A method for measuring the glass transition temperature of filler-containing polymers

A glass transition and polymer technology, applied in the direction of material thermal development, investigation stage/state change, etc., can solve the problems of Tan-Delta temperature change curve fluctuation, inability to obtain glass transition temperature, difficult to obtain, etc., to achieve stability Effect of Glass Transition Temperature

Active Publication Date: 2022-05-06

XI AN JIAOTONG UNIV

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

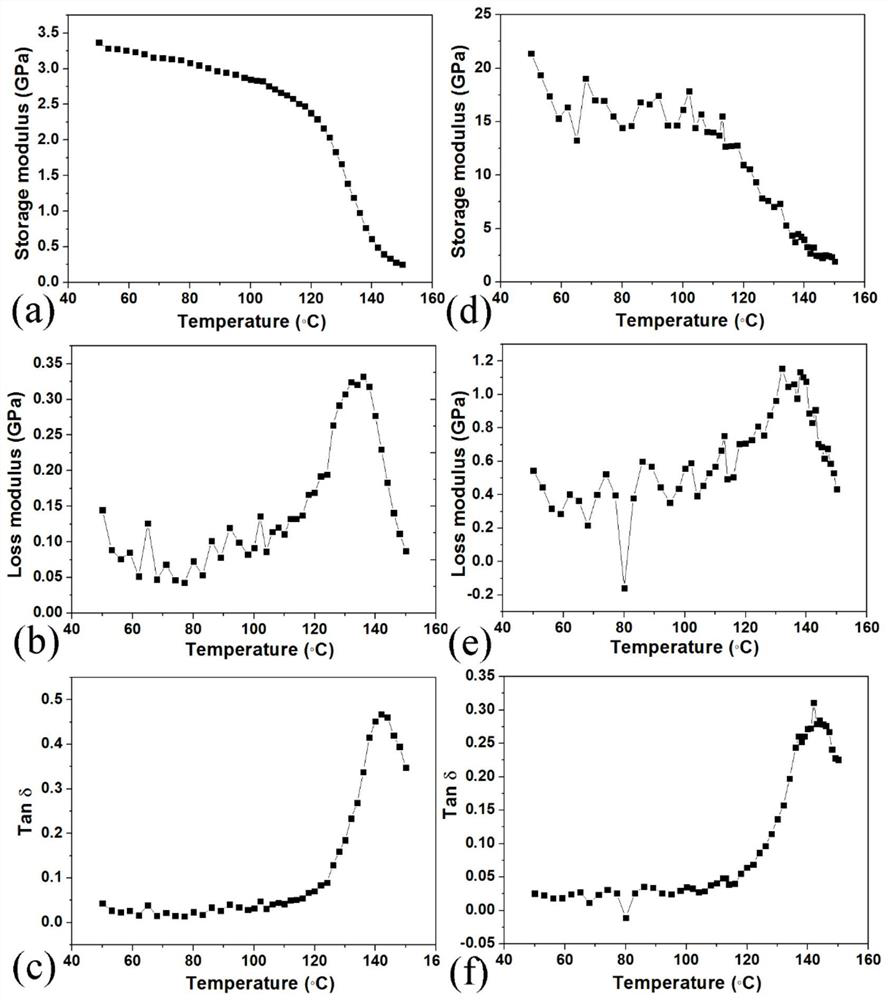

However, for micro-nano-scale polymer materials containing fillers, especially when the fillers are of different sizes and unevenly distributed, there are large differences in the storage modulus, loss modulus and even Tan-Delta measured at different positions of the sample. Using this method The obtained storage modulus, loss modulus and Tan-Delta curves vary greatly with temperature, and it is difficult or even impossible to obtain an accurate glass transition temperature

