Tool for measuring size of automobile suspension

A vehicle suspension and suspension technology, which is applied in the direction of measuring devices, manufacturing tools, workpiece clamping devices, etc., can solve the problems of hole distance measurement error, limited clamping surface, and downward movement of the support arm, so as to improve the measurement accuracy, The effect of preventing the suspension from tilting and avoiding measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

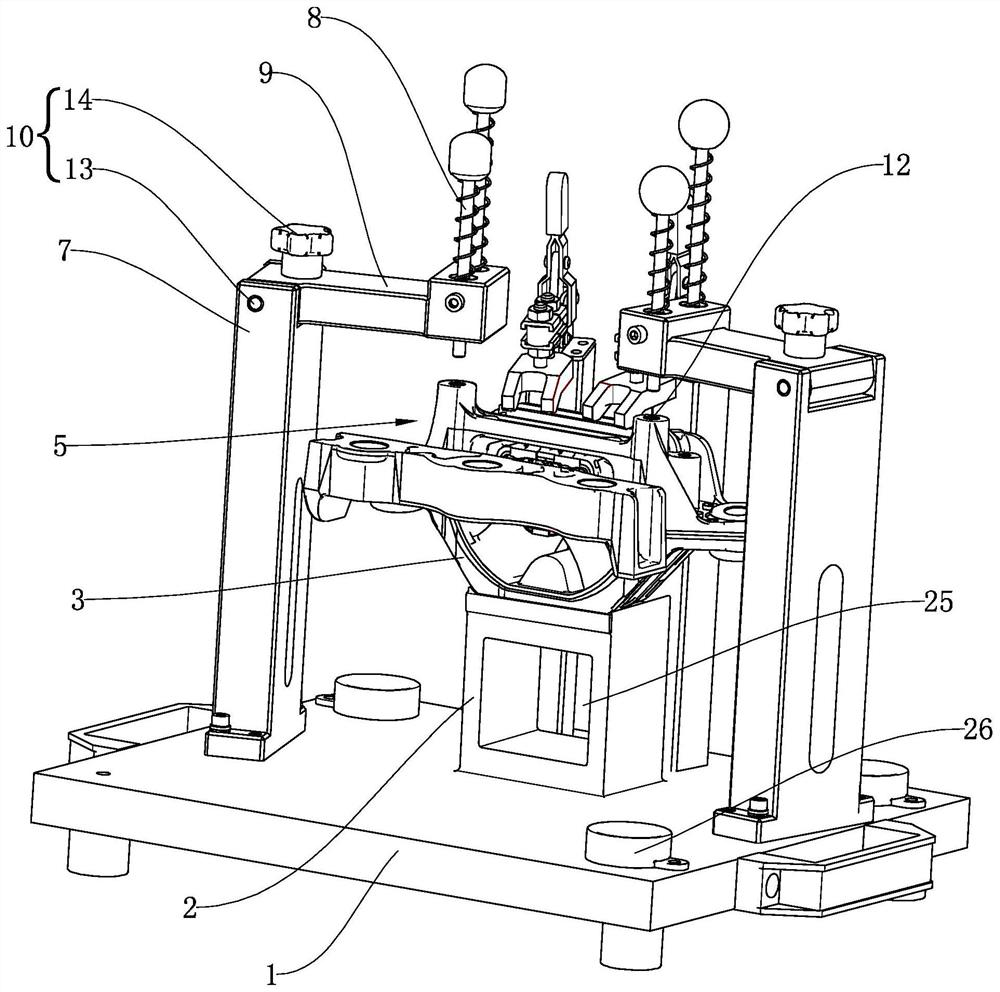

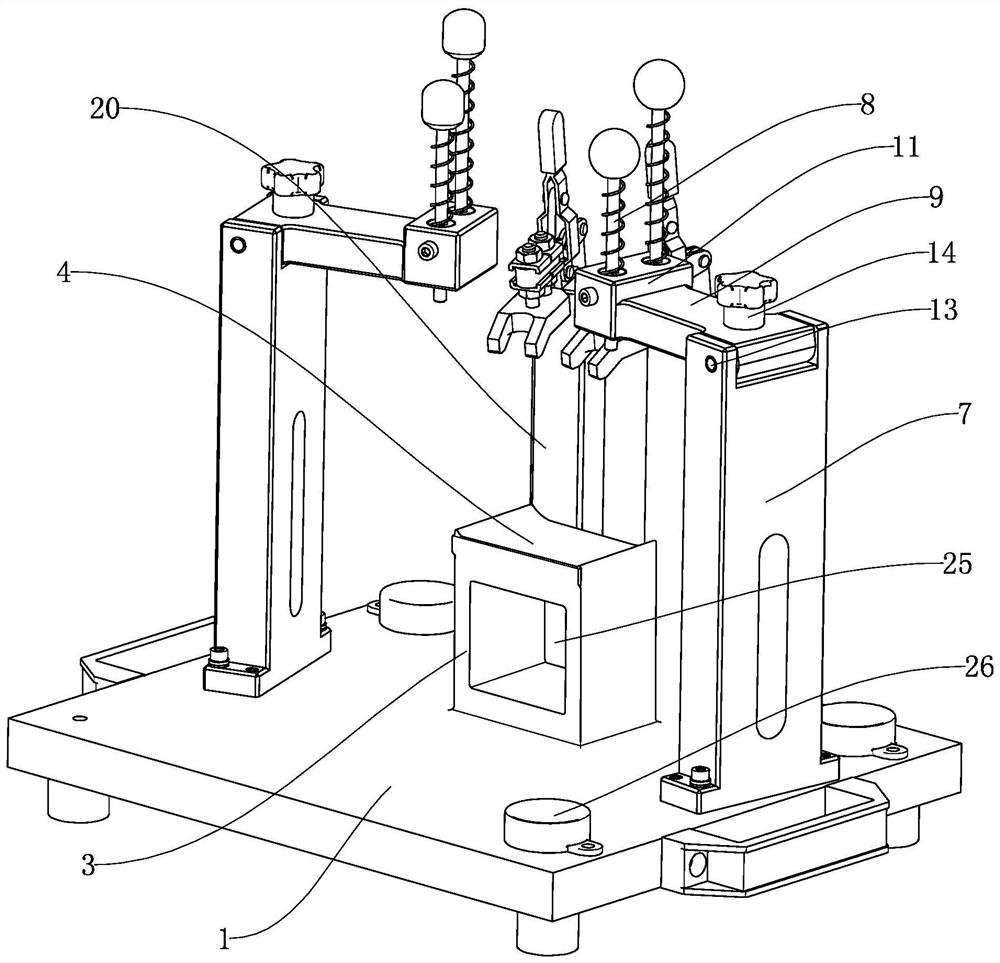

[0025] Embodiment one: if Figure 1-Figure 2 As shown, a tool for measuring the size of an automobile mount, comprising: a base 1;

[0026] The suspension limit seat 2 is fixed on the base 1, the upper top surface of the suspension limit seat 2 is provided with a limit groove 4 matching the suspension lower shell 3, and the suspension 5 Place it horizontally on the suspension limit seat 2 by inserting the suspension lower shell 3 into the limit groove 4;

[0027] A pressing mechanism, the pressing mechanism is arranged on the rear side of the suspension limit seat 2, and is used to press the suspension 5 on the suspension limit seat 2;

