A sound insulation wall for building municipal engineering construction

A technology of engineering construction and sound insulation wall, which is applied in the direction of buildings, building types, noise absorption devices, etc., can solve the problems of cumbersome installation and disassembly, low efficiency, waste of time, etc., and achieve easy disassembly and recycling, convenient installation and disassembly, and guarantee The effect of translucency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

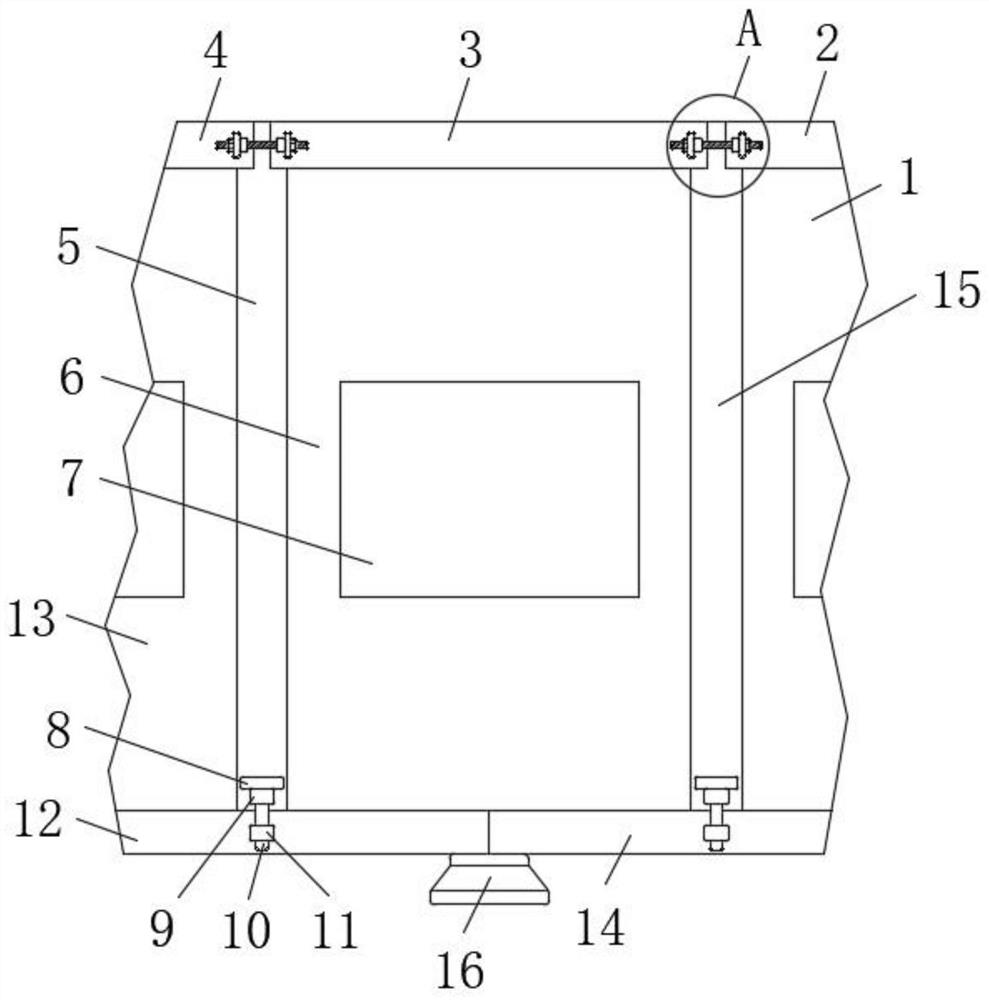

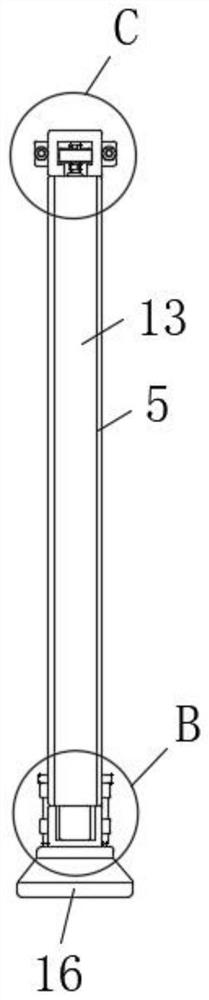

[0036] see figure 1 , figure 2 , Figure 9 and Figure 10 Shown: a sound insulation wall for building municipal engineering construction, including a first bottom plate 12, the upper surface wall of the first bottom plate 12 is provided with a chute 29, and by setting the chute 29, the first slider 31 can slide Sliding in the groove 29 pushes the first soundproof wall 13, the first soundproof wall 13 slides in the chute 29 through the second slider 30, splices the first soundproof wall 13 and the first bottom plate 12, and pushes the first support plate 5, the first support plate 5 slides in the chute 29 through the first slider 31, pushes it to the designated position, inserts the clamping rod 10 into the second clamping sleeve 11, and limits and fixes the first support plate 5, which is convenient for Disassemble and recycle, so that the first support plate 5 can move on the upper surface wall of the first bottom plate 12, one end of the first bottom plate 12 is butted w...

Embodiment 2

