Method and device for measuring glass transition temperature of resin casting body

A glass transition and resin casting technology, applied in the investigation phase/state change and other directions, can solve the problems of high cost, low demand and complexity, and achieve the effect of low equipment cost, small reading error and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

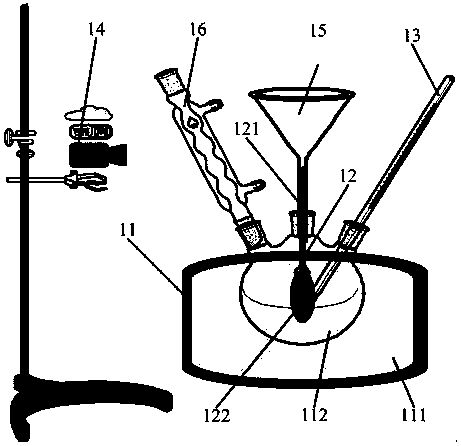

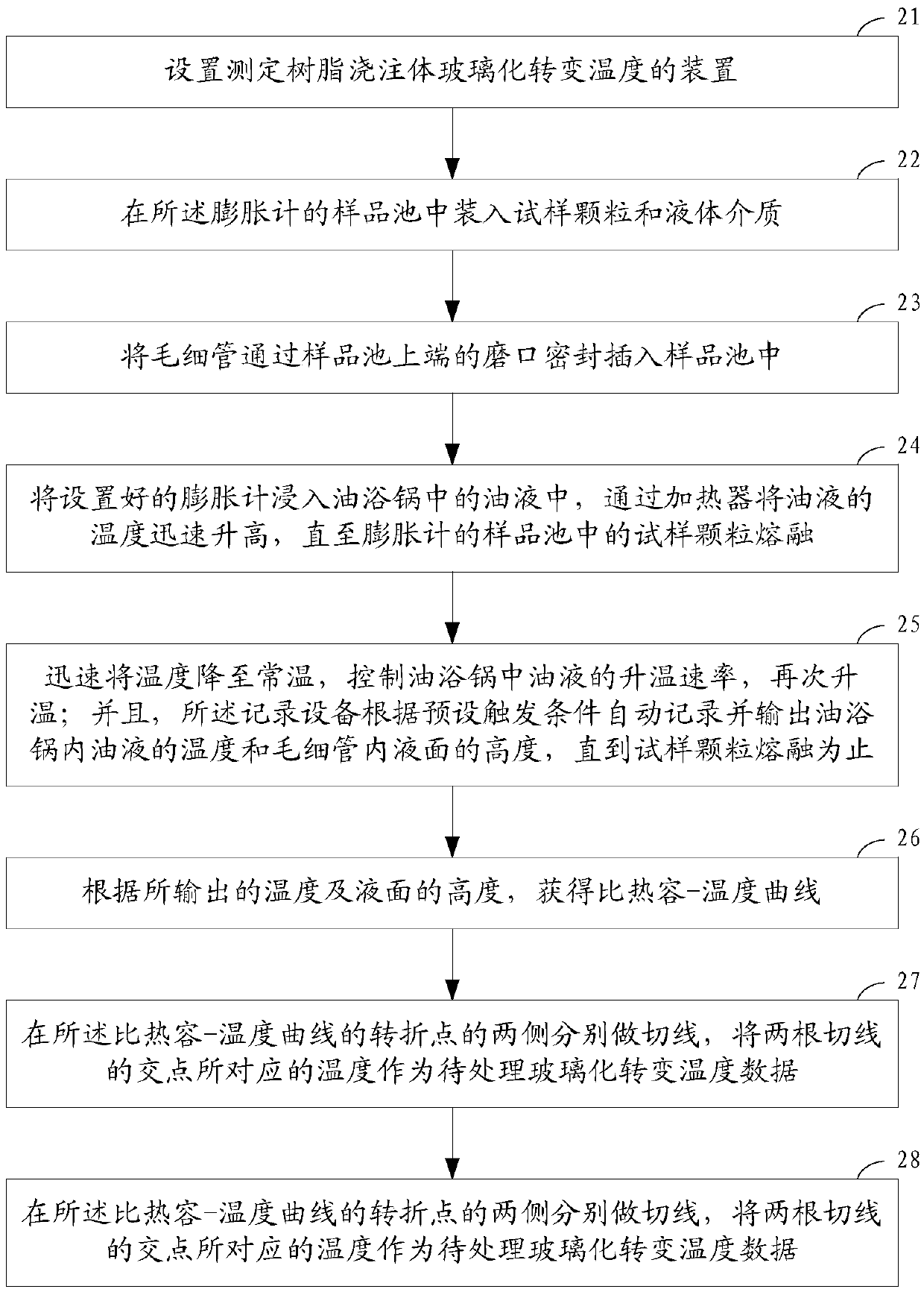

[0043] figure 1 It is a structural schematic diagram of a device for measuring the glass transition temperature of a cast resin body in an embodiment of the present invention. Such as figure 1 As shown, the device for measuring the glass transition temperature of the cast resin in the embodiment of the present invention includes: an oil bath 11, a dilatometer 12, a thermometer 13 and a recording device 14;

[0044] The oil bath pot 11 includes a heater 111 and a pot 112 body, the pot body 112 is provided with oil, and the heater 111 is used to add the pot body 112, so that the temperature of the oil liquid remains preset constant temperature;

[0045] The dilatometer 12 includes a capillary 121 and a sample cell 122, the upper end of the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com