A New Energy Vehicle Electric Drive System with Auxiliary Heat Dissipation

A new energy vehicle, auxiliary cooling technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the influence of the internal structure and performance of the motor, the service life of the motor, the motor housing without independent heat dissipation, the failure of the motor, etc. problem, to achieve the effect of simple structure, efficient heat dissipation, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

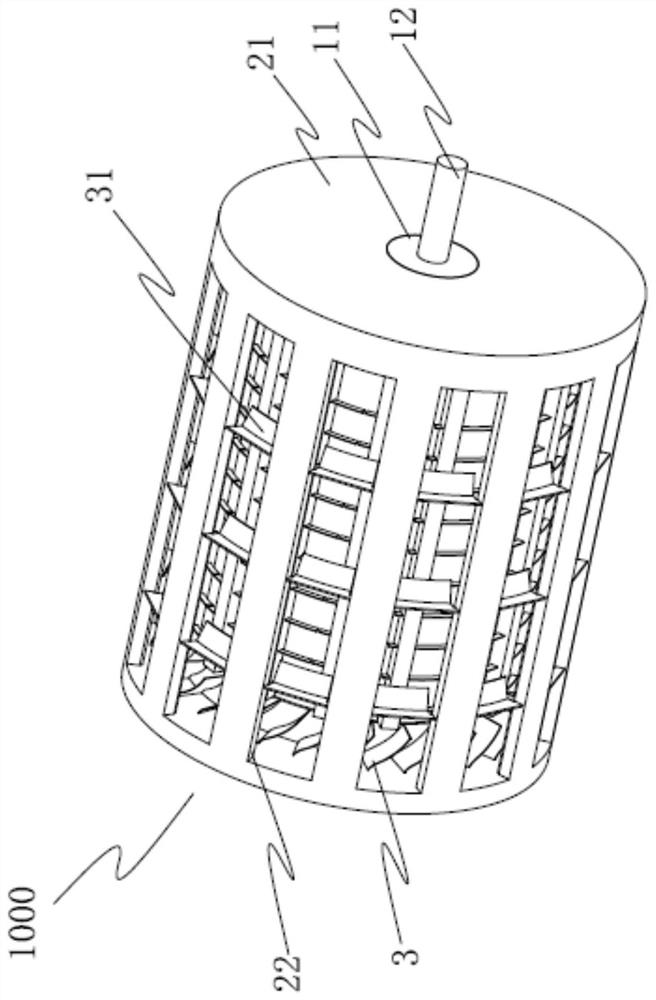

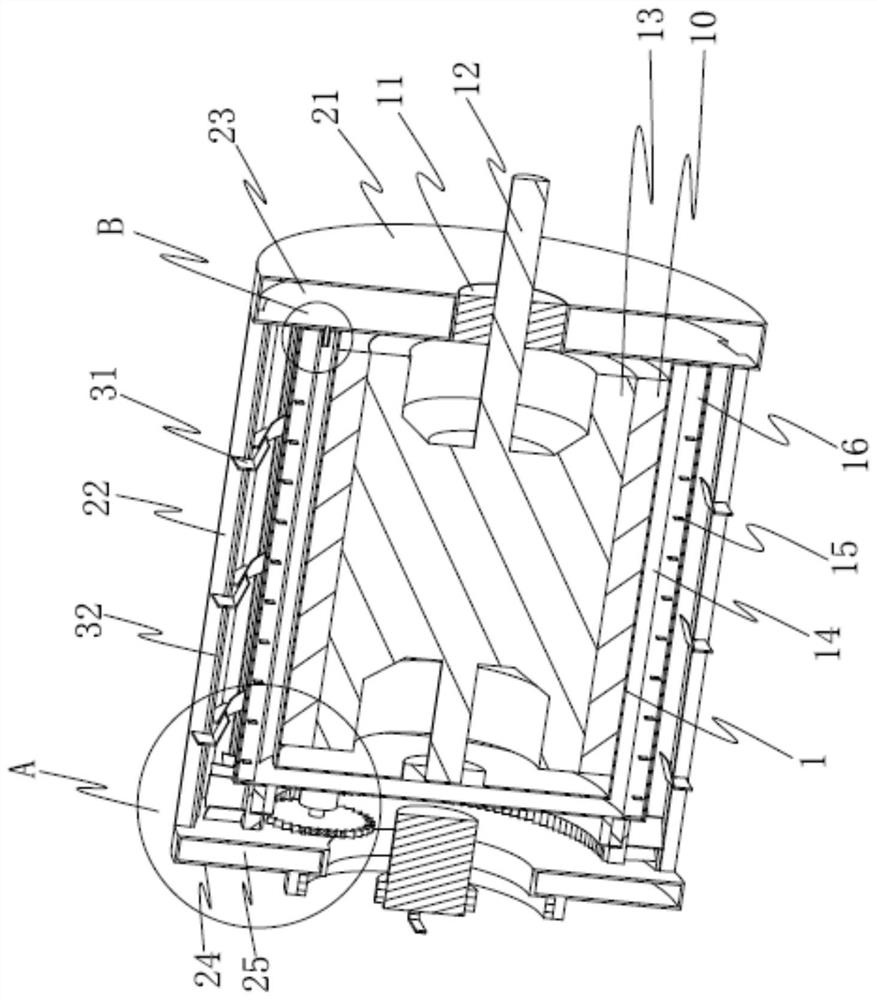

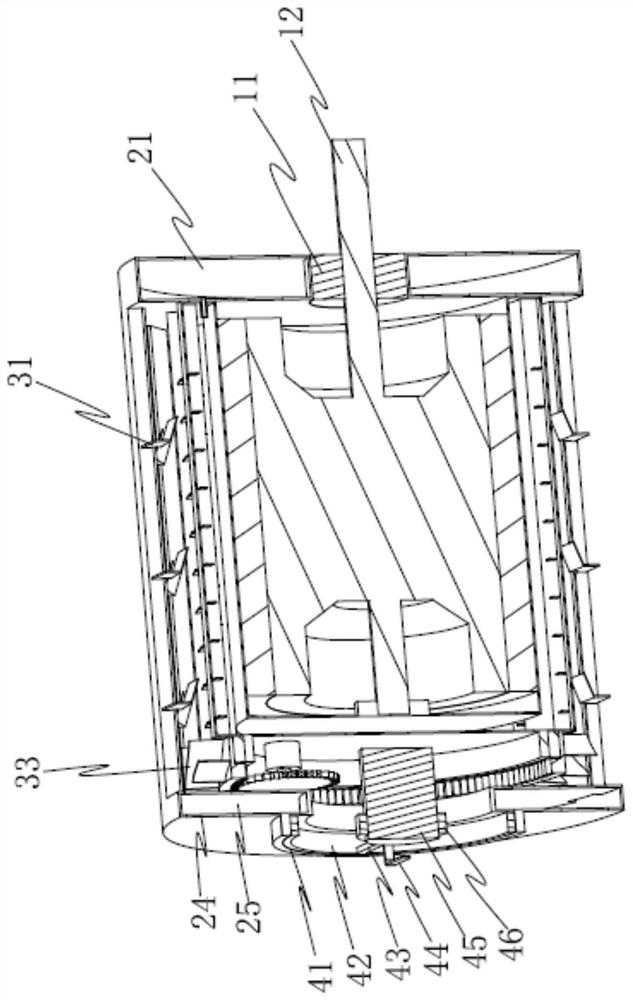

[0022] see Figure 1-Figure 7 , a new energy vehicle electric drive system for auxiliary heat dissipation, including a drive motor 1000 and a transmission mechanism, the drive motor 1000 is connected to the transmission mechanism, the drive motor 1000 includes a motor housing 1, and the motor housing 1 is provided with a stator 10, the stator 10 is provided with a rotor 13, the rotor 13 is connected with a rotating shaft 12, the front end of the motor housing 1 is opened, and the motor housing 1 is provided with a The first annular cooling chamber 14 is provided with a front cover 21 at the front end of the motor housing 1, and a shaft hole 211 is provided on the front cover 21, and a first bearing 11 is provided in the shaft hole 211. The rotating shaft 12 extends forward through the first bearing 11, and a second annular cooling chamber 23 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com