Constant-temperature reaction container and constant-temperature method

A technology for a reaction vessel and a reactor, applied in the field of reactors, can solve the problems of easy loss when removing and placing, experiment failure, and the trouble of increasing fixed vessels, and achieves the effects of reducing liquid evaporation, preventing experiment failure, and improving the effect of constant temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

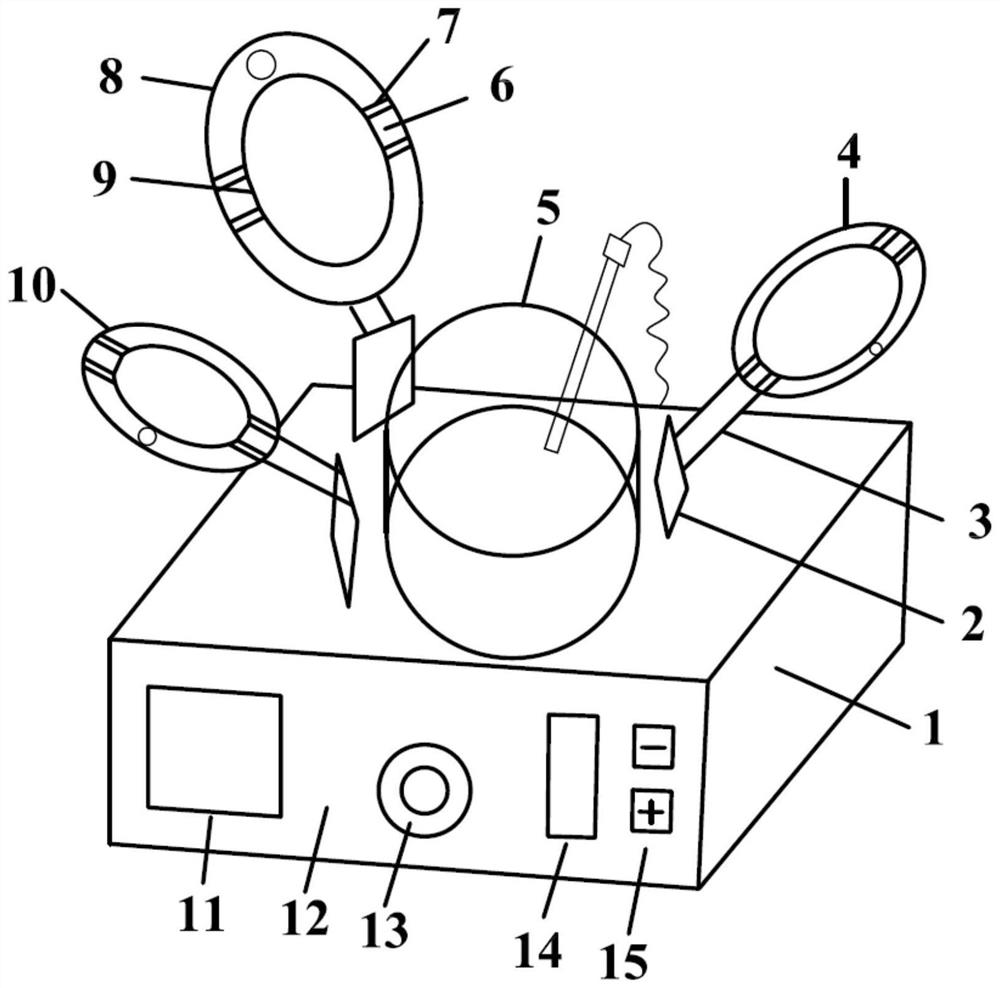

[0027] Embodiment 1: as figure 1 and 2 As shown, a constant temperature reaction vessel includes a magnetic stirrer 1, a constant temperature liquid bath 5, a combined collar member, a temperature sensor and a reactor, the constant temperature liquid bath 5 is fixedly arranged at the center of the top of the magnetic stirrer 1, and the reactor The bottom end is arranged on the magnetic surface at the top of the magnetic stirrer 1, the bottom of the reactor is arranged in the constant temperature liquid bath 5, the combined collar member is arranged on the top of the constant temperature liquid bath 5, and the combined collar member is provided with a positioning piece, The top of the constant temperature liquid bath 5 reactor is fixedly arranged on the combined collar member through a positioning piece, and the temperature sensor passes through the combined collar member and extends into the reactor;

[0028]The bottom end of the magnetic surface of the magnetic stirrer 1 is ...