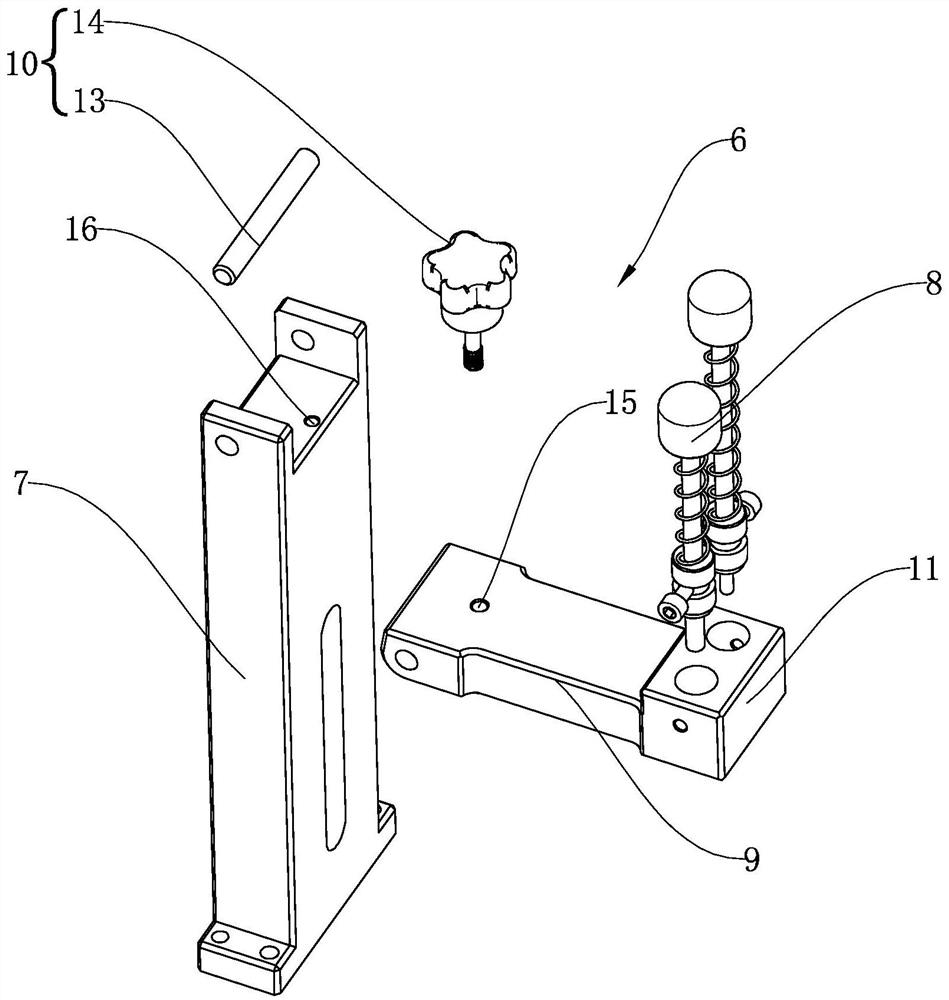

[0028] The pre-compression mechanism includes pre-compression components 6 symmetrically arranged on both sides of the suspension limit seat 2, and is used to initially compress the suspension 5 on the suspension limit seat 2. After the compression mechanism compresses the suspension 5 , the preload assembly 6 resets.

[0029] Other structu...

Embodiment 3

[0030] Embodiment three: other structures are identical with embodiment two, and its difference is: as Figure 4 As shown, the pressing mechanism includes two sets of pressing assemblies 17. The pressing assembly 17 includes a pressure head 18, a pressure head mounting seat 19 and a vertical rod 20 fixed on the base 1. The top of the vertical rod 20 faces the suspension limit seat. 2 Oblique setting, the indenter mounting seat 19 includes the indenter connecting arm 21, the support 22 and the clamping piece 23 for clamping and fixing the indenter connecting arm 21 on the support 22, and the support 22 is fixed on the vertical rod 20 On the top surface, the rear end of the pressure head connecting arm 21 is hinged with the support 22, the lower end of the clamping part 23 is hinged with the support 22, and the pressure head 18 is detachably fixed on the pressure head connection arm 21 by fasteners , When pressing, the free end of the pressure head 18 presses the middle part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com