Sealing insulation structure for underground high-current female joint

A sealed insulation, high current technology, applied in the direction of fixed/insulated contact members, circuits, connections, etc., can solve problems such as unsatisfactory reliability and complex structure, improve workability, reduce wall thickness, and improve insulation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

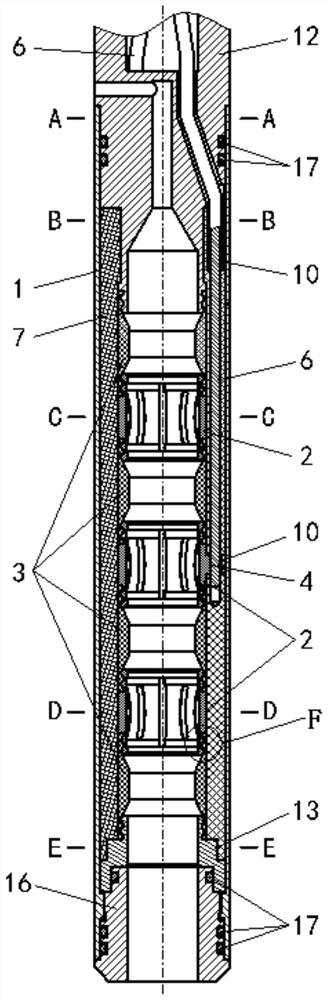

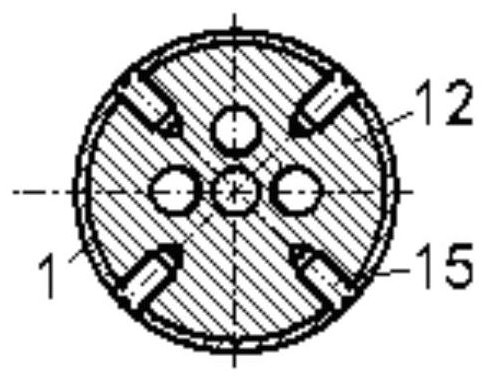

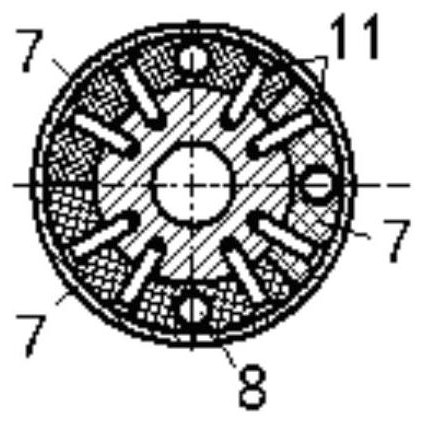

[0028] This example Figure 1 to Figure 12 As shown, the present invention will be described in detail by taking the sealing and insulating structure for a high-current female joint connecting three wires as an example.

[0029] In this example, three electrified rings 2 are used, and the three electrified rings 2 are evenly distributed along the axial direction of the outer tube 1. Both ends of the three electrified rings 2 are separated by a sealing insulating ring 3, and the electrified rings above the top electrified ring 2 and the bottom electrified ring 2 below is also provided with sealing insulation ring 3. A trapezoidal ring groove 14 is crimped between the live ring 2 of metal structure and the sealing insulating ring 3 of non-metal structure to form an integral sealing structure. Each electrified ring 2 is provided with a connecting ear 4 for connecting to the wire 6, and the connecting ear 4 on the three electrified rings 2 is arranged in a staggered manner, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com