Embodiment 2

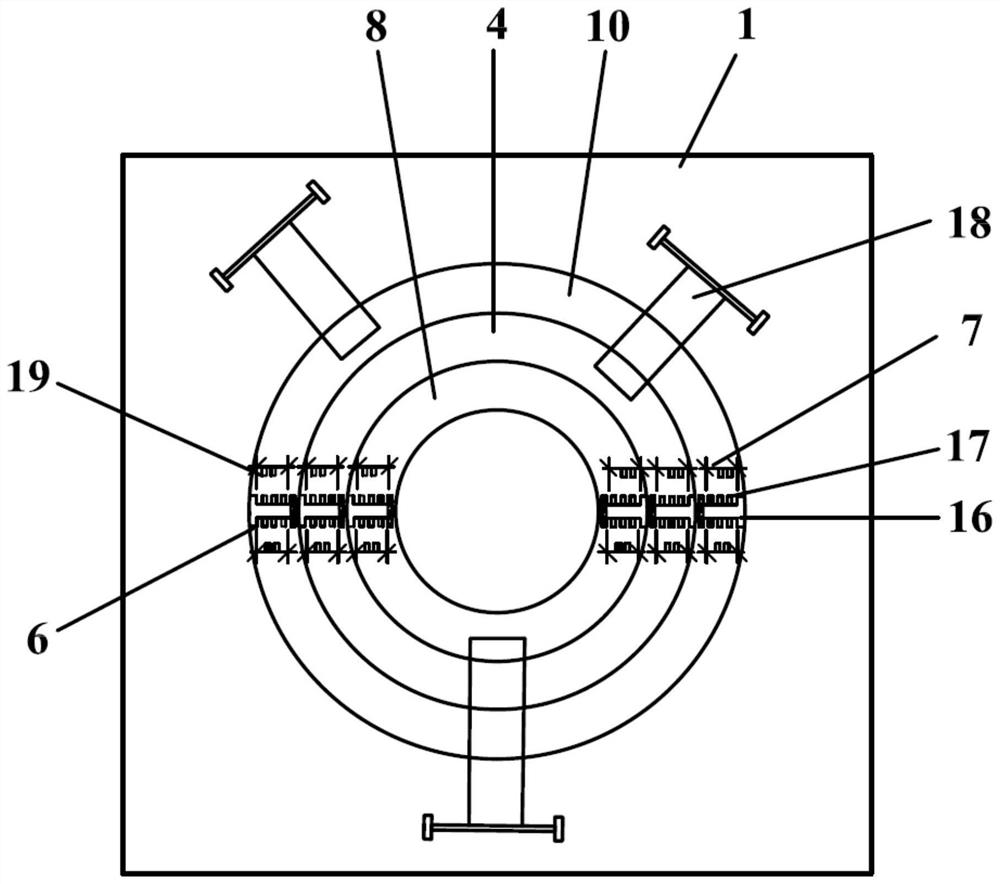

[0032] Embodiment 2: the constant temperature reaction vessel of this embodiment is basically the same as the constant temperature reaction vessel of embodiment 1, the difference is: as Figure 1-3 As shown, the combined collar components include collar I4, collar II8 and collar III10. When combined, collar I4, collar II8 and collar III10 are concentric rings, and the outer diameter of collar III10 is equal to the constant temperature liquid bath The outer diameter of the pot 5, the inner diameter of the collar I4 is equal to the outer diameter of the collar II8, the inner diameter of the collar II8 is equal to the outer diameter of the collar III10, the collar I4 is connected with a connecting rod I3, and the other end of the connecting rod I3 rotates Set on the top of the support rod I2, the bottom end of the support rod I2 is fixed on the housing of the magnetic stirrer 1, the collar II8 is connected with the connecting rod II18, and the other end of the connecting rod II18 ...