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

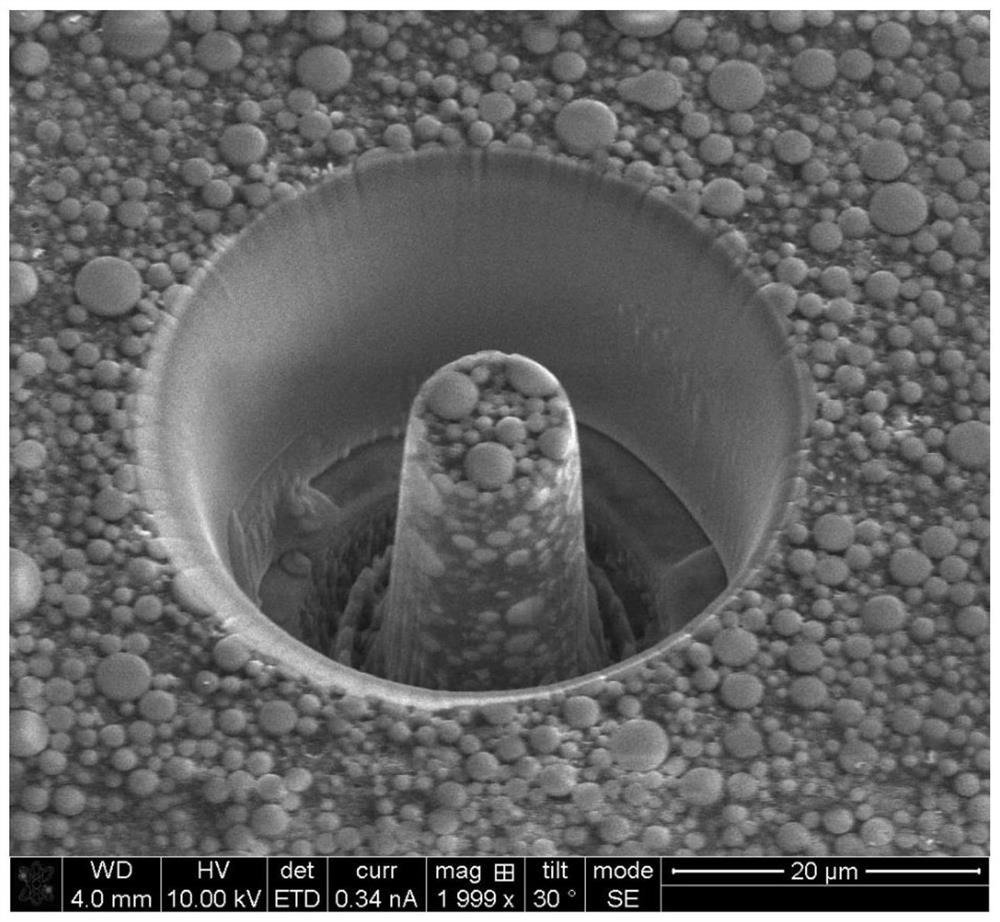

[0028] Example 1: Glass transition temperature test specimen of micron-scale underfill (epoxy resin containing silica filler) sample:

[0029] Underfill (Epoxy Resin with Silica Filler)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for measuring the glass transition temperature of a filler-containing polymer. The glass transition temperature of a filler-containing polymer is measured by using the dynamic mechanical analysis function of a nanomechanical tester combined with a heating platform, and a smooth temperature can be obtained. Storage modulus-temperature curve, loss modulus-temperature curve, and ratio of loss modulus to storage modulus-temperature curve, and then obtain accurate glass transition temperature according to the definition of glass transition temperature. This method has good application prospects in the fields of polymer material application, glass transition temperature measurement and so on.

Description

technical field [0001] The invention relates to the technical field of glass transition temperature evaluation, in particular to a method for measuring the glass transition temperature of filler-containing polymers. Background technique [0002] Glass transition is an inherent property of amorphous polymer materials, glass transition temperature (T g ) is one of the characteristic temperatures of polymer materials, which directly affects the use performance and process performance of materials, and determines the use temperature of materials, so it has been an important content of polymer physics research for a long time. When the glass transition occurs, many physical properties, especially the mechanical properties, will change drastically, and the polymer will change from a rigid glass state to a soft rubber state. In principle, all physical properties that change abruptly or discontinuously during the glass transition, such as modulus, specific heat, thermal expansion c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N25/12G01N25/20

CPCG01N25/12G01N25/20

Inventor 秦元斌解德刚单智伟付琴琴

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com