Machine tool

A technology of machine tool and holding mechanism, which is applied in the direction of metal processing machinery parts, accessories of tool holders, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings.

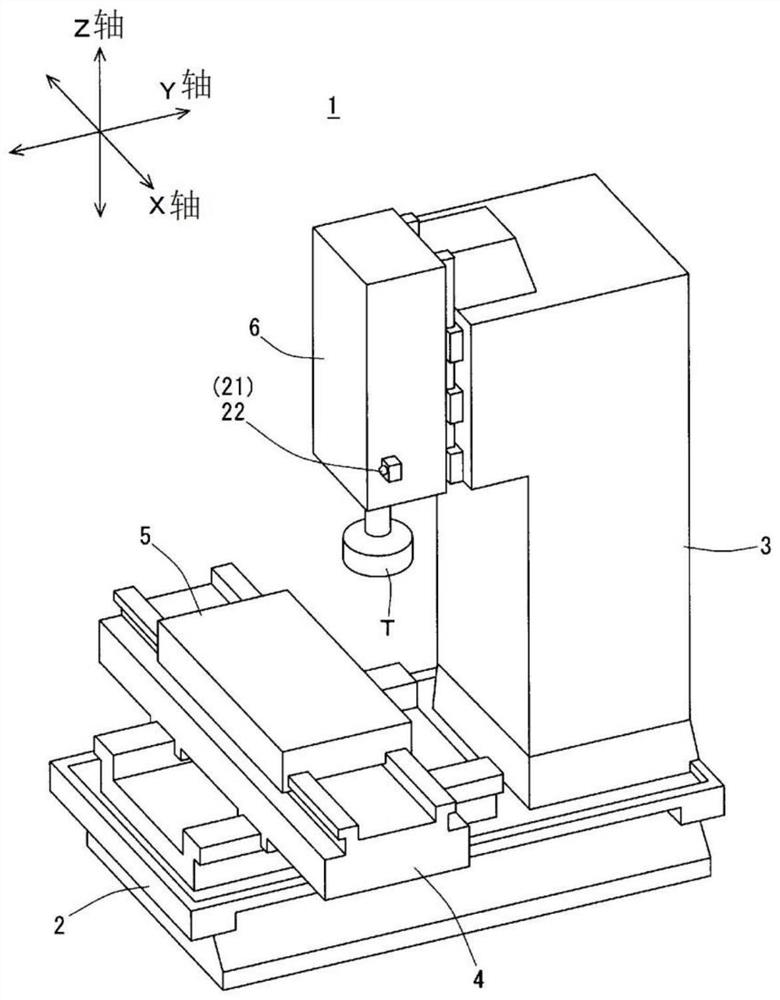

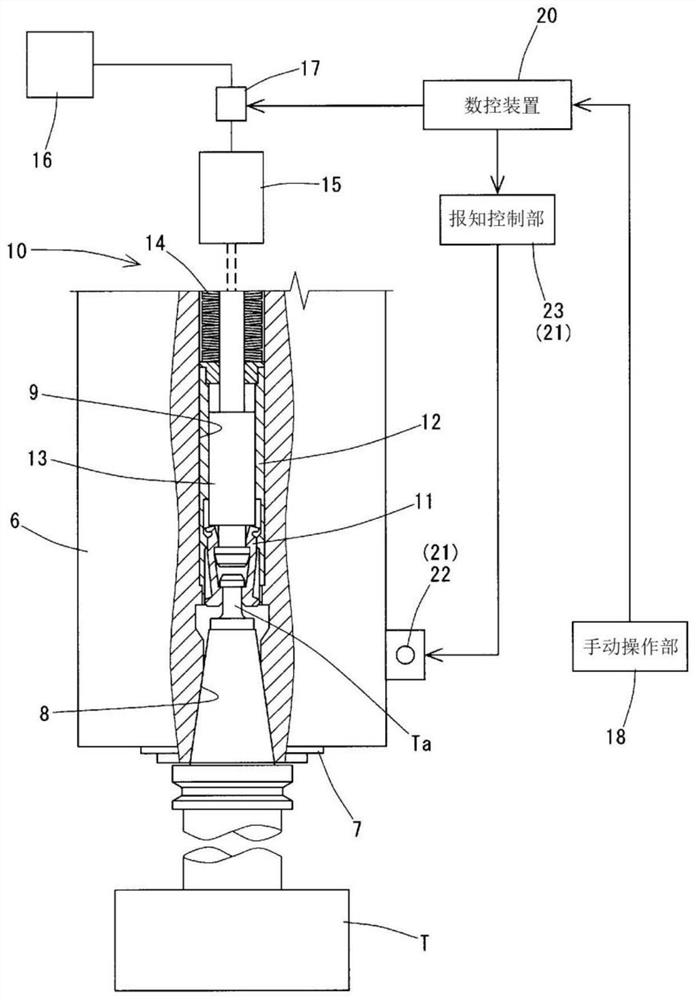

[0048] like figure 1 As shown, the machine tool 1 of this example is a vertical machining center, possessing the figure 1 The machine base 2 shown, the column 3 erected on the machine base 2, the bed saddle 4 that can be moved on the machine base 2 in the Y-axis direction, and the bed saddle 4 that can be moved in the X-axis direction The table 5 on the top, and the spindle head 6 supported on the column 3 in a movable manner in the Z-axis direction, and figure 2 The manual operation part 18, the numerical control device 20, the hesitation state notification part 21, etc. are shown. In addition, the X-axis, Y-axis, and Z-axis are moving axes orthogonal to each other, and the Z-axis is a vertical axis.

[0049] like figure 2 As shown, the spindle head 6 holds the spindle 7 and the spindle 7 can rotate around the vertical axis. A tapered mounting hole (hol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap