A method and system for realizing the visualization of the operating point of an axial flow fan

An axial flow fan, working point technology, applied in wind power generation, mechanical equipment, machines/engines, etc., can solve the problems of fan surge, stall, unfavorable to the stable and economic operation of the fan and its associated system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

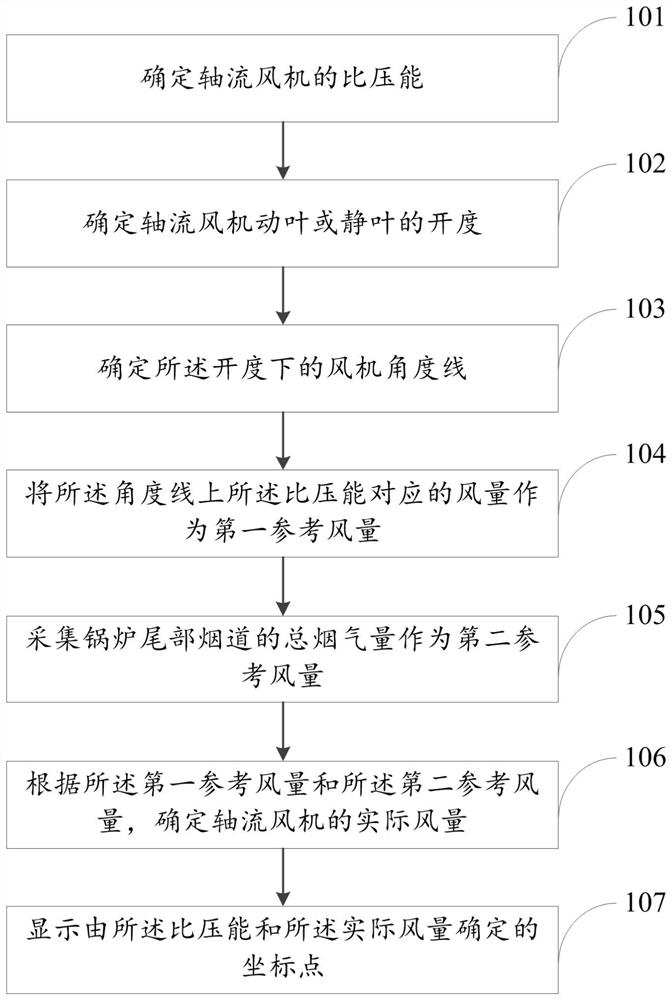

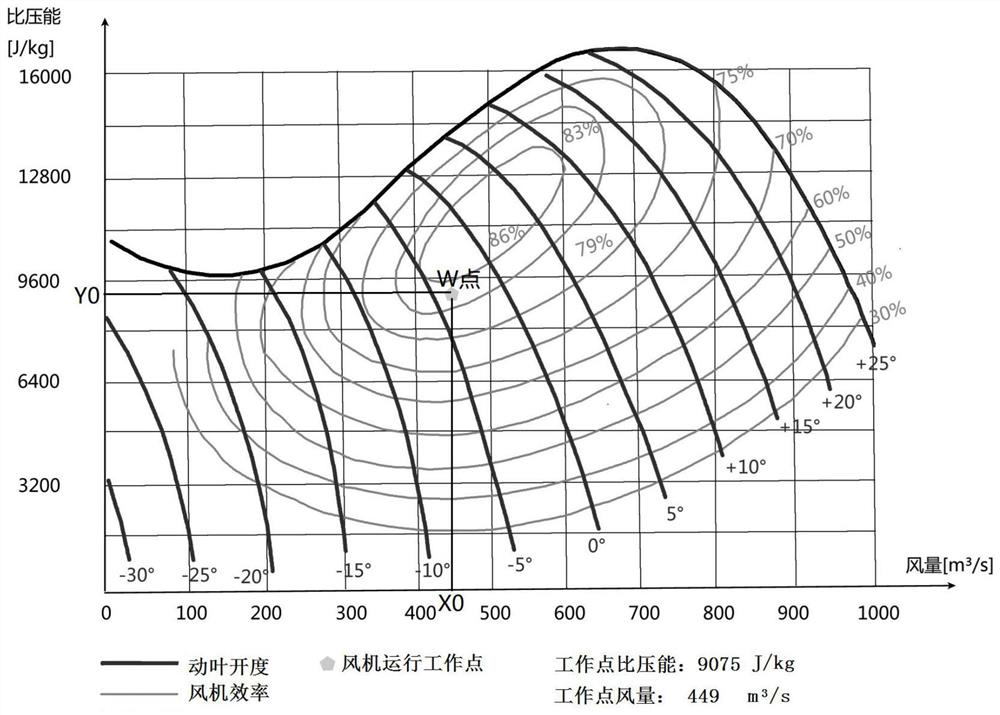

[0050] see figure 1 , this embodiment provides a method for realizing the visualization of the operating point of the axial flow fan, the method includes the following steps:

[0051] Step 101: Determine the specific pressure energy of the axial flow fan.

[0052] In practical applications, the inlet wind pressure, outlet wind pressure and flue gas temperature of the axial flow fan are collected online in real time, and are calculated according to the formula Calculate the specific pressure energy of the axial flow fan in real time, where, ΔP=P o -P i , ΔP is the differential pressure of the axial flow fan, P o is the outlet air pressure of the axial flow fan, P i is the inlet wind pressure of the axial flow fan, ρ is the density of flue gas, ρ 0 The flue gas apparent density is designed for the boiler, and t is the inlet flue gas temperature of the axial flow fan.

[0053] Step 102: Determine the opening m of the rotor blades or stationary blades of the axial flow fa...

Embodiment 2

[0070] see Figure 4 , this embodiment provides a system for realizing the visualization of the operating point of the axial flow fan, the system includes:

[0071] The specific pressure energy determination module 401 is used to determine the specific pressure energy of the axial flow fan;

[0072] The blade opening degree determination module 402 is used to determine the opening degree of the rotor blade or stator blade of the axial flow fan;

[0073] An angle line determining module 403, configured to determine the fan angle line under the opening degree;

[0074] The first reference air volume determination module 404 is configured to use the air volume corresponding to the specific pressure energy on the angle line as the first reference air volume;

[0075] The second reference air volume determination module 405 is used to collect the total flue gas volume of the tail flue of the boiler as the second reference air volume;

[0076] An actual air volume determination m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com