Leg mechanism and quadruped robot

A leg mechanism and drive mechanism technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of inability to stretch, low terrain passability, poor shock absorption effect, etc., to improve terrain passability, enhance buffering capacity, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

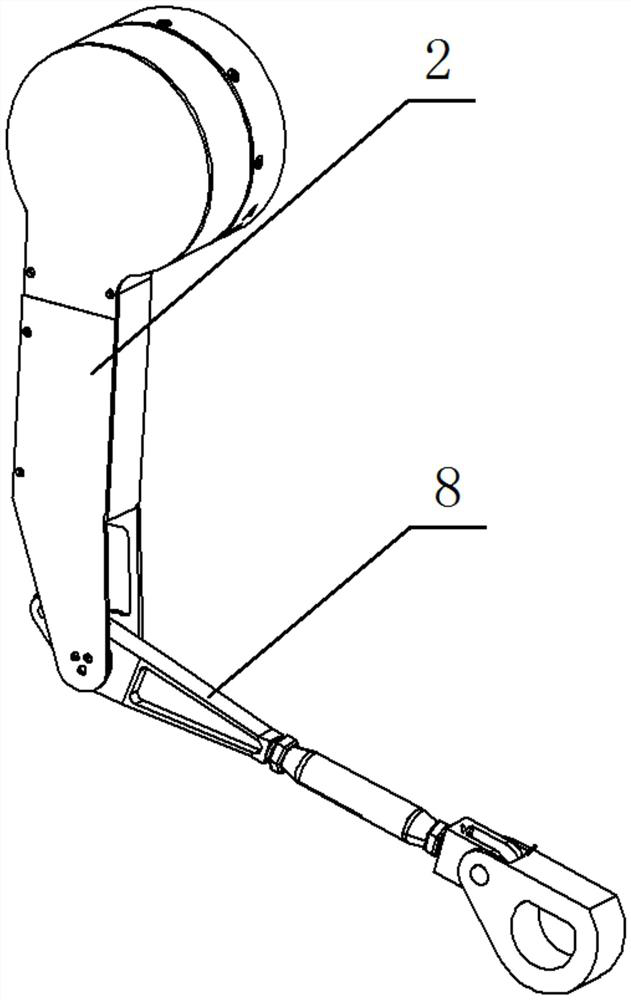

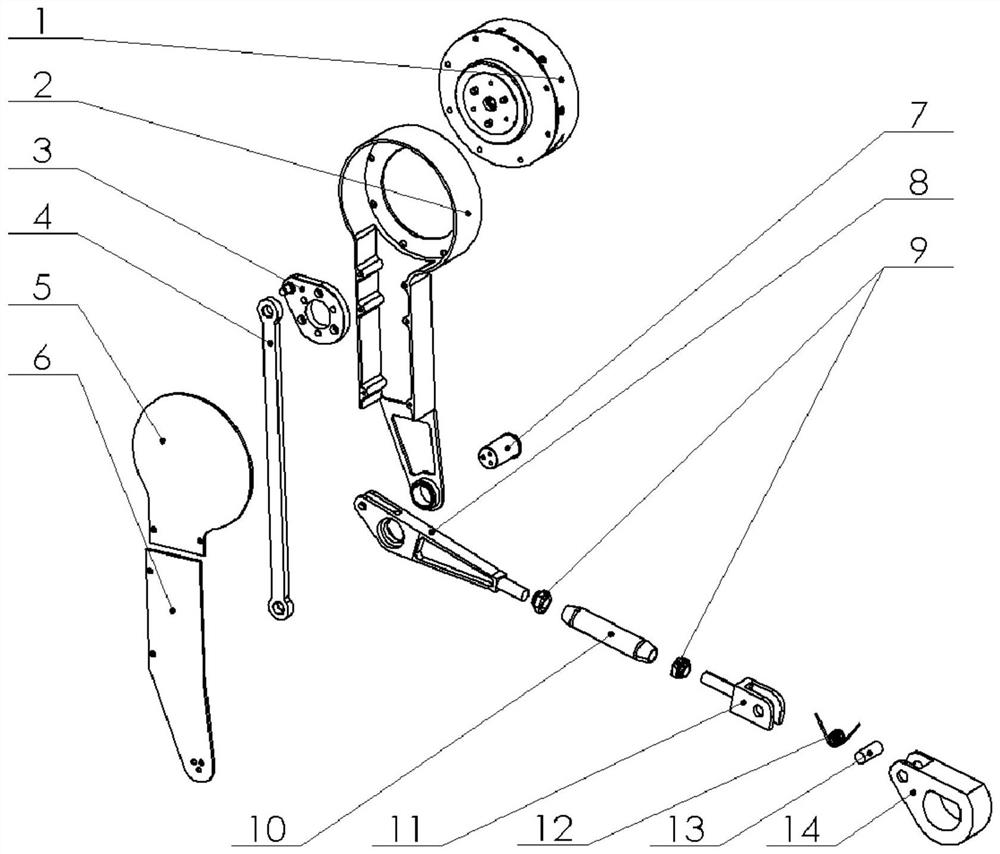

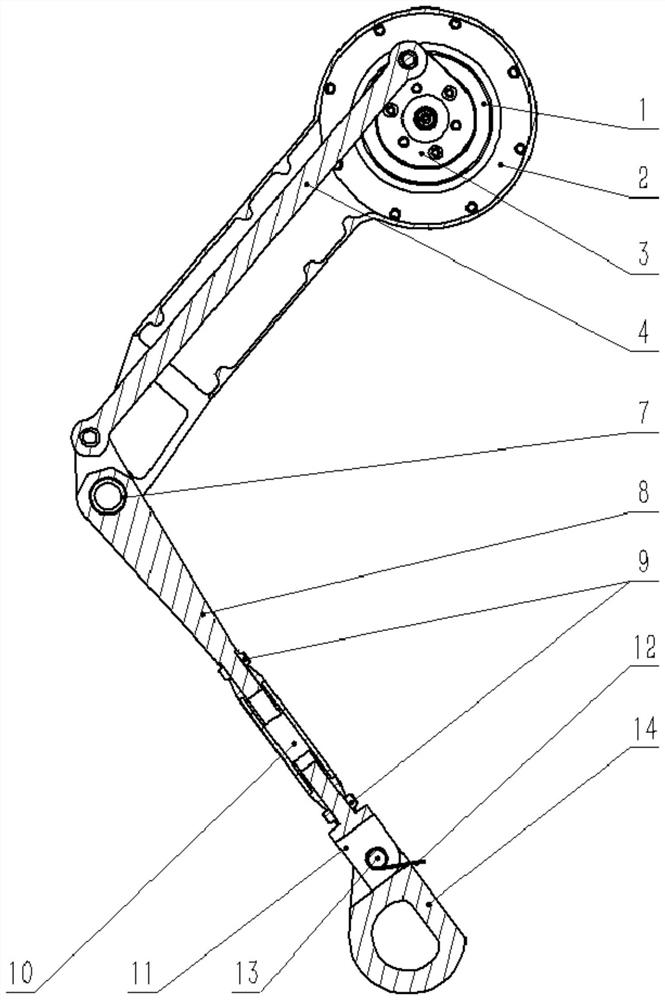

[0027] Such as Figure 1 to Figure 3 Shown is an embodiment of a leg mechanism of the present invention. A leg mechanism, the leg mechanism includes a thigh 2 and a calf hinged by a rotating shaft 7, a driving mechanism is provided on the thigh 2, the driving mechanism is connected with the calf through the first rod 4, and the driving mechanism drives the calf through the first rod 4. For sports, the end of the calf is provided with a flexibly connected foot module 14, and the calf is provided with a telescopic adjustment structure, which can telescopically adjust the length of the calf to adapt to different degrees of rough terrain and obstacles of different sizes.

[0028] In this embodiment, the thigh 2 also includes a housing, the housing is formed by splicing the first thigh housing 5 and the second thigh housing 6, the driving mechanism penetrates into the housing, the first rod 4 is located inside the housing, and the driving The mechanism includes a motor 1 and a mot...

Embodiment 2

