Method of eradicating axial leakage of gear wheel pump

A gear pump, axial technology, applied in pumps, engine seals, rotary piston pumps, etc., can solve problems such as reduction of suction lift, and achieve the effect of reducing suction lift and solving leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

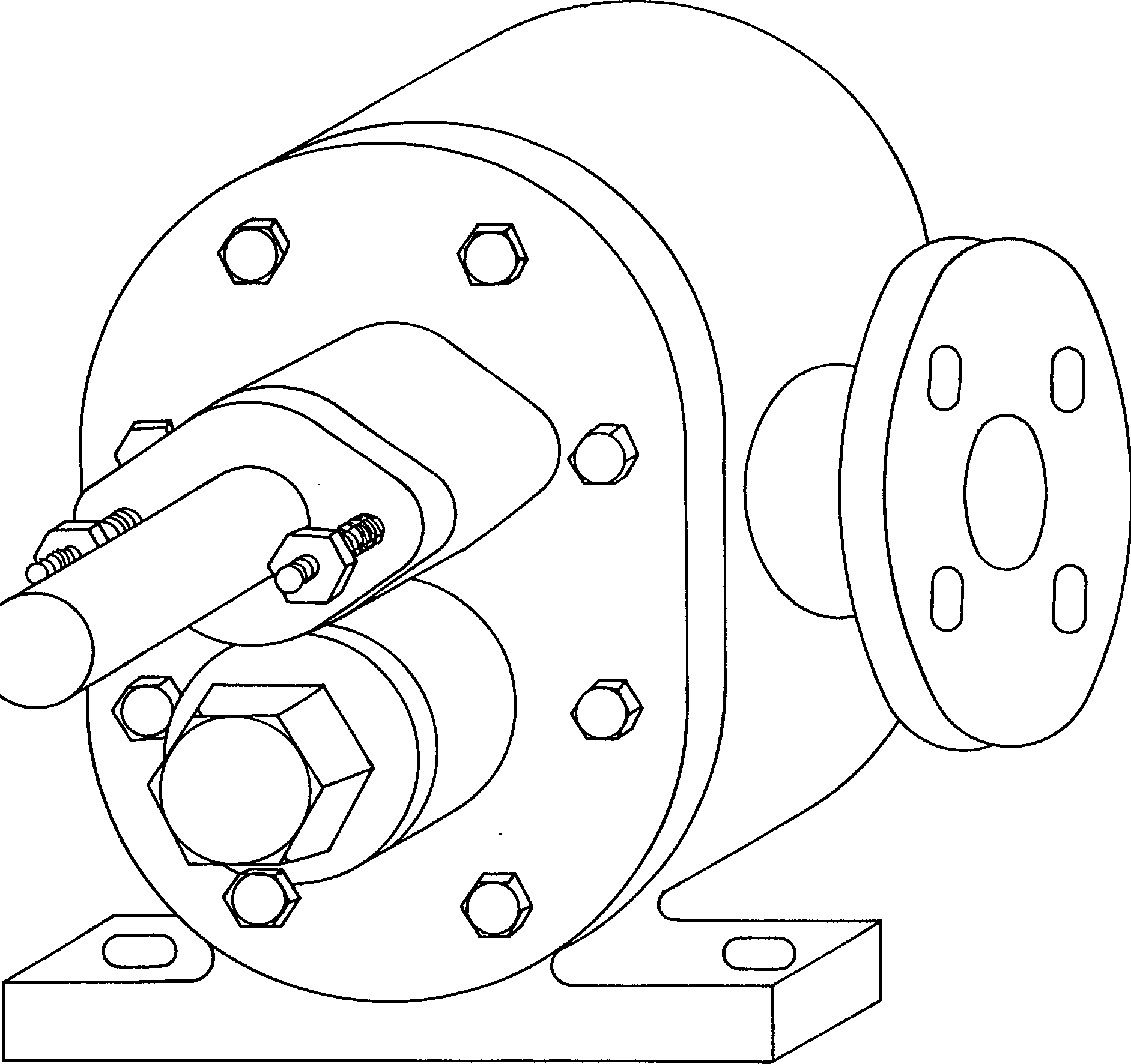

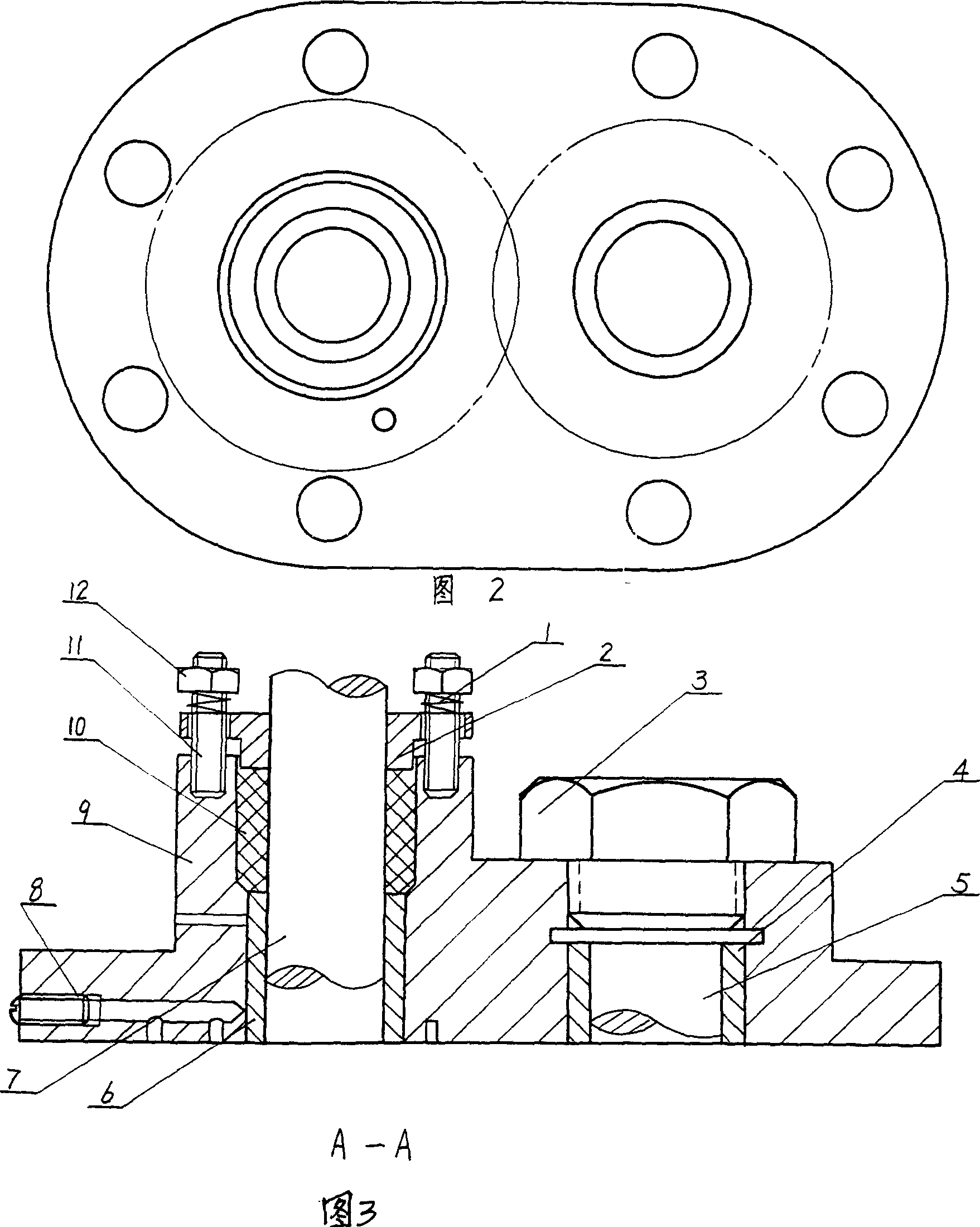

[0011] In the view of Figure 3A-A, add a ring groove concentric with the shaft hole around the inner plane driving wheel shaft hole of the pump cover (9), and drill a deep pump cover vertically within the suction range of the corresponding pump outside the groove For the small hole in the center of the thickness, drill a straight through hole on the outer end surface of the pump cover to connect the small hole in the suction range outside the groove with the annular groove, and plug the hole on the outer end surface of the pump cover with a plug (8). Then put the driving wheel shaft (7) and the driven gear shaft (5) into the left upper sleeve (6) and right upper sleeve (4) respectively, and fix the pump cover (9) to the pump body with bolts Put the sealing material (10) into the stuffing bin, press on the gland (2) of the stuffing bin, then screw on the plugging bolt (11), put on the compression spring (1), tighten with the nut (12), and finally Screw on the blocking nut (3) above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com