Method for determining glass-transition temperature of polymer film

A glass transition and polymer technology, applied in the investigation stage/state change, etc., to achieve good accuracy, good repeatability, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

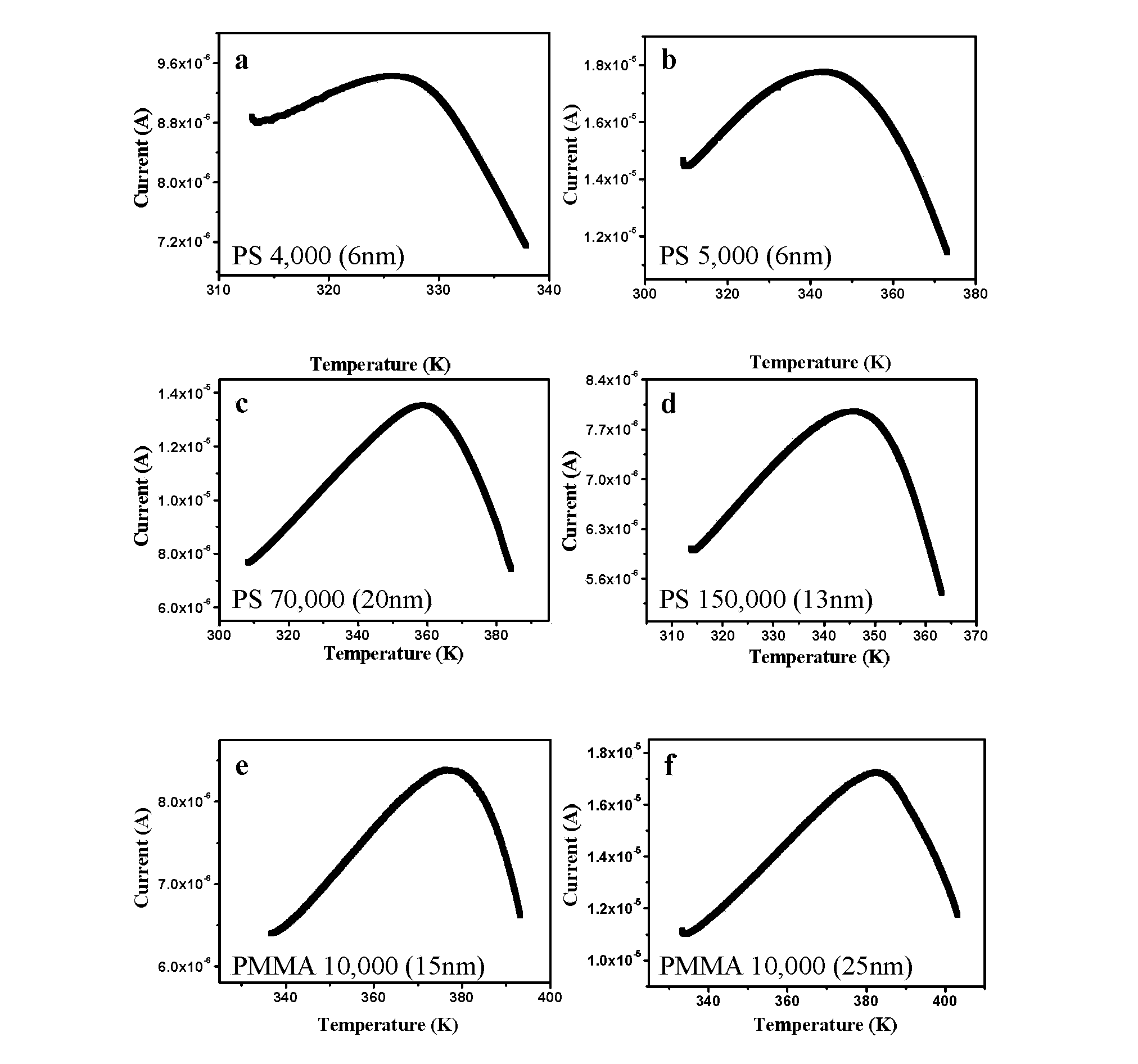

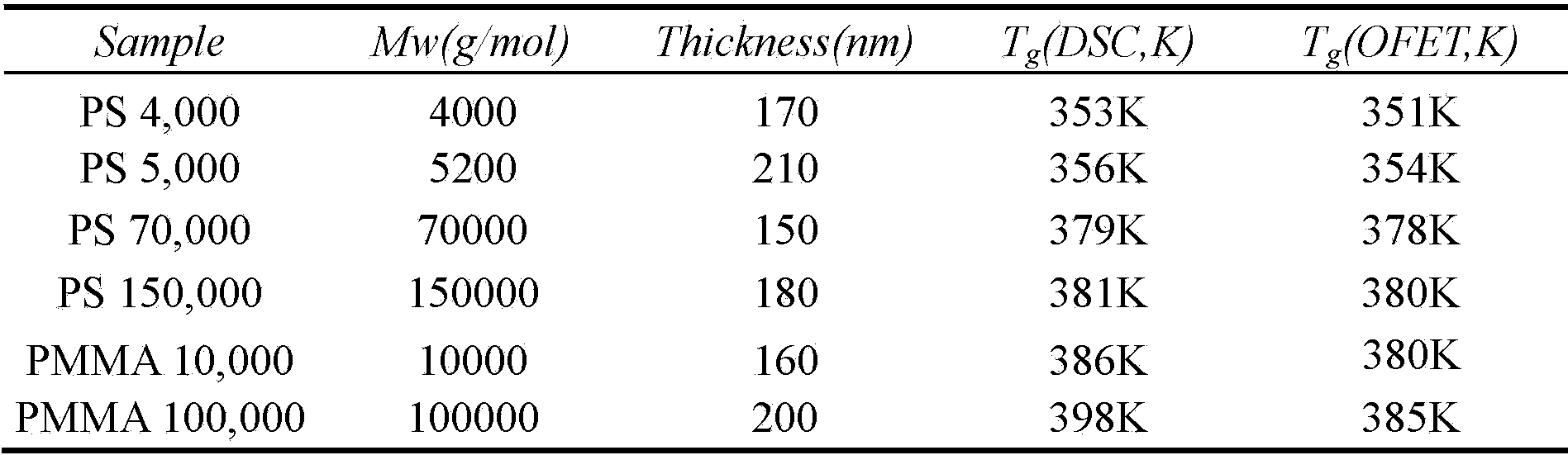

[0034] The organic field effect transistor device is placed on the Keithley 4200 micro-operation probe station equipped with a hot stage, and the output curve of the source and drain current changes with temperature. The gate voltage is constant at -60V, and the source and drain voltage is constant at -45V. The source-drain current output curve of the organic field effect transistor in the heating process, the temperature corresponding to the turning point of the source-drain current output curve is the glass transition temperature of the polymer sample to be tested.

[0035] Wherein, the material constituting the polymer thin film layer of the organic field effect transistor is a polymer sample to be tested.

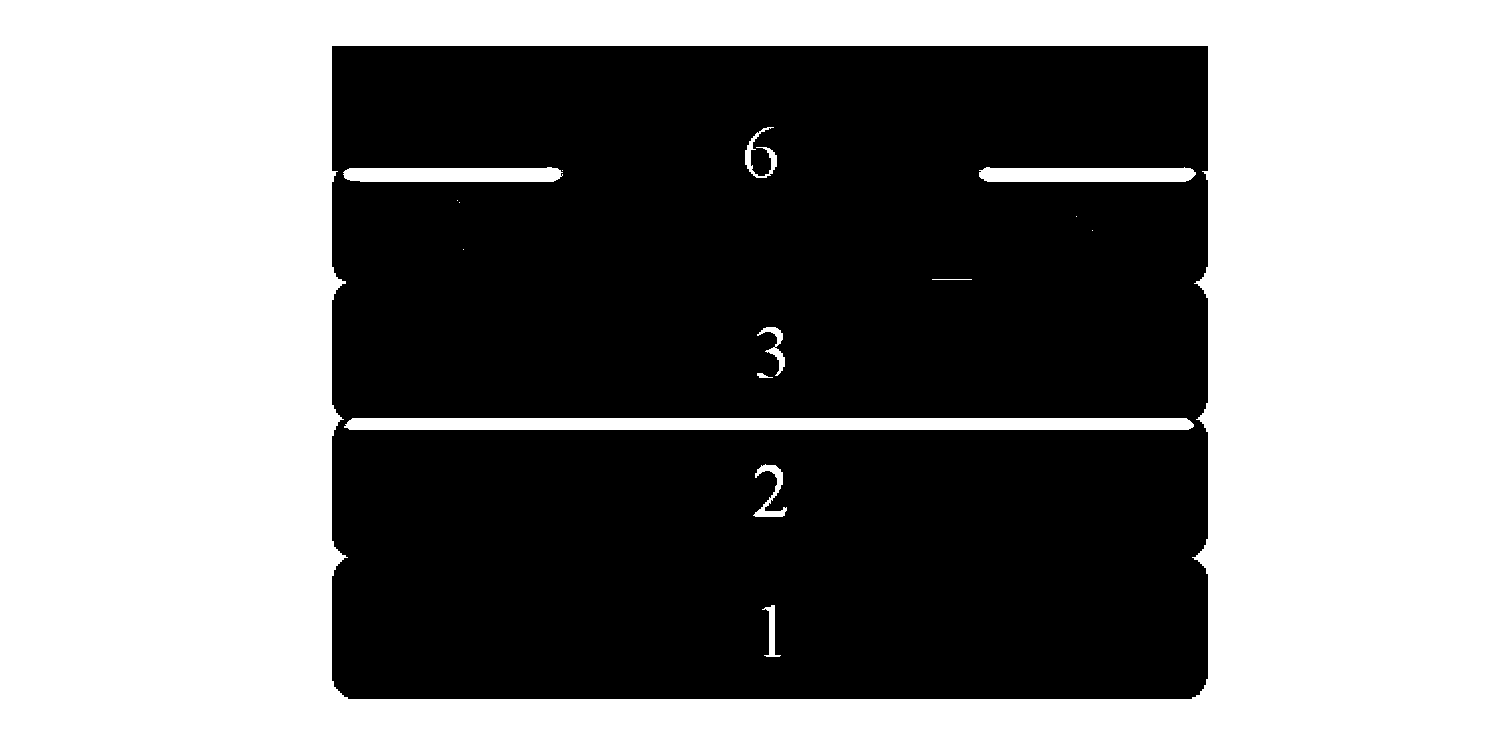

[0036] The structure diagram of the organic field effect transistor is shown in figure 1 shown. Wherein, 1 is the gate electrode (silicon wafer) with inorganic insulating layer (silicon dioxide), 2 is the polymer thin film layer (that is, the polymer sample to be teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com