[0033] This embodiment is similar to Embodiment 1, the difference is that the side of the lifting ear 11 close to the sole module 14 is provided with a limiter, one end of the limiter is a right angle, the other end of the limiter is an arc angle, and the sole module 14 The side connected to the lifting lug limiter is a straight line, and the length of the straight line is greater than the length of the limiter. When the sole module 14 rotates around the spring pin 13, the straight edge of the sole module can surround the limiter. The arc angle is rotated, and the right angle of the stopper will be against the straight edge of the sole module 14 to limit the rotation of the sole module 14 .

[0034]Wherein, the limiting member enables the rotation range of the sole module 14 and the lifting ear 11 to be 0°-90°. The sole module 14 is wrapped with polyurethane rubber for shock absorption. When the sole module 14 touches the ground, the polyurethane rubber wrapped outside can red...

Embodiment 3

[0037] An embodiment of a quadruped robot. A quadruped robot, including four leg mechanisms of embodiment 2 in the quadruped robot, the leg mechanism can adjust the overall height of the quadruped robot, can adapt to terrains of different ruggedness and obstacles of different heights, and can The terrain passing ability of the quadruped robot is improved, and there is no need to be equipped with various robot spare parts and models. The sole module 14 adopts a simple mechanism and uses a spring to realize the shock absorption function, which enhances the buffering capacity of the quadruped robot, and is suitable for the quadruped robot. The precision components provide better protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com