Embodiment 3

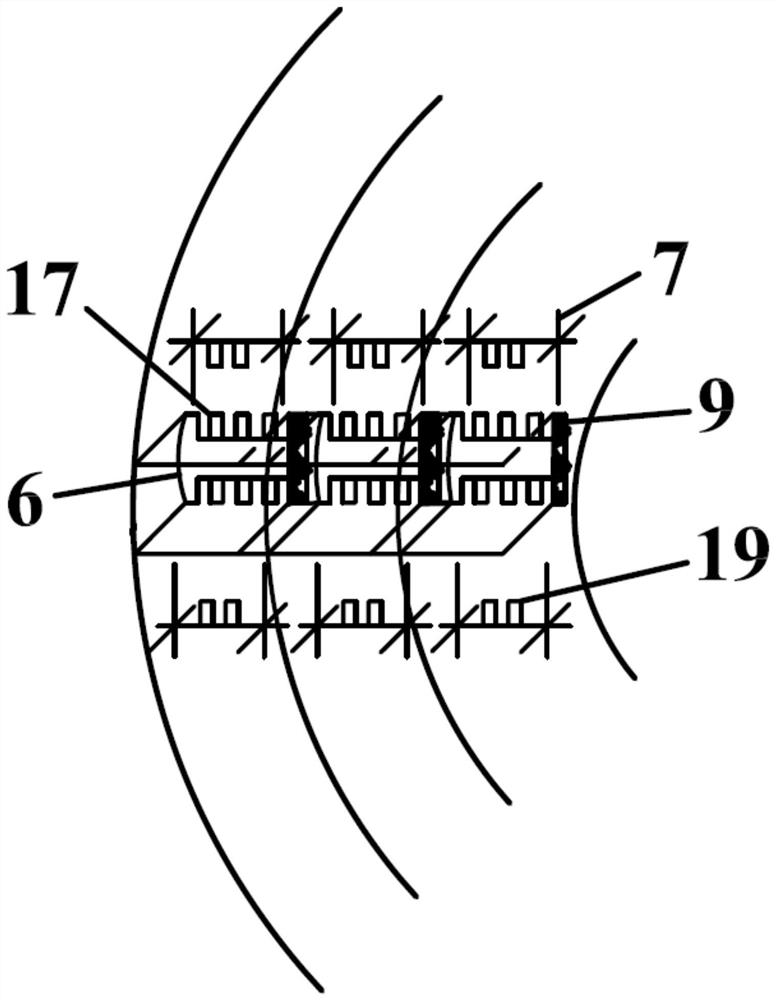

[0040] Embodiment 3: The constant temperature reaction vessel of this embodiment is basically the same as the constant temperature reaction vessel of Example 2, the difference is that: the height of the collar I4, the collar II8 and the collar III10 are the same and the top surface is located on the same horizontal plane, and the level is smooth The top surfaces of block I, horizontal slider II, horizontal slider III6, horizontal slider IV, horizontal slider V and horizontal slider VI are on the same level and higher than the top surface of collar I4, horizontal slider I, horizontal The top side walls of the slider II, the horizontal slider III6, the horizontal slider IV, the horizontal slider V and the horizontal slider VI are all provided with locking teeth I17;

[0041] Both sides of horizontal chute I are provided with vertical chute I, both sides of horizontal chute II16 are provided with vertical chute II, both sides of horizontal chute III are provided with vertical chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com