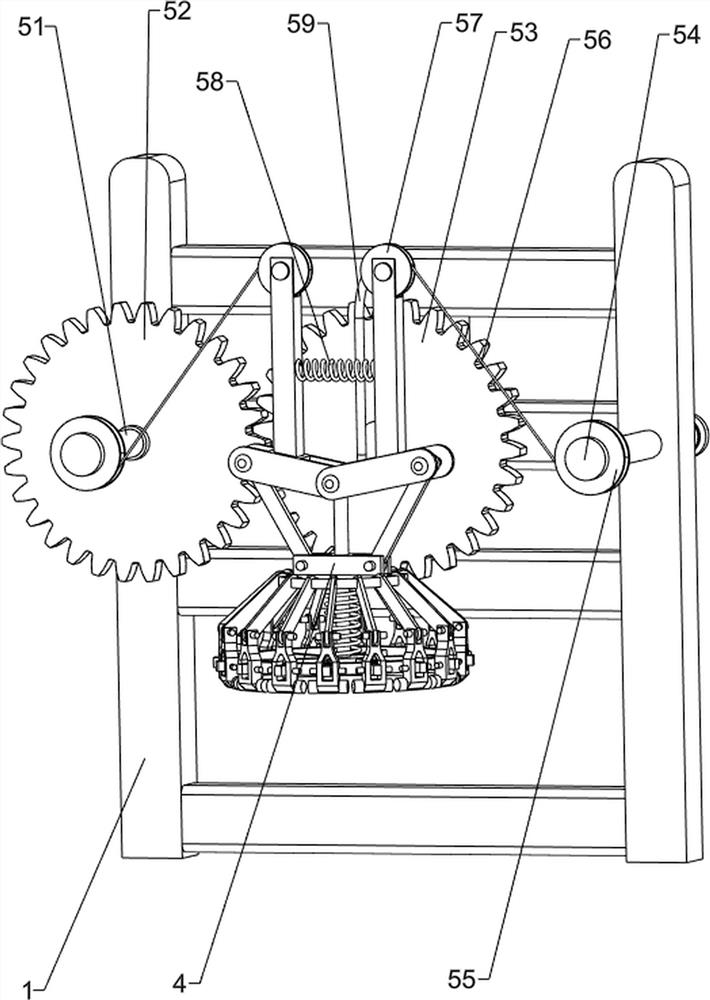

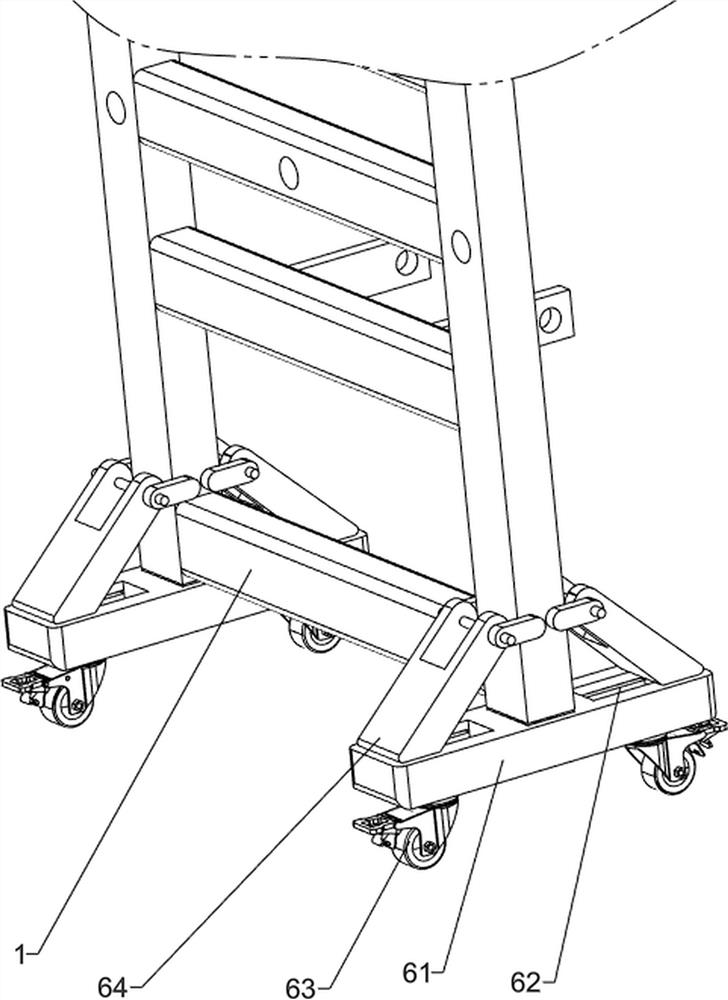

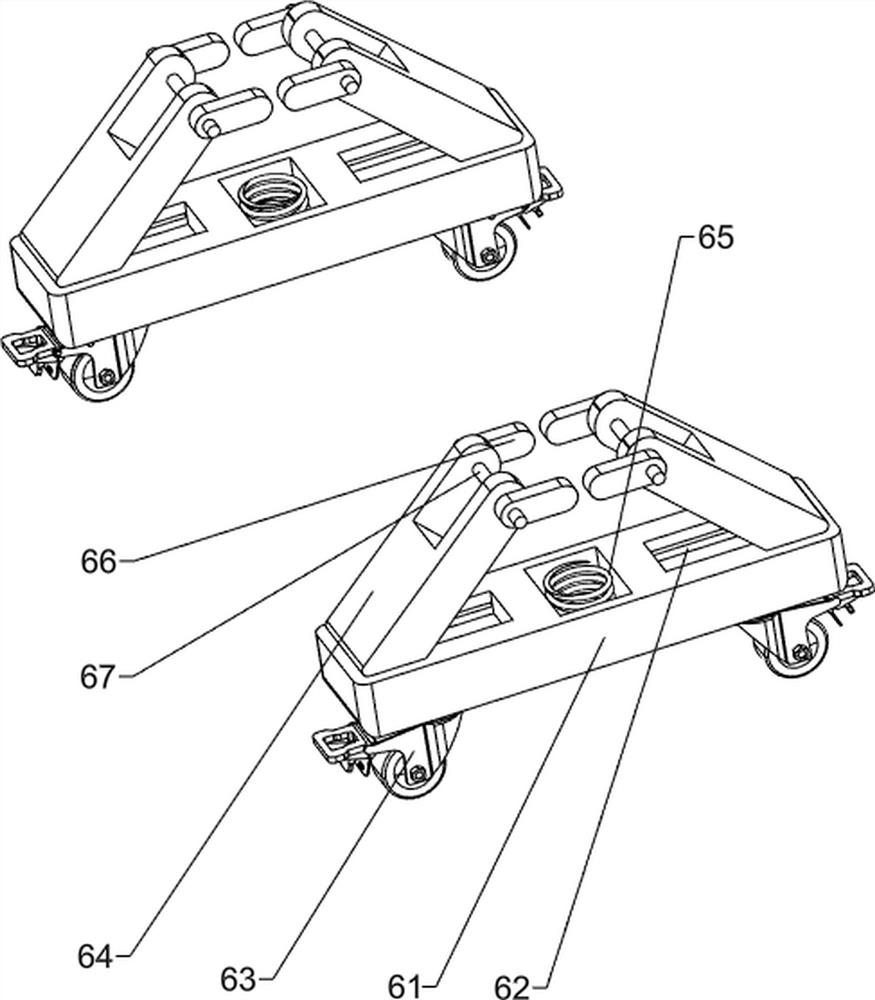

[0025] A paint bucket automatic sealing device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, it includes a fixed frame 1, a motor 2, a positioning frame 3, a sealing pliers 4, a pressing mechanism 5 and a moving mechanism 6, a motor 2 is installed on the top of the fixed frame 1, and a positioning frame 3 is arranged on the lower part of the front side of the fixed frame 1. The upper part of the front side of the fixed frame 1 is provided with a pressing mechanism 5, the pressing mechanism 5 is provided with a sealing pliers 4, the sealing pliers 4 is located above the positioning frame 3, and the bottom of the fixed frame 1 is provided with a moving mechanism 6.

[0026] The sealing efficiency of manual paint buckets is low and the seal is not tight. This equipment can realize automatic sealing with high efficiency and tight seal. Move, thereby make this equipment move, wait for this equipment to move to a large amount of paint ...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 and Figure 6 As shown, a lifting mechanism 7 is also included. The rear portion of the fixed frame 1 is provided with a lifting mechanism 7. The lifting mechanism 7 is connected with the main rotating shaft 510. The lifting mechanism 7 includes a cross bar 71, a second bevel gear set 72, and a rack 73. And the one-way gear 74, fixed frame 1 rear portion rotation type is provided with cross bar 71, is provided with second bevel gear set 72 on the cross bar 71, and second bevel gear set 72 is connected with main rotating shaft 510 bottoms, and cross bar 71 left and right One-way gears 74 are arranged on both sides, and racks 73 are arranged on the left and right sides of the rear portion of the fixed frame 1 , and the racks 73 mesh with the one-way gears 74 .

[0033] When the output shaft at the bottom of the motor 2 rotates to make the main rotating shaft 510 rotate forward, the main rotating shaft 510 rotates to drive the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com