Support quick mounting and replacing device and method for quickly mounting and replacing support

A bearing and fast technology, applied in the erection/assembly of bridges, construction, building maintenance, etc., can solve the problems of time-consuming and labor-intensive, the overall deviation of the upper and lower space, and inability to achieve, and achieves excellent anchoring effect, compact structure, and design. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

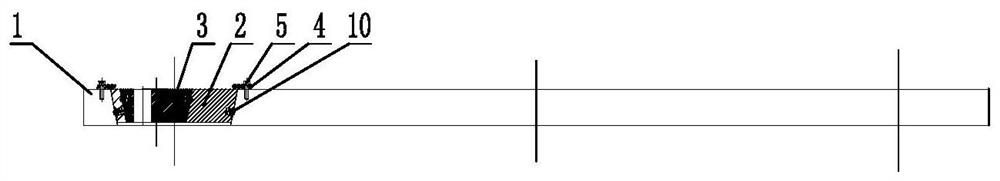

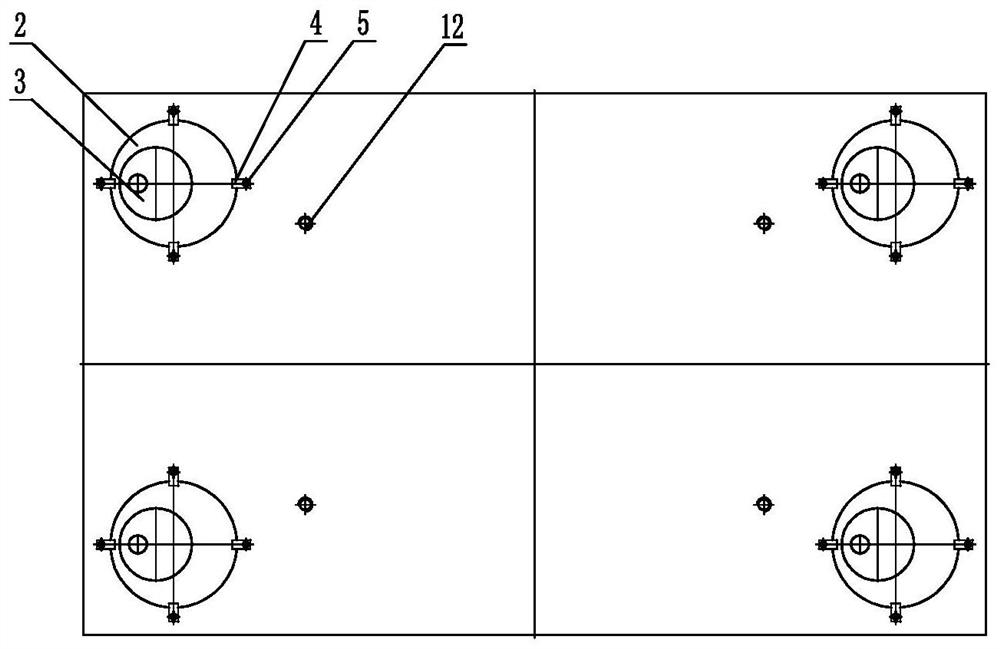

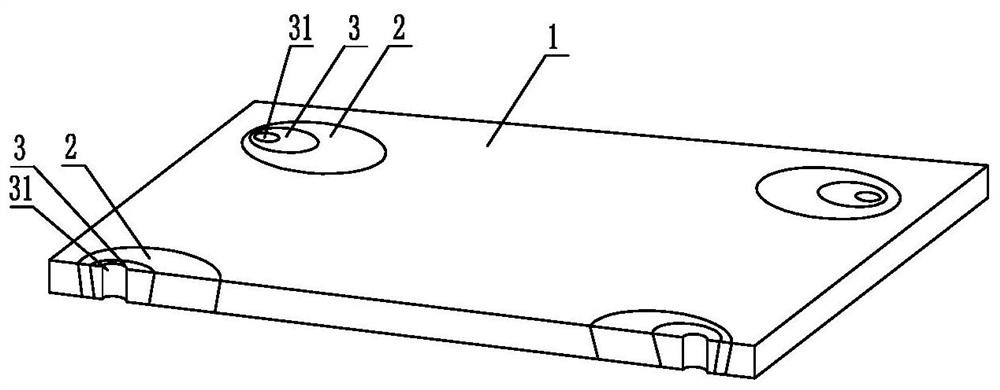

[0050] A fast installation and replacement device for a support, including a base plate 1, an adjustment block 2 and a connection block 3 installed in cooperation with the base plate, the adjustment block is installed in the reserved through hole 11 of the base plate, and the connection block 3 is installed in the adjustment block In the eccentric conical hole 21 of 2, the connecting block 3 has a mounting through hole 31 and a connecting bolt 9, and the adjusting block 2 and the connecting block 3 installed in the reserved through hole 11 of the substrate constitute a quick hole adjustment mechanism ;

[0051] The reserved through hole 11 is a conical through hole. The large orifice of the conical through hole is uniformly arranged on the mounting surface of the substrate, and the small orifice is arranged on the connecting surface of the substrate. The arc surface between is the inner conical surface Ⅰ111;

[0052] The regulating block 2 is a flat conical block installed in...

Embodiment 2

[0061] A method for quick installation and replacement of a support, the method is a method for quickly installing and replacing a support with the quick installation and replacement device for a support described in Embodiment 1: including a method for quickly installing and replacing a prefabricated beam support with the device and a method of quickly replacing old bridge bearings;

[0062] (1) The method for quickly installing a prefabricated beam support with a quick installation and replacement device for a support includes the following steps:

[0063] S1. When the prefabricated beam is prefabricated in the beam yard, a fast installation and replacement device for the support is prefabricated into the beam body. Within the range of 10 times to 20 times of the position, the prefabricated beam support can be installed to the set position of the prefabricated beam body and pier);

[0064] S2. Connect a support quick installation and replacement device at the design positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com