[0044] A soundproof wall for building and municipal engineering construction, which is different from Embodiment 1 in that, please refer to image 3 , Figure 4 and Figure 5 Shown: the upper surface wall of the first sound insulation wall 13 is movably connected with the first top plate 4 through the movable device, and the lower wall of the first top plate 4 is provided with a slide rail 25. It is worth noting that the first sound insulation is pushed The wall 13, the first soundproof wall 13 rolls in the slide rail 25 through the roller 26, and the first soundproof wall 13 is spliced with the first top plate 4, and one end of the first top plate 4 is overlapped with one side of the baffle 32, so The baffle 32 is fixedly connected to the upper surface wall of the first support plate 5 , and the other side of the baffle 32 overlaps with the second top plate 3 to push the first soundproof wall 13 , and the first soundproof wall 13 slides through the rollers 26 . The rail 2...

Embodiment 3

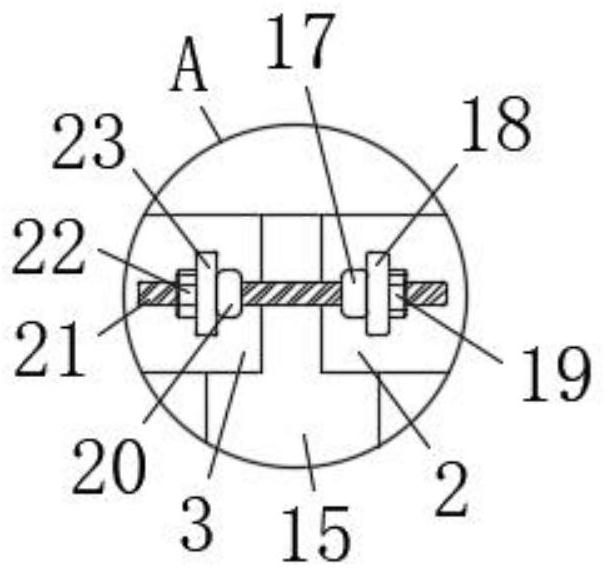

[0050] A soundproof wall for building and municipal engineering construction, which is different from Embodiment 1 in that, please refer to Image 6 , Figure 7 and Figure 8 Shown: the other side of the second support plate 15 is overlapped with the third top plate 2, a second sound insulation wall 6 is arranged between the first support and the second support plate 15, and the second support plate 15 A third soundproof wall 1 is provided on one side of the frame, push the first soundproof wall 13, the first soundproof wall 13 rolls in the slide rail 25 through the roller 26, and the first soundproof wall 13 is spliced with the first top plate 4, the first top plate 4 and the second top plate 3 are fixed by the threaded rod 21, the first nut 22 and the second nut 19, and the first soundproof wall 13, the second soundproof wall 6 and the third soundproof wall 1 are more convenient to install and disassemble by splicing and fixing, which is convenient for After being